Semimetal magnetic material with high spin polarization

A technology of magnetic materials and polarizability, applied in the direction of magnetic materials, magnetic objects, material selection, etc., can solve problems such as insufficiency, and achieve the effect of being conducive to application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

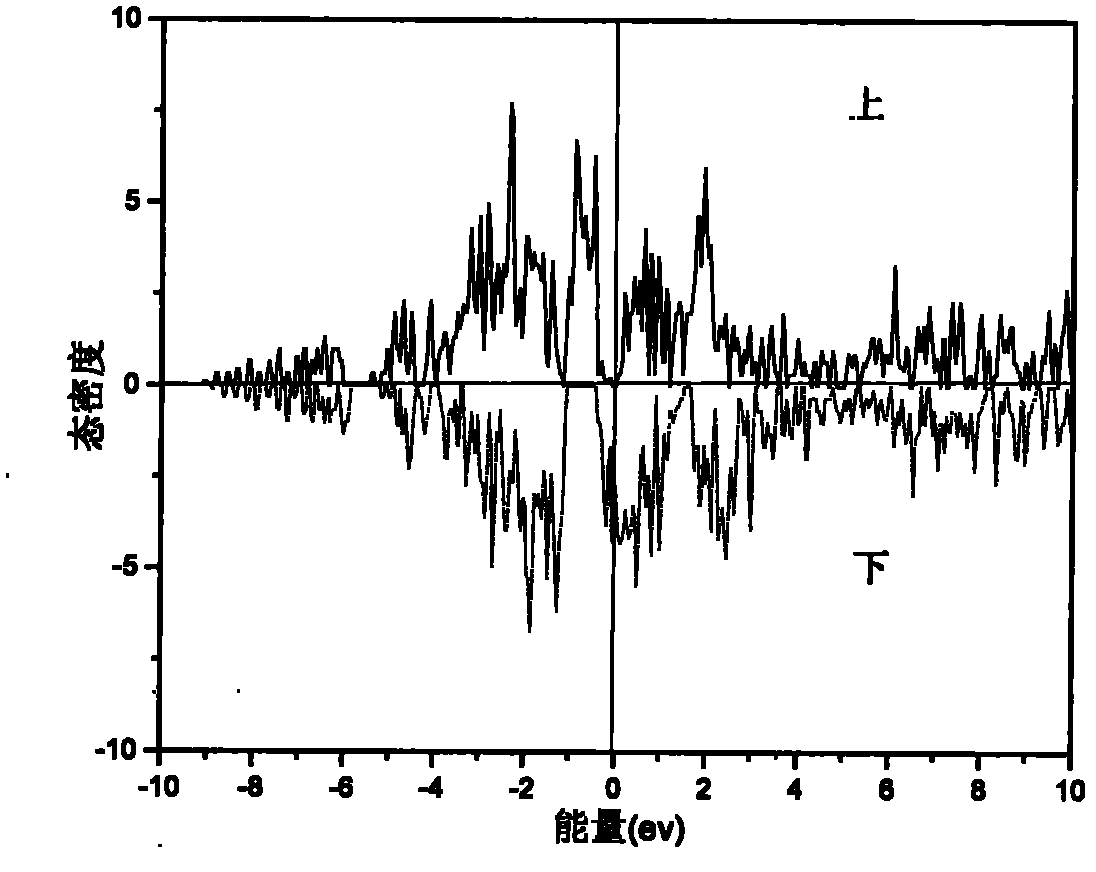

[0020] The chemical formula of the material is V 2 Magnetic alloy of CoAl; the calculated spin polarizability is 100%, which is a typical semi-metallic material.

[0021] The data used in this patent is the measurement result of the sample obtained by arc melting method, and its preparation process includes the following steps:

[0022] 1. According to chemical formula V 2 CoAl ratio (x=2, y=1, N=Al, w=0), three kinds of element molar ratios V:Co:A=2:1:1, calculate the required quality of three kinds of elements accordingly; Use Electronic balance weighing, accurate to 0.0001g, mixing the raw materials into the electric arc furnace crucible; the purity of the raw materials used is greater than 99.9%;

[0023] 2. Melting by conventional arc melting method. Vacuum the electric arc furnace to 1×10-1 -1 ×10 -6 Pa, filled with argon, arc melting under 1MPa positive pressure for 2 minutes, and then cooled. Repeat the smelting 4 times in this way to make the alloy material even...

