Heusler alloy intercalated mnga-based vertical magnetic tunnel junction and preparation method

A perpendicular magnetic, tunnel junction technology with applications in the fabrication/processing of electromagnetic devices, material selection, field-controlled resistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

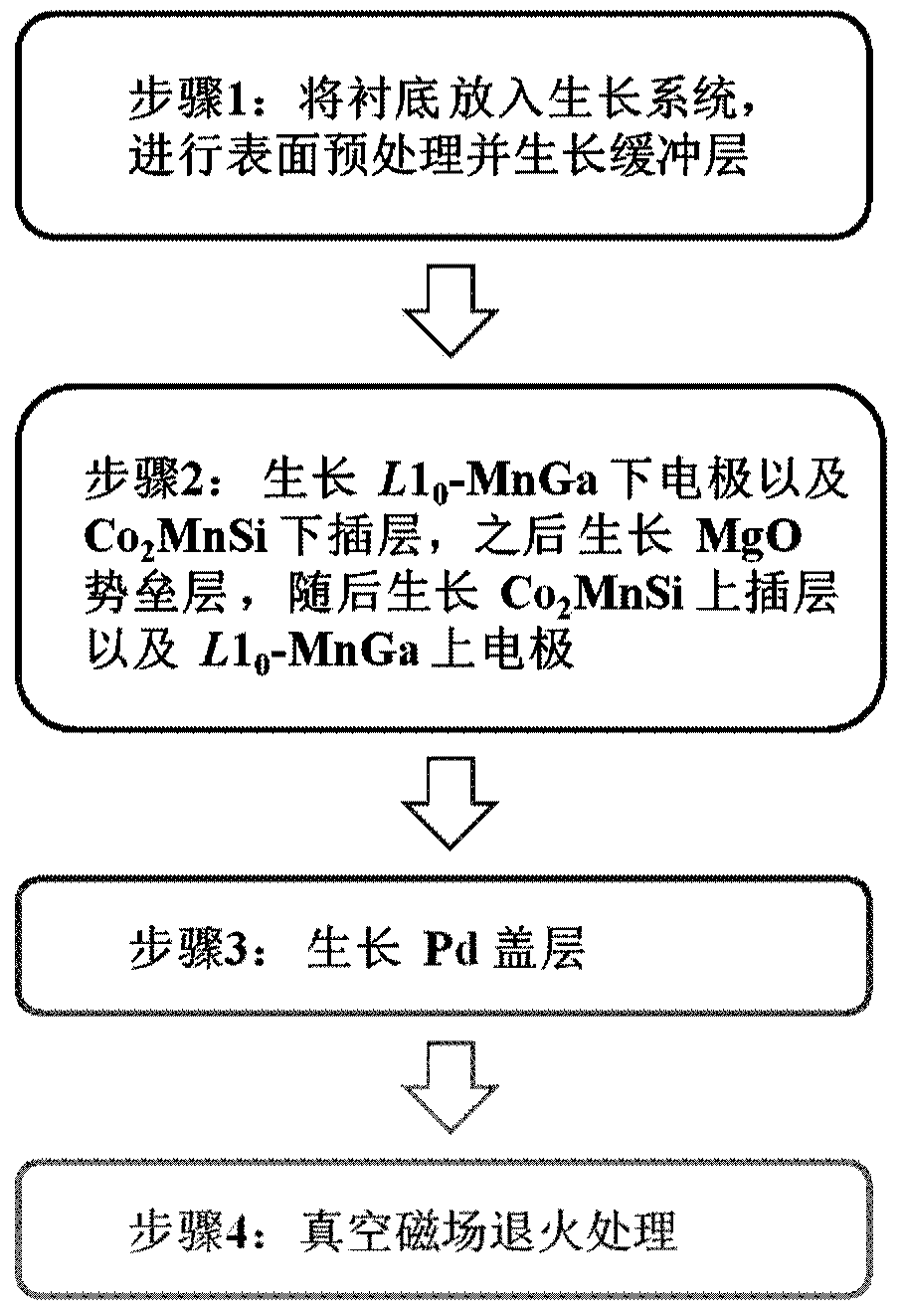

Method used

Image

Examples

Embodiment Construction

[0028] In order to set forth the specific embodiment of the present invention more clearly, a specific example of a Heusler alloy intercalated MnGa-based vertical magnetic tunnel junction will be described below:

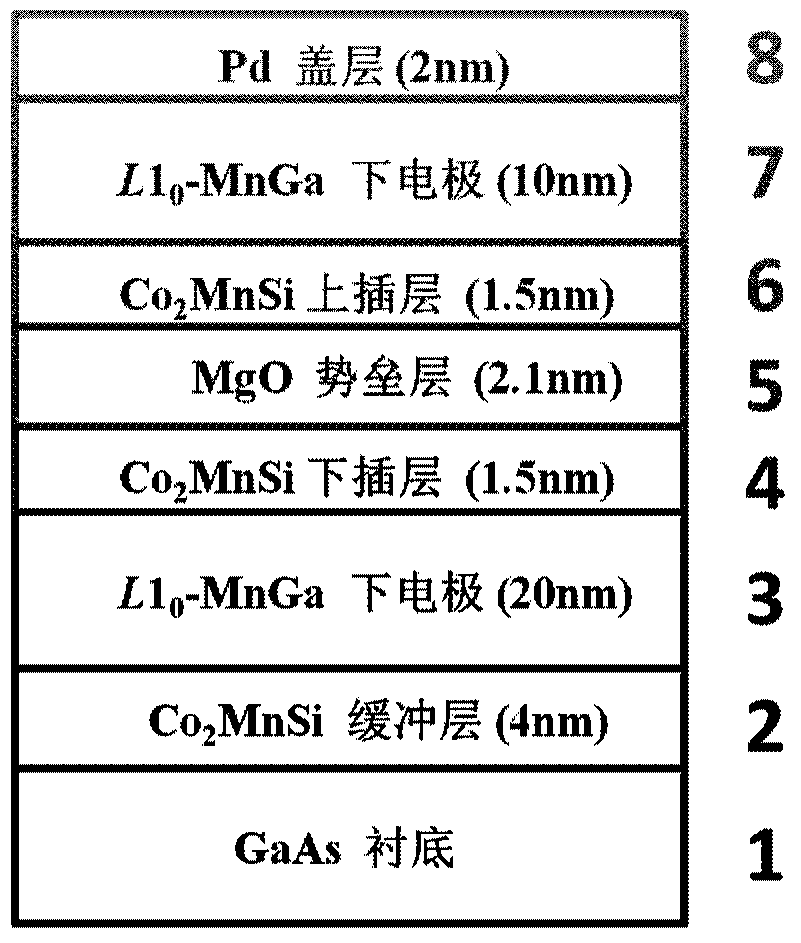

[0029] see figure 1 As shown, the present invention provides a kind of Heusler alloy as the intercalated MnGa-based vertical magnetic tunnel junction, comprising:

[0030] A substrate 1, which is a semi-insulating GaAs (001) material, is the basis for realizing the epitaxial growth of a multilayer film;

[0031] A buffer layer 2, grown epitaxially on the substrate 1, consists of about 4 nm thick semi-metal Heusler alloy Co 2 MnSi film composition for smoothing the substrate surface and buffering the lattice mismatch between the substrate and the long layer structure;

[0032] The lower electrode 3 is epitaxially grown on the buffer layer 2, consisting of about 20nm of L1 0 -MnGa thin film composition; the electrode material has high vertical magnetic anisotropy, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com