Stepped drill reamer for machining aircraft skin rivet holes

A technology for aircraft skin and rivet holes, applied in step drills, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of unsatisfactory processing quality, low processing efficiency, and high production cost, and avoid wear and tear. The effect of large or chipped tools, improved processing efficiency, and less space occupied by tool magazines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

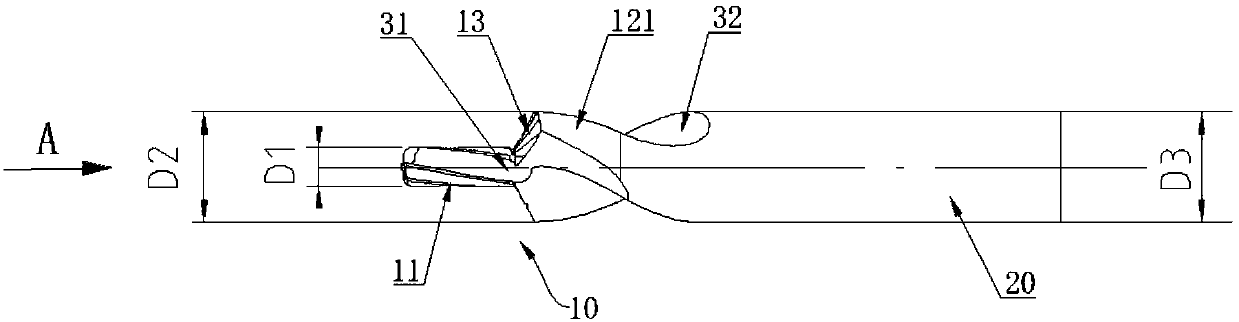

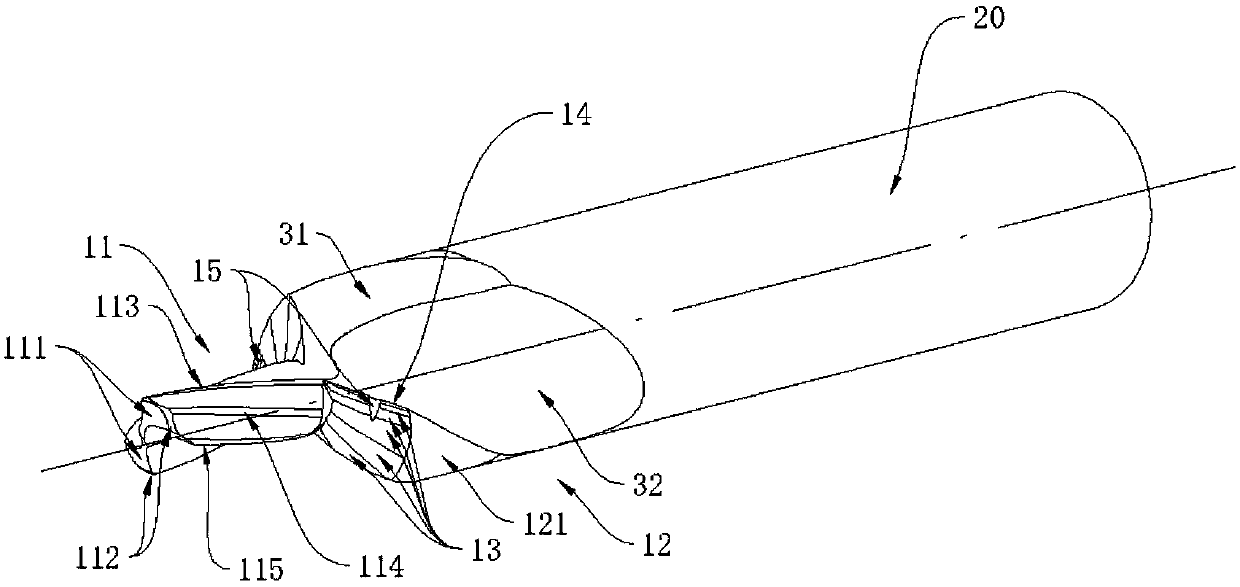

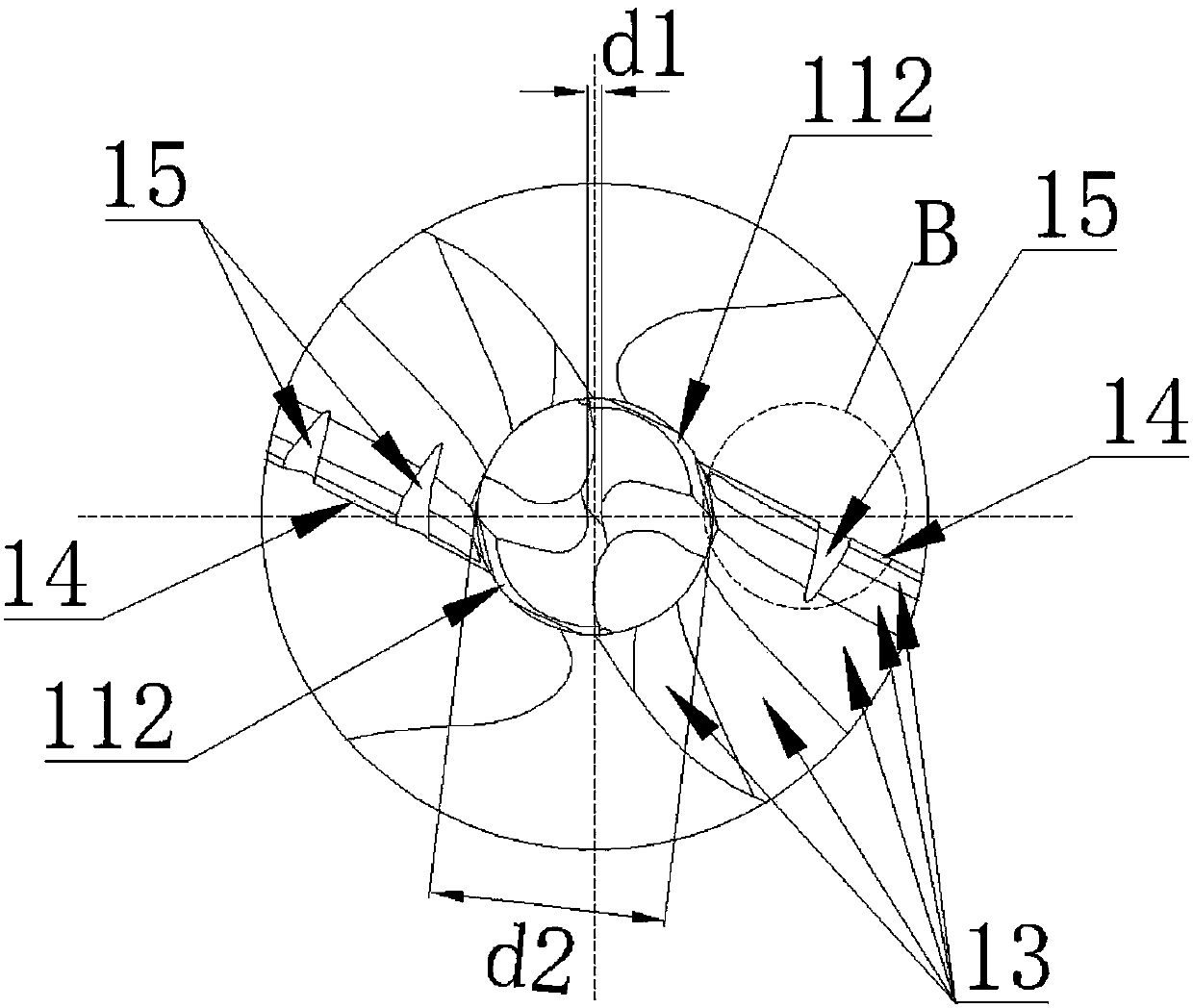

[0030] See figure 1 , the present invention is used to process the step drill reamer of aircraft skin rivet hole, and it comprises the tool handle 20 that diameter is D3 and the cutter body 10 that is concentrically arranged at the front end of the handle, the cutter body 10 is connected concentrically from front to back to form An integral first cylinder 11 and a second cylinder 12, the diameter D1 of the first cylinder 11 is smaller than the diameter D2 of the second cylinder 12; the first cylinder 11 is the drill head, the second cylinder 12 is the reamer part, the There are two symmetrical first flutes 31 along the center on the outer peripheral surface and two blades 111 are formed on the outer peripheral surface of the first cylinder 11, and two second rows symmetrical along the center are arranged on the outer peripheral surface of the second cylinder 12. Chip flutes 32, the two first chip flutes 31 on the outer peripheral surface of the first cylinder 11 both extend to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com