Embodiment 2

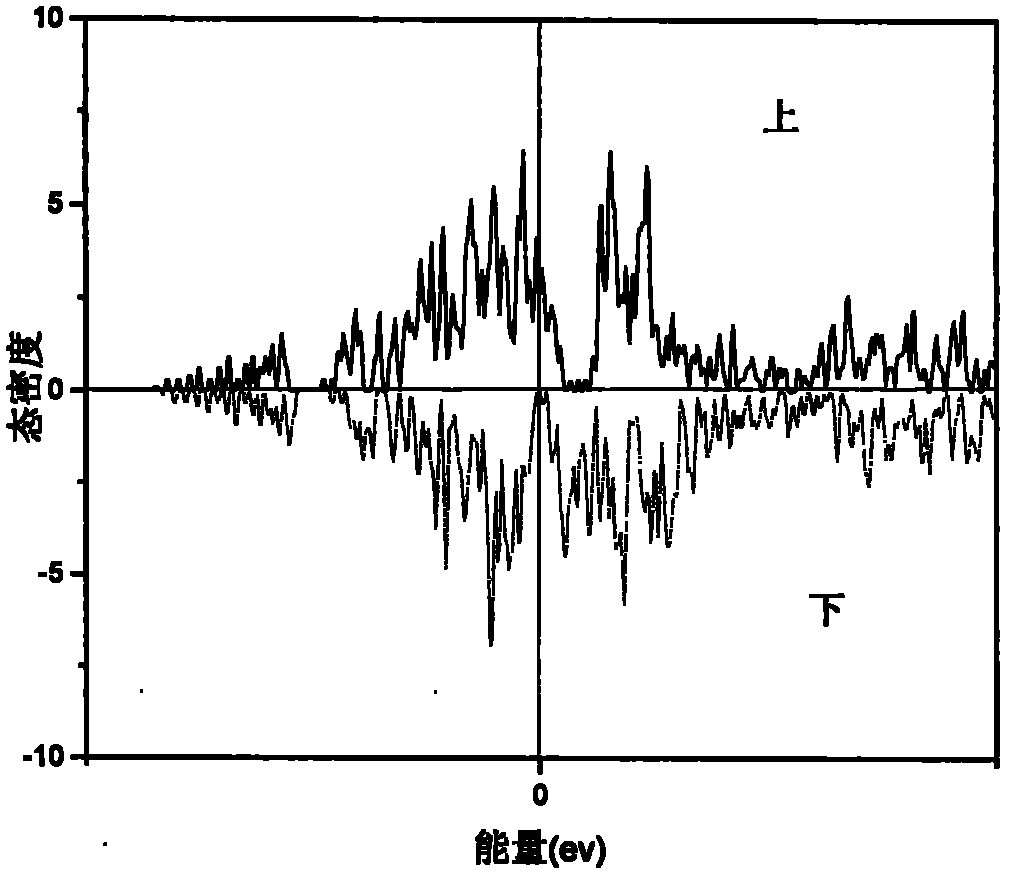

[0026] The chemical formula of the material is V 2 Magnetic alloy of MnAl (x=2, y=0, w=1, N=Al, M=Mn). The molar ratio of the three elements V:Mn:Al=2:1:1, the arc smelting pressure is 1MPa positive pressure, the time is 3 minutes, the number of repeated smelting is 3 times, and other preparation and measurement methods are the same as in Example 1. The calculated spin polarizability is 100%, which is a typical semi-metallic material. The shape of the calculated energy density curve is shown in figure 2 . The spin polarizability and saturation magnetization were measured, and the obtained values are shown in Table 1.

Embodiment 3

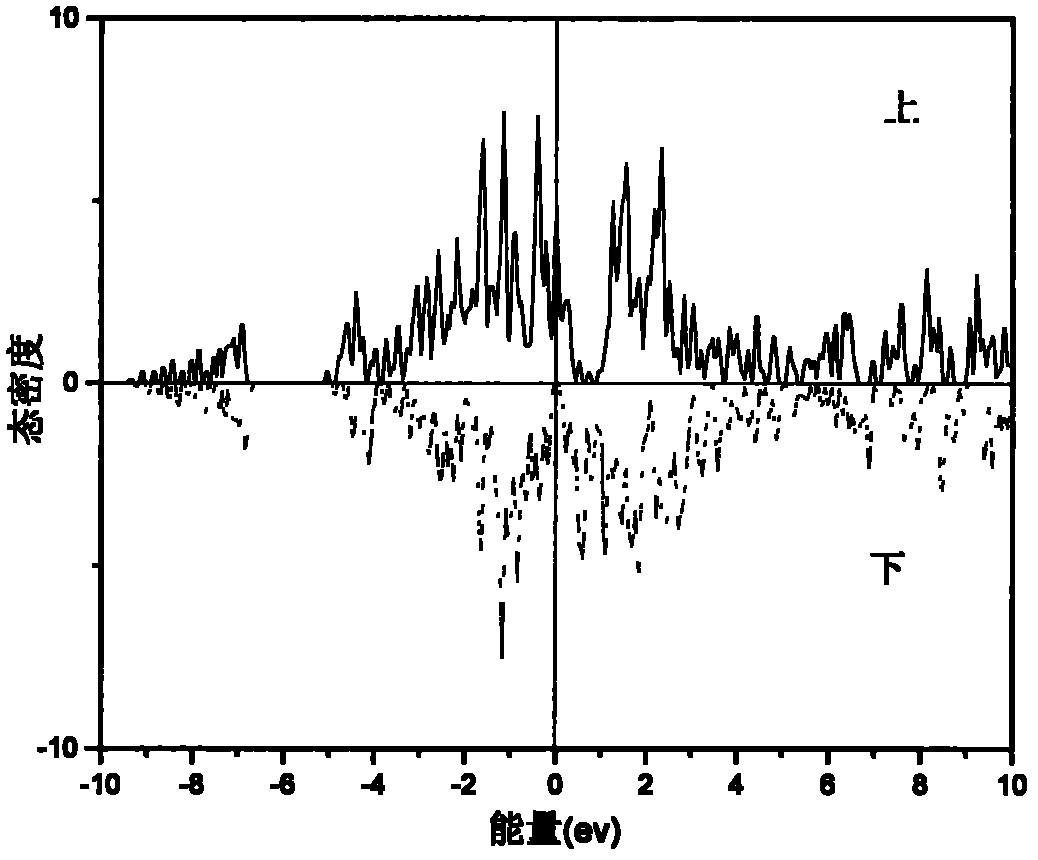

[0028] The chemical formula of the material is V 2 Magnetic alloy of FeAl (x=2, y=0, w=1, N=Al, M=Fe). The molar ratio of the three elements V:Fe:Al=2:1:1, arc melting under the protection of flowing argon, the time is 2 minutes, the number of repeated melting is 4 times, other preparation and measurement methods are the same as in Example 1. The calculated spin polarizability is 100%, which is a typical semi-metallic material. The spin polarizability and saturation magnetization were measured, and the obtained values are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com