Patents

Literature

39results about How to "Avoid affecting movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

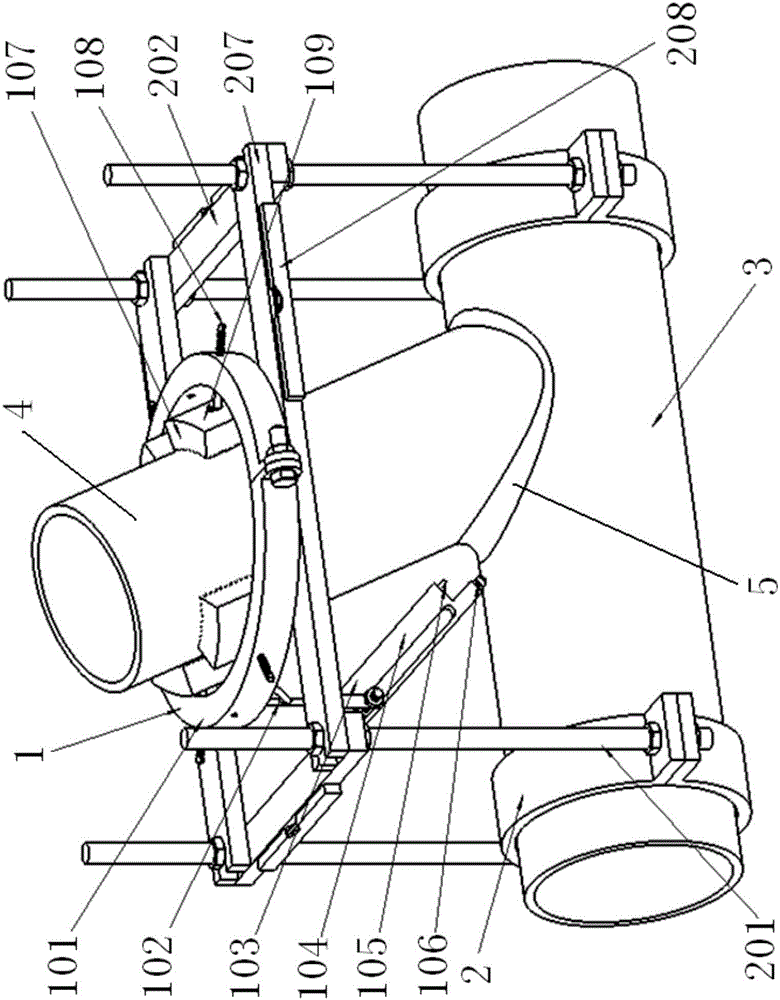

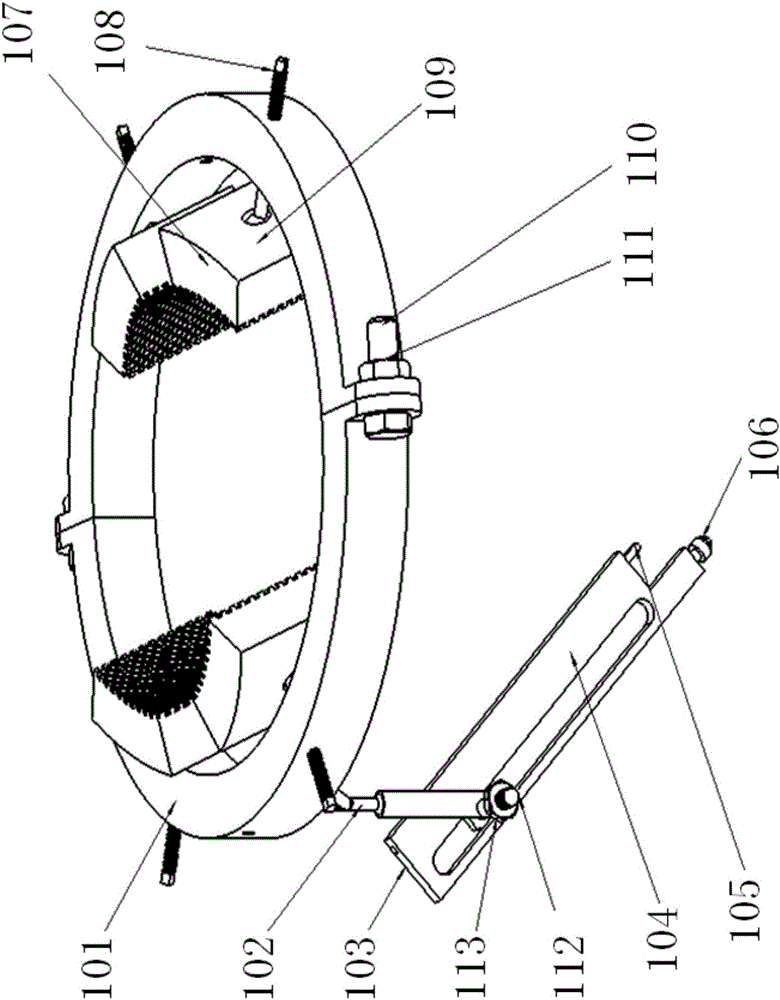

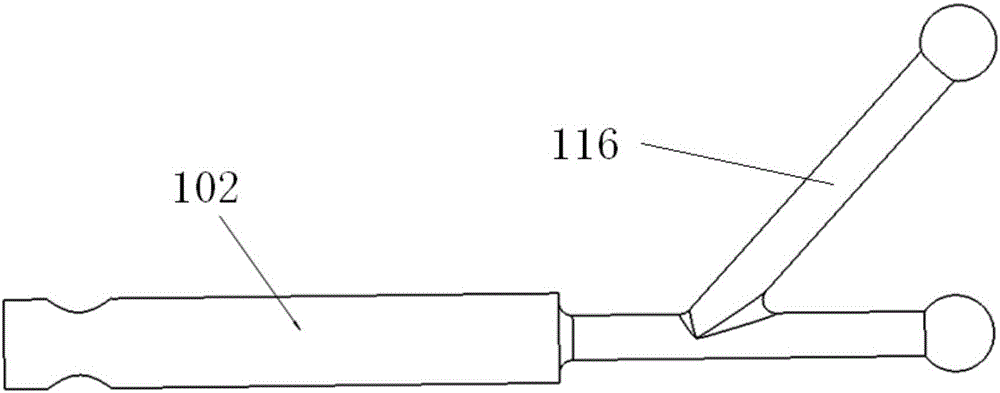

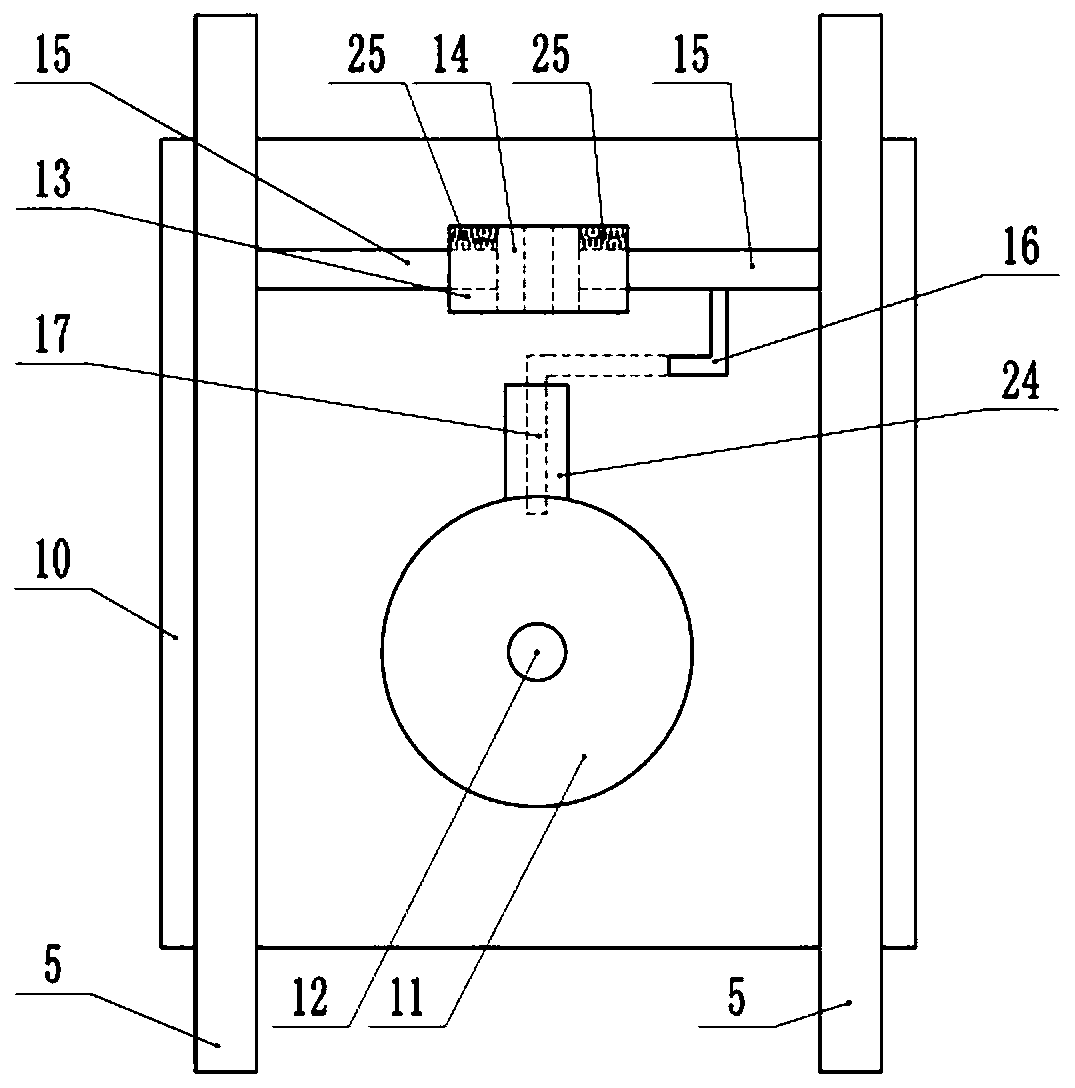

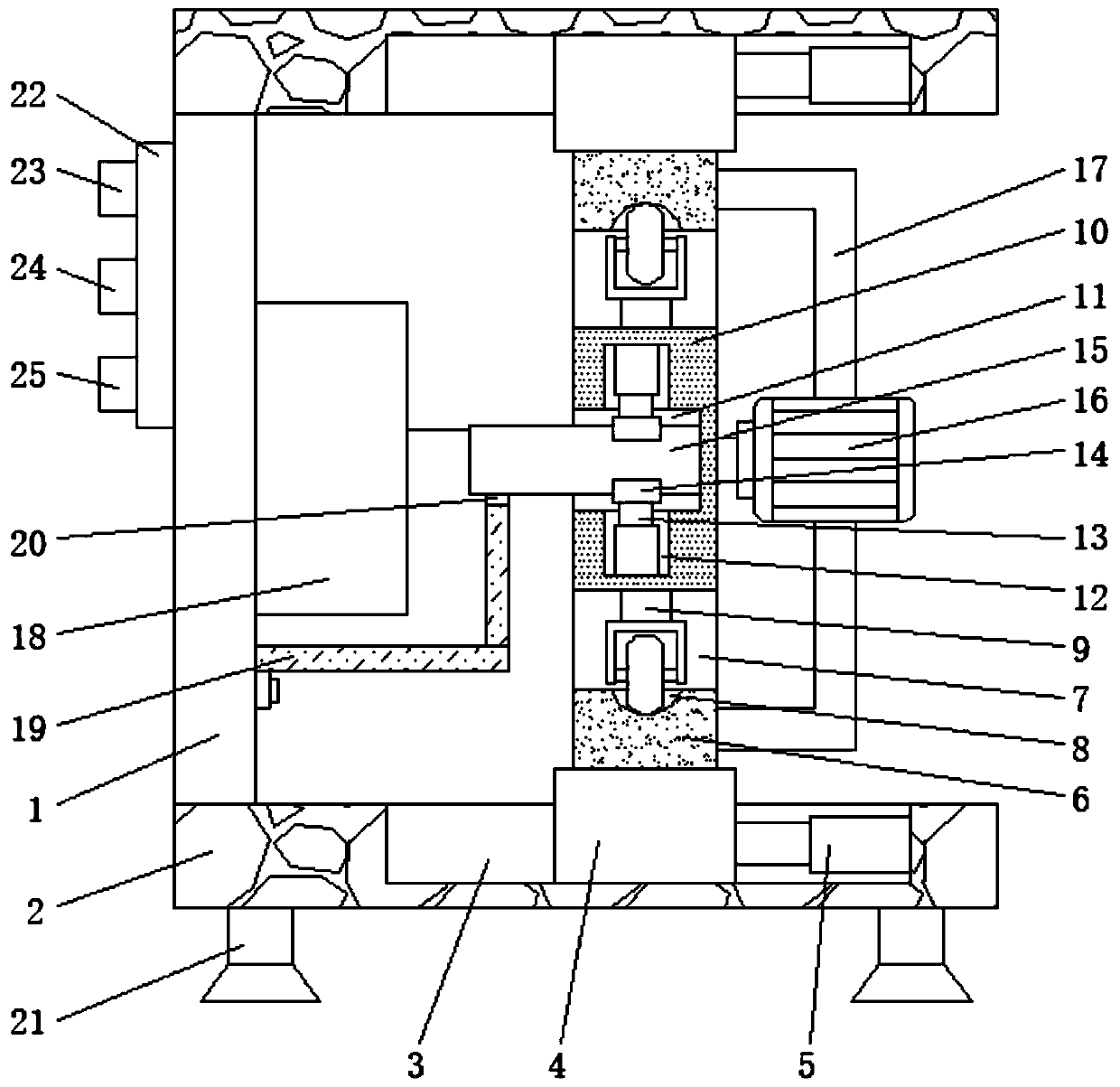

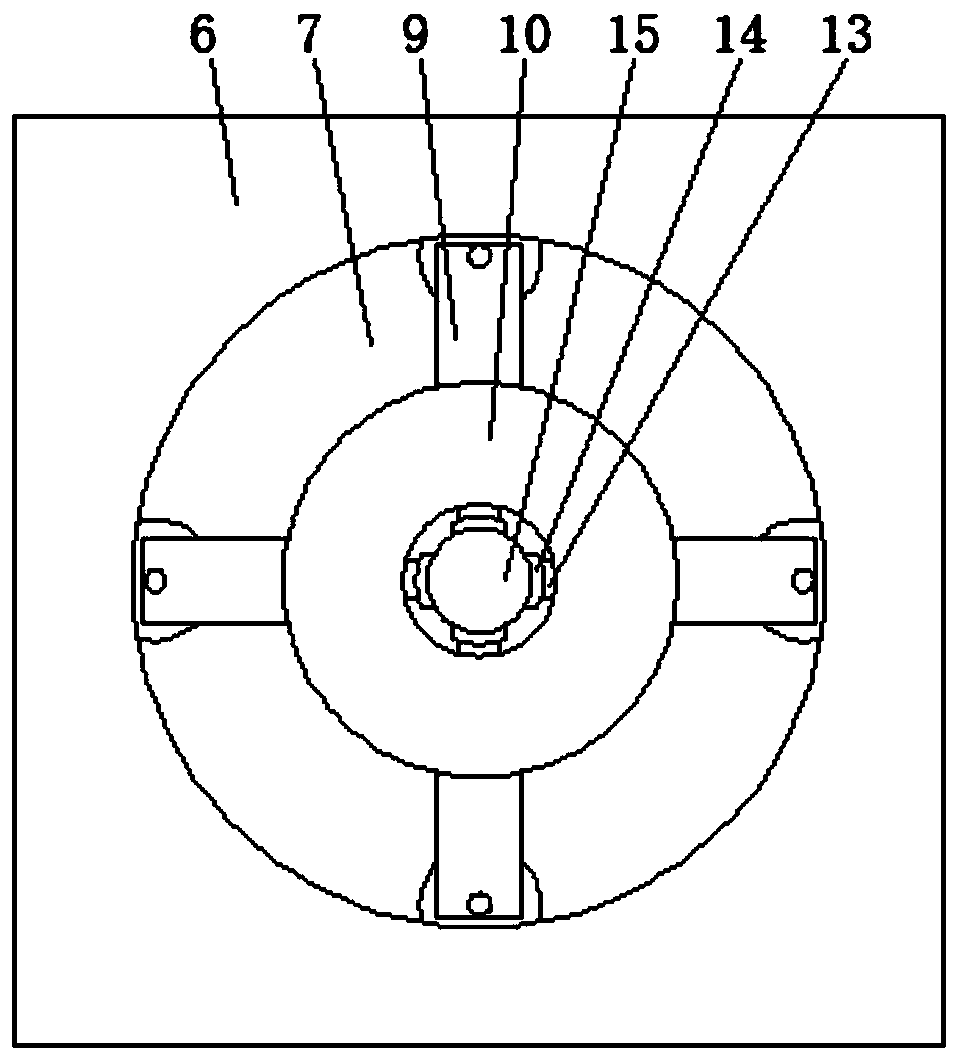

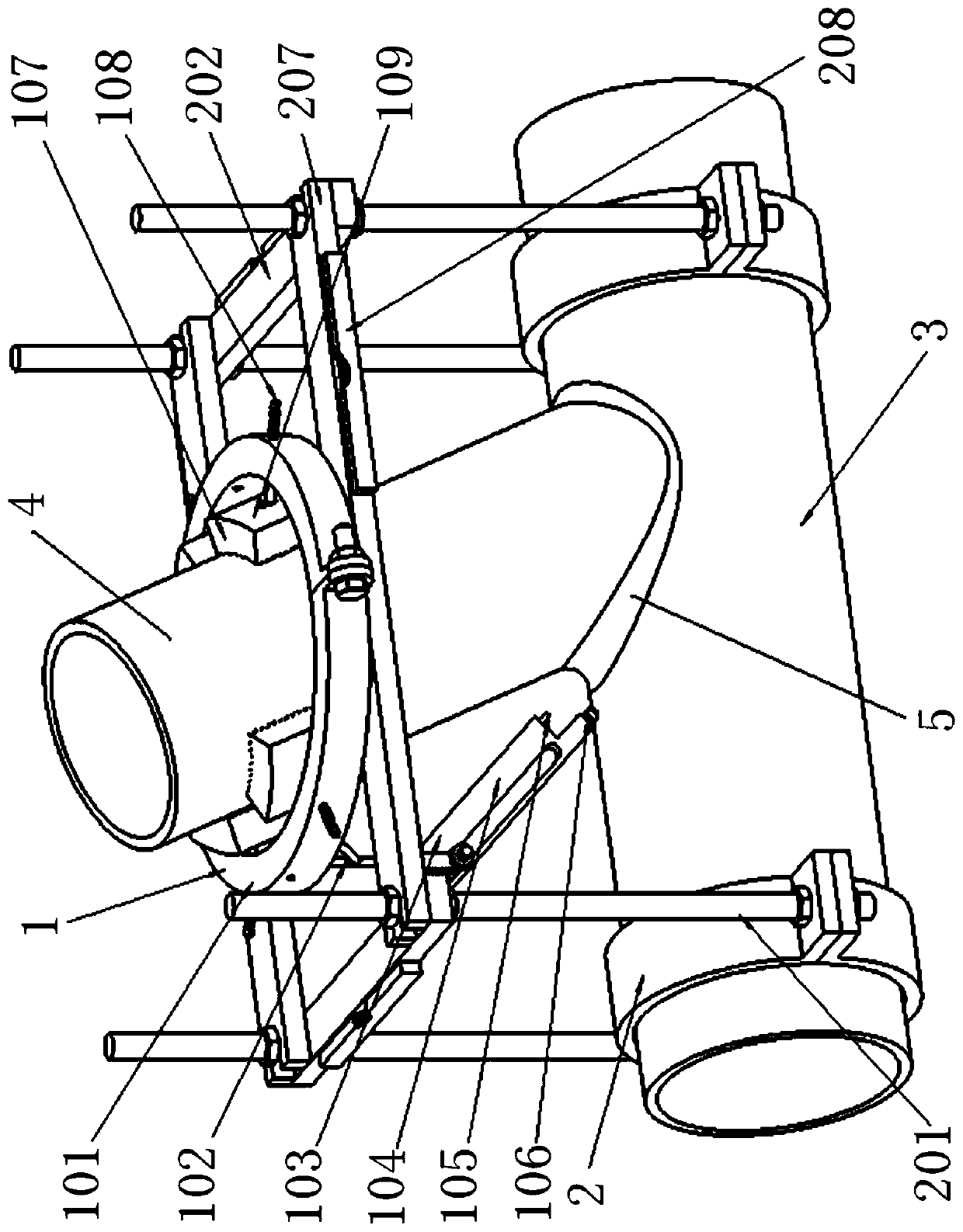

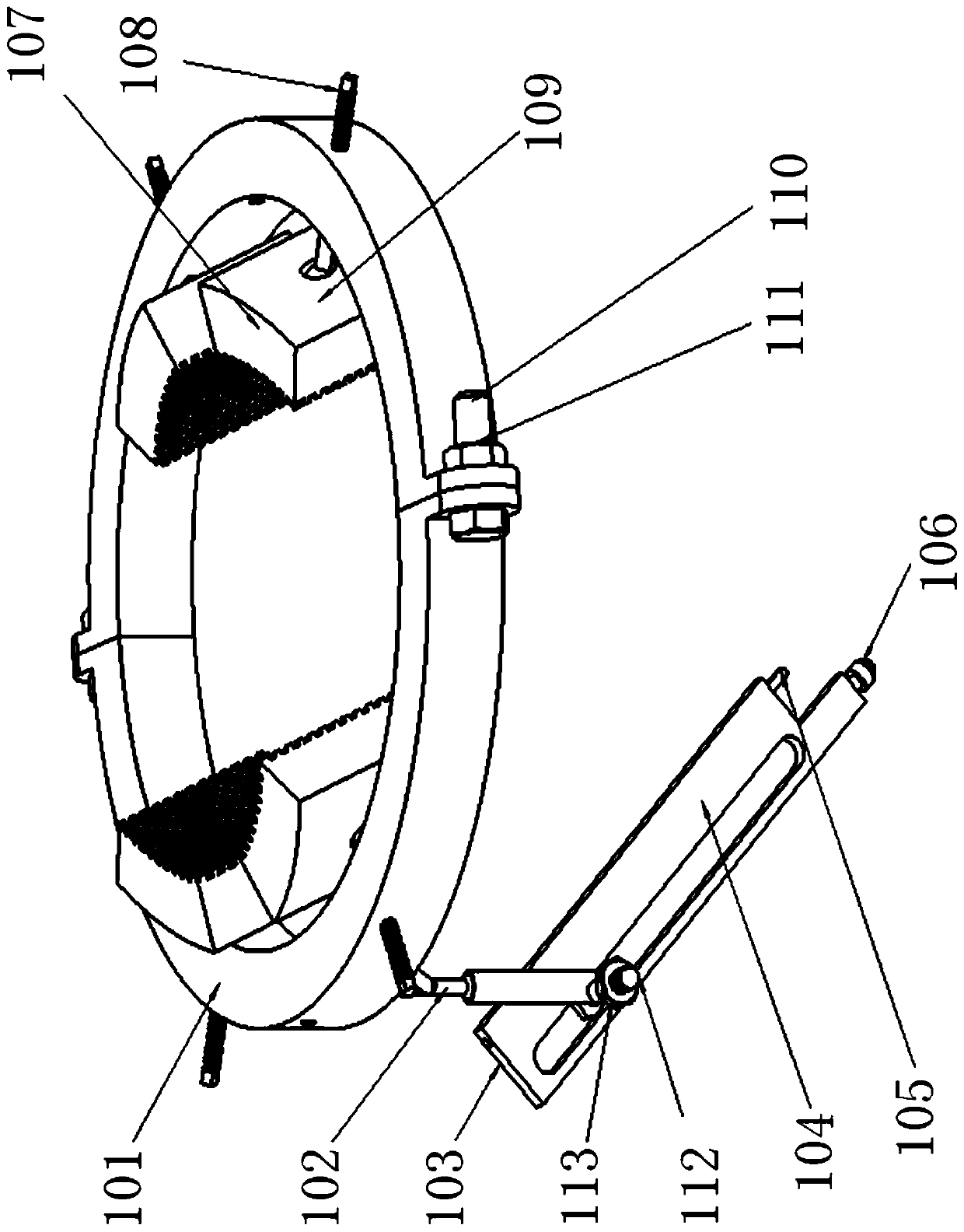

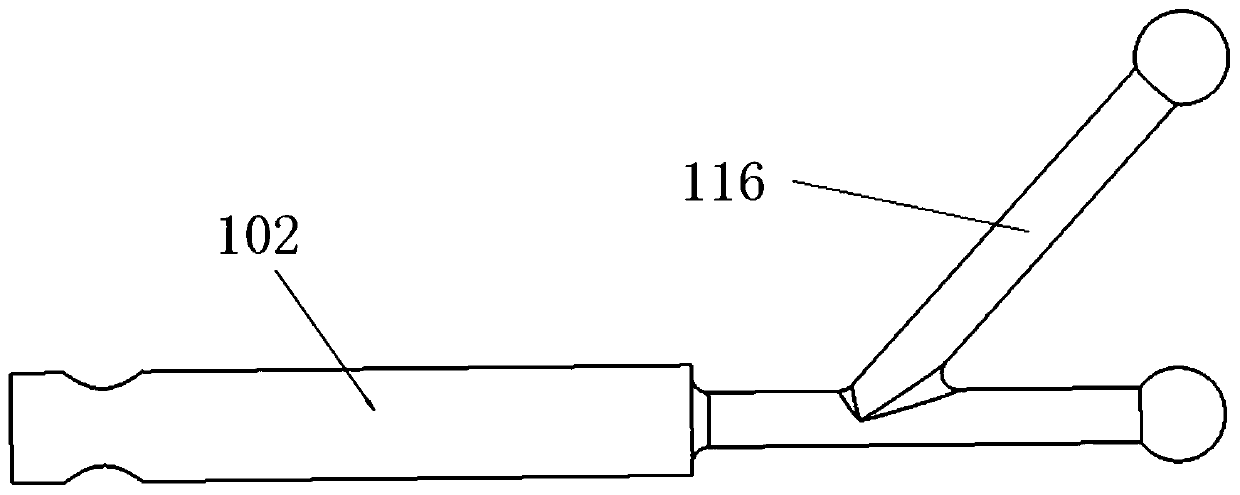

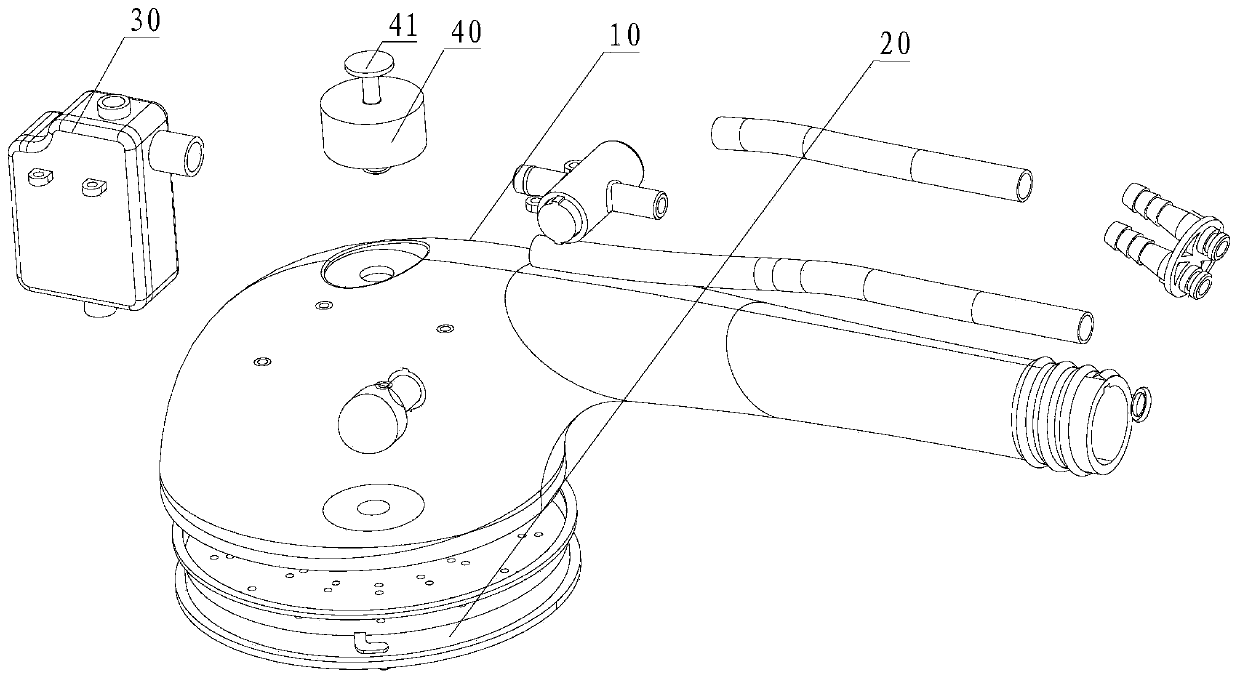

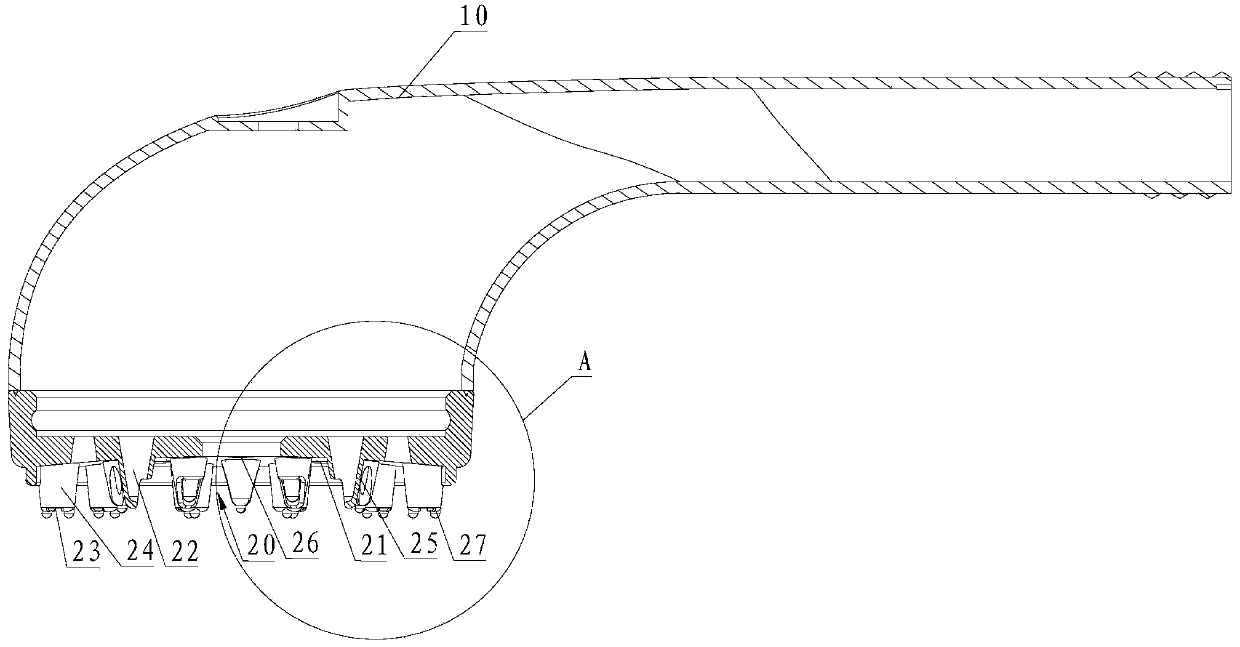

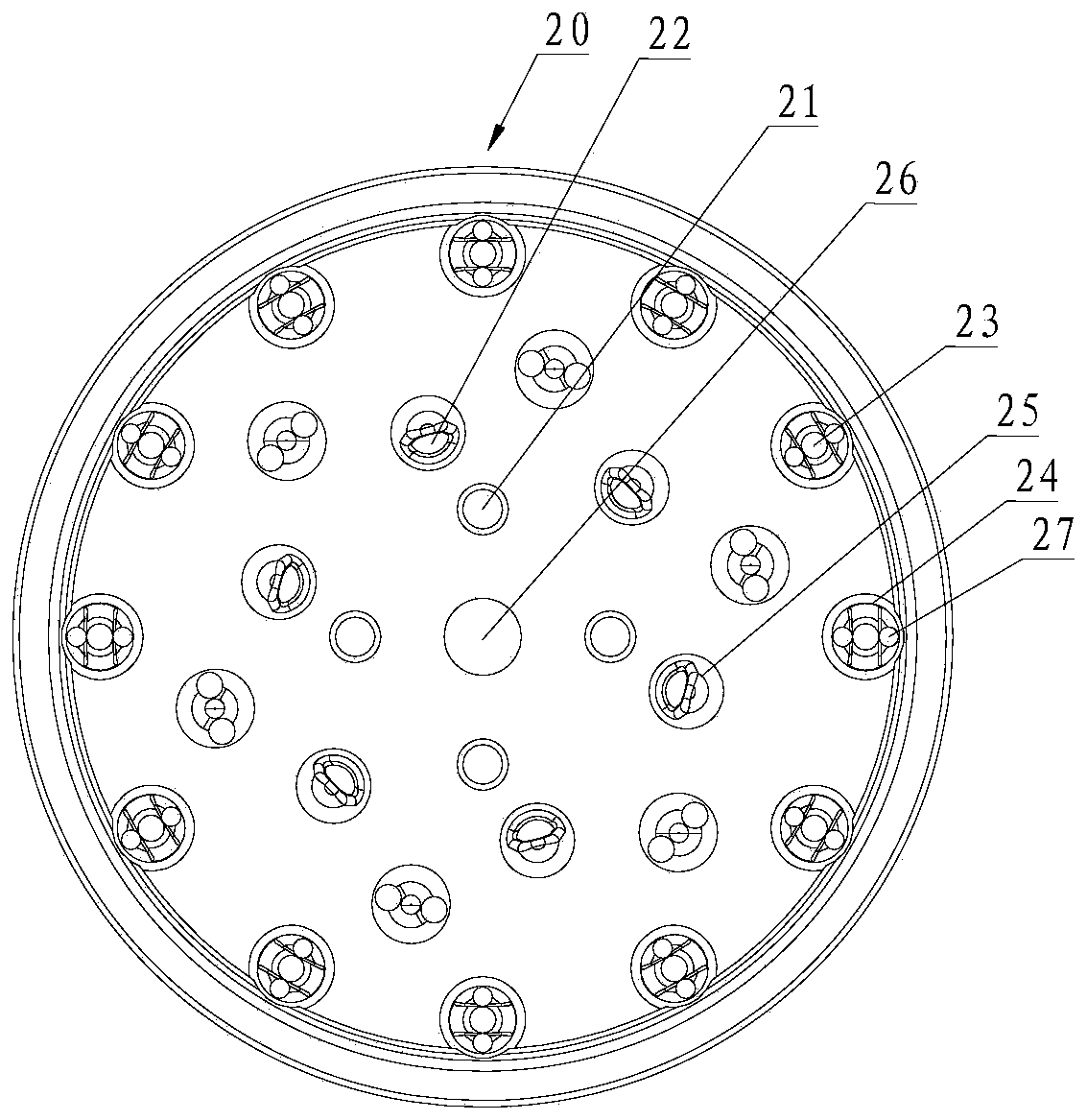

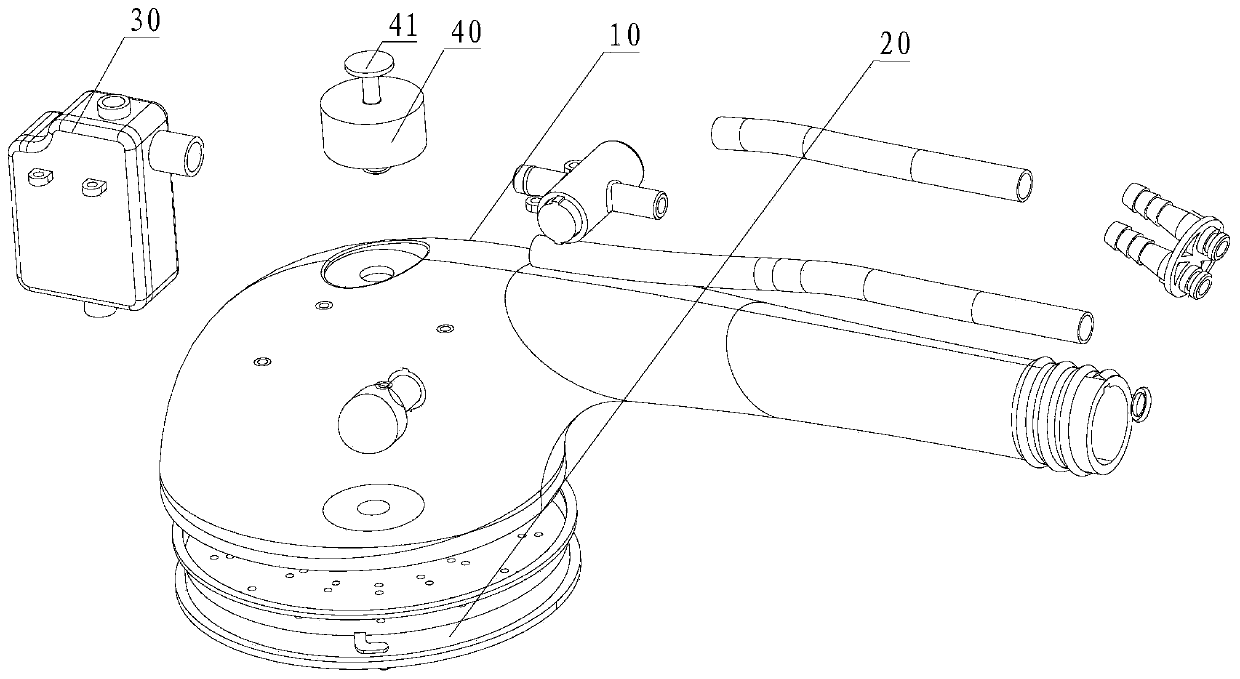

Magnetic memory detection device for cross manifold weld

ActiveCN106645383AGuaranteed accuracyAvoid analysis errorsMaterial magnetic variablesFillet weldStraight tube

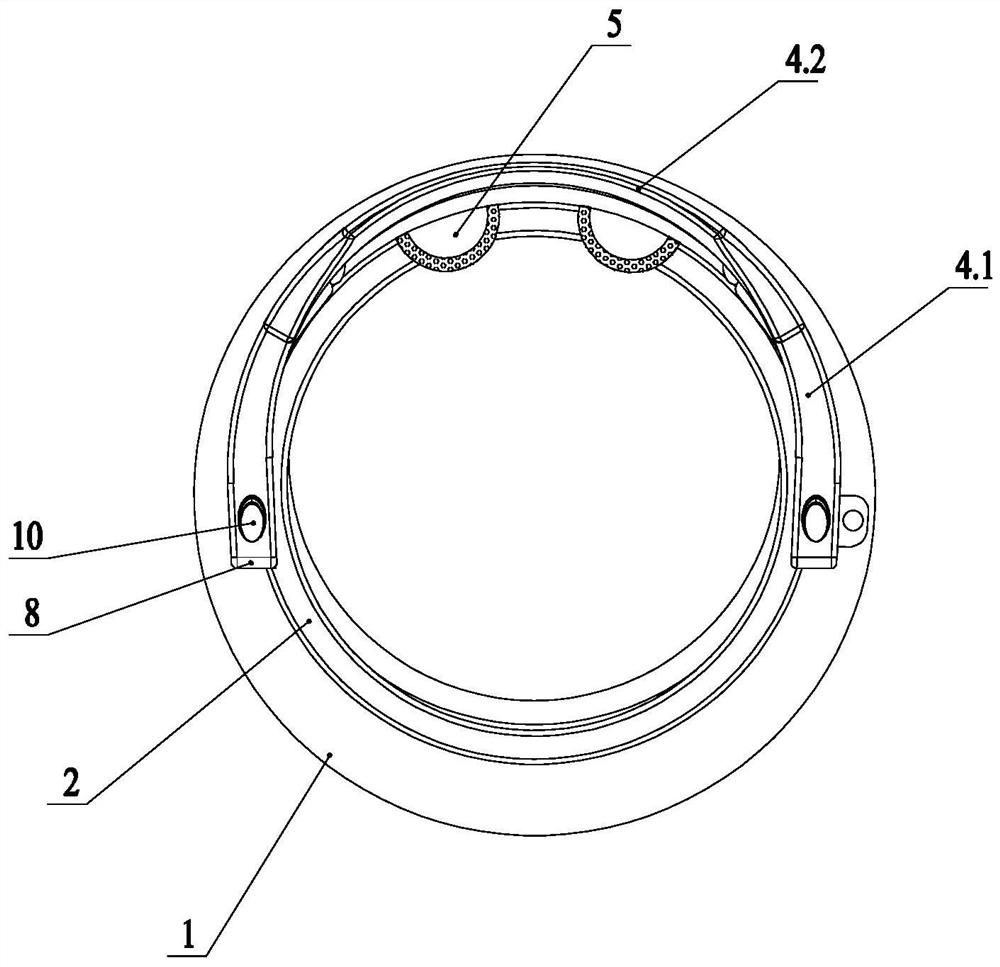

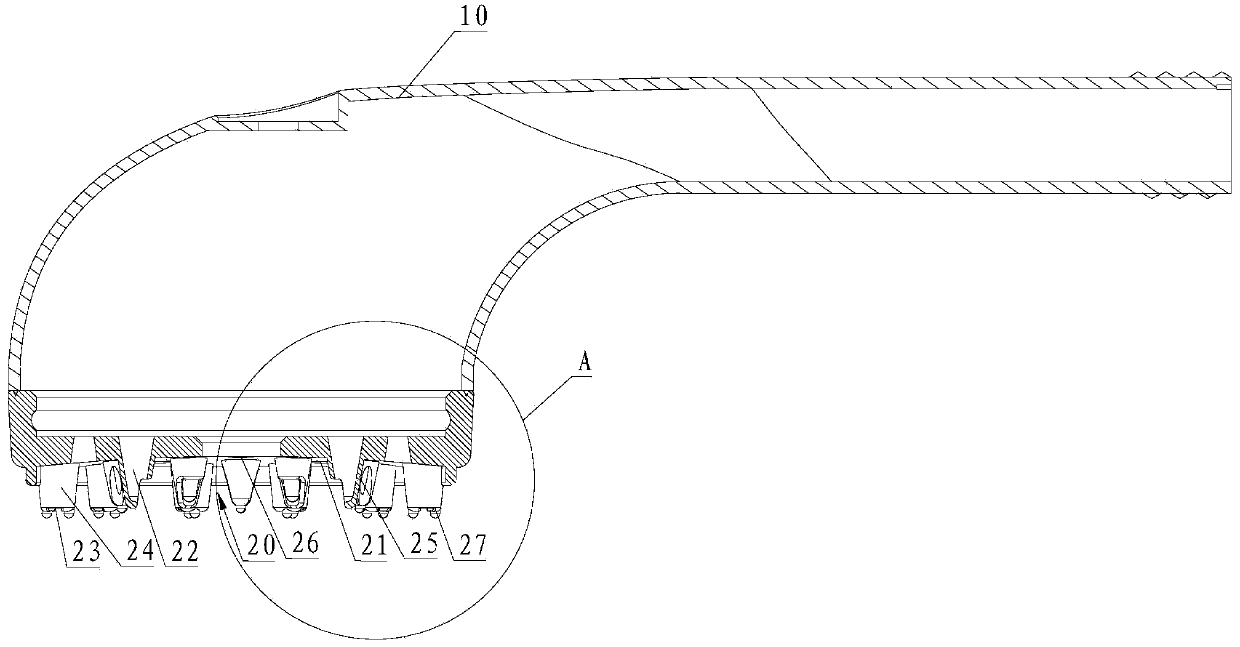

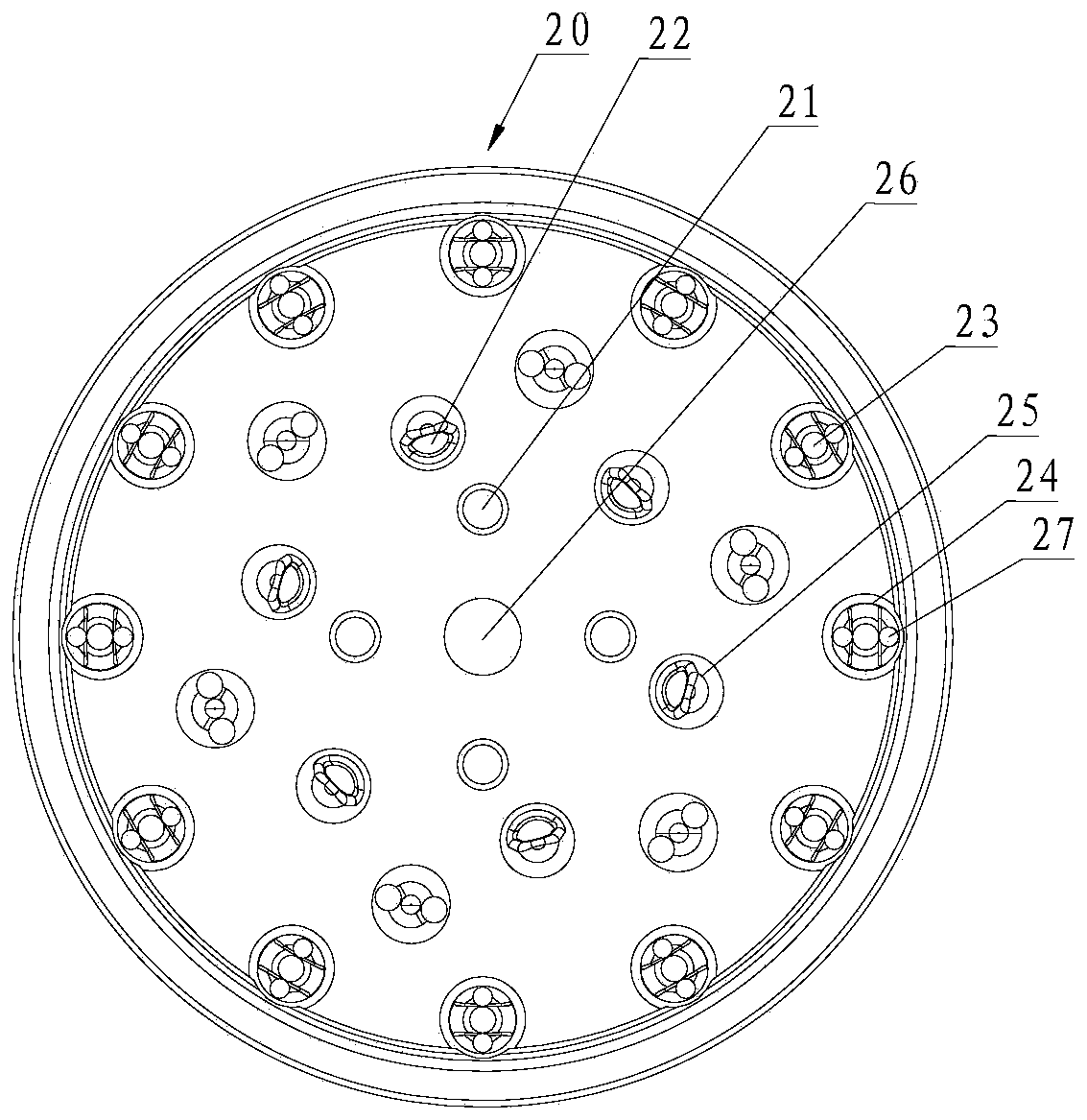

