R-Fe-B series permanent magnet and production method thereof

A production method and technology for permanent magnets, which are applied to magnetic objects, permanent magnets, magnetic materials, etc., can solve the problem of uneven concentration distribution of rare earth elements dysprosium or terbium, and achieve the effect of improving grain boundary phase and improving magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

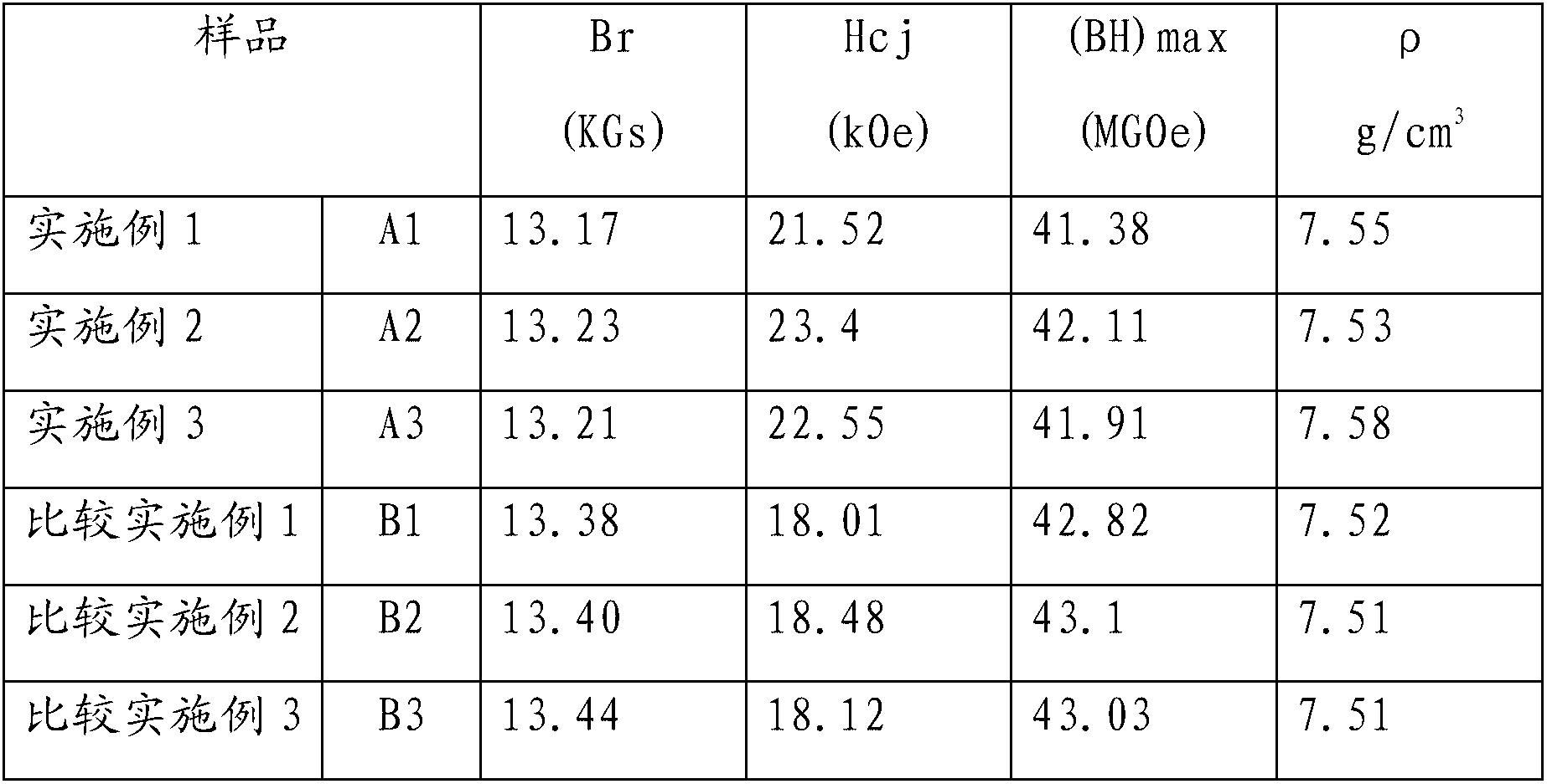

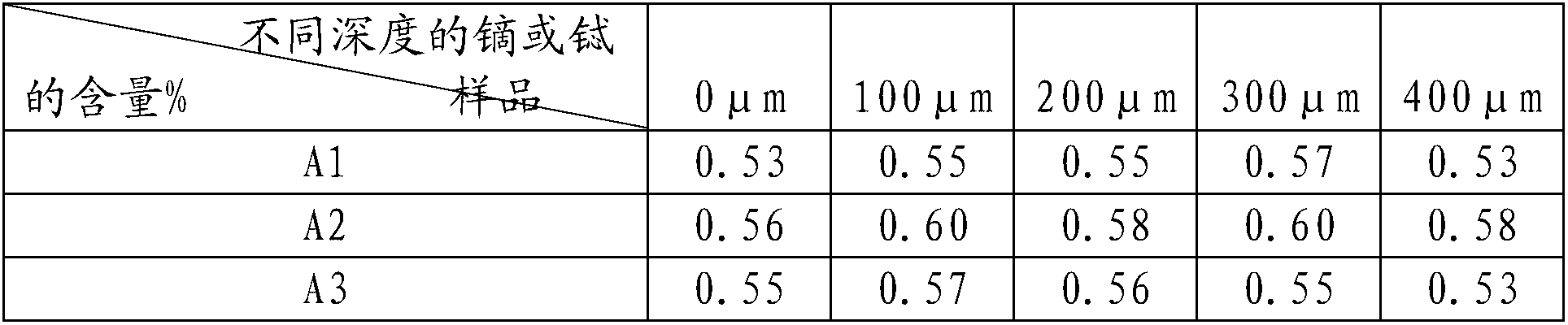

Embodiment 1 and comparative Embodiment 1

[0043]31% Nd, 68.3% Fe, 0.5% by mass by using at least 99% pure Nd, Al, Fe, Cu and ferroboron in an argon atmosphere for high-frequency melting, and pouring the melt onto a chilled roll Alloy of Al, 0.2% Cu, 1% B. The alloy is hydrogenated and pulverized into a coarse powder of 0.05-1 mm, and the coarse powder is ball-milled to 150-200 μm, and then the ball-milled powder is jet-milled to obtain a magnetic powder of 3-6 μm. Add the KH151 silane coupling agent to the magnetic powder, and stir at a high speed of 1800 r / min for 30 minutes so that the magnetic powder and the coupling agent are fully mixed and ready for use. Dysprosium ethoxide was added to the surface-coupled magnetic powder, and stirred at a high speed of 1800 rpm for 30 minutes to fully mix the magnetic powder and the dysprosium-containing organic matter. Wherein, the addition amount of the silane coupling agent is 1wt% of the NdFeB magnetic powder. Dysprosium content in organic matter accounts for 0.8wt% of Nd...

Embodiment 2 and comparative Embodiment 2

