Assistant alloy for improving coercive force of NdFeB permanent magnet material and application method

A technology of auxiliary alloys and application methods, which is applied in the manufacturing of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., and can solve the problems of substandard comprehensive performance of materials and high production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

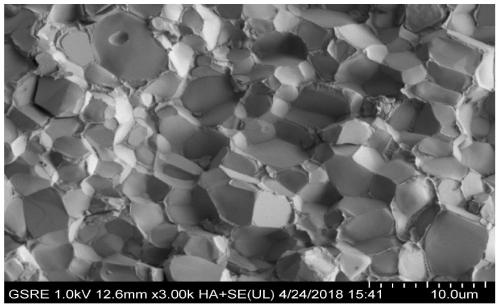

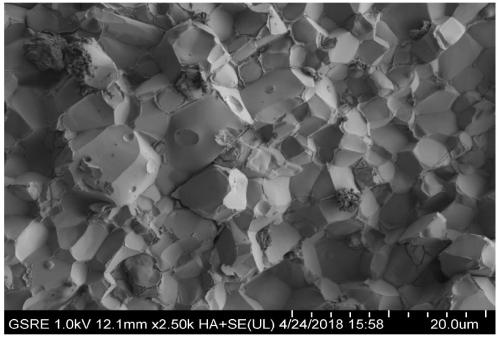

Image

Examples

Embodiment 1

[0038] Step 1, preparation and smelting NdFeB main alloy, its molecular formula is (Pr 0.17 Nd 0.53 Ce 0.25 Gd 0.05 ) 2.6 (Fe 0.98 Cu 0.002 AI 0.015 Zr 0.003 ) 14 B 1.06 .

[0039] Step 2, preparation and smelting auxiliary alloy, the molecular formula of auxiliary alloy is (Pr 0.5 Ce 0.2 Nd 0.3 ) 6 Fe 12.5 Cu 0.5 Al, smelting auxiliary alloy, requires the line speed of the copper roller to be 1.4m / s, the pouring temperature to be 1400-1430℃, and the refining time to be 5min.

[0040] In step 3, hydrogen explosion crushing and subsequent dehydrogenation treatment are performed on the main and auxiliary alloys respectively; the temperature of the dehydrogenation treatment is 560° C., and the time is 3 hours.

[0041] In step 4, antioxidants are added to the main and auxiliary alloys respectively, and mixed respectively; the amount of antioxidants added is 2‰ of the weight of hydrogen fragments.

[0042]Step 5, the main and auxiliary alloys are jet milled into p...

Embodiment 2

[0048] Except that the main and auxiliary alloy weight ratio in step 5 is changed (main alloy: auxiliary alloy=100: 3), other steps and process conditions are the same as in embodiment 1.

Embodiment 3

[0050] Except that the main and auxiliary alloy weight ratio in step 5 is changed (main alloy: auxiliary alloy=100:5), other steps and process conditions are the same as in embodiment 1.

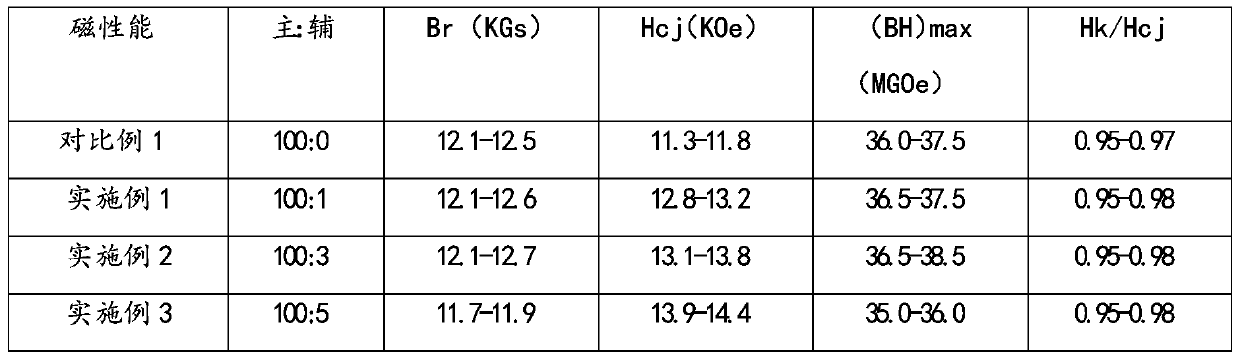

[0051] The magnetic properties of the NdFeB permanent magnet prepared by the above method were tested using the NIM-10000H bulk rare earth permanent magnet nondestructive testing system. The test results are shown in Table 1:

[0052] Table 1 Magnetic performance data

[0053]

[0054] It can be seen from Table 1 that the NdFeB permanent magnet prepared by the method of the present invention has better magnetic properties than the NdFeB permanent magnet prepared by the traditional single alloy process, especially the intrinsic coercive force is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com