The invention provides a magnetic memory detection device for a cross manifold weld, used for detecting a weld (5) between a straight pipe (3) and an inclined pipe (4), wherein the magnetic memory detection device for the cross manifold weld comprises a magnetic memory sensor detection driving mechanism (1) and an assistant adjusting support (2), the magnetic memory sensor detection driving mechanism (1) comprises a detection unit (103) and a circular rail (115) capable of sleeving the outside of the inclined pipe (4), and the detection unit (103) can detect the detected weld (5) during the process of moving along the circular rail (115); the magnetic memory detection device for the cross manifold weld can perform omni-directional barrier-free detection on oblique crossing pipe intersecting line fillet welds with small angle areas. The error caused by manual operation during measuring can be greatly reduced, the smooth and stable detection process and accurate measuring result are ensured, and the measuring efficiency is greatly improved.

Owner:PETROCHINA CO LTD +1

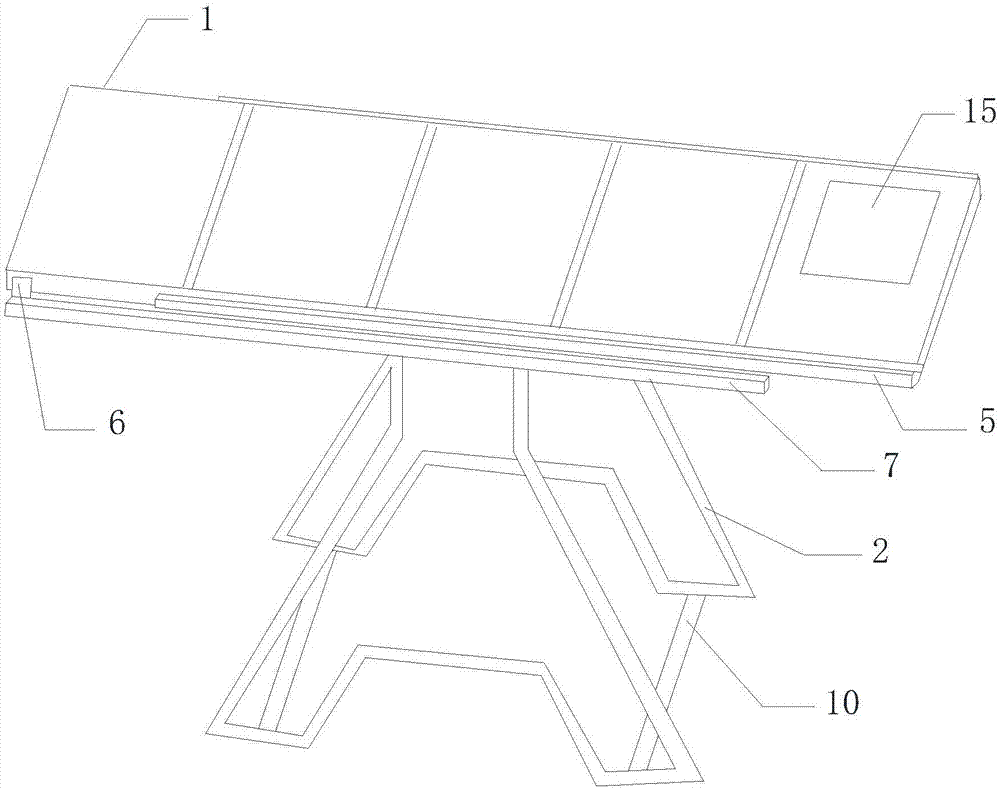

Multifunctional table

InactiveCN107874497AIncrease diversityEasy to storeServing tablesConvertible furnitureEngineeringSmall footprint