[0048] The mass percentage of 33% Nd-Pr is made by using at least 99% weight purity Nd-Pr (80% Nd) alloy, Fe and boron iron in an argon atmosphere for high-frequency melting, and pouring the melt onto a quenching roll , 66% Fe, 1% B alloy. The process for preparing the modified magnetic powder is the same as in Example 1, and the coupling agent is changed to TC-WT titanate coupling agent. Wherein, the addition amount of the titanate coupling agent is 1.2wt% of the NdFeB magnetic powder. The organic matter is changed to ethoxylated terbium, and the content of terbium in the organic matter accounts for 0.85wt% of the NdFeB magnetic powder.

[0049] The surface-modified magnetic powder is molded at room temperature and under an orientation field with a magnetic field strength of 2T. After orientation pressing, the green body is subjected to cold isostatic pressing to increase the density of the green body. The isostatic pressure is 160 MPa. Then put the body into a vacuum sinte...

Embodiment 3 and comparative Embodiment 3

[0052] The mass fraction is 31%Nd, 68.3%Fe, 0.5% by using Nd, Al, Fe, Cu and ferroboron with a purity of at least 99% by weight in an argon atmosphere for high-frequency melting, and pouring the melt onto a chilled roll Alloy of Al, 0.2% Cu, 1% B. The process for preparing the modified magnetic powder is the same as in Example 1, and the coupling agent is a mixture of silane coupling agent and titanate coupling agent. Wherein, the addition amount of the coupling agent is 1.0wt% of the NdFeB magnetic powder, and the mixing ratio of the silane coupling agent and the titanate coupling agent is 2:1. Dysprosium content in organic matter accounts for 0.8wt% of NdFeB magnetic powder.

[0053] The surface-modified magnetic powder is molded at room temperature and under an orientation field with a magnetic field strength of 2T. After orientation pressing, the green body is subjected to cold isostatic pressing to increase the density of the green body. The isostatic pressure is 175 MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com