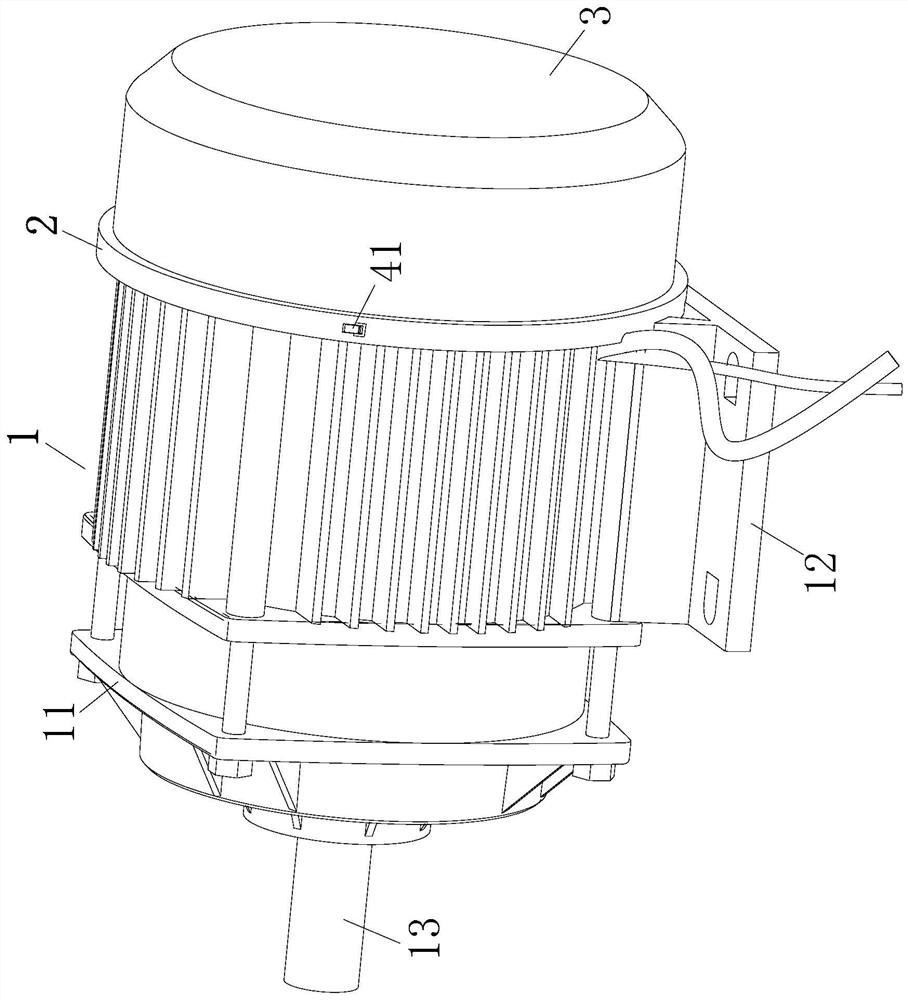

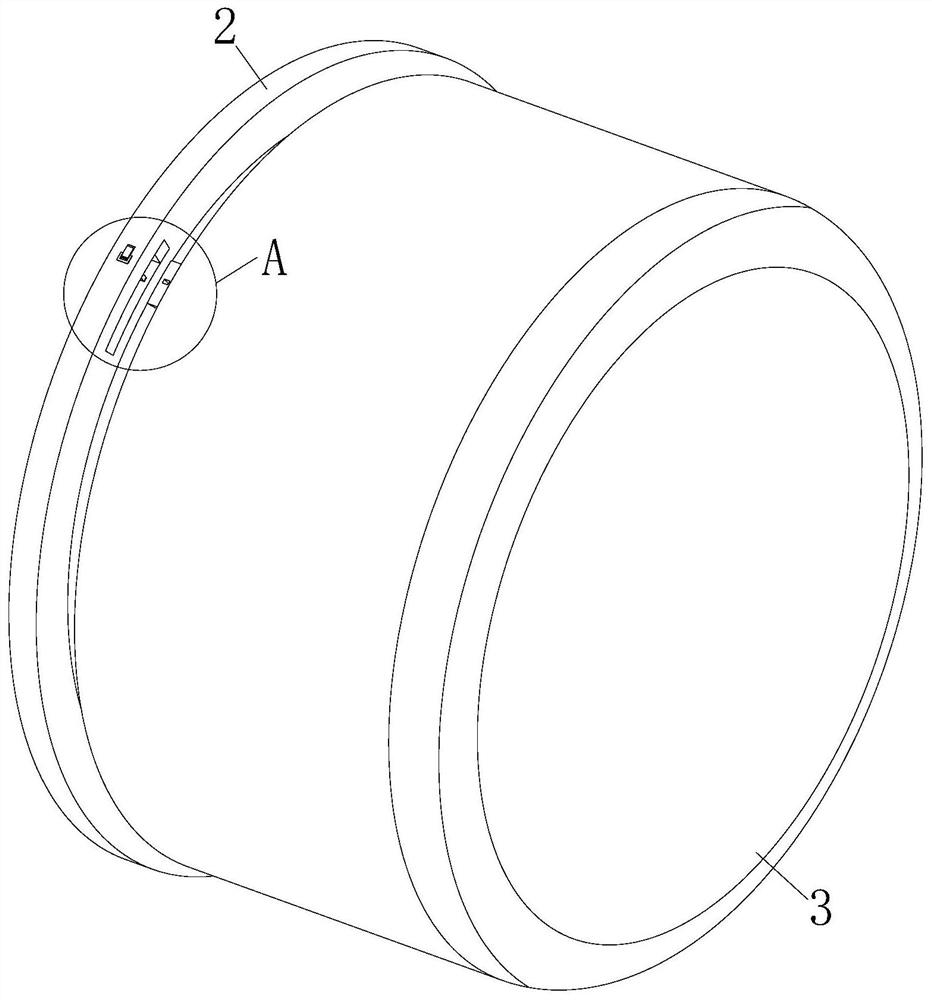

DC drive permanent magnet variable-frequency motor

A variable frequency motor and DC drive technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems that affect the use of motors, complex motor structures, and larger volumes, so as to improve convenience and practicability and reduce interference. , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

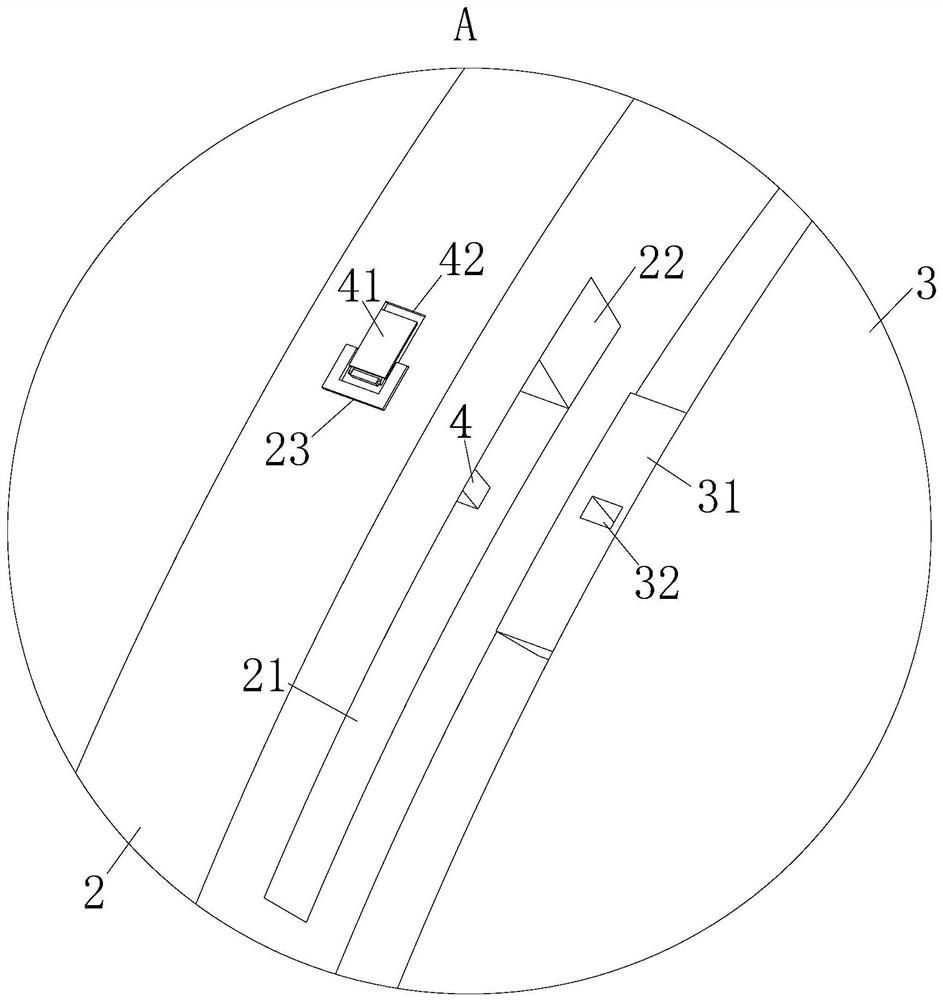

[0025] As an embodiment of the present invention, the length of the locking plate 4 is the same as the sum of the depths of the No. 1 locking groove 32 and the No. 2 locking groove 23, and the top end of the locking plate 4 is rotatably connected with a rotating plate. 41, the side wall of the fixed ring 2 on the side of the No. 2 locking groove 23 is provided with a storage groove 42 matched with the rotating plate 41; during work, by setting the length of the locking plate 4, the locking plate 4 The outer end is flush with the side wall of the fixed ring 2 in the working state, preventing the outer end of the locking plate 4 from being disturbed by external force or affecting the assembly of the motor due to excessive protruding from the outer end of the fixed ring 2, but with this Simultaneously, the locking plate 4 is inconveniently pulled out from the inside of the two locking grooves. At the same time, at the same time, the top of the locking plate 4 is rotated to be conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com