Owner:施东钱

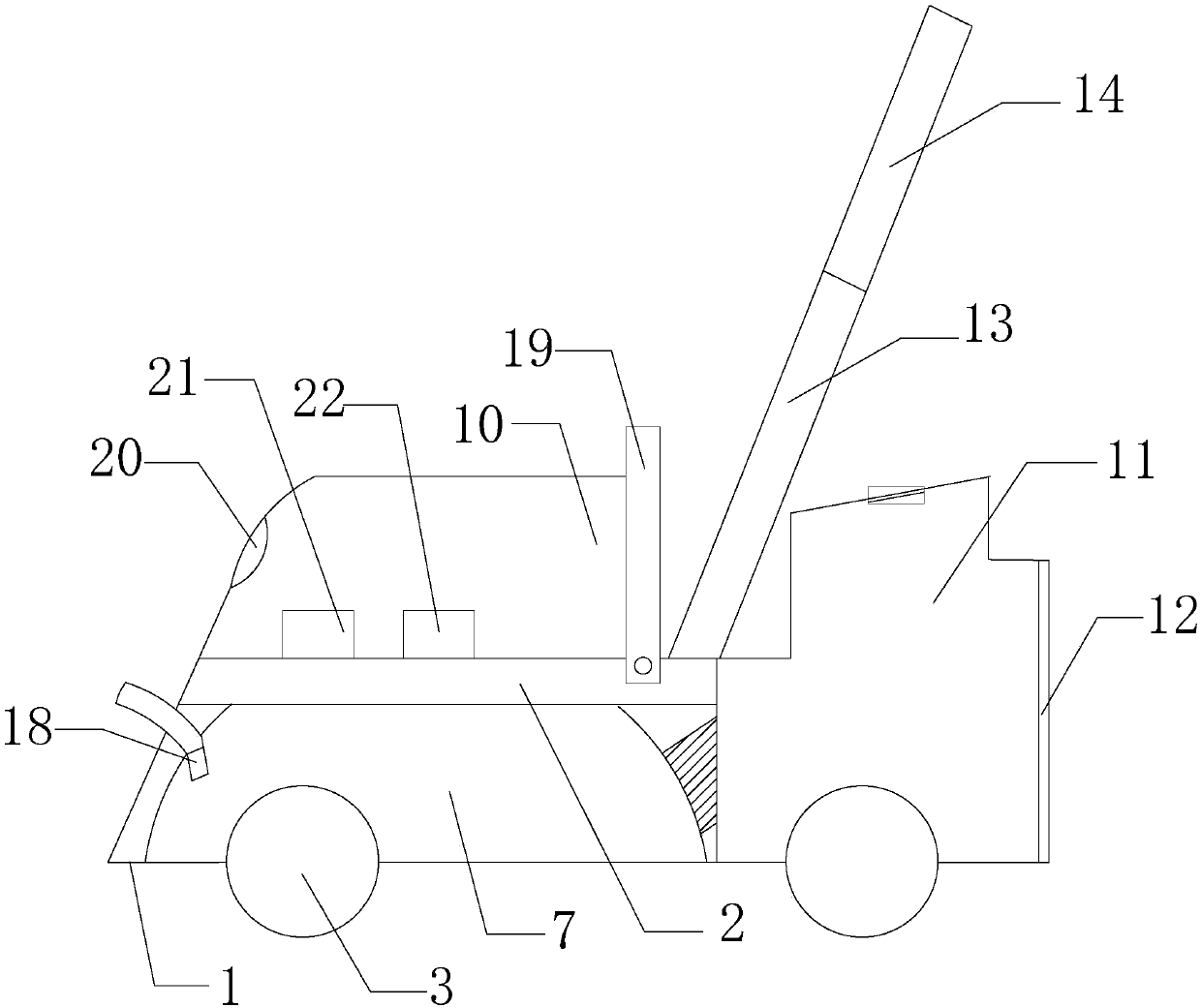

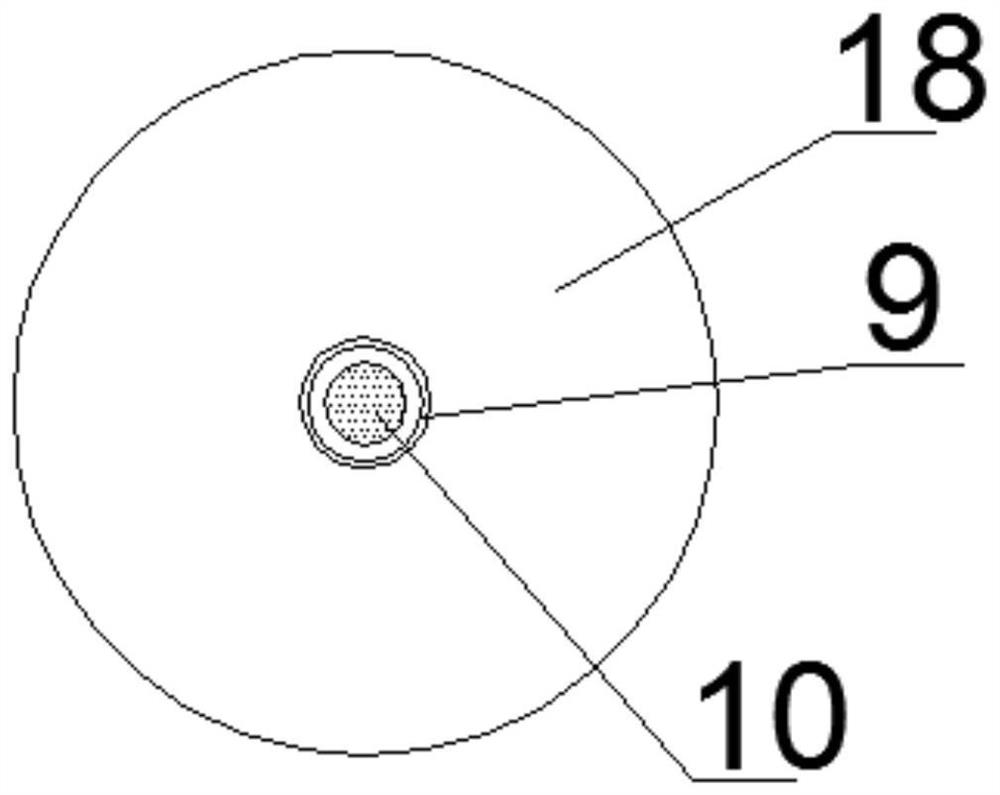

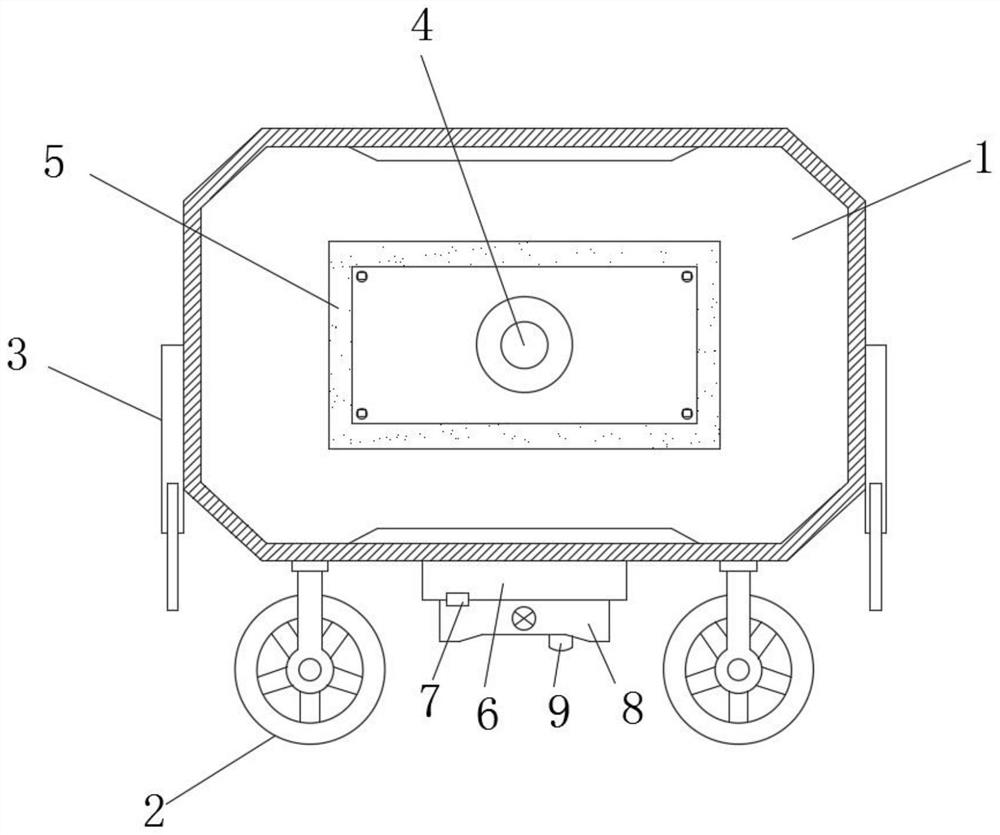

Crawler fire-fighting robot

InactiveCN111821624AEasy to removeAvoid affecting movementTelevision system detailsDeflectorsStructural engineeringControl theory

The invention discloses a crawler fire-fighting robot. The crawler fire-fighting robot comprises a fire-fighting robot body, wherein a camera is arranged at the top of the fire-fighting robot body, asensing antenna is arranged at the side, close to the camera, of the top of the fire-fighting robot body, and a protection mechanism is connected to the position, located between the camera and the sensing antenna, of the top of the fire-fighting robot body; and a cleaning mechanism is arranged in the side wall of one side of the fire-fighting robot body. The crawler fire-fighting robot has the beneficial effects that the protection mechanism is arranged so that the sensing antenna and the camera can be well protected, and the problem that fire extinguishing work cannot be completed due to thedamaged sensing antenna and the damaged camera caused by the fact that falling objects hit the sensing antenna and the camera is solved; and the cleaning mechanism is arranged so that sundries on theadvancing route of the robot body can be well pushed away, and the problem that the water spraying direction is changed due to the fact that movement of the robot body is affected is avoided.

