Assembled type movable blast wall

An explosion-proof wall, assembled technology, applied in the direction of protective buildings/shelters, building types, buildings, etc., can solve the problems of long construction time, large total weight, insufficient resistance, etc., to achieve rapid assembly, light overall weight, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

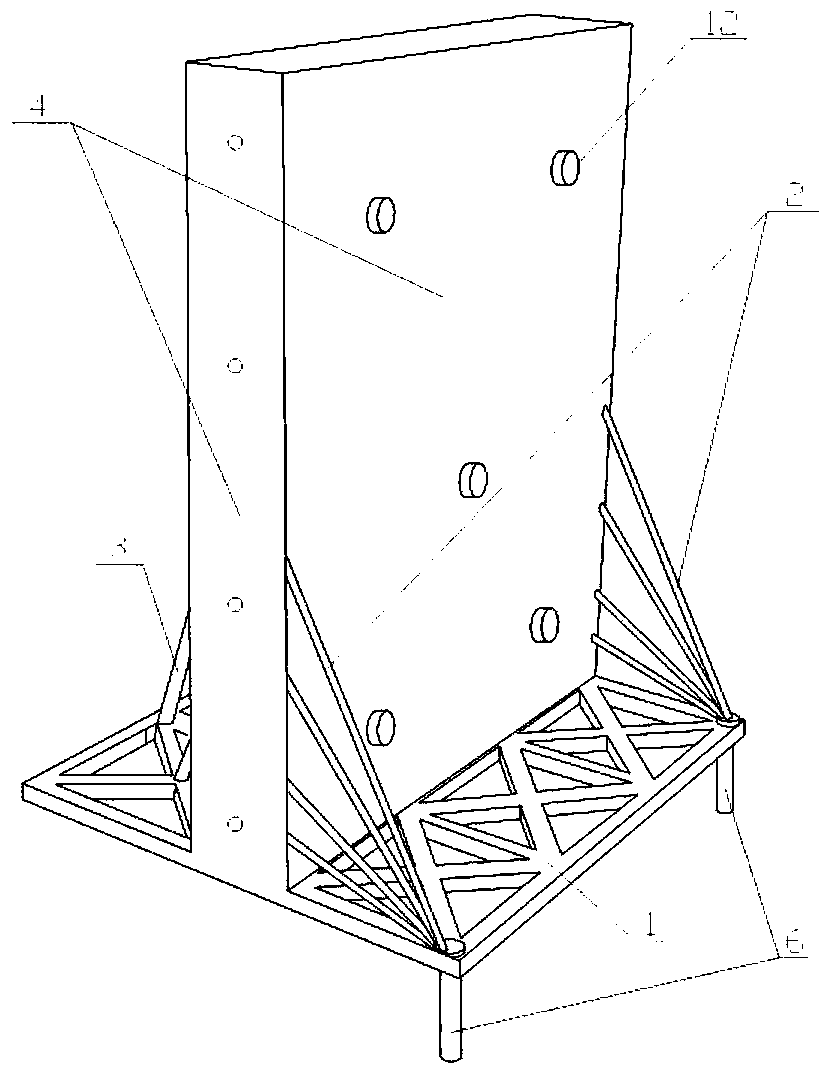

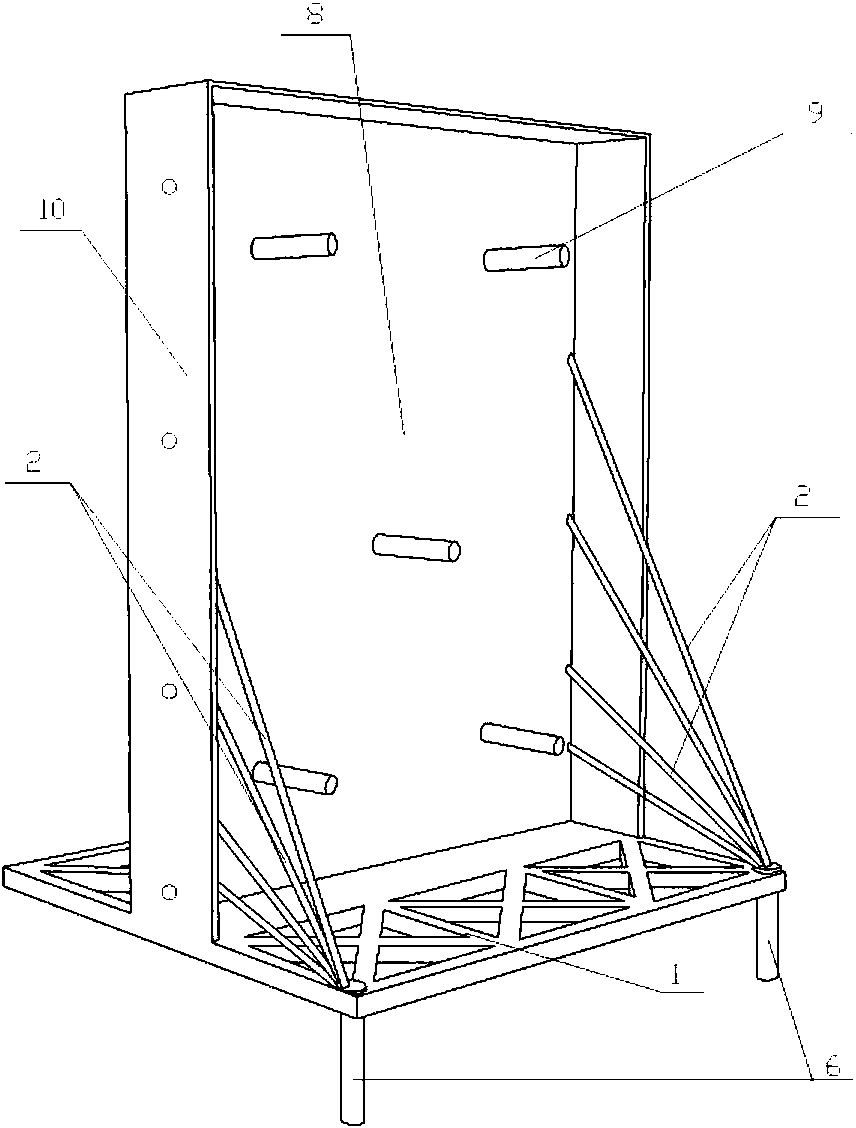

[0033] This embodiment is a mobile explosion-proof wall that can be assembled quickly, and is composed of multiple explosion-proof wall units, which can be assembled within a few minutes to form a defense system. The number of explosion-proof wall units is determined according to the explosion-proof range, and the mobile explosion-proof wall described in this embodiment is composed of five explosion-proof wall units.

[0034] The multiple explosion-proof wall units have the same structure, and in this embodiment, one of them is taken as an example to describe in detail.

[0035] The explosion-proof wall unit includes a base 1, a front tie rod 2, a rear pressure rod 3, a supporting frame 4, an energy-absorbing layer 5, a stabilizing pile 6 and connecting pieces 7 including bolts and nuts.

[0036] The support frame 4 is a rectangular box-shaped frame structure, which is composed of a support panel 8 made of light high-strength steel, a connecting screw 9, a frame 10 and a front...

Embodiment 2

[0044] This embodiment is a mobile explosion-proof wall that can be assembled quickly, and is composed of multiple explosion-proof wall units, which can be assembled within a few minutes to form a defense system. The number of explosion-proof wall units is determined according to the explosion-proof range, and the mobile explosion-proof wall described in this embodiment is composed of ten explosion-proof wall units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com