Shearing-type metal bending energy-wasting damper

A shear type, damper technology, applied in the direction of bridge parts, building components, bridges, etc., to achieve the effect of large deformation and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

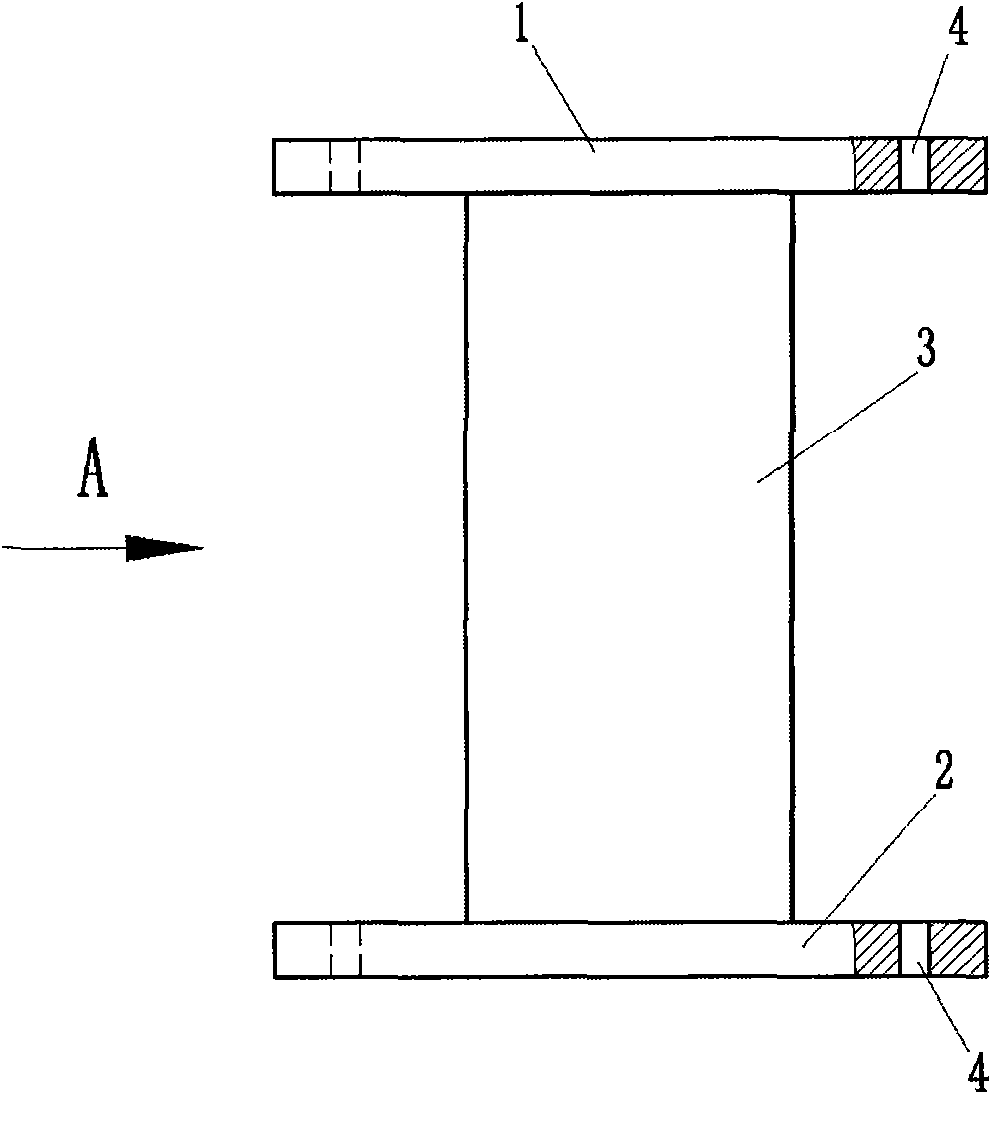

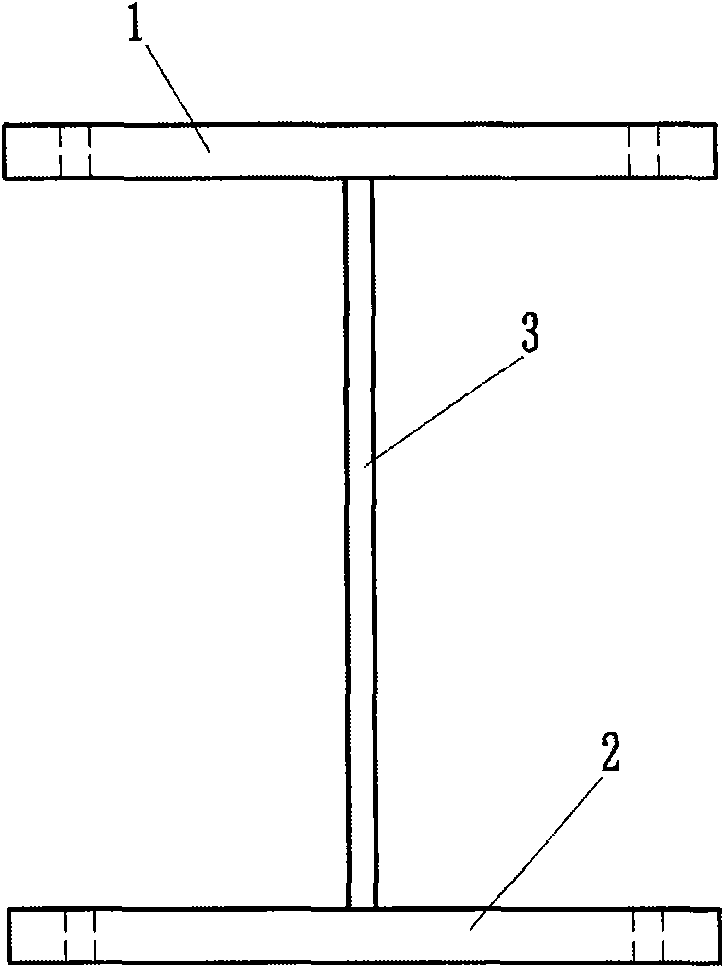

[0036] Such as figure 1 , figure 2 The shown shear type metal bending energy dissipation damper of the present invention includes an upper connection plate 1, a lower connection plate 2 and a core steel energy dissipation element, the core steel energy dissipation element is a steel plate 3 arranged on a plane, and the two ends of the steel plate 3 are respectively It is firmly welded together with the upper connecting plate 1 and the lower connecting plate 2. In order to facilitate the connection with other components, the upper connecting plate 1 and the lower connecting plate 2 are respectively provided with connecting structures for connecting with other structures. In this example, the connecting structures are through holes 4 .