Owner:唐翠华

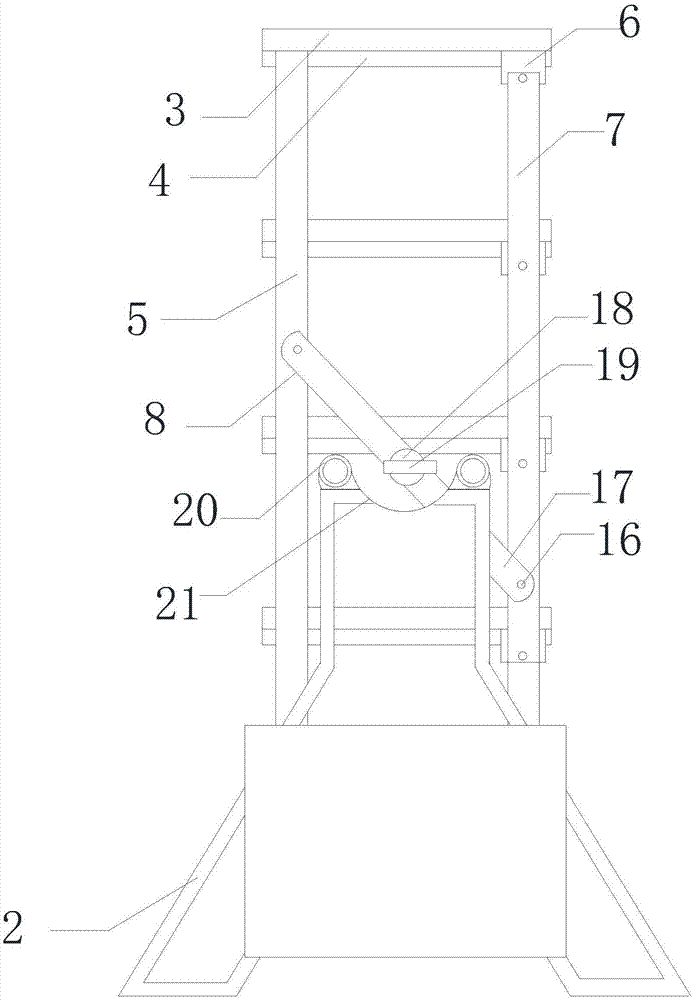

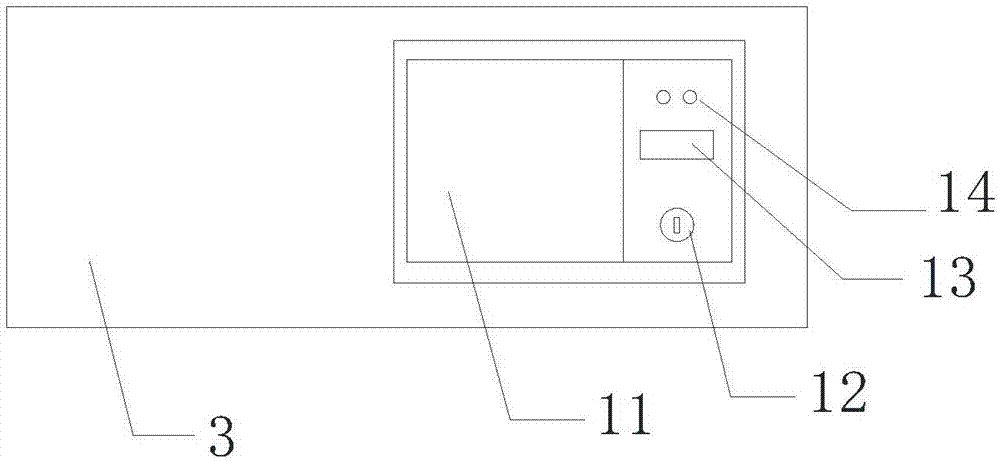

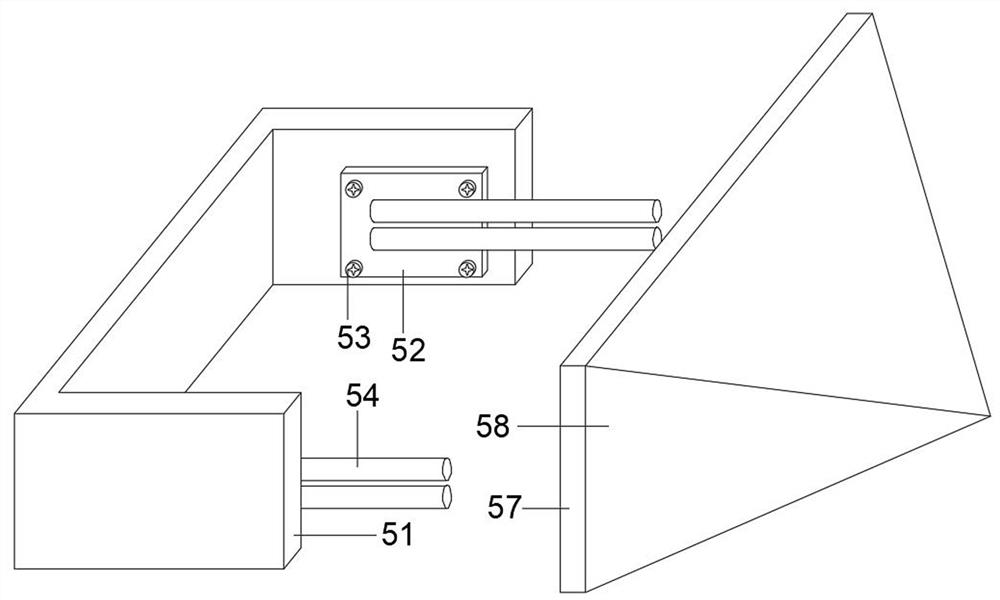

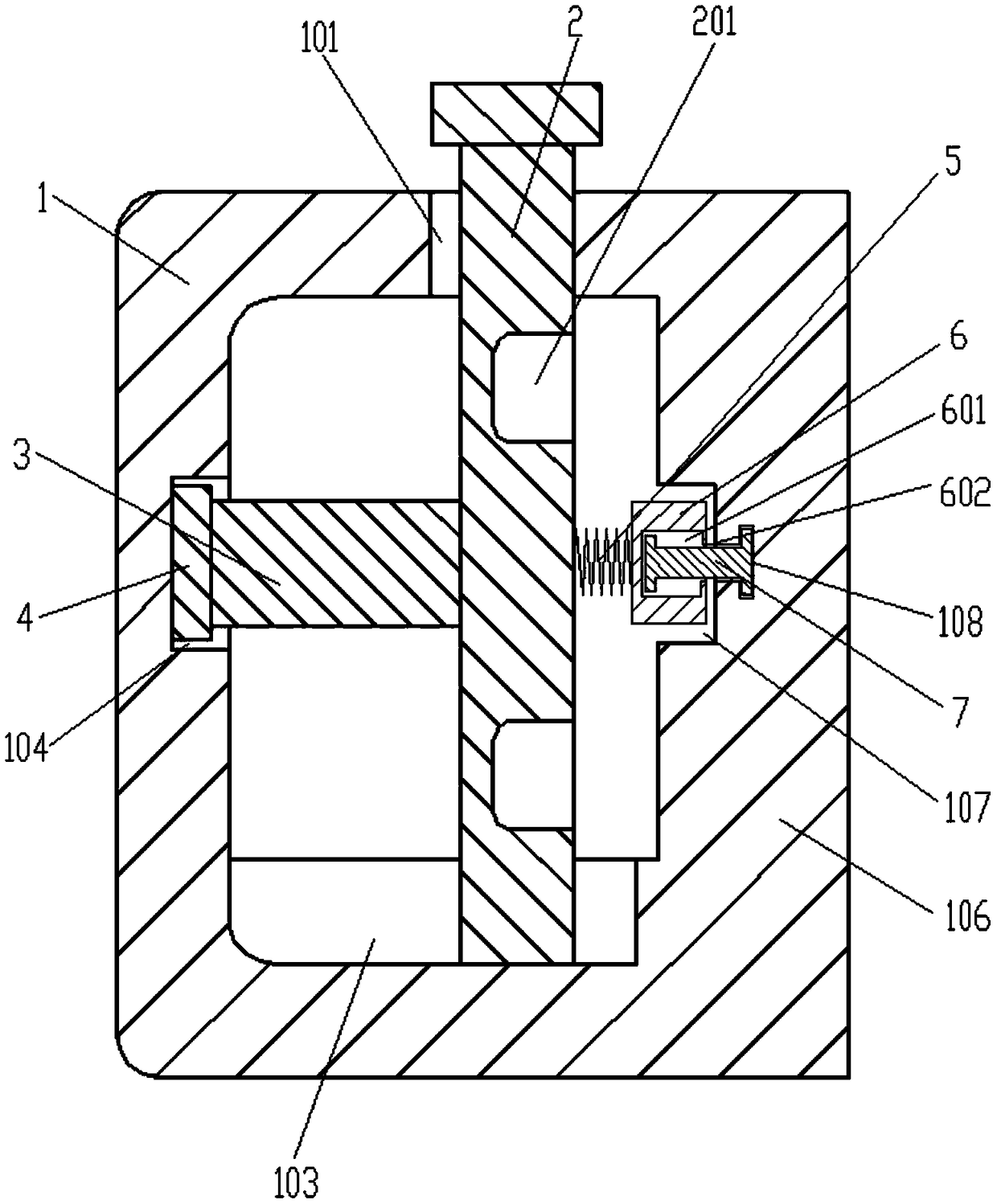

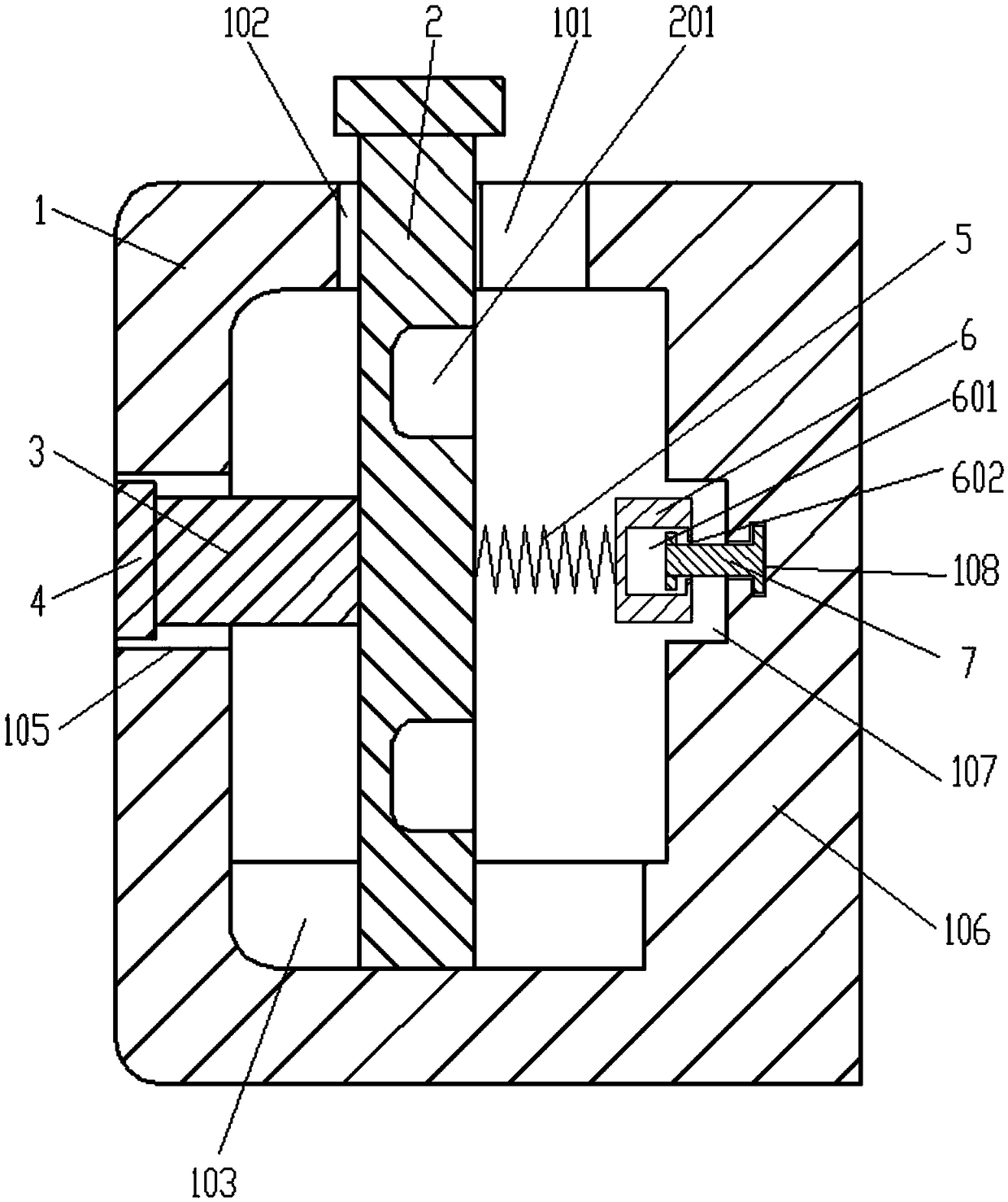

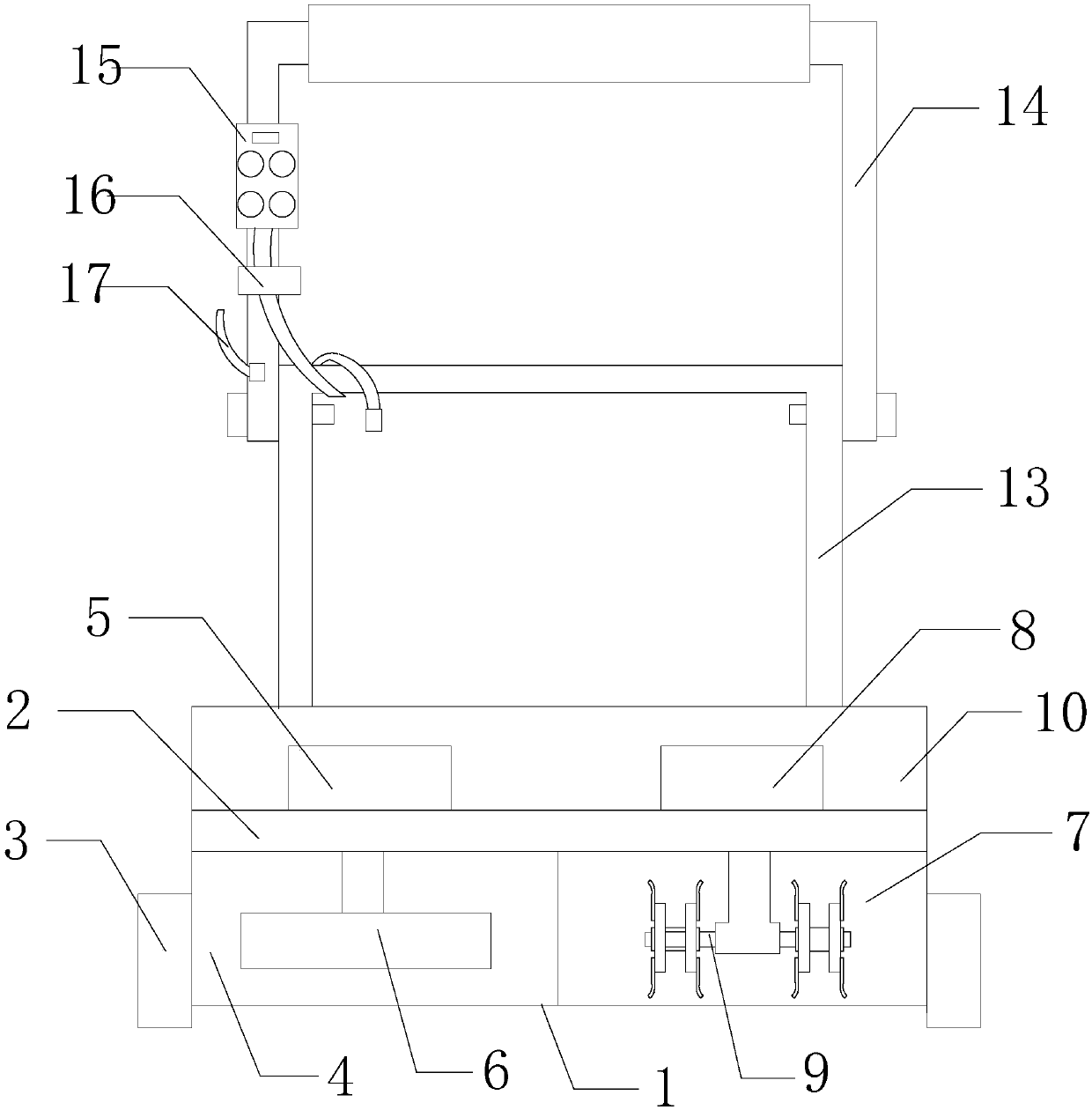

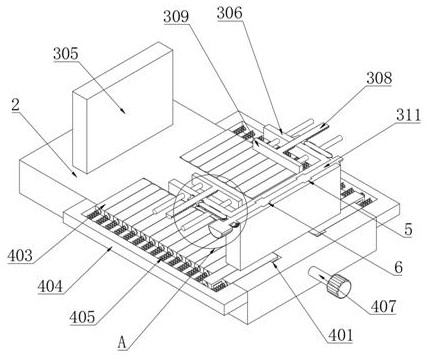

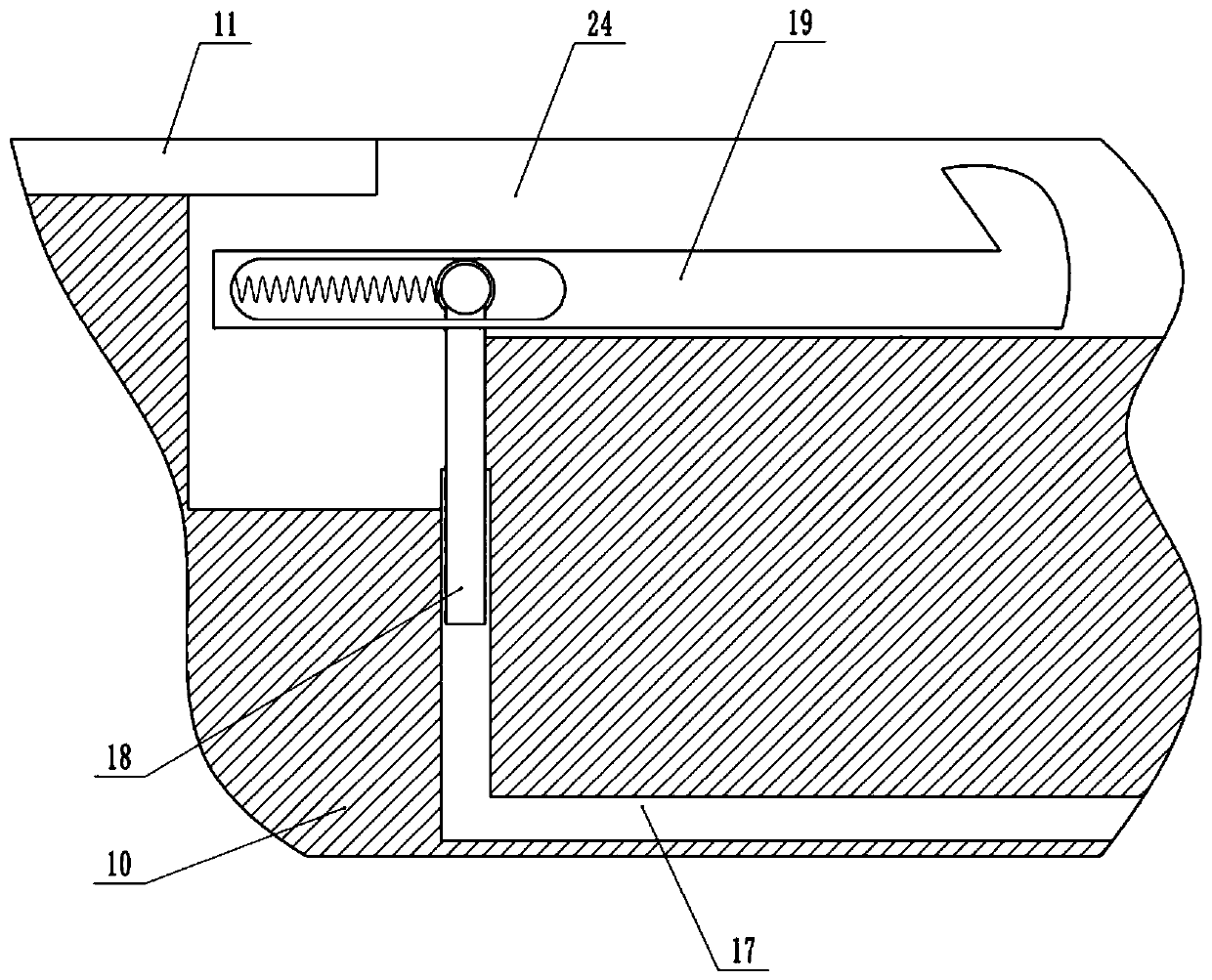

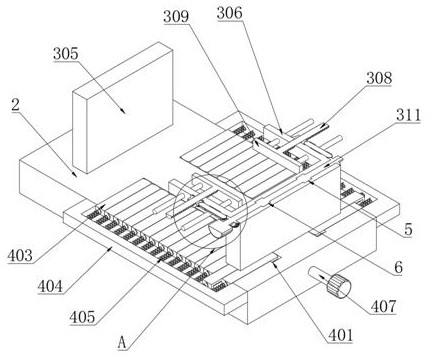

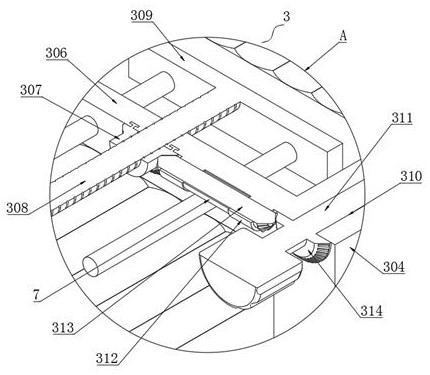

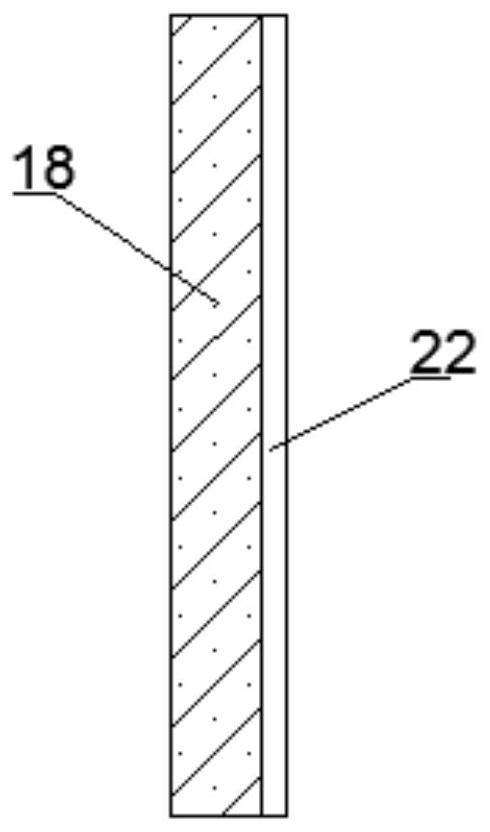

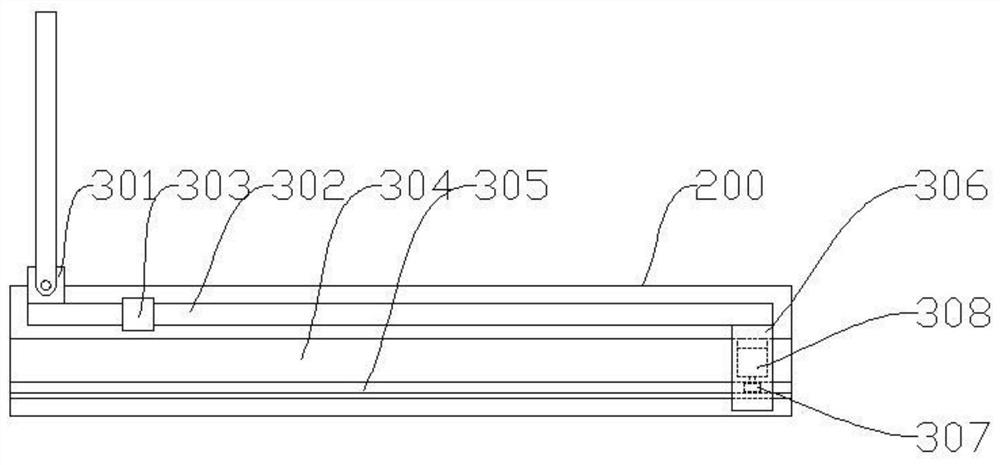

Anti-disengaging sliding type wire managing rack device for computer hardware connecting wires

InactiveCN109399373AReduce problems during useAvoid affecting movementFilament handlingMechanical engineeringEngineering

The invention provides an anti-disengaging sliding type wire managing rack device for computer hardware connecting wires. The anti-disengaging sliding type wire managing rack device comprises a wire arranging rack and a wire managing board. The wire arranging rack is of a cuboid structure, a hollow inner cavity is formed in the wire arranging rack, and openings are formed in the two ends of the wire arranging rack. A pressing plate for fastening arranged wires is formed on a rear side plate of the wire arranging rack, a sliding clamping groove is formed in a top plate of the wire arranging rack, the two ends of the sliding clamping groove are symmetrically connected with release clamping grooves, a slot is formed in the inner side of a front side plate of the wire arranging rack, and the two ends of the slot are symmetrically connected with inserting holes. A lower sliding groove is formed in a bottom plate of an inner cavity of the wire arranging rack, the lower end of the wire managing board adapts into the lower sliding groove, the upper end of the wire managing board penetrates through the sliding clamping groove and is arranged outside the wire arranging rack, an inserting block is arranged on the side, away from the pressing plate, of the wire managing board, a spring is arranged on the side, close to the pressing plate, of the wire managing board, one end of the spring is connected with a positioning block, a positioning sliding groove adapting to the positioning block is formed in the inner side face of the pressing plate, and a sliding guide anti-disengaging structure is arranged between the positioning block and the positioning sliding groove. It is guaranteed that the positioning block can smoothly enter the positioning sliding groove again after retreating from the positioning sliding groove, and the problems generated in the using process of the wire managing rack device are reduced.

Owner:吴秦豫

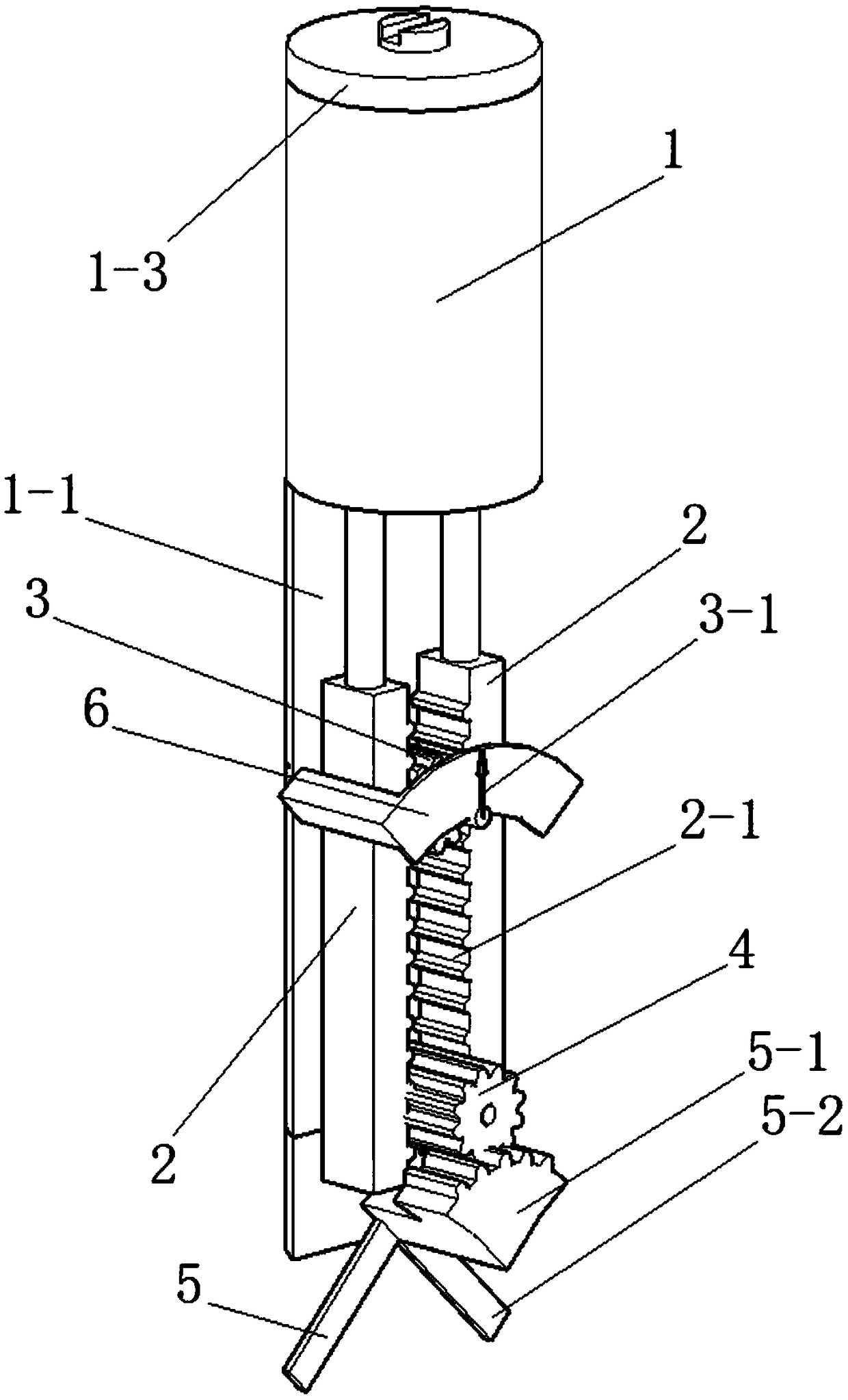

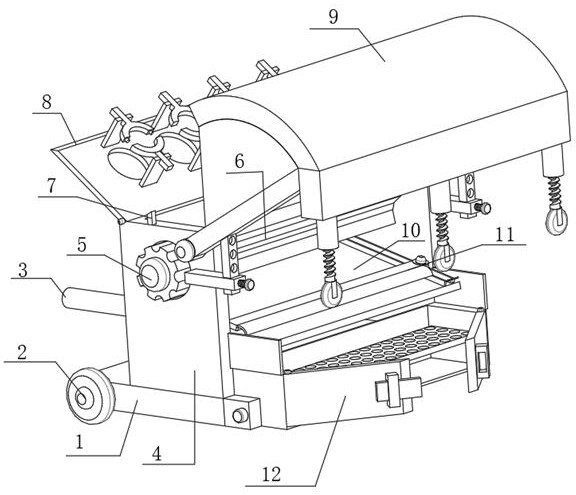

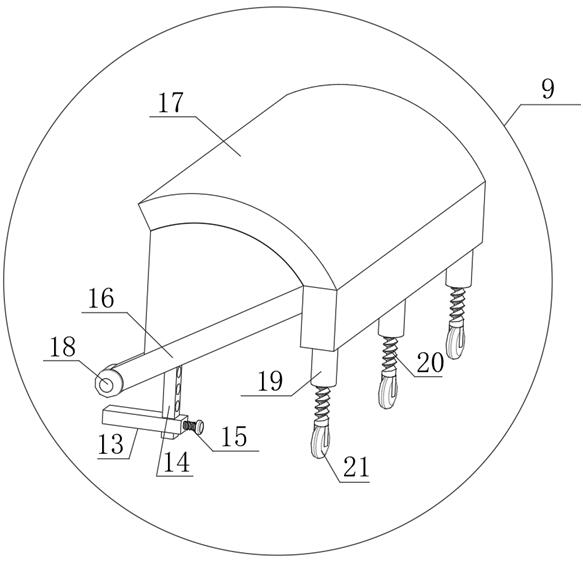

Novel mower

The invention discloses a novel mower. The mower comprises a mower body, the mower body is provided with a support, traveling mechanisms are arranged on both sides of the lower portion of the support,a cutter is arranged in the support, a first motor is mounted on the cutter, a blade is mounted on the output shaft of the first motor, a chassis is arranged on one side of the cutter, a second motoris mounted on the chassis, and weeding wheels are mounted on the output shaft of the second motor; water spraying nozzles are arranged on the inner wall of the cutter and the inner wall of the chassis, and the water spraying nozzles are connected with hoses; the mower body is provided with an infrared sensor, the infrared sensor is connected with a controller, the controller is arranged in a motor hood, the controller is connected with a direction device, and the controller is connected with the traveling mechanisms, the first motor and the second motor separately. By means of the novel mower, manual mowing and automated mowing can be achieved, meanwhile the mower has various functions such as water spraying, low noise, ripping and the like, the mowing process is simplified, the working efficiency is improved, and the working time is shortened.

