Automatic format digital jet printing system and printing method

A digital jet printing and printing system technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of large footprint, high equipment cost, lack of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

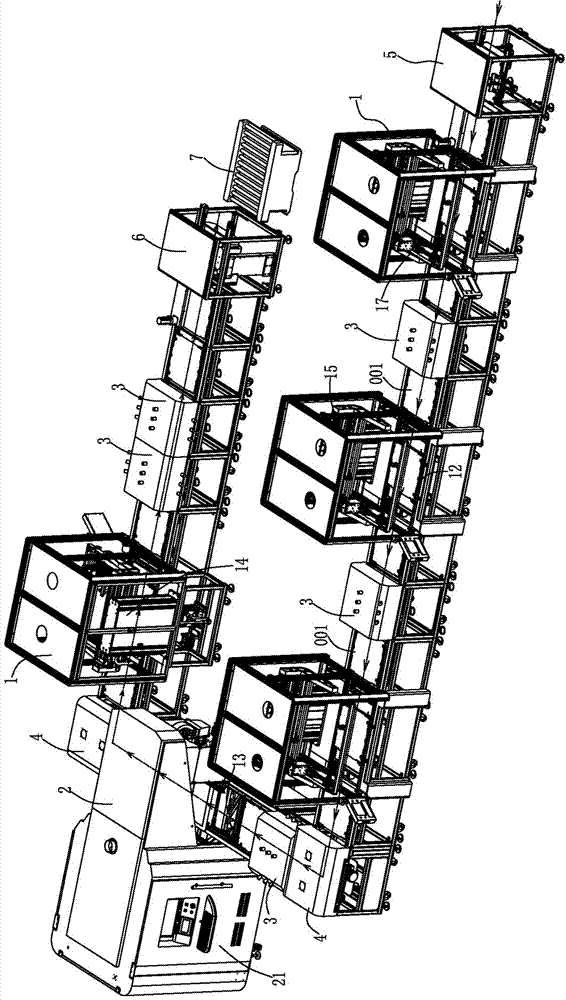

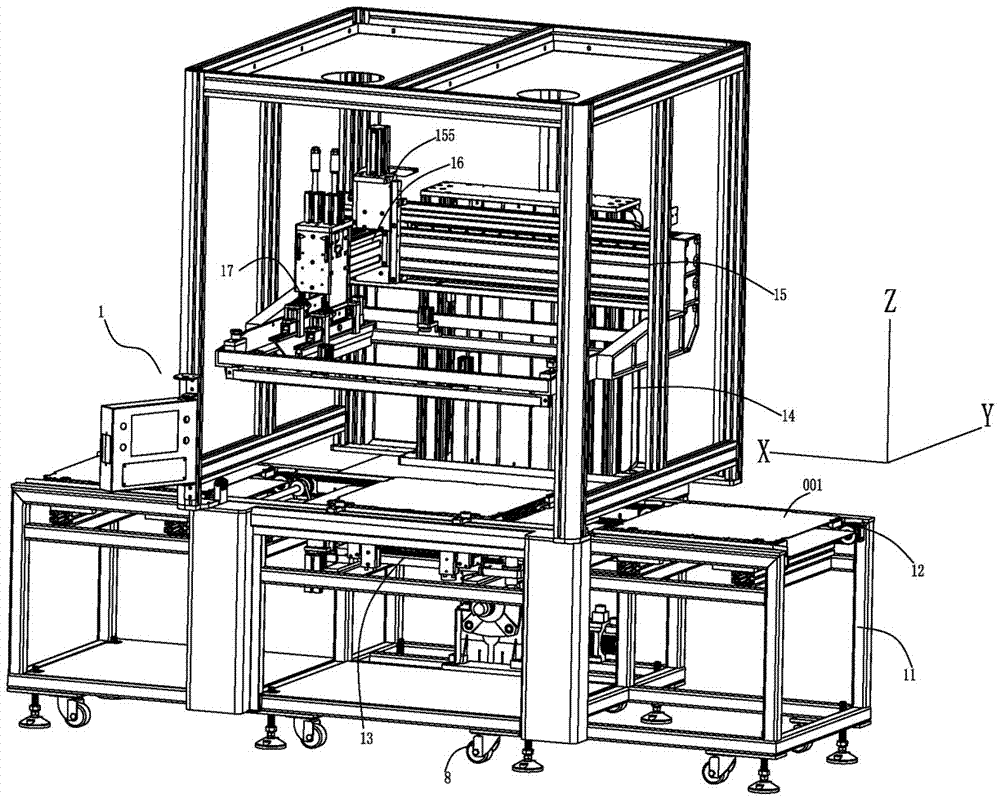

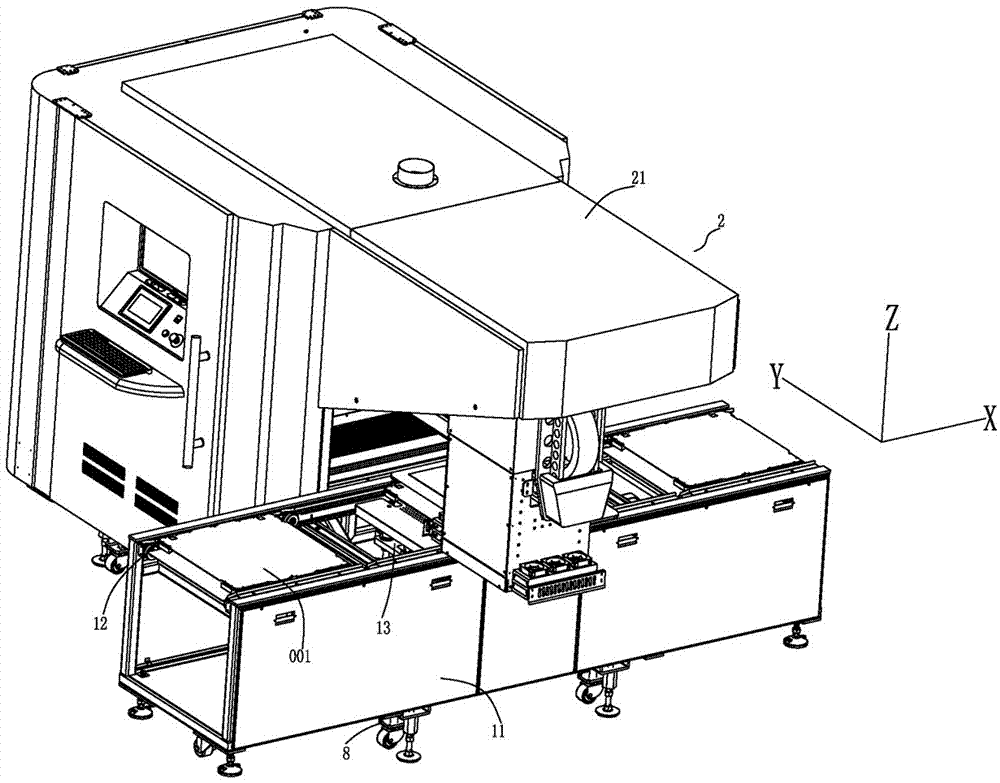

[0047] Example 1, such as Figure 1-16 As shown, a format automatic digital jet printing printing system, which includes a control system (belonging to the electrical control part, which controls the work of the entire printing system), multiple movable screen printing mechanisms 1, digital jet printing mechanism 2, and several movable ovens Component 3, several reloading components 4, discharging component 5 and receiving component 6; refer to the attached figure 1, the two ends of the digital printing mechanism 2 are docked with the movable screen printing mechanism 1 through the movable oven assembly 3 and / or the transfer assembly 4, and the two adjacent movable screen printing mechanisms 1 pass through at least one The movable oven assembly 3 is connected, and the plurality of movable screen printing mechanisms 1, movable oven assembly 3, transfer assembly 4 and digital printing mechanism 2 are matched to form a printing system in which the number of printing colors can be...

Embodiment 2

[0059] The format automatic digital jet printing printing system in the above-mentioned embodiment 1 can be implemented in the following manner during printing. This printing method requires a digital jet printing mechanism, several movable screen printing mechanisms, several movable oven components, several transfer components and The specific steps for discharging components and receiving components are:

[0060] A. Build a printing production line consisting of the digital printing mechanism, some of the movable screen printing mechanisms, some of the movable oven components, some of the transfer components, and the discharging and receiving components;

[0061] B. Place the silk screen material to be printed on the carrier board, and transfer the stacked carrier boards to the printing production line piece by piece through the discharging assembly;

[0062] C. The carrier board is conveyed sequentially on the printing production line. After the screen printing on the carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com