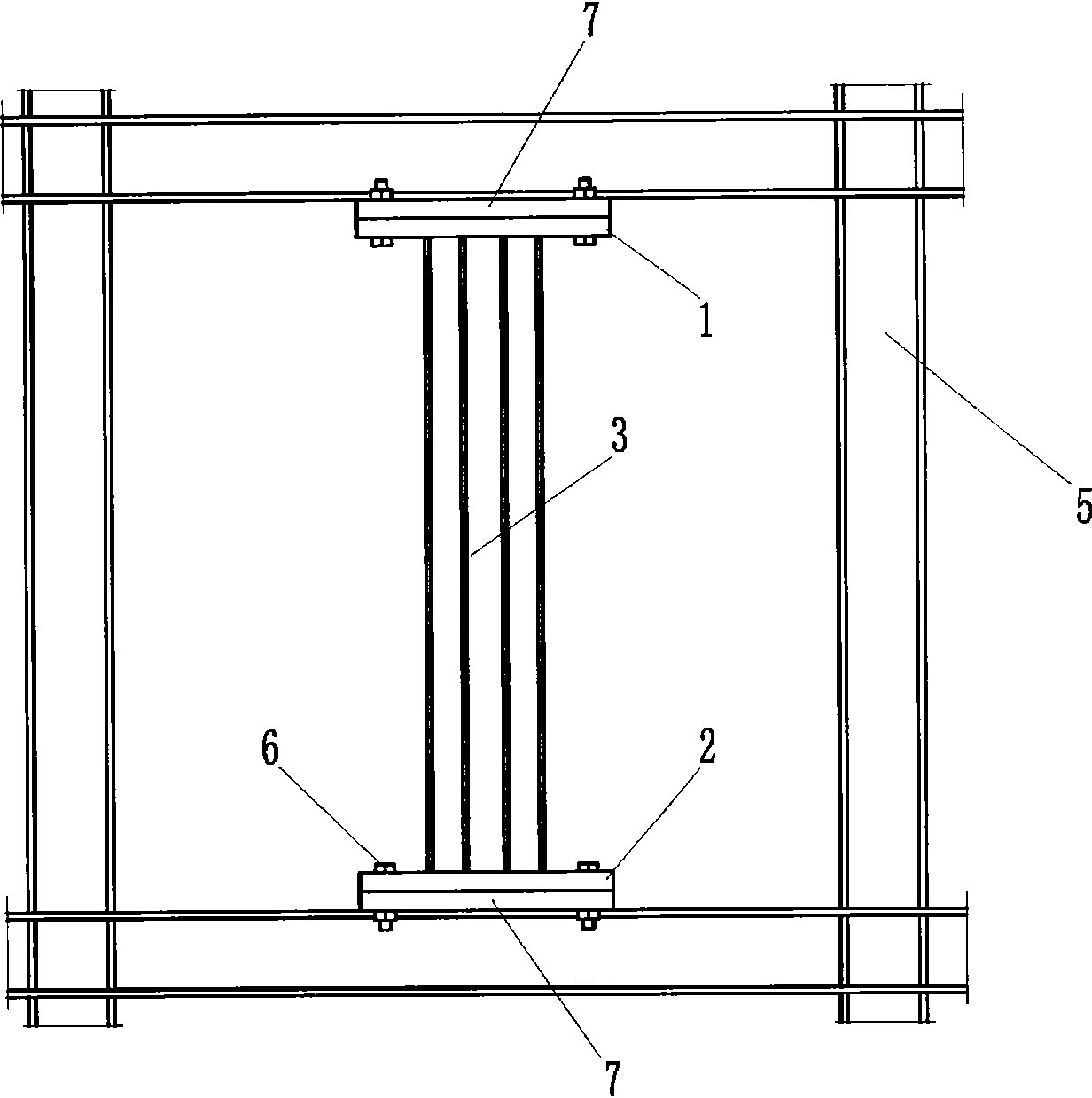

[0037] When used in frame structures, such as image 3 , Figure 4 As shown, the connecting flange 7 corresponding to the upper and lower connecting plates is welded and fixed on the steel frame 5, and the upper connecting plate 1 and the lo...

Embodiment 2

[0043] Based on the technical principle described in Embodiment 1, since the shear type metal bending energy dissipation damper of the present invention can achieve a large amount of deformation, the overall size of the present invention can be controlled to be small. Such as Figure 5 , Image 6 As shown, the difference from Embodiment 1 is that when the size of the shear type metal bending energy dissipation damper of the present invention is very small, an auxiliary bracket 9 can be added on the steel frame, and then the upper connecting plate 1 and the steel frame can be fixed. The provided connection flanges 7 are connected, and the lower connection plate 2 is connected with the connection flanges 7 fixedly provided on the auxiliary bracket 9 , so that the present invention is firmly connected to the steel frame 5 . When the steel frame 5 is deformed by the shear force F1 and F2, since the present invention uses a steel plate with a small bending stiffness as the energy-...

Embodiment 3

[0046] Such as Figure 7 , Figure 8 The difference between the shear type metal bending energy dissipation damper of the present invention and the first embodiment is that when the present invention is subjected to a shear load, the middle part of the core steel energy dissipation element bears a small moment, in order to reduce the system stiffness And to save steel, part of the material is appropriately cut off in the middle of the steel plate 3, and the steel plate 3 is made into an approximate "I" shape, so that the cross-sectional size of the middle part of the steel plate is smaller than the cross-sectional size of both ends. In addition, in order to withstand the large shear force and increase the number of steel plates, a total of three steel plates are set as the core steel energy-dissipating elements. When setting, the three steel plates are arranged parallel to each other, and an appropriate distance is reserved between each other as a reserved space for deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com