Owner:徐应盈

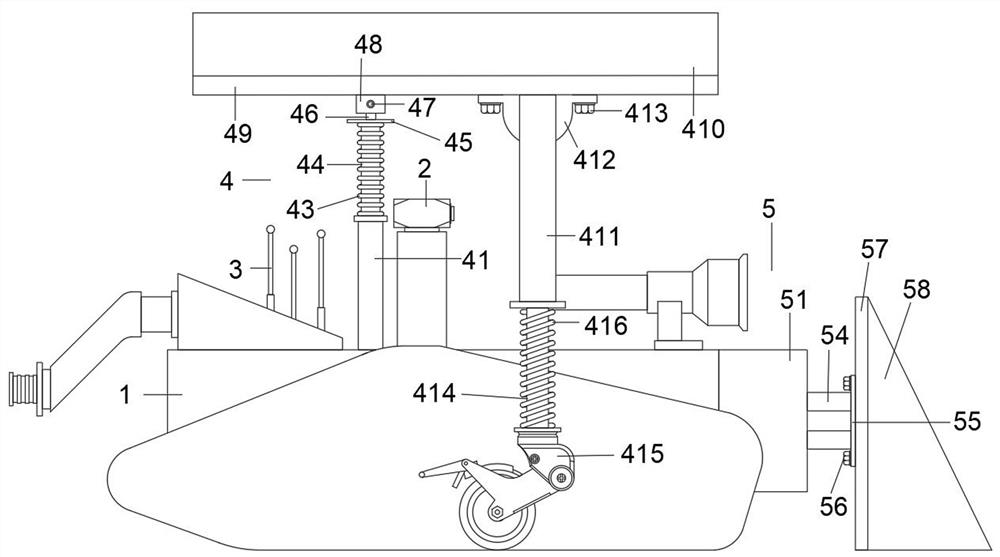

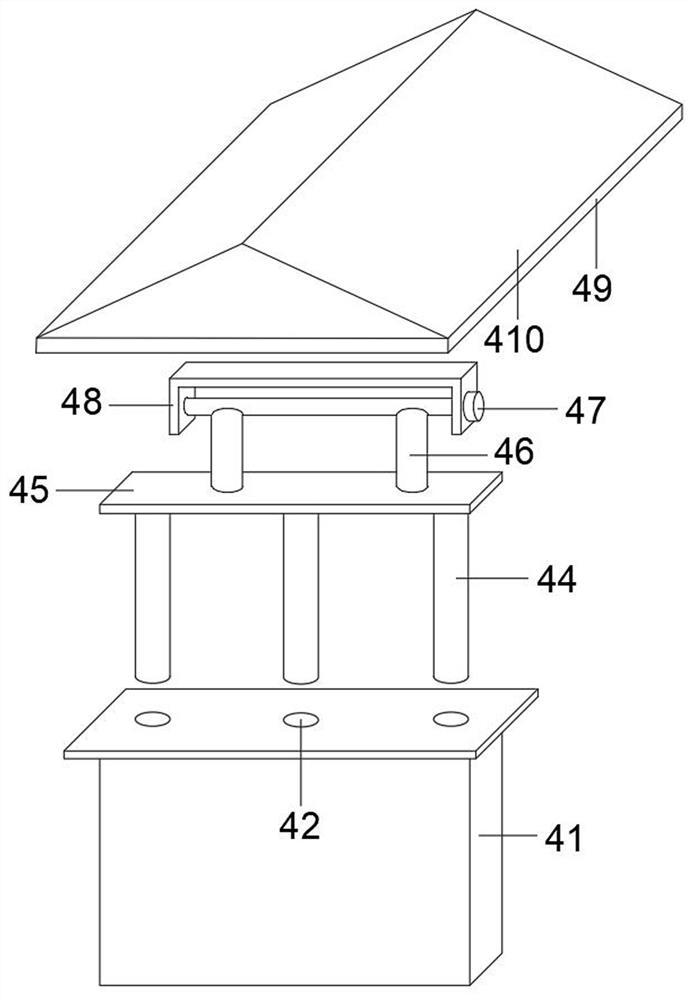

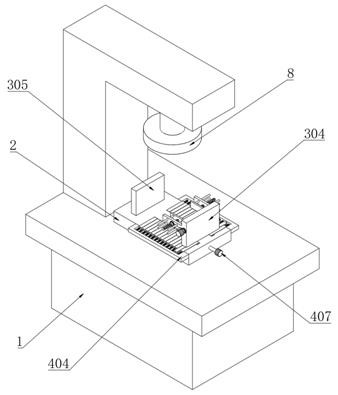

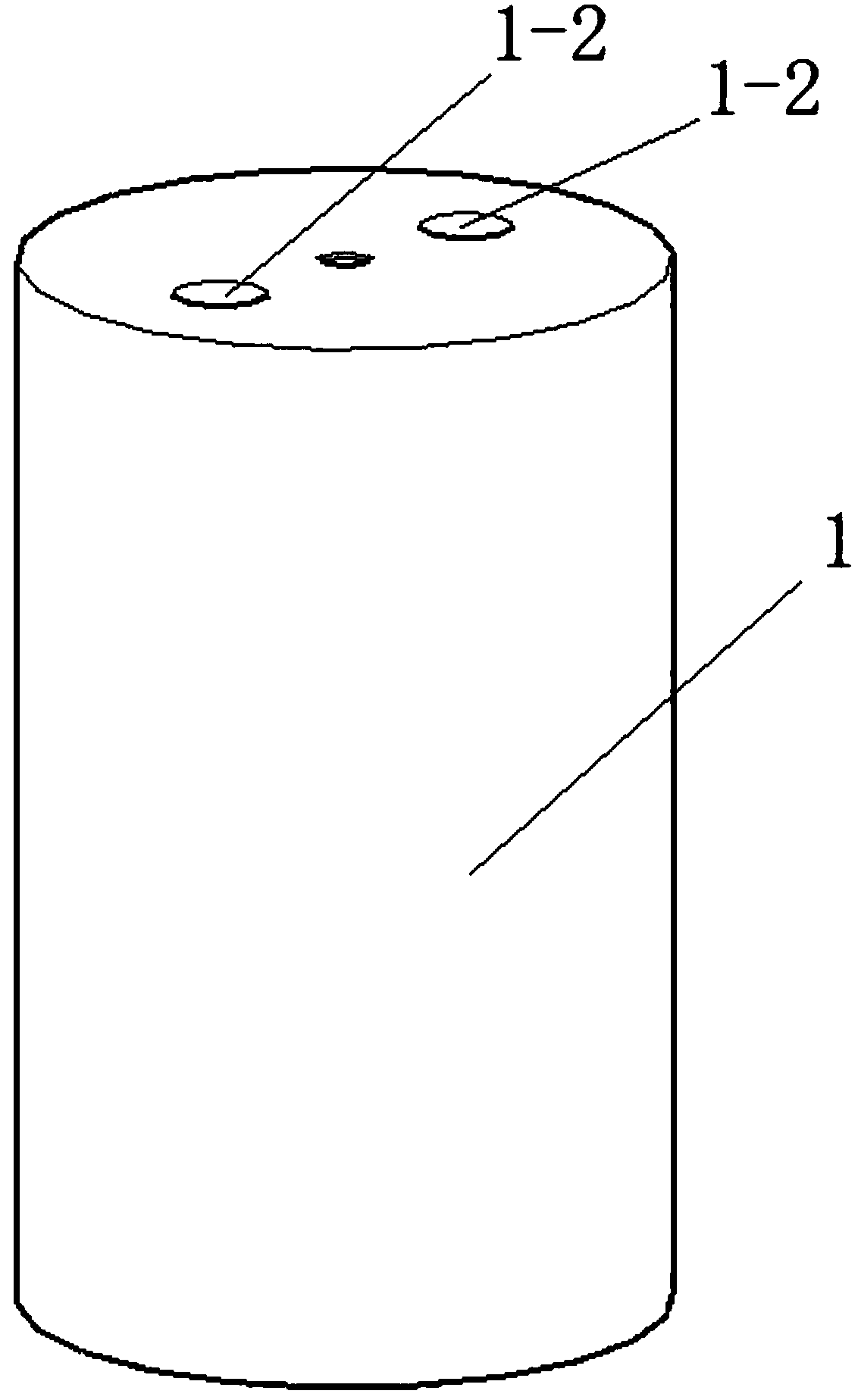

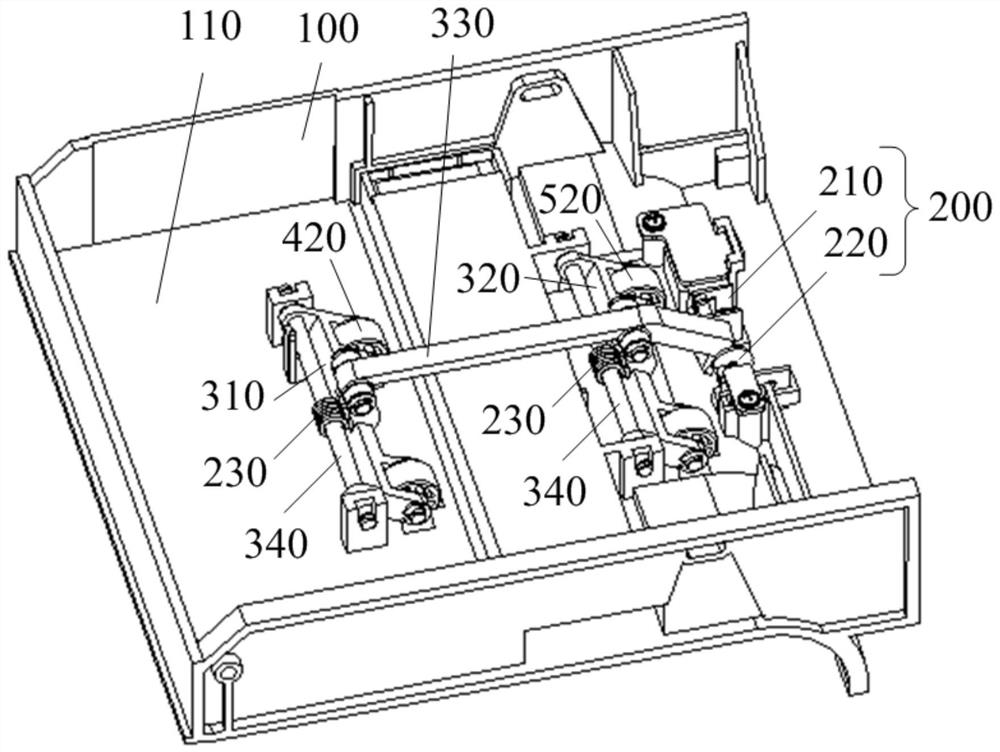

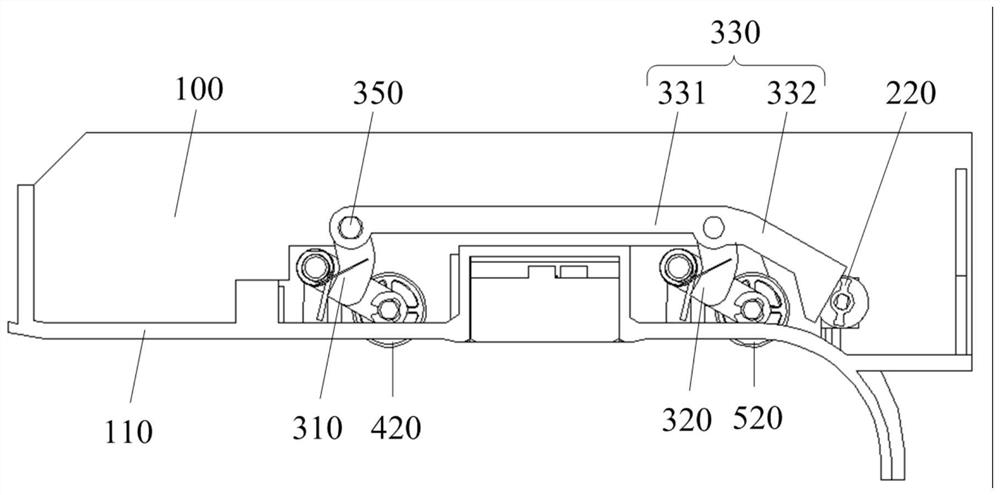

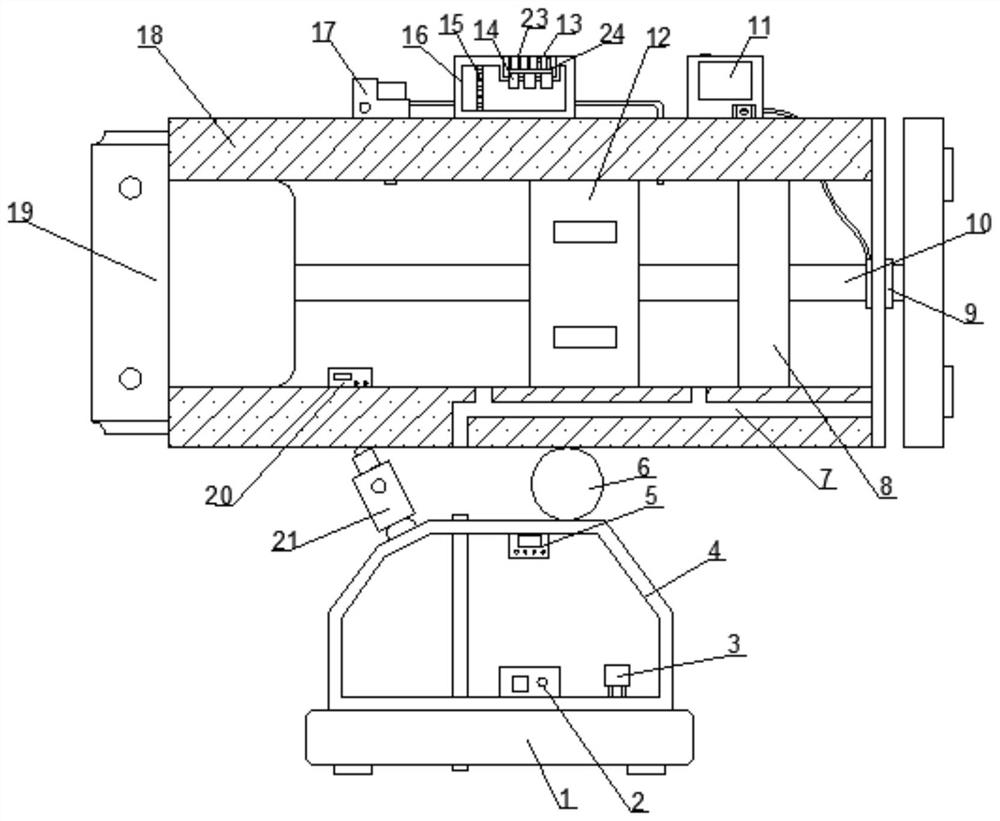

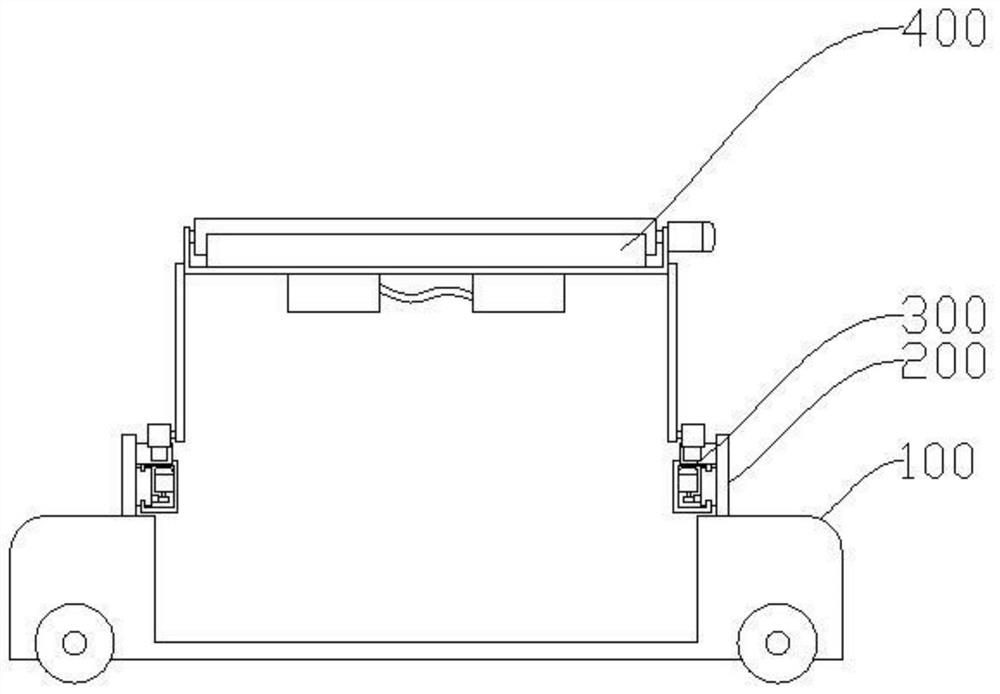

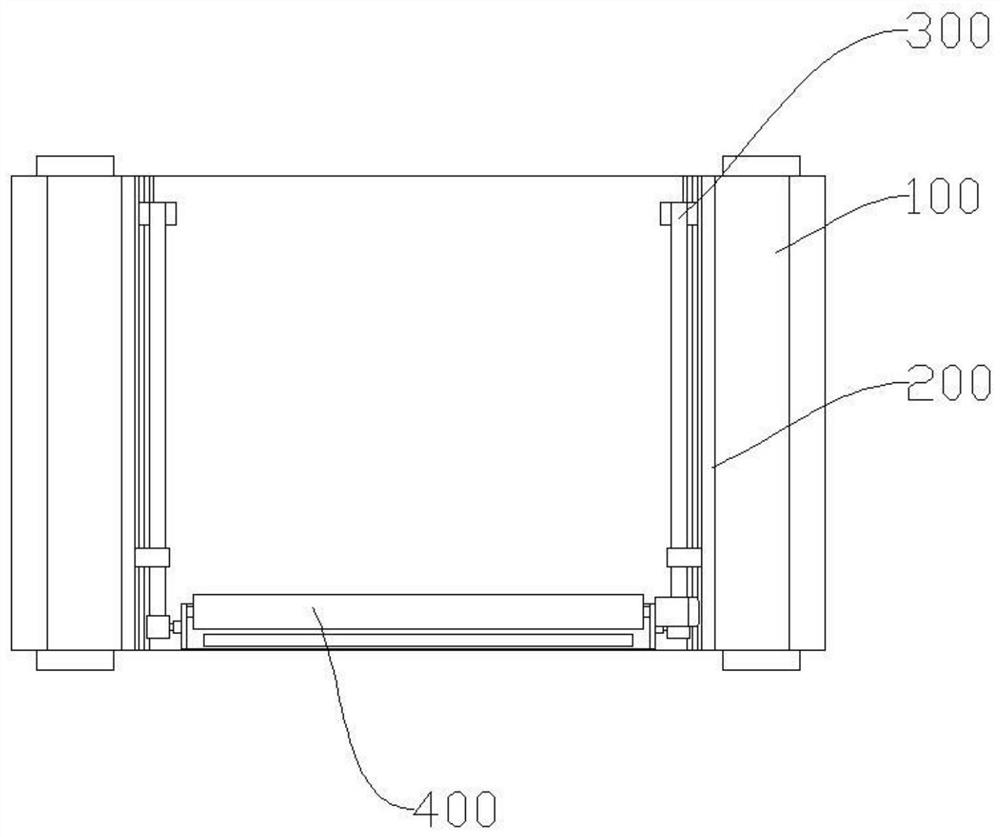

New energy battery integral press-down assembling device

ActiveCN113725456AEasy to movePrecise positioningPrimary cell manufactureAssembling battery machinesNew energyStructural engineering

The invention discloses a new energy battery integral press-down assembling device, and the device comprises an assembling device body used for fixing a battery box so as to realize integral press-down assembling of a battery body into the battery box, and the assembling device body comprises a sliding seat and a camera visual judgment system arranged above the sliding seat. The camera visual judgment system can judge whether the battery box is fixed at a preset position or not and whether the posture is right or not; a positioning assembly is arranged on the sliding seat, and comprises a fixed plate fixed to the position, close to one end, of the sliding seat, a sliding plate arranged to the position, close to the other end, of the sliding seat and oppositely spaced from the fixed plate, and clamping plates symmetrically arranged to the positions, close to the two sides, of the sliding seat. The sliding plate can horizontally move against or away from the fixed plate; the two clamping plates can synchronously and horizontally move in a manner of abutting against or leaving away from each other; the fixed plate, the sliding plate and the two clamping plates jointly clamp and fix the battery box. Therefore, the speed and accuracy of fixing the battery box can be effectively improved, the positioning is firm, and the fixing posture of the battery box is correct.

Owner:厦门微亚智能科技股份有限公司

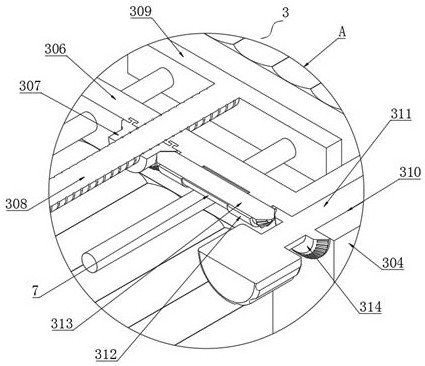

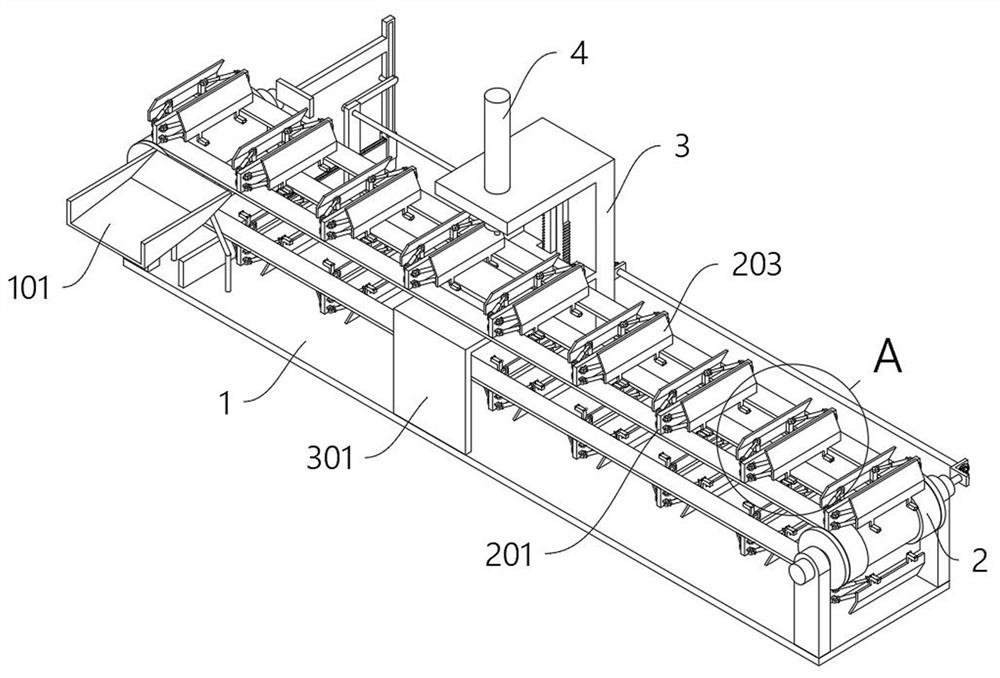

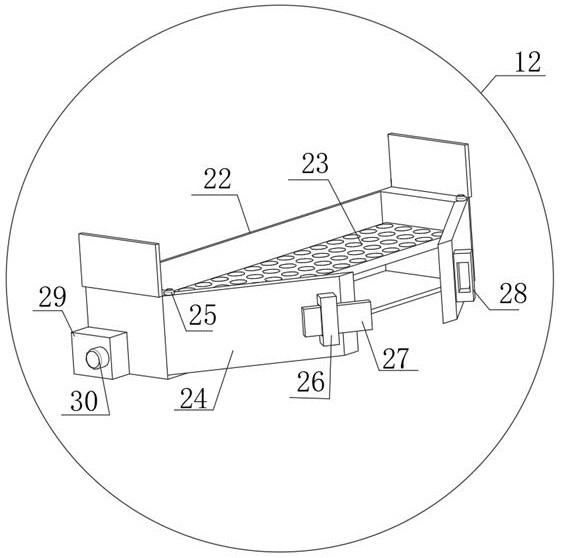

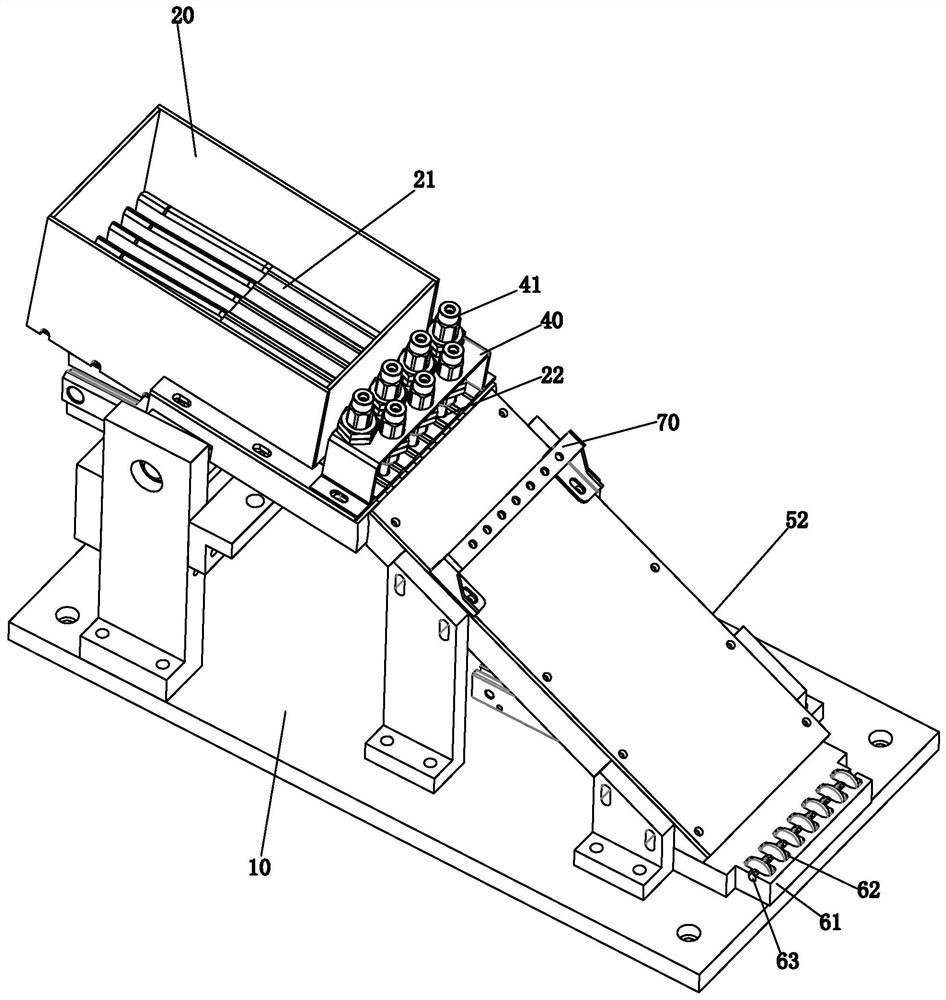

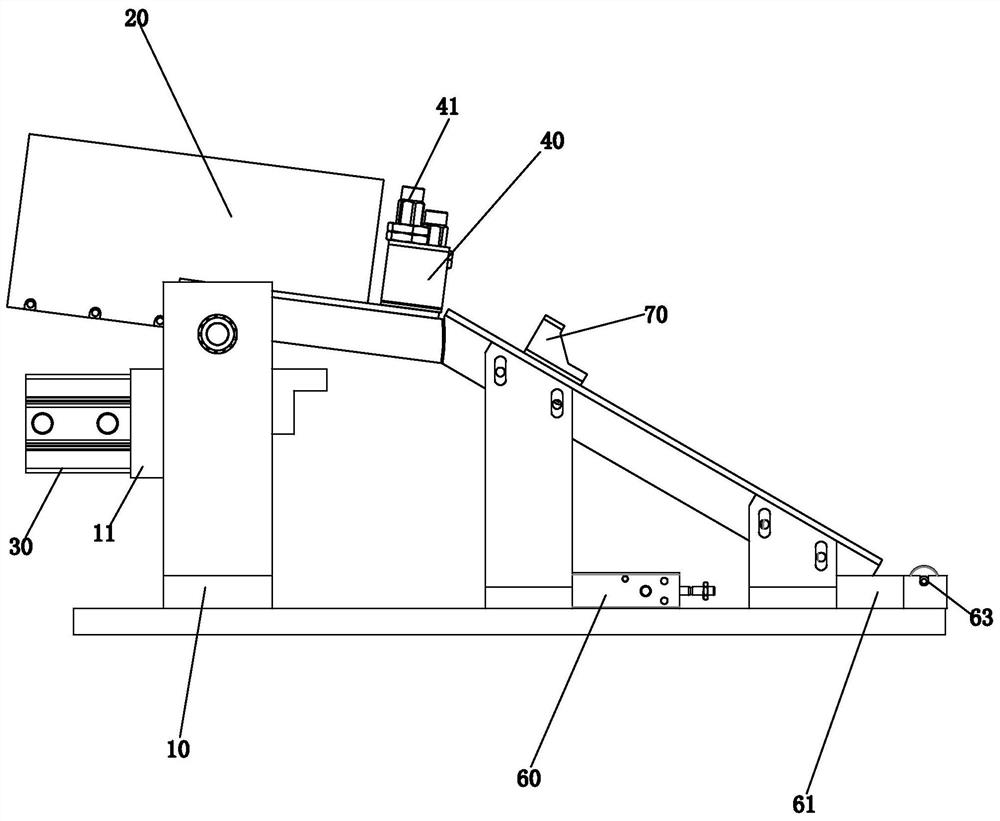

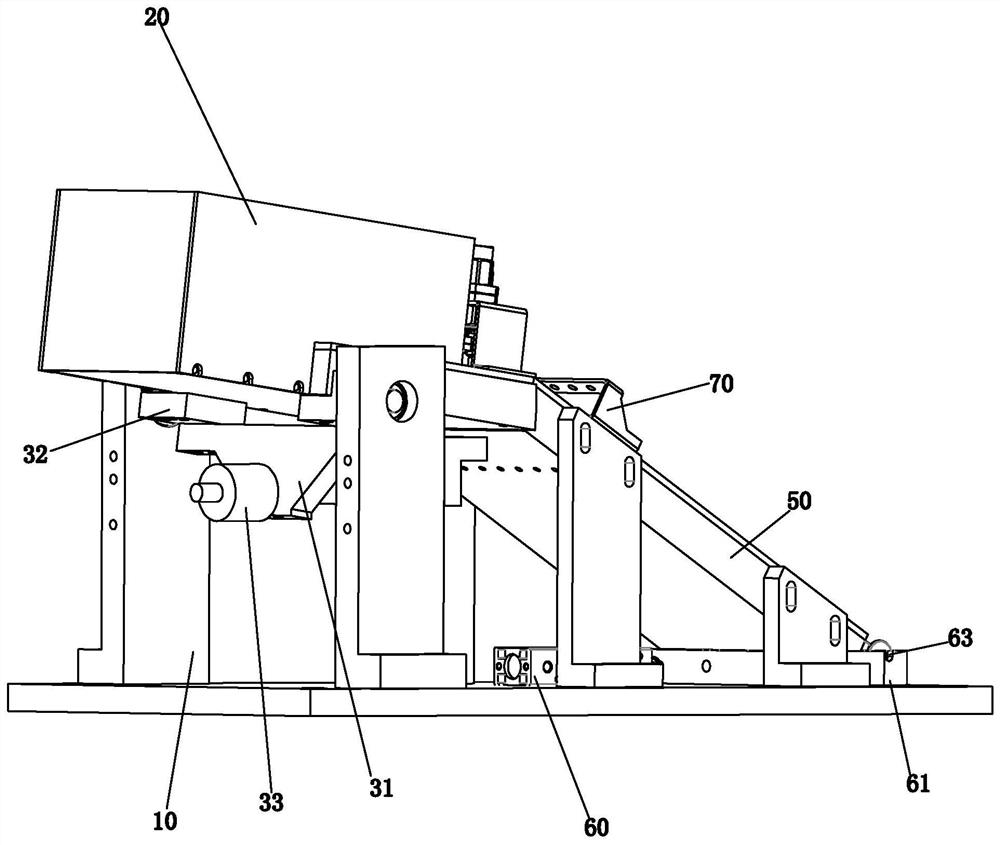

Slotting equipment used before production of preserved kumquats

PendingCN112021610AAvoid affecting movementAvoid hard dropsFood treatmentElectric machineryEquipment use

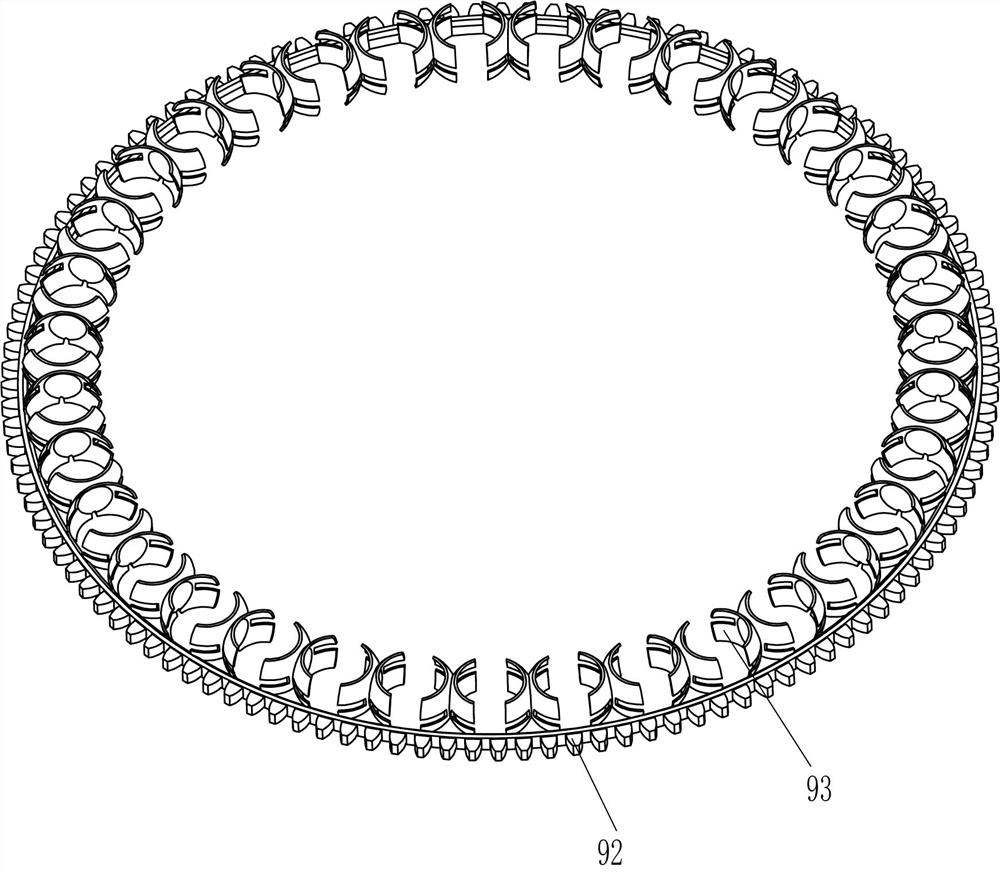

The invention relates to slotting equipment, in particular to slotting equipment used before preserved kumquat production. The slotting equipment before preserved kumquat production can replace manpower to slot kumquats, is labor-saving, can continuously slot the kumquats and is high in working efficiency. The slotting equipment used before preserved kumquat production comprises a base, and supporting plates are fixedly connected to one side of the base at intervals; and a round frame is fixedly connected among the end parts of the three supporting plates far away from the base, and a discharge port is formed in the eccentric position of one side, facing the base, of the round frame. A proper amount of kumquats are poured into the discharging hopper, the kumquats fall into the right portion in the round frame through the conical barrel to make contact with the arc-shaped containing plate, a gear motor is started to rotate forwards, the outer gear ring can drive the arc-shaped containing plate to rotate reversely, the kumquats are driven to move to be slotted by the arc-shaped cutter, manual kumquat slotting is not needed, and labor is saved; work efficiency is high.

