Overall pressing assembly device for new energy battery

An assembly device and new energy technology, applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of slow battery box speed, weak positioning, and incorrect battery box fixed posture, etc., to achieve Fast fixing speed, good protection effect and stable moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

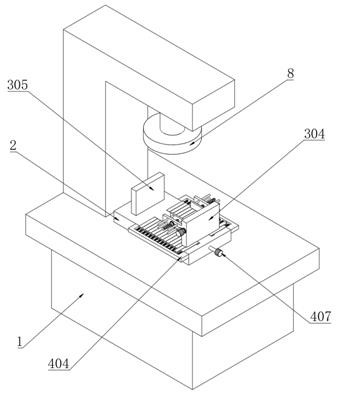

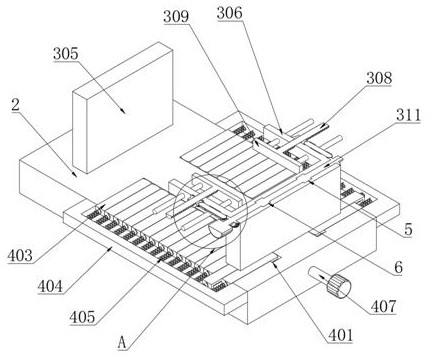

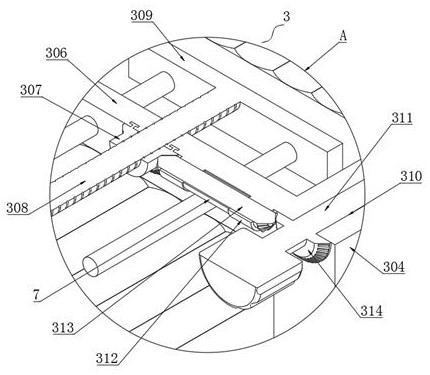

[0037] Example: such as Figure 1-5As shown, the utility model provides a technical solution, including an assembly device body 1 used to fix the battery box to realize the battery body as a whole to be press-fitted into the battery box. The assembly device body 1 includes a sliding seat 2 and a The camera visual judgment system 8, the camera visual judgment system 8 can judge whether the battery box is fixed at the preset position and whether the posture is correct; the sliding seat 2 is provided with a positioning assembly 3, and the positioning assembly 3 includes a sliding cavity 301, a sliding block 302, a support Rod 303, sliding plate 304, fixed plate 305, support plate 306, nut 307, clamping screw 308, splint 309, linkage hole 310, linkage rod 311, rotating cylinder 312, driven rod 313 and bevel gear 314, sliding seat 2 A sliding chamber 301 is opened on one side of the interior, and a sliding block 302 is slidably embedded in the sliding chamber 301. A support rod 303...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com