Laser-induced liquid metal transfer printing circuit, preparation method and flexible pressure sensor

A pressure sensor and liquid metal technology, which is applied in the field of flexible circuits and flexible sensors, can solve the problems of difficult to achieve precise measurement of micro pressure, limited laser peak power, and increased manufacturing steps, and achieves reduced cross-sectional area, high sensitivity, The effect of increasing the resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

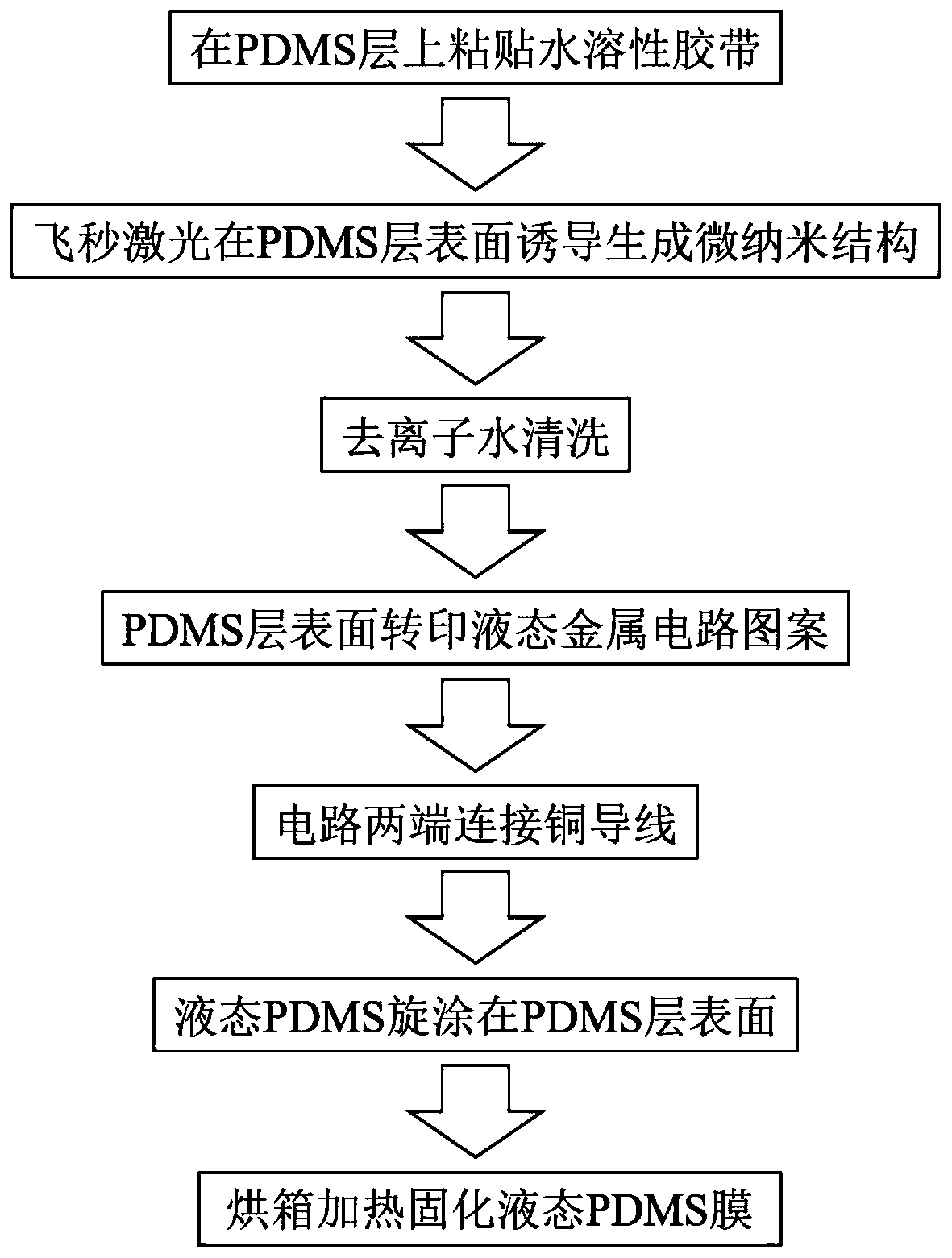

[0035] As an aspect of the present invention, such as figure 1 As shown, a method for preparing a laser-induced liquid metal transfer circuit is provided, using a femtosecond laser to induce the formation of micro-nano structures on the surface of the PDMS layer, thereby changing the adhesion of the PDMS layer surface to liquid metal, and combining the selective transfer of liquid metal Printing to realize the processing of laser-induced liquid metal transfer circuit, including the following steps:

[0036] (1) Paste a layer of water-soluble tape on the PDMS layer to avoid the impact of splashing debris on the area not processed by the femtosecond laser during subsequent femtosecond laser processing;

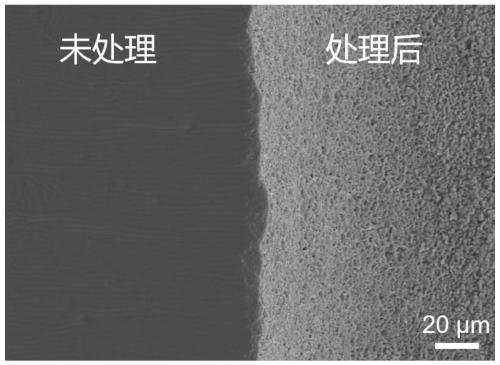

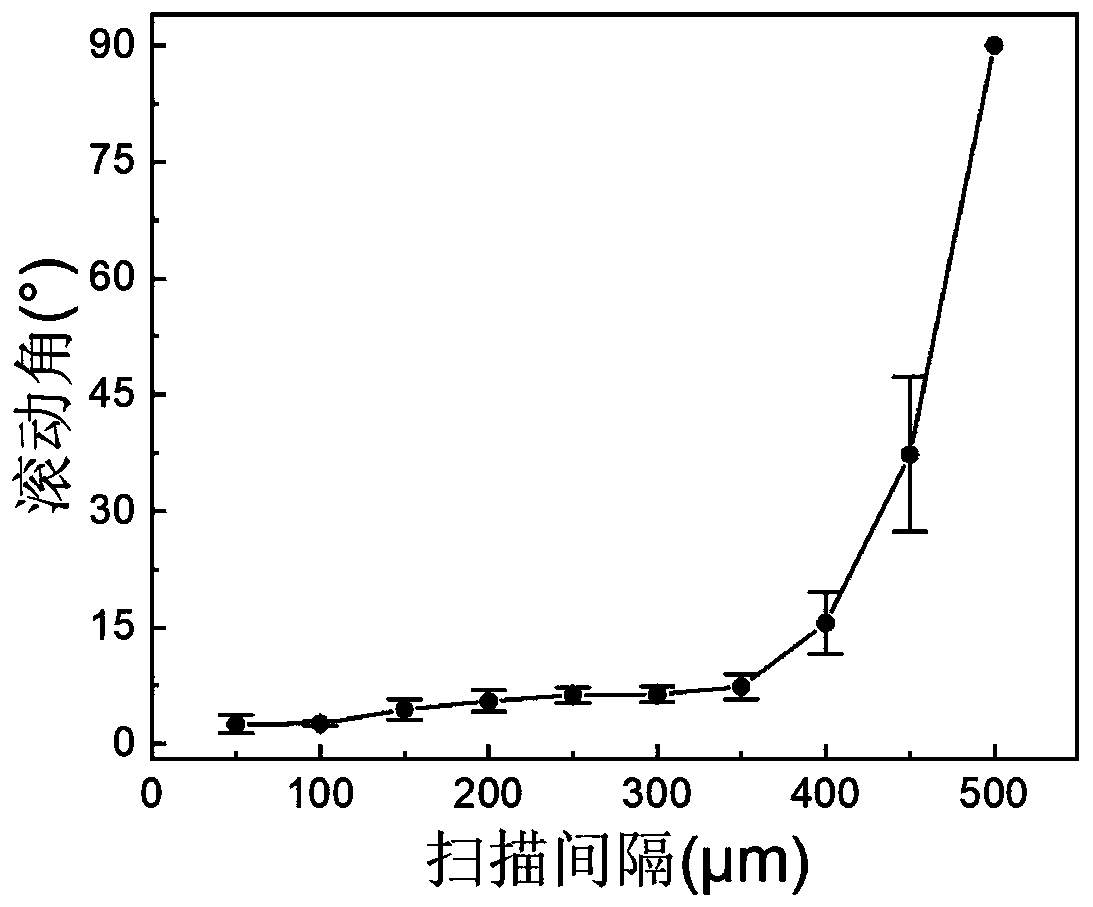

[0037] (2) Using a femtosecond laser according to a pre-designed circuit pattern, under the guidance of a scanning galvanometer, perform femtosecond laser scanning processing on the surface of the PDMS layer treated in step (1). In the femtosecond laser processing area, the fem...

Embodiment 1

[0070] The components of liquid PDMS, PDMS prepolymer and PDMS curing agent, were purchased from Dow Corning, USA, and the model was Sylgard 184Kit.

[0071] use as figure 1 In the laser-induced liquid metal transfer circuit prepared by the preparation method of the laser-induced liquid metal transfer circuit, such as Figure 5 As shown, the thickness of the PDMS layer is 500 μm, and the thickness of the encapsulated PDMS film is 500 μm. The circuit pattern is spiral, the total length of the spiral is 180mm, the length of the entire spiral pattern area is 24mm, and the width is 18mm. The cross-section of the liquid metal microchannel is 1.5 mm wide and 25 μm thick.

[0072] The PMMA plate of the flexible pressure sensor has a length of 10mm, a width of 10mm, and a thickness of 1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com