Owner:姜伟豪

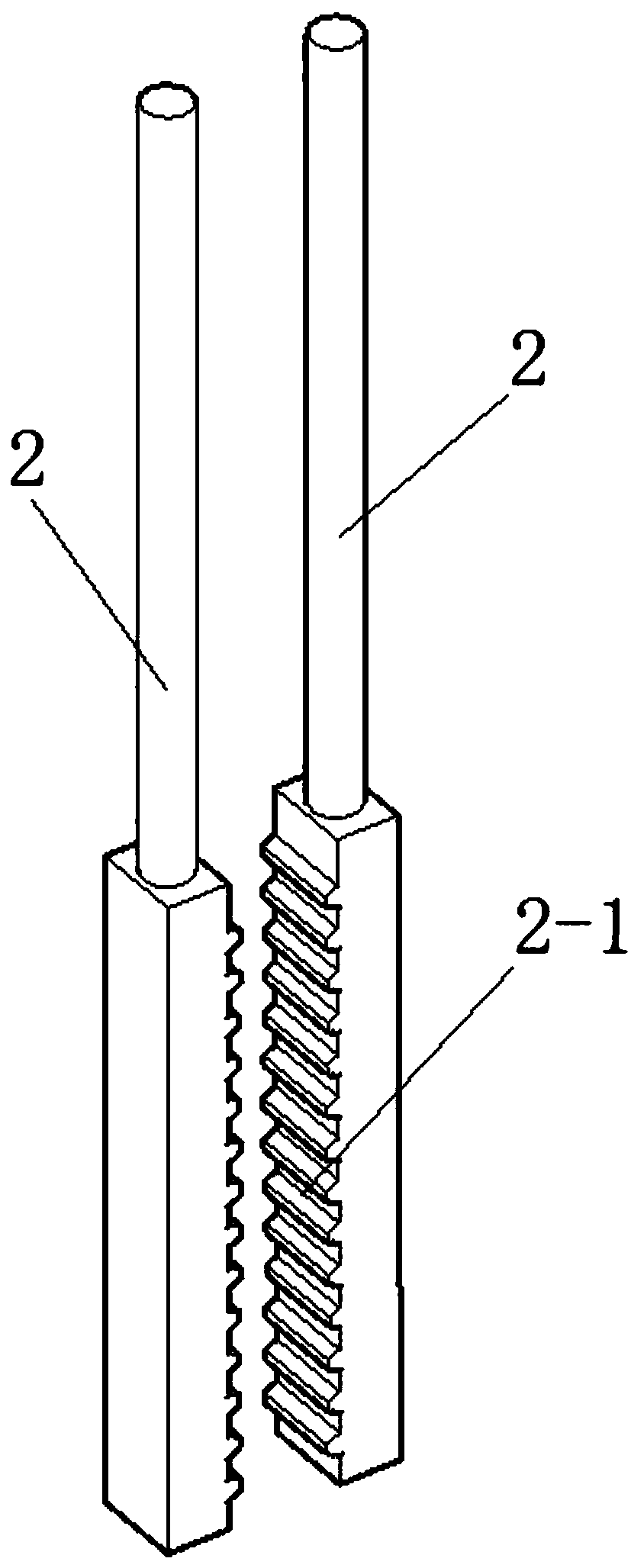

Shaft workpiece alignment device and alignment method thereof

InactiveCN108381228AIngenious structureQuick alignmentPositioning apparatusMetal-working holdersBackplaneEngineering

The invention discloses a shaft workpiece alignment device and an alignment method of the shaft workpiece alignment device. The shaft workpiece alignment device comprises a fixing base, balancing rods, a pointer gear, an input gear, a measuring claw assembly and a scale plate. A back plate which downwards extends is arranged on the fixing base. The two balancing rods are arranged in parallel, andthe tops of the two balancing rods stretch into the fixing base and are connected with the fixing base in a sliding mode. Racks are fixedly arranged at the bottoms of the two balancing rods, and the tooth surfaces of the racks are arranged in a face-to-face mode. The pointer gear and the input gear are arranged on the back plate in a rotating mode and mesh with the two racks. The input gear is located below the pointer gear. The diameters of the pointer gear and the input gear are equal, and the moduli of the pointer gear and the input gear are equal. A pointer is fixedly arranged in the center of the front end face of the pointer gear. The measuring claw assembly drives the input gear to rotate. The shaft workpiece alignment device is ingenious in structure, high in accuracy and convenient to use, rapid alignment of the cylindrical axis of a shaft workpiece is achieved, the operation working procedure is simplified, and the production quality and the production efficiency are improved.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

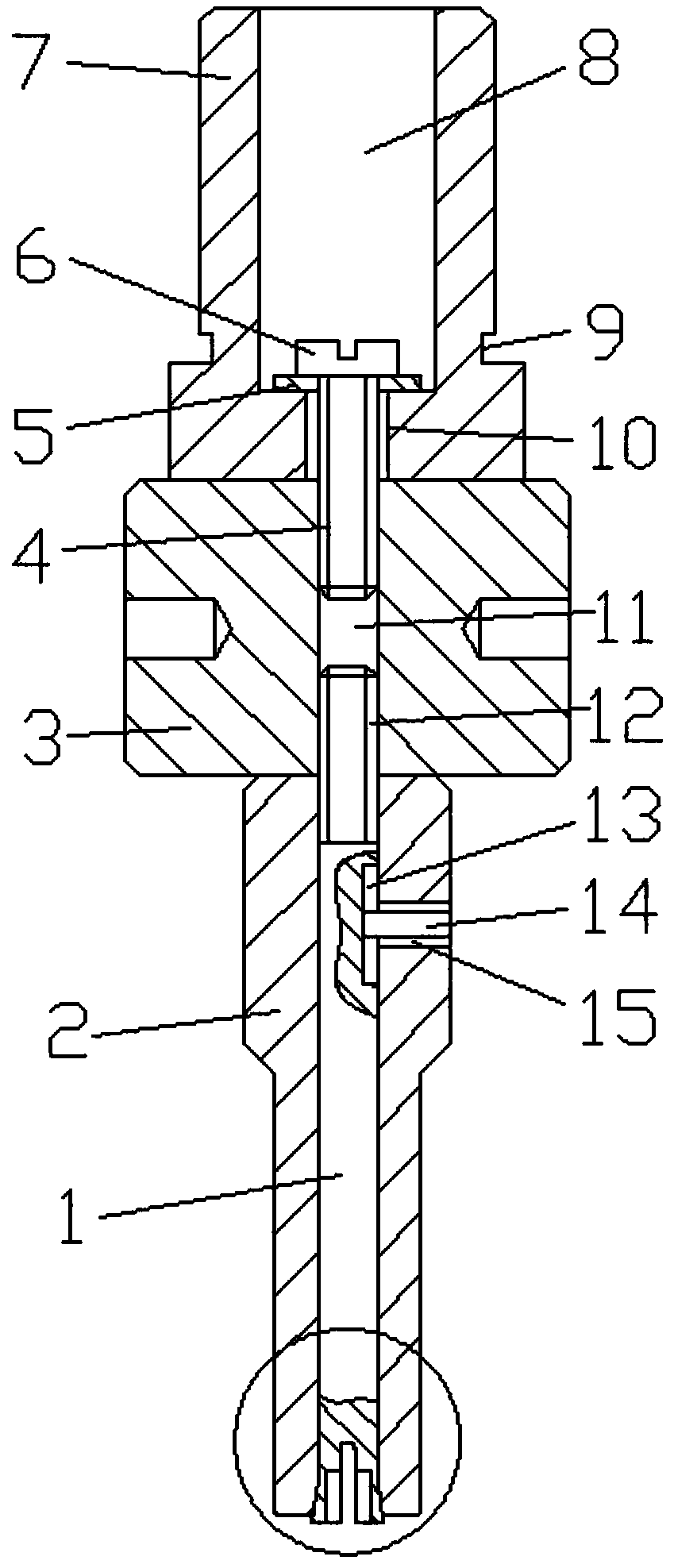

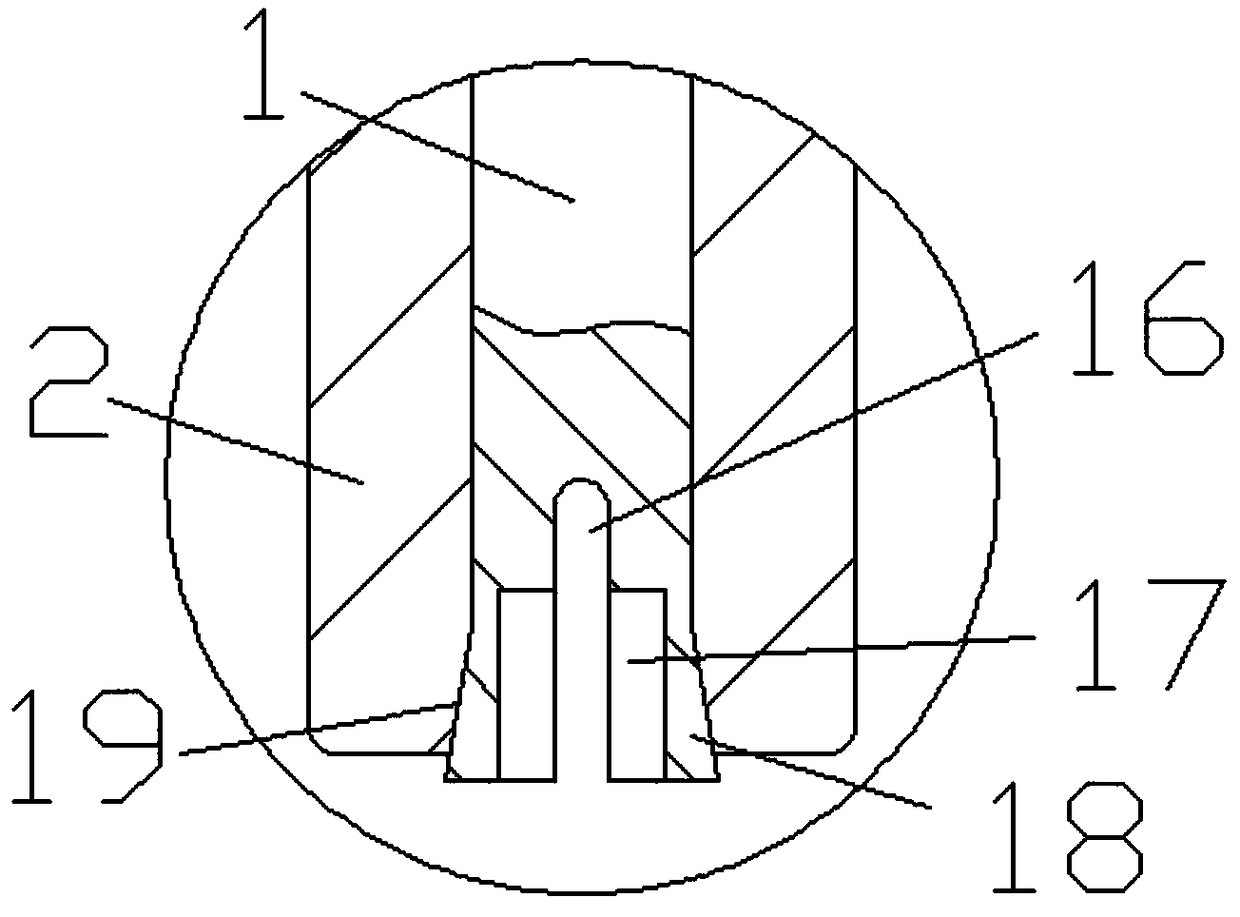

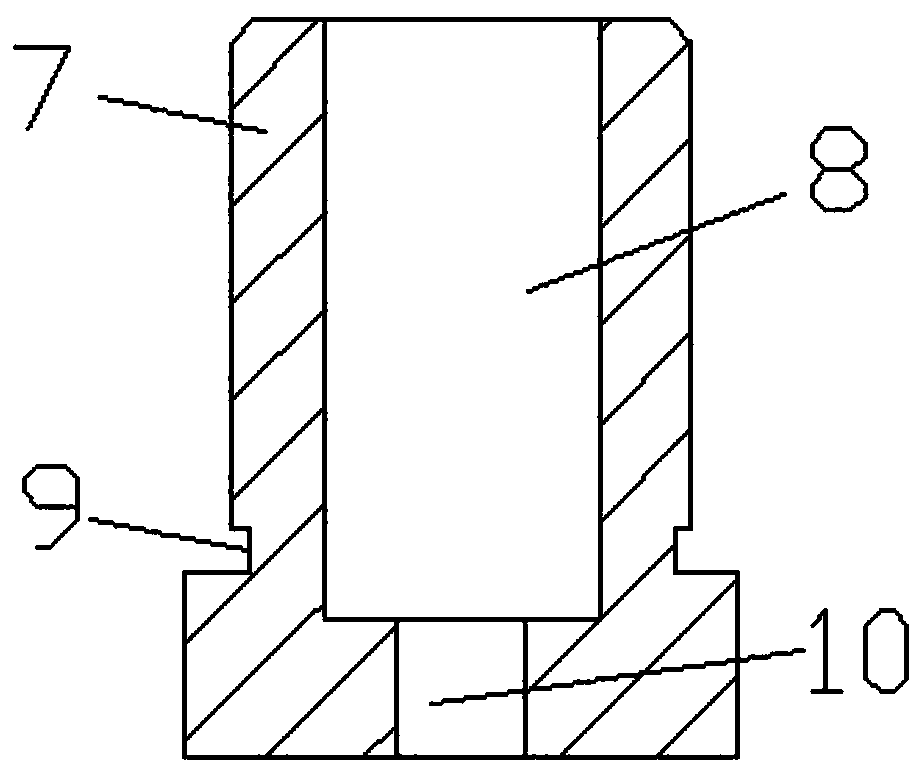

Pressing-sleeve tool structure

InactiveCN109227470APrevent movementAvoid affecting movementMetal-working hand toolsPunchingEngineering

The invention discloses a pressing-sleeve tool structure. The pressing-sleeve tool structure comprises a pressing head, a nut is arranged below the pressing head, a threaded hole is vertically formedin shaft center of the nut, and a sleeve is arranged below the nut; a fixing hole is formed in the upper end of the pressing head, a connecting hole is formed in the pressing head at the lower end ofthe fixing hole, a screw is movably arranged in the connecting hole, and a threaded hole formed in the upper end of the nut is connected to the lower end of the screw through a first thread; a pullingrod is movably arranged in an inner cylinder of the sleeve, a threaded hole formed in the lower end of the nut is movably connected to the upper end of the pulling rod through a second thread, a strip-type limiting groove is vertically formed in the pulling rod, a limiting threaded hole is formed in the sleeve on one side of the strip-type limiting groove, and an adjusting screw is movably connected to the limiting threaded hole through a thread. The pressing-sleeve tool structure has the advantages that static-pressure press fitting is achieved, a punching head is not prone to deflection, apin can be subjected to press fitting in the perpendicular direction, it can be avoided that the external-circle diameter of the pin can be increased, it is avoided that assembling of a product is influenced, the product quality is good, the machining efficiency is high, and the percent of pass is high.

Owner:GUIZHOU HONGLIN MACHINERY

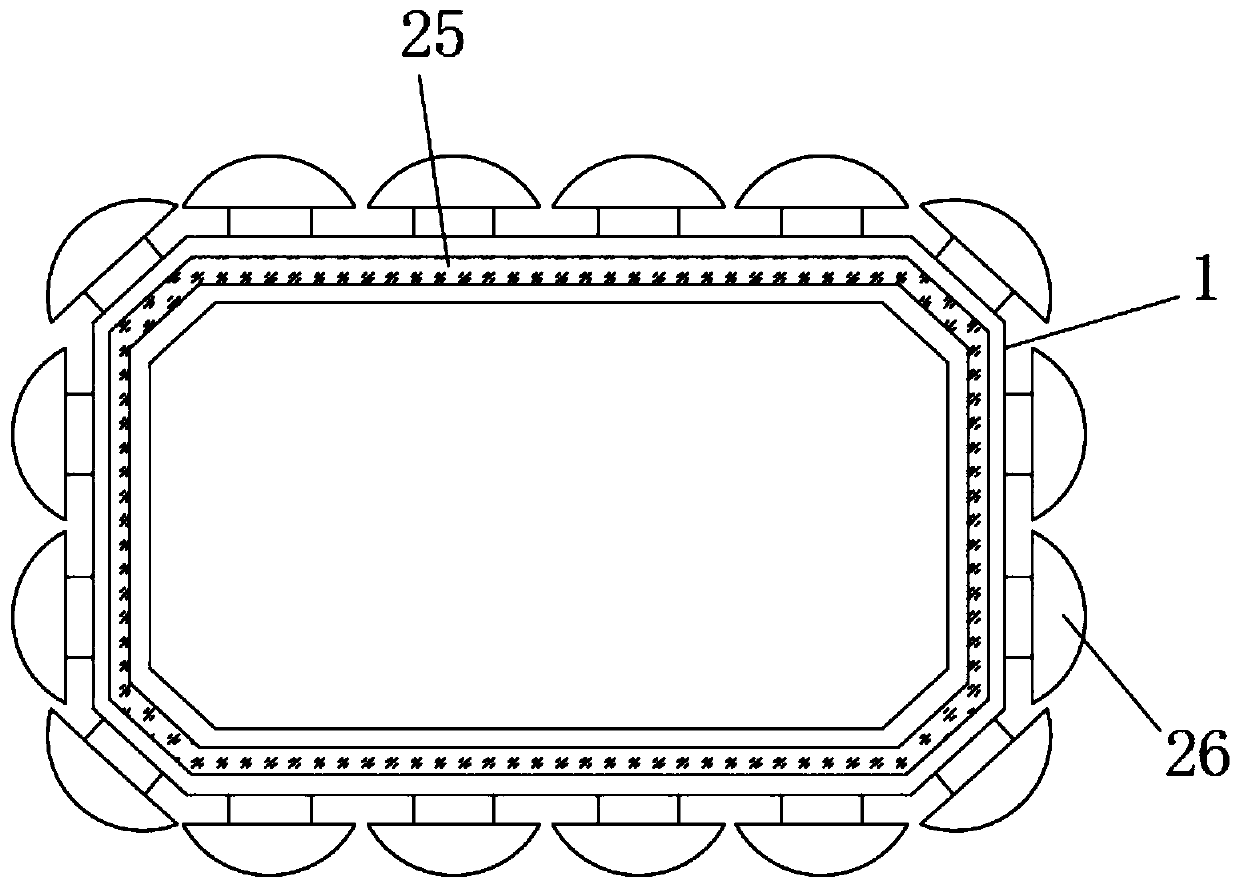

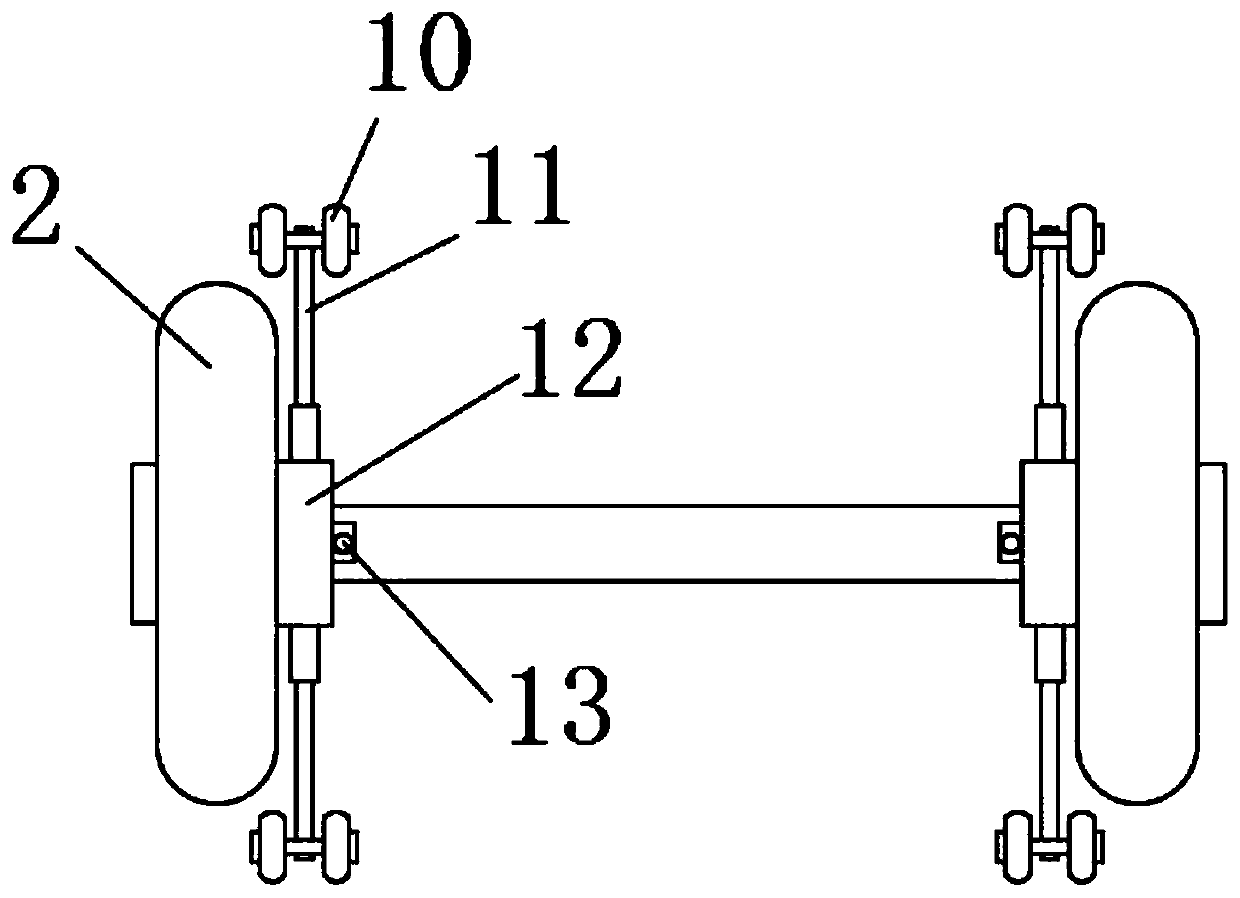

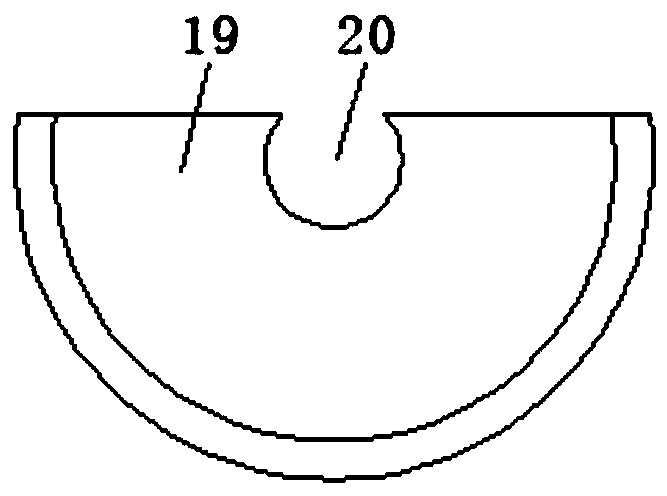

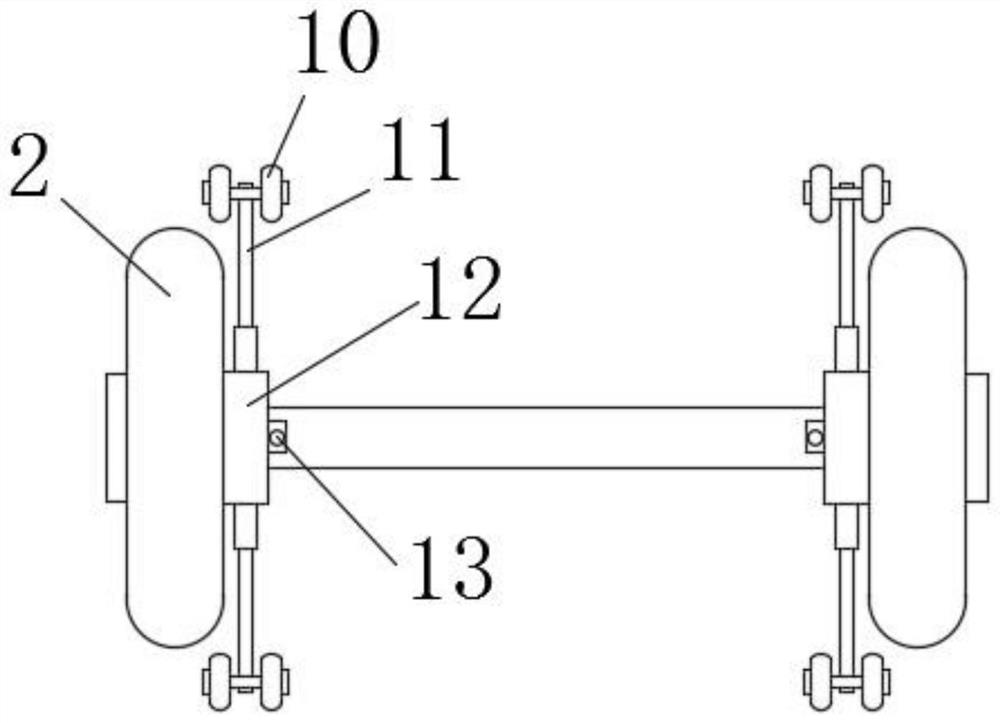

Anti-explosion structure of downhole polling robot

ActiveCN109866234AImprove hardness and stiffnessImprove the ability to resist explosionWithdrawing sample devicesManipulatorAir springCheck valve

The invention discloses an anti-explosion structure of a downhole polling robot. The anti-explosion structure comprises a polling robot shell, rollers and an infrared camera. The rollers are located at the bottom of the polling robot shell, the infrared camera is located on one side of the surface of the polling robot shell, and anti-explosion boxes are welded to the side faces of the bottom of the polling robot shell. Through the arrangement of a blocking anti-explosion metal material layer and nickel-based alloy semicircular blocks, the hardness and the rigidity of the polling robot shell are improved; through the arrangement of the anti-explosion boxes and metal anti-explosion plates, the anti-explosion performance of the polling robot shell is improved, and damage of downhole emergencies to the polling robot shell is reduced; through the arrangement of a sucking pump and a check valve, downhole air is sampled, and the downhole air can be conveniently detected; through the arrangement of electric telescopic rods and first anti-explosion wheels, the situation that barriers block movement of the rollers is effectively avoided; and through the arrangement of air springs and a laminated rubber shock insulating support, vibration generated by the polling robot shell is effectively reduced when explosions happen.

Owner:安徽玄离智能科技股份有限公司

punching device

ActiveCN108326170BAvoid squeezingNot easy to damageMetal-working feeding devicesPositioning devicesPunchingBiochemical engineering

Owner:CHONGQING JIANAN IND & TRADE

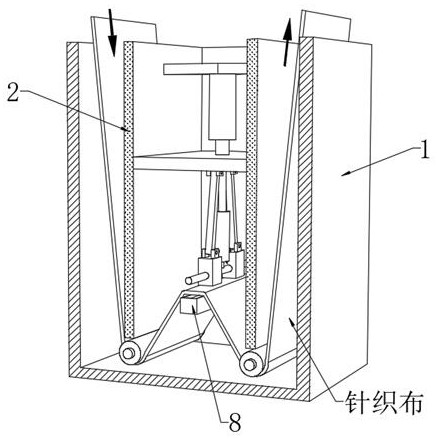

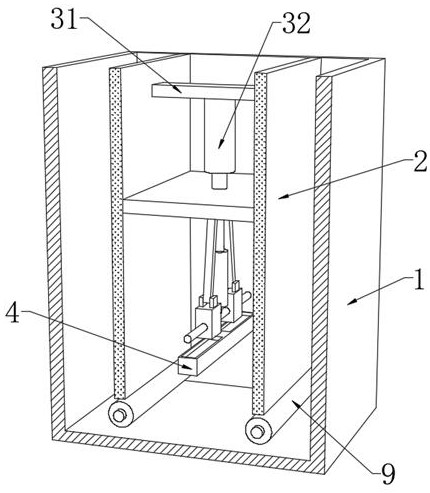

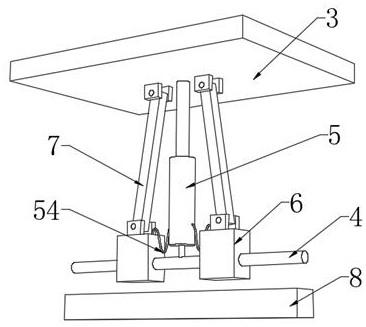

High-efficiency smoothing type dyeing device for knitted fabric

ActiveCN114672946AAlleviate the problem of poor staining qualityImprove dyeing qualityLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsMechanical engineeringColoring agents

The invention discloses a high-efficiency smoothing type dyeing device for knitted fabric, and belongs to the technical field of knitted fabric production equipment.The high-efficiency smoothing type dyeing device for knitted fabric comprises a dyeing barrel and a dyeing agent filled in the dyeing barrel, two partition plates are fixedly connected in the dyeing barrel, and a fixing plate is fixedly connected between the two partition plates; according to the knitting fabric flattening device, a telescopic air cylinder and a flattening sliding sleeve are arranged in a matched mode, the knitting fabric can be continuously flattened under driving of an electric push rod, and the reverse side of the knitting fabric can be flattened through matched arrangement of a flattening piece and magnetic fluid; in addition, in the process of smoothing the knitted fabric, the mobility of the coloring agent can be improved through the movement of the square plug, the coloring agent penetrates through the front face and the back face of the knitted fabric, and the dyeing quality of the knitted fabric is improved. Therefore, the dyeing quality of the knitted fabric is improved.

Owner:南通百源纺织有限公司

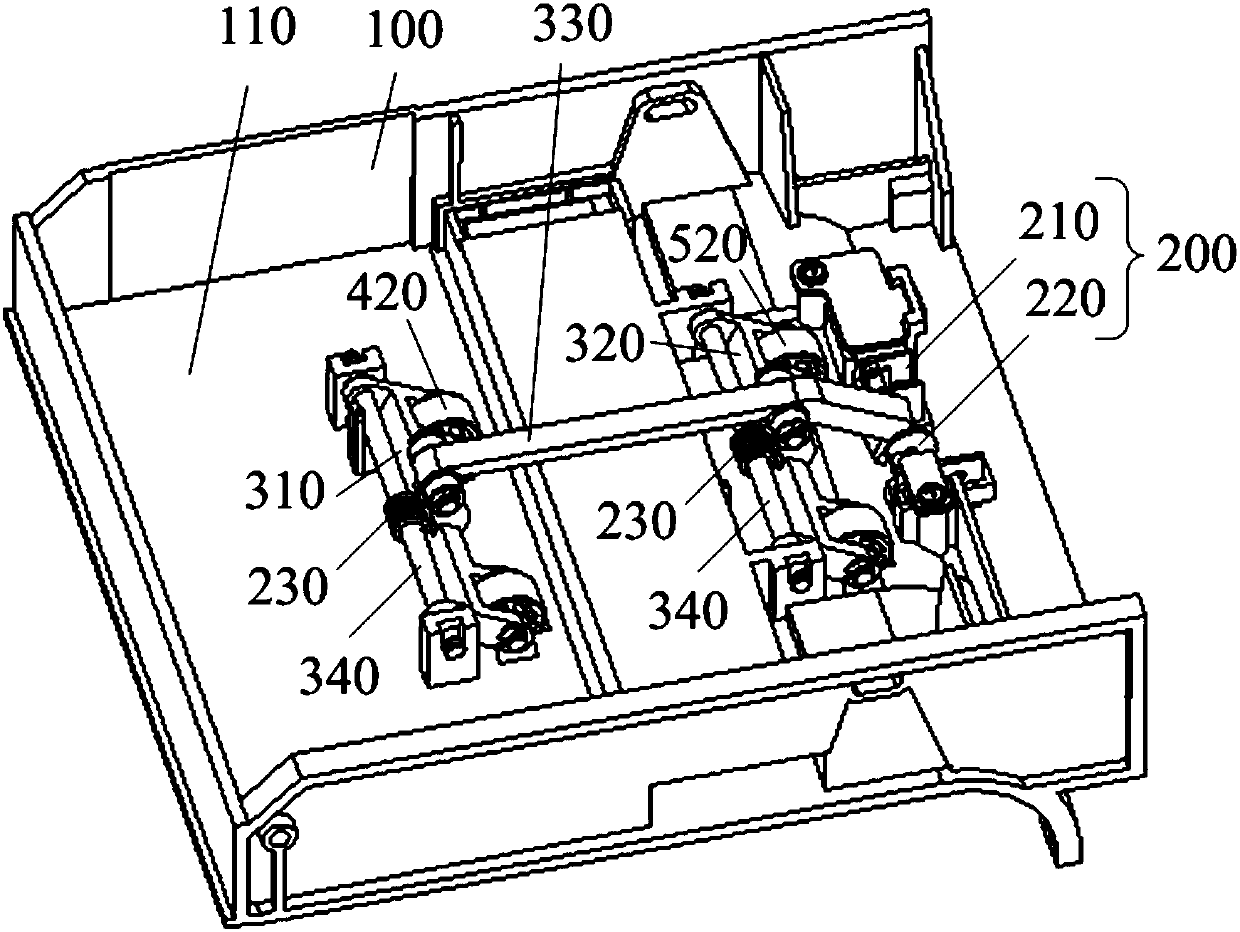

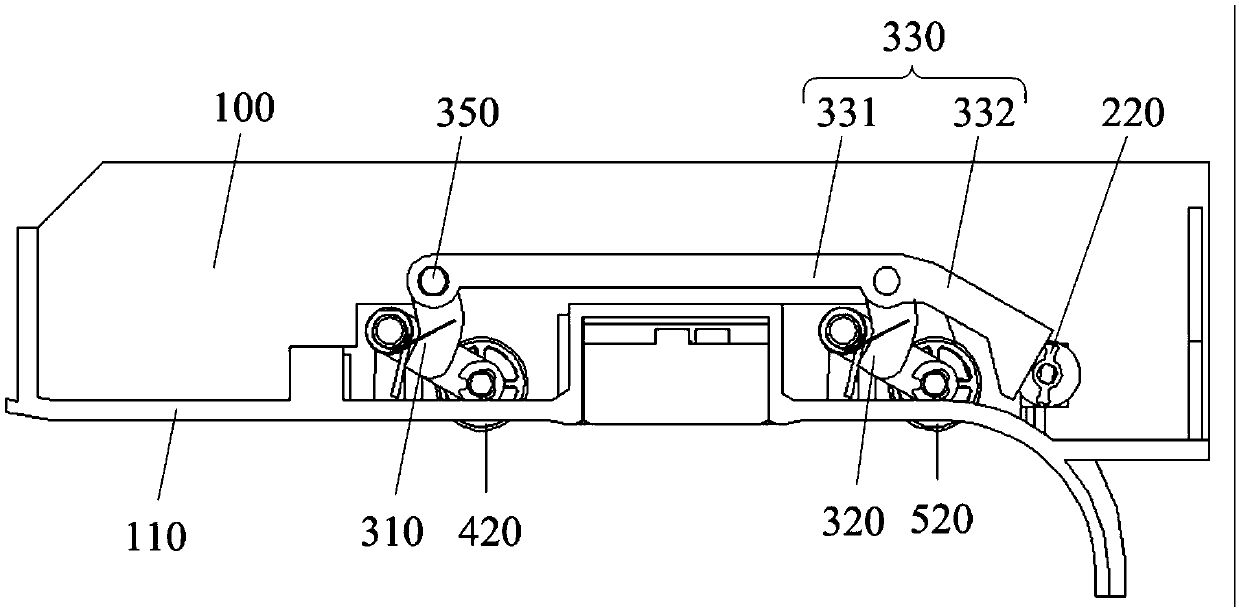

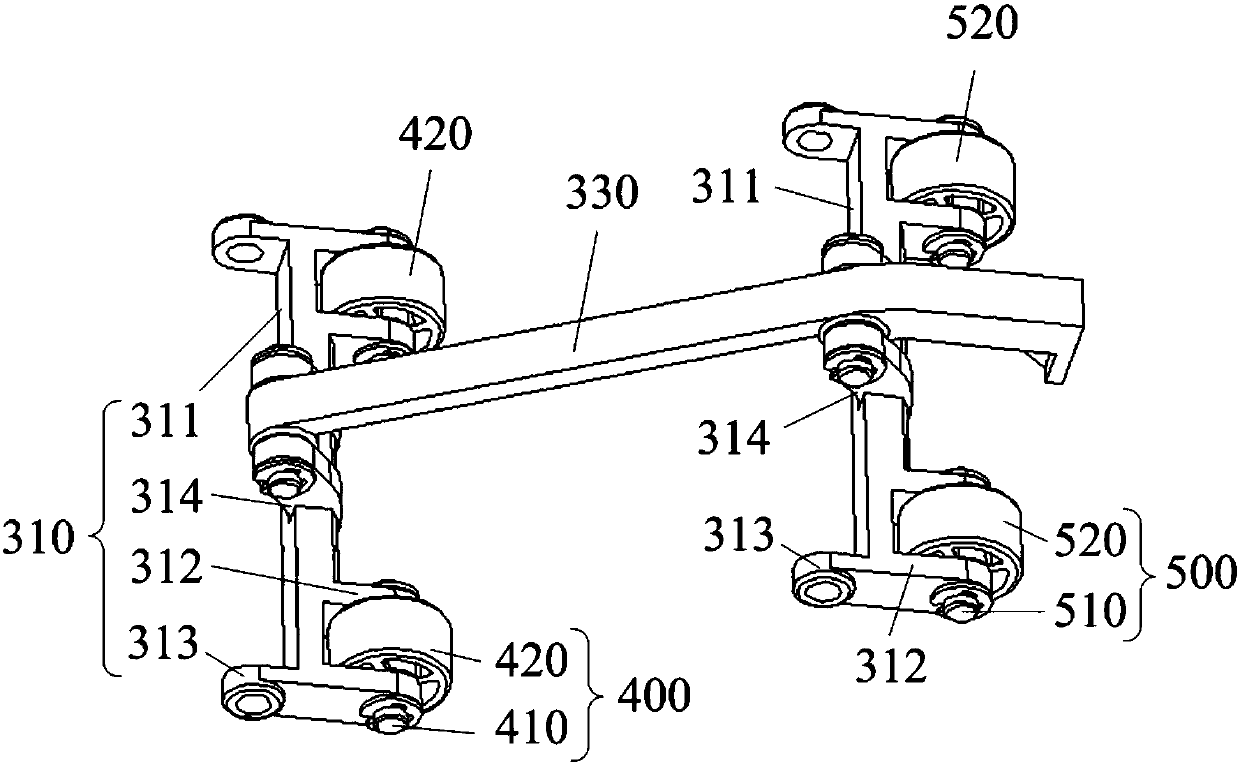

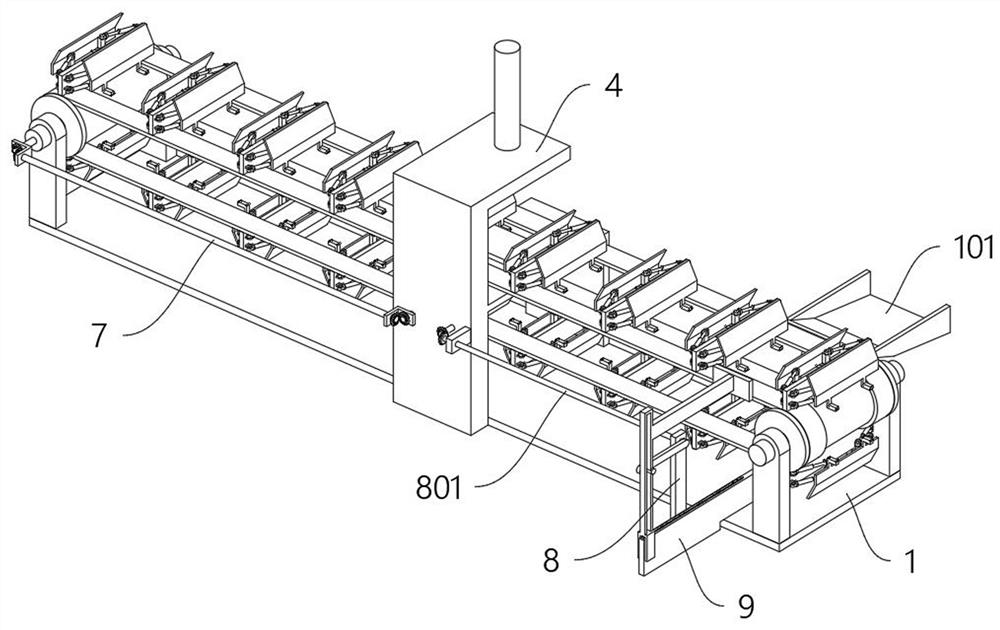

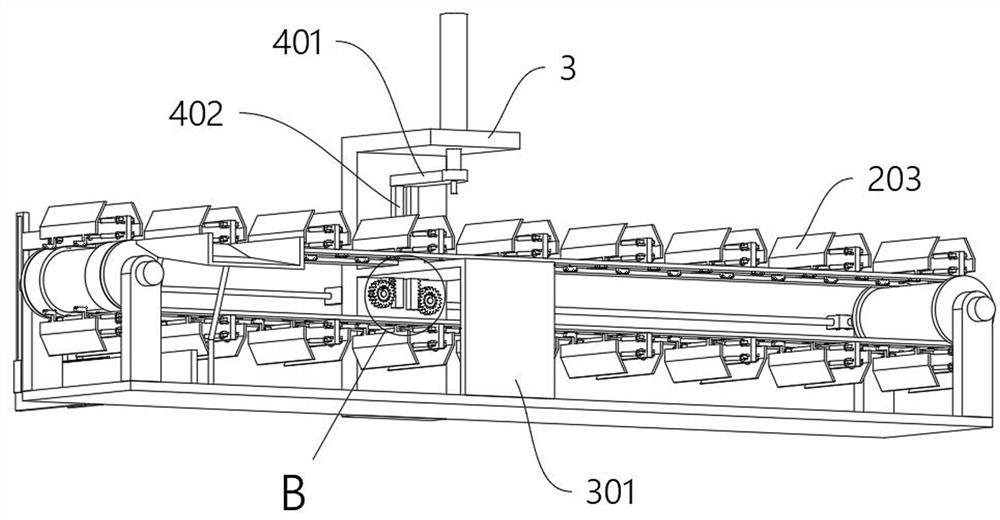

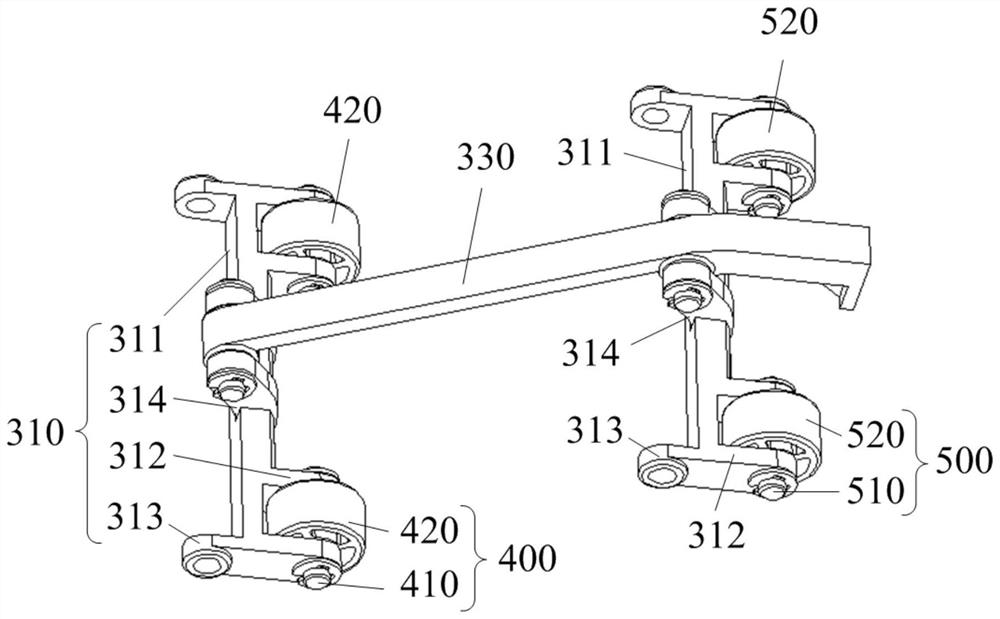

Floating roller mechanism and bill processing device

The invention provides a floating roller mechanism and a bill processing device and relates to the technical field of financial machinery. The floating roller mechanism comprises a machine frame, a drive assembly, a supporting assembly, a first floating roller and a second floating roller. The first floating roller and the second floating roller are supported by the supporting assembly, the firstfloating roller and the second floating roller are arranged in parallel in a spaced manner and both can freely rotate around own axes. The supporting assembly is movably connected with the machine frame. The drive assembly is in transmission connection with the supporting assembly. The drive assembly is configured to drive the supporting assembly to be located at a first position or a second position relative to the machine frame. When the supporting assembly is located at the first position, the first floating roller and the second floating roller conduct downward press at the same time. Whenthe supporting assembly is located at the second position, the first floating roller and the second floating roller rise at the same time. The floating roller mechanism relieves the technical problemthat in a relevant technology, since the position of the floating roller is fixed, bill deviation correcting by a deviation correcting mechanism is influenced.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

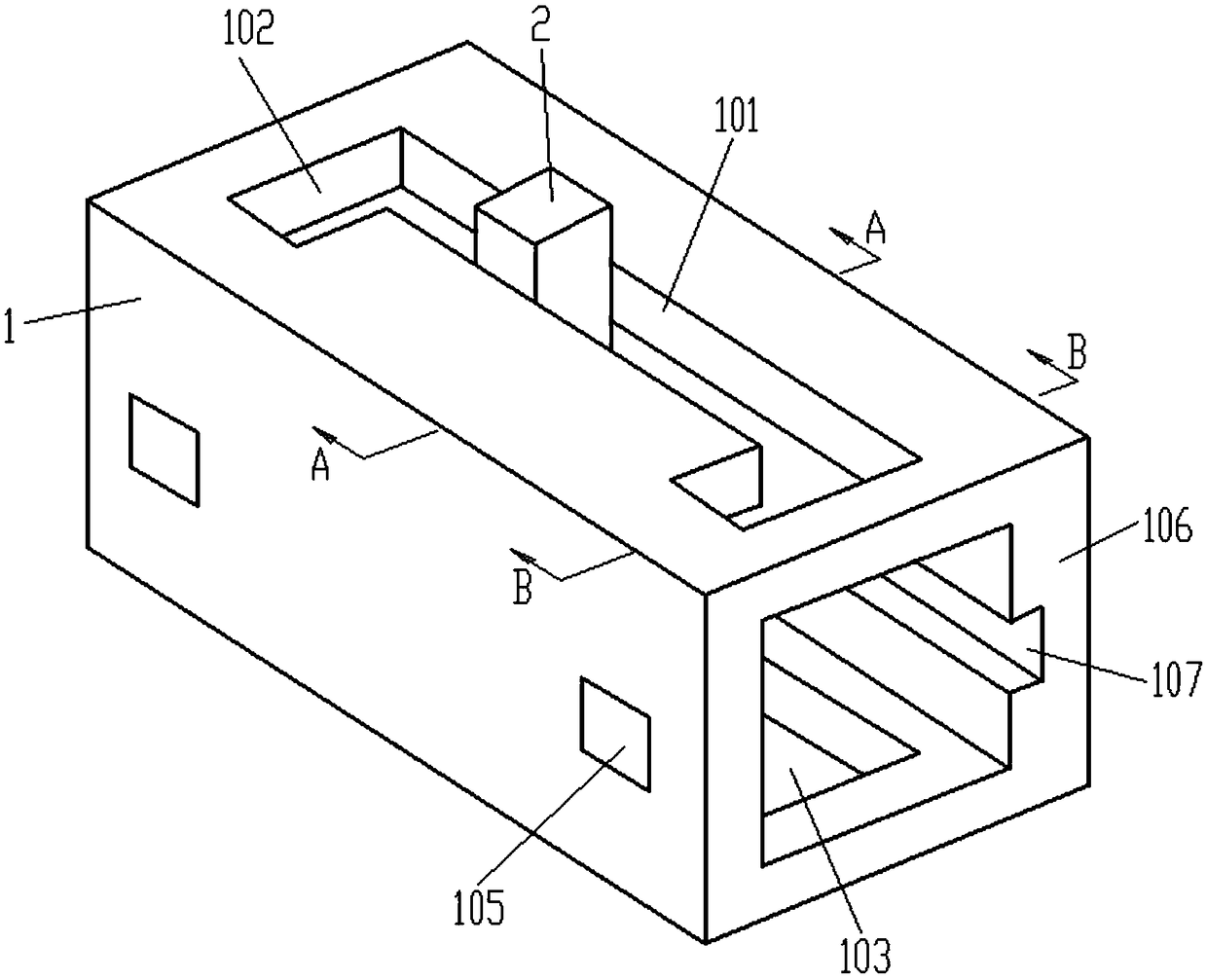

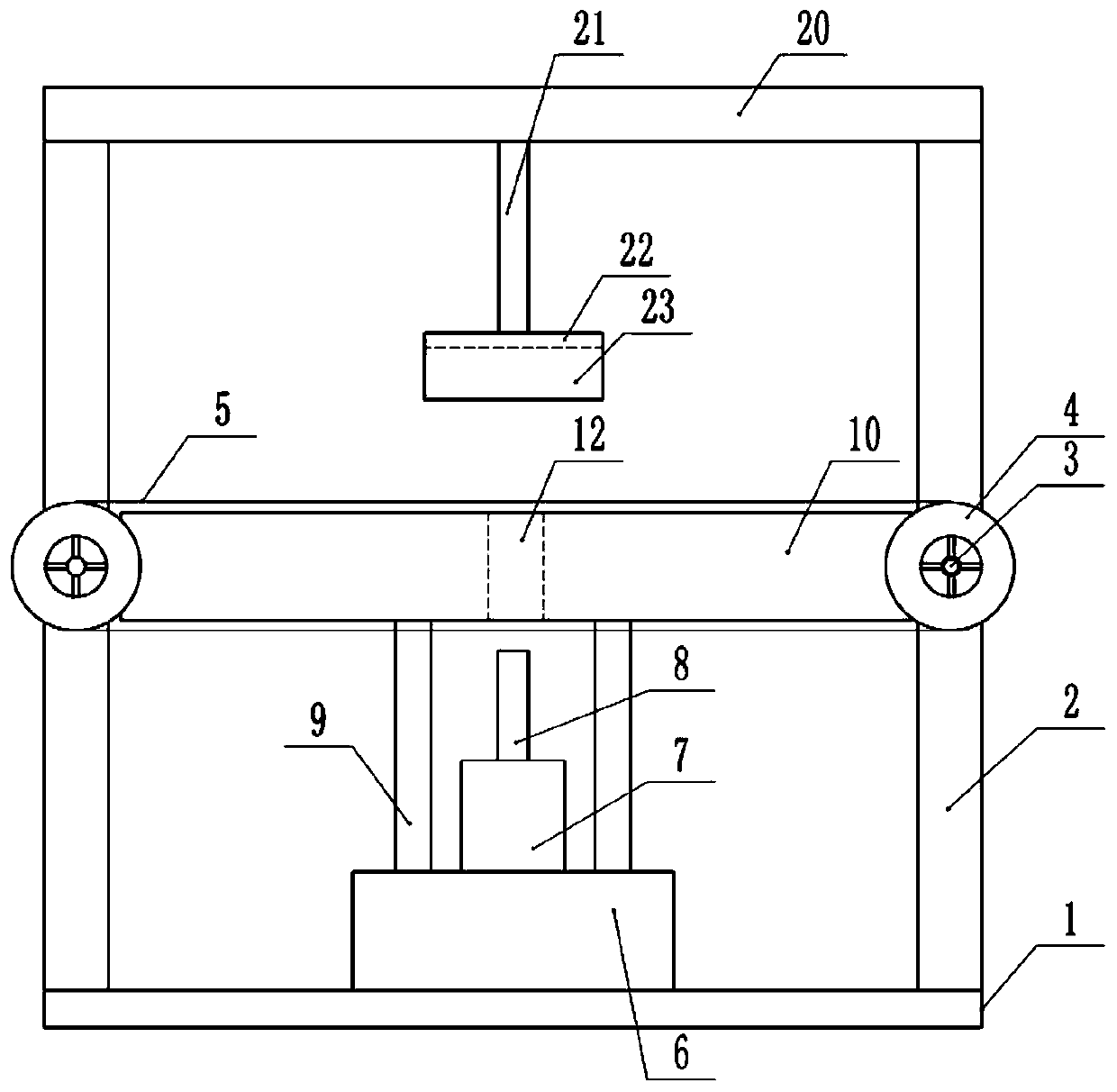

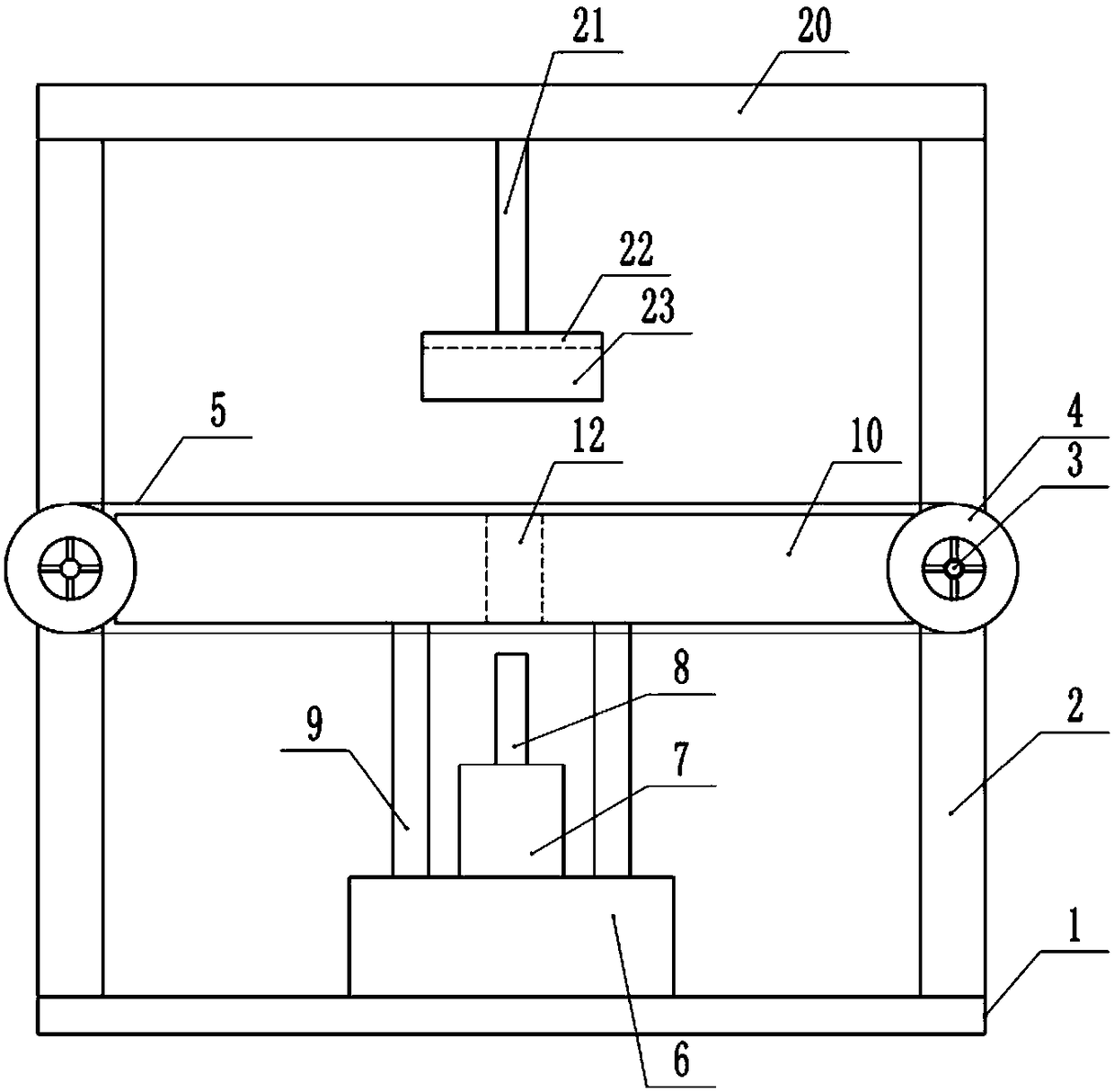

Punching device

ActiveCN108326170AAvoid squeezingNot easy to damageMetal-working feeding devicesPositioning devicesPunchingBiochemical engineering

The invention belongs to the technical field of punching equipment and particularly discloses a punching device. The punching device comprises a base, wherein a pillar, a first groove, a bayonet rod,a cavity structure, a push rod and a slider are arranged on the base; a cross shaft is arranged on the pillar; belt pulleys are arranged on the cross shaft; conveying belts are connected between beltpulleys on the same sides of the pillar; a support table is arranged in the middle of the base; an air cylinder is arranged on the support table; a punch is arranged at the upper end of a piston rod of the air cylinder; a support rod is arranged on a workbench; a storage plate is arranged on the support rod; a through hole is formed in the storage plate; a sleeve is arranged on the storage plate;an electromagnet and an ejector rod are arranged in the sleeve; the push rod is connected with the ejector rod. The punching device is mainly used for part punching and solves the problem that the part punching size is affected by poor part clamping effect.

Owner:CHONGQING JIANAN IND & TRADE

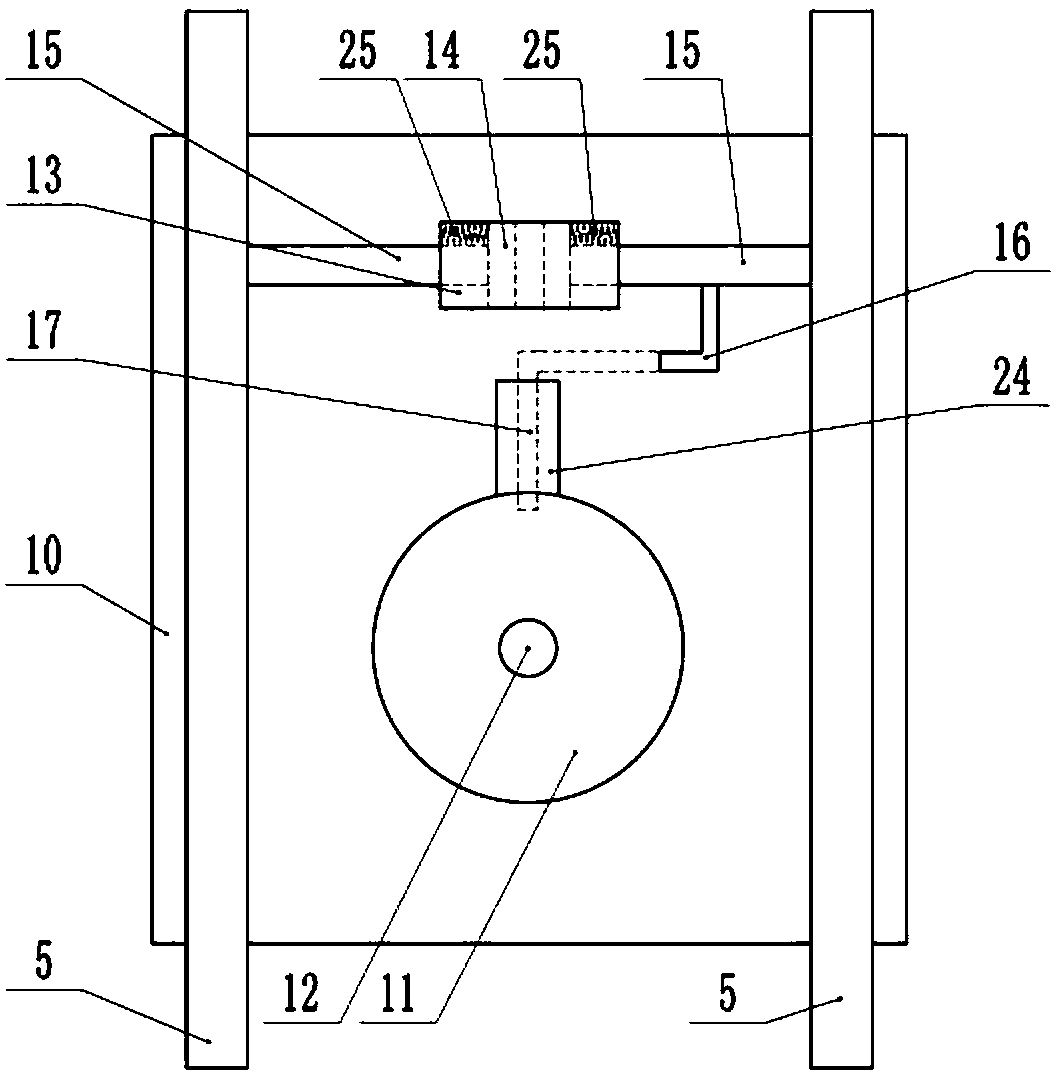

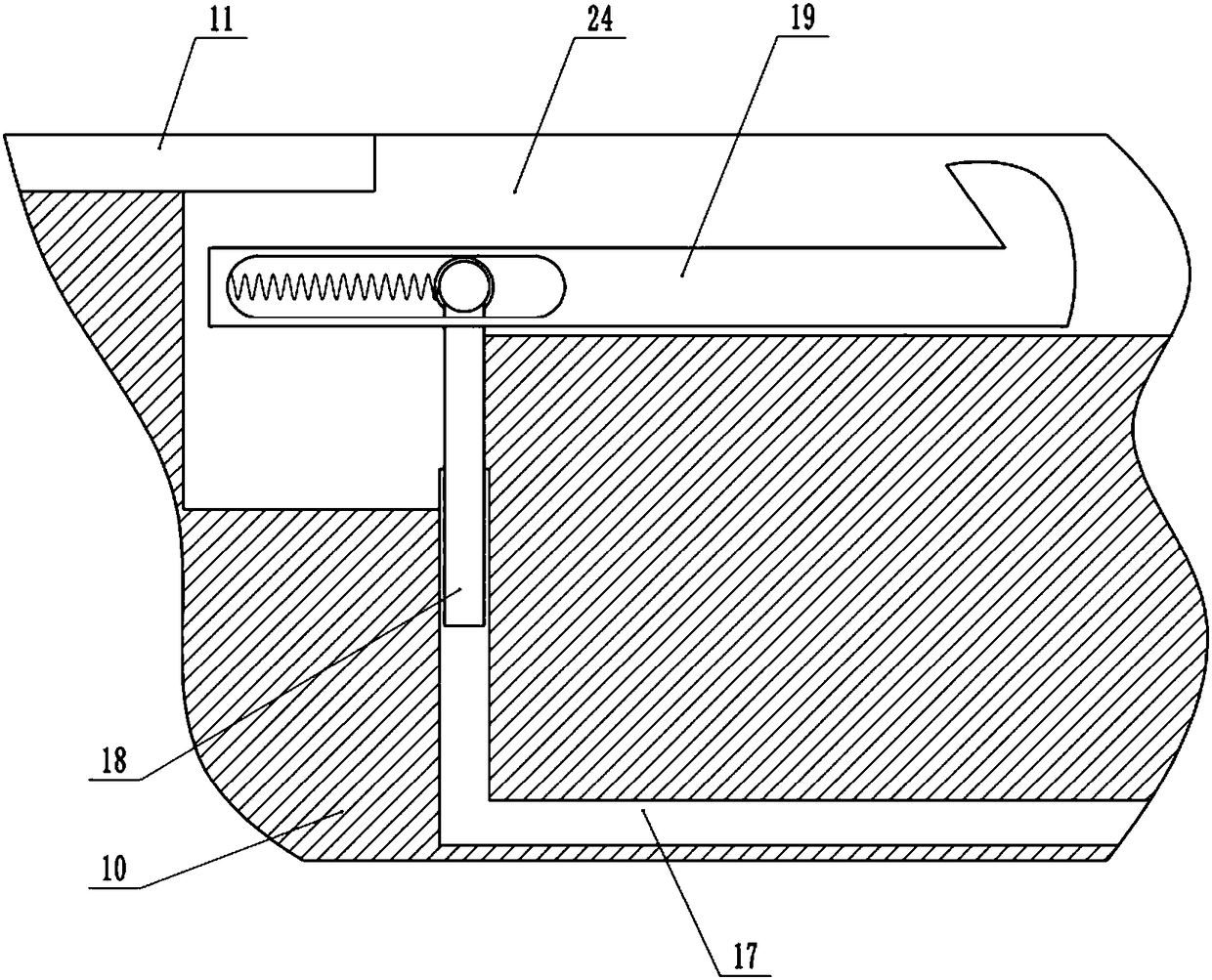

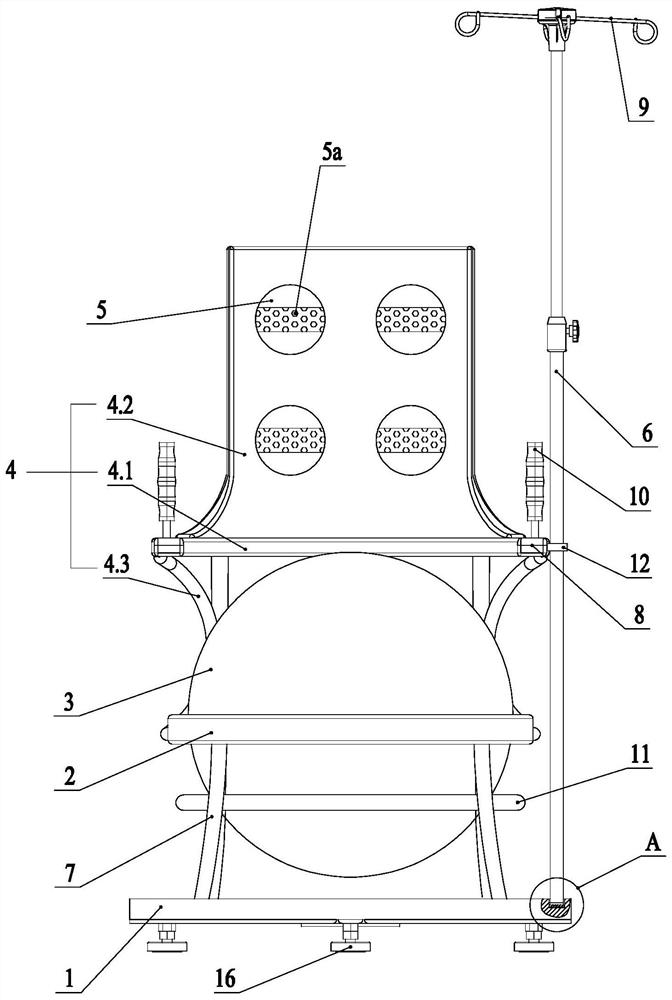

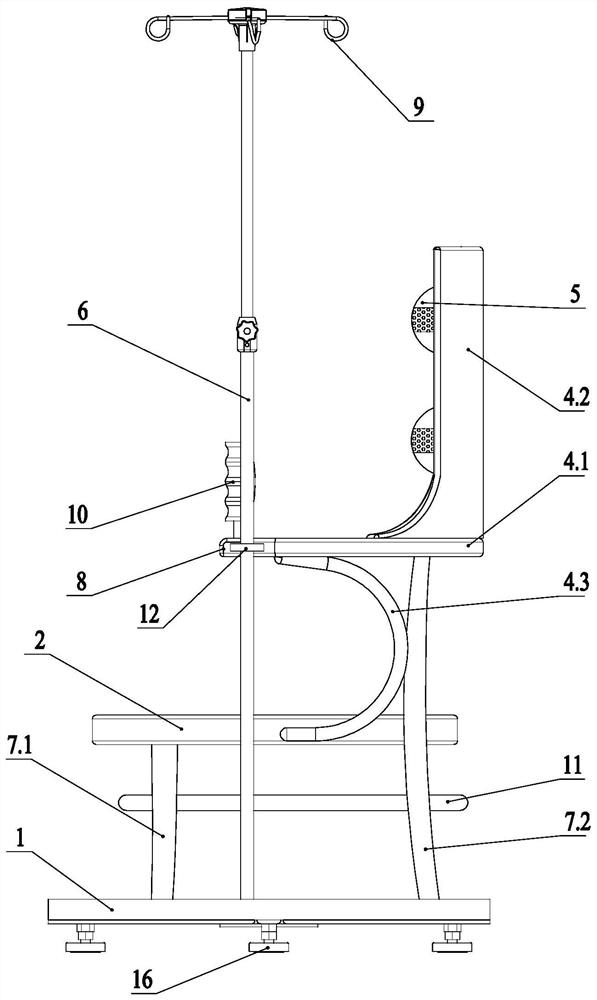

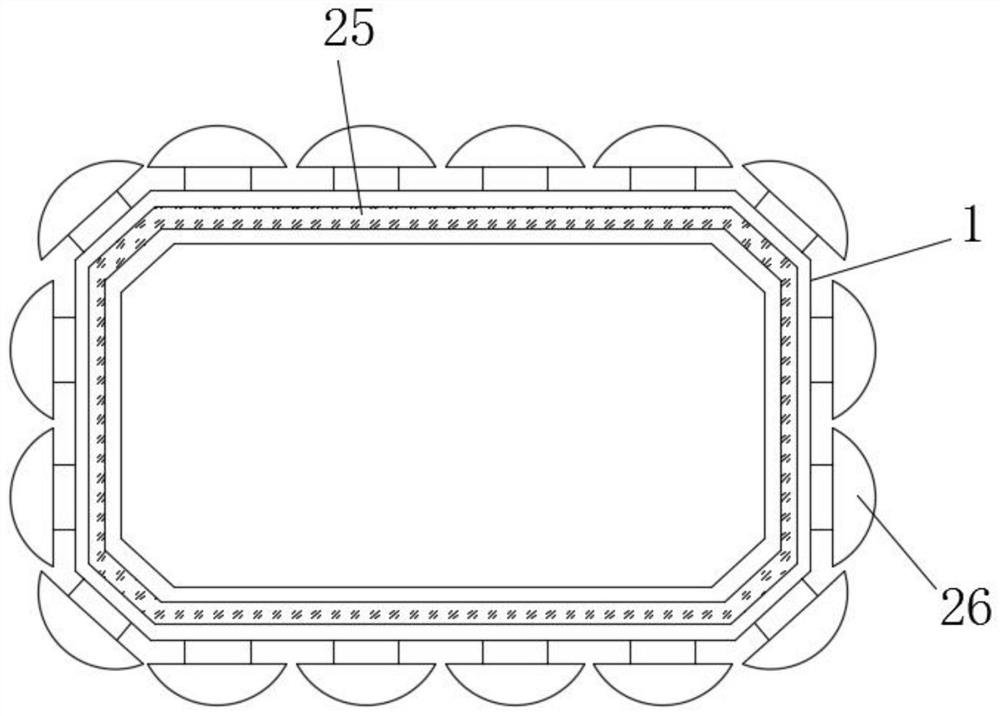

Multifunctional parturition ball chair

PendingCN112022604AEasy to fixEnsure safetyOperating chairsInfusion devicesPhysical medicine and rehabilitationMassage

The invention relates to a multifunctional parturition ball chair. The multifunctional parturition ball chair is characterized by comprising a base, a positioning ring, a parturition ball, a back frame, a plurality of massage balls, armrests and an infusion support, wherein the positioning ring is arranged above the base and fixed to the base through a plurality of vertical rods; the parturition ball is placed in the positioning ring; the back frame is fixedly connected to the base and the positioning ring; the massage balls are arranged on the surface of the front side of the back frame; thearmrests are arranged on the two sides of the back frame; and the infusion support is vertically mounted beside the armrests, and hooks are arranged on the infusion support. The multifunctional parturition ball chair is ingenious in structure and reasonable in design, safety of a lying-in woman during exercise can be guaranteed, discomfort of the waist and the back of the lying-in woman can be relieved, the lying-in woman can lean against the back frame to have a rest, fatigue is relieved, comfort is improved, and besides, the lying-in woman can exercise during infusion.

Owner:AFFILIATED HOSPITAL OF JIANGSU UNIV

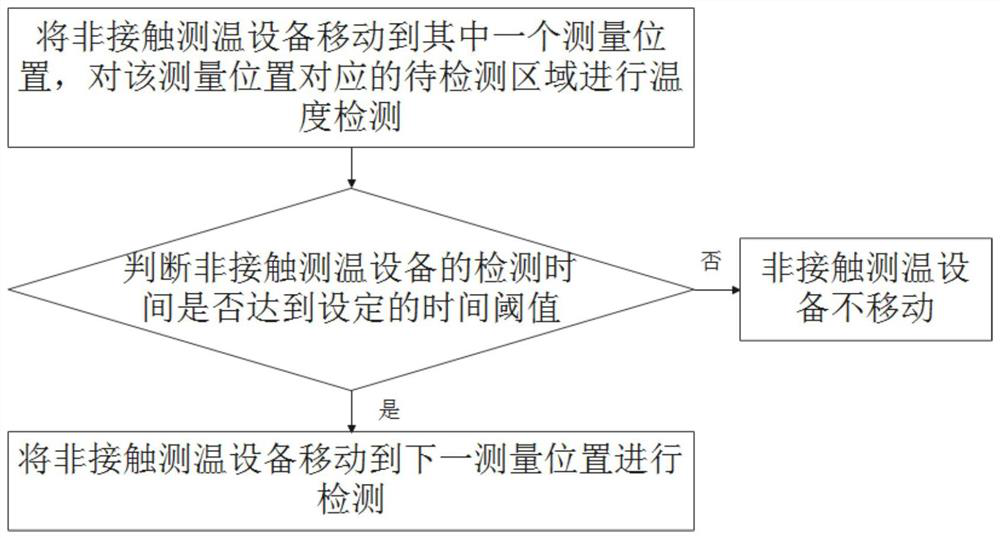

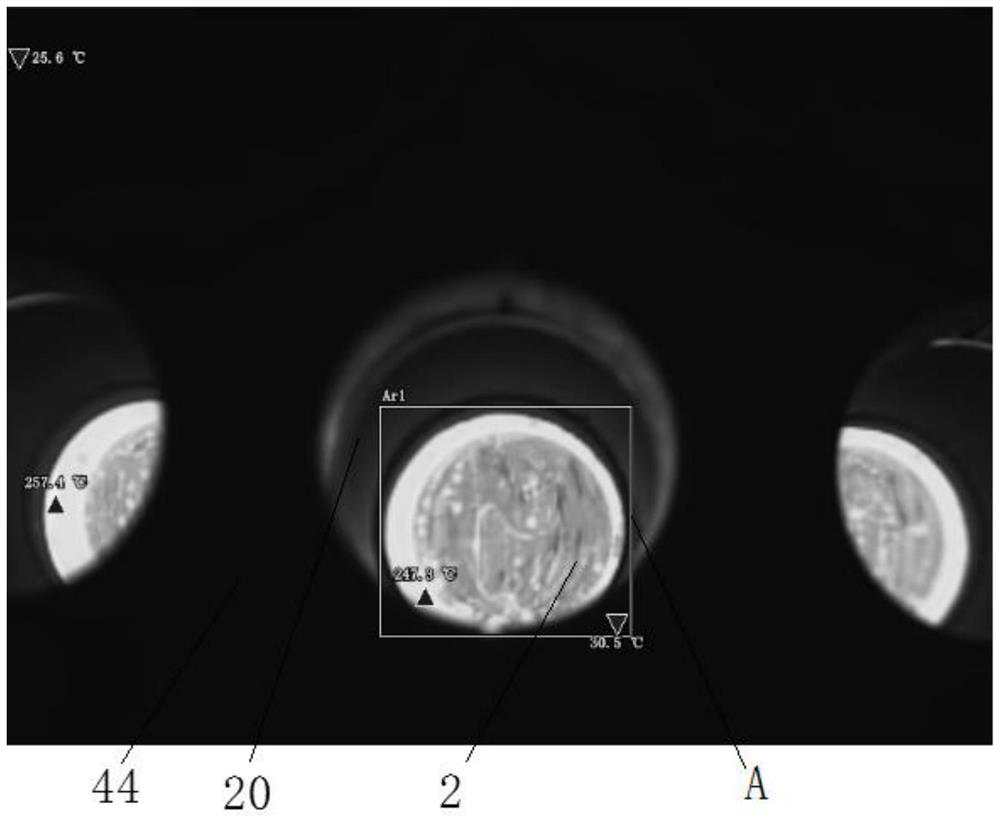

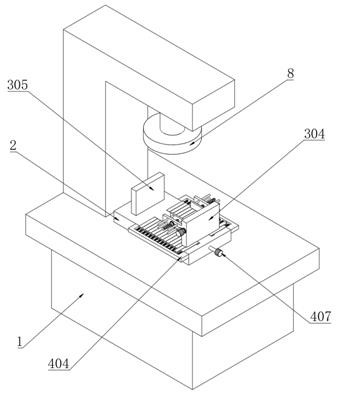

Method and device for detecting temperature of spinning assembly

PendingCN113739956APrevent fallingAvoid affecting movementSpinnerette packsArtificial thread manufacturing machinesSpinningEngineering

The invention discloses a method and device for detecting the temperature of a spinning assembly, and belongs to the technical field of spinning equipment. A spinning machine comprises at least two groups of spinning assemblies, and the at least two groups of spinning assemblies form at least two areas to be detected; and non-contact temperature measuring equipment used for measuring the temperature of the spinning assembly is provided with at least two measuring positions, and the at least two measuring positions are in one-to-one correspondence with the at least two to-be-detected areas. The method comprises the following steps: S1, moving non-contact temperature measurement equipment to one measurement position, and carrying out temperature detection on a to-be-detected area corresponding to the measurement position; and S2, judging whether the detection time of the non-contact temperature measurement equipment reaches a set time threshold value or not, if so, moving the non-contact temperature measurement equipment to a next measurement position, and otherwise, not moving the non-contact temperature measurement equipment. According to the invention, one non-contact temperature measuring device is used to detect the temperature of the to-be-detected area formed by the at least two spinning assemblies, the cost is saved, and the detection is convenient.

Owner:CHINESE TEXTILE ACAD +1

Overall pressing assembly device for new energy battery

InactiveCN114420989AEasy to movePrecise positioningAssembling battery machinesFinal product manufactureNew energyControl theory

The invention discloses a new energy battery integral press-down assembling device which comprises an assembling device body used for fixing a battery box so as to realize integral press-down assembling of a battery body into the battery box, and the assembling device body comprises a sliding seat and a camera visual judgment system arranged above the sliding seat. The camera visual judgment system can judge whether the battery box is fixed at a preset position or not and whether the posture is right or not; a positioning assembly is arranged on the sliding seat and comprises a fixed plate fixed to the position, close to one end, of the sliding seat, a sliding plate arranged to the position, close to the other end, of the sliding seat and oppositely spaced from the fixed plate, and clamping plates symmetrically arranged to the positions, close to the two sides, of the sliding seat. The sliding plate can horizontally move against or away from the fixed plate; the two clamping plates can synchronously and horizontally move in a manner of abutting against or leaving away from each other; the fixed plate, the sliding plate and the two clamping plates jointly clamp and fix the battery box; the speed and accuracy of fixing the battery box can be effectively improved, the positioning is firm, and the fixing posture of the battery box is correct.

Owner:厦门竣铭科技有限公司

Push-pull device for welding fixture

PendingCN109702397ARealize resetEasy to pullWelding/cutting auxillary devicesAuxillary welding devicesPush and pullEngineering

The invention discloses a push-pull device for a welding fixture. The push-pull device for the welding fixture comprises a welding fixture body, connecting blocks are arranged on one side of the welding fixture body, fixed blocks are welded to each connecting block, and rotating shafts are rotatably arranged on the fixed blocks through bearings. First protrusion blocks are symmetrically welded tothe end parts of the rotating shafts, second protrusion blocks are welded into annular grooves, and springs are fixedly connected between the first protrusion blocks and the second protrusion blocks.Rotating rods are welded to the rotating shafts, first push-pull rods are welded to the rotating rods, and second push-pull rods are arranged on the first push-pull rods. According to the push-pull device for the welding fixture, when an employee pulls the second push-pull rods, the rotating shafts rotate through the action of the bearings, so that the second push-pull rods rotate to a position where is most suitable for the employee to push and pull; and meanwhile, the rotating shafts drive the first protrusion blocks to rotate to the second protrusion blocks, the springs are compressed, whenthe second push-pull rods are loosened, the springs automatically rotate the rotating shafts to an original position, and the reset of the second push-pull rods is realized.

Owner:HANTENG AUTOMOBILE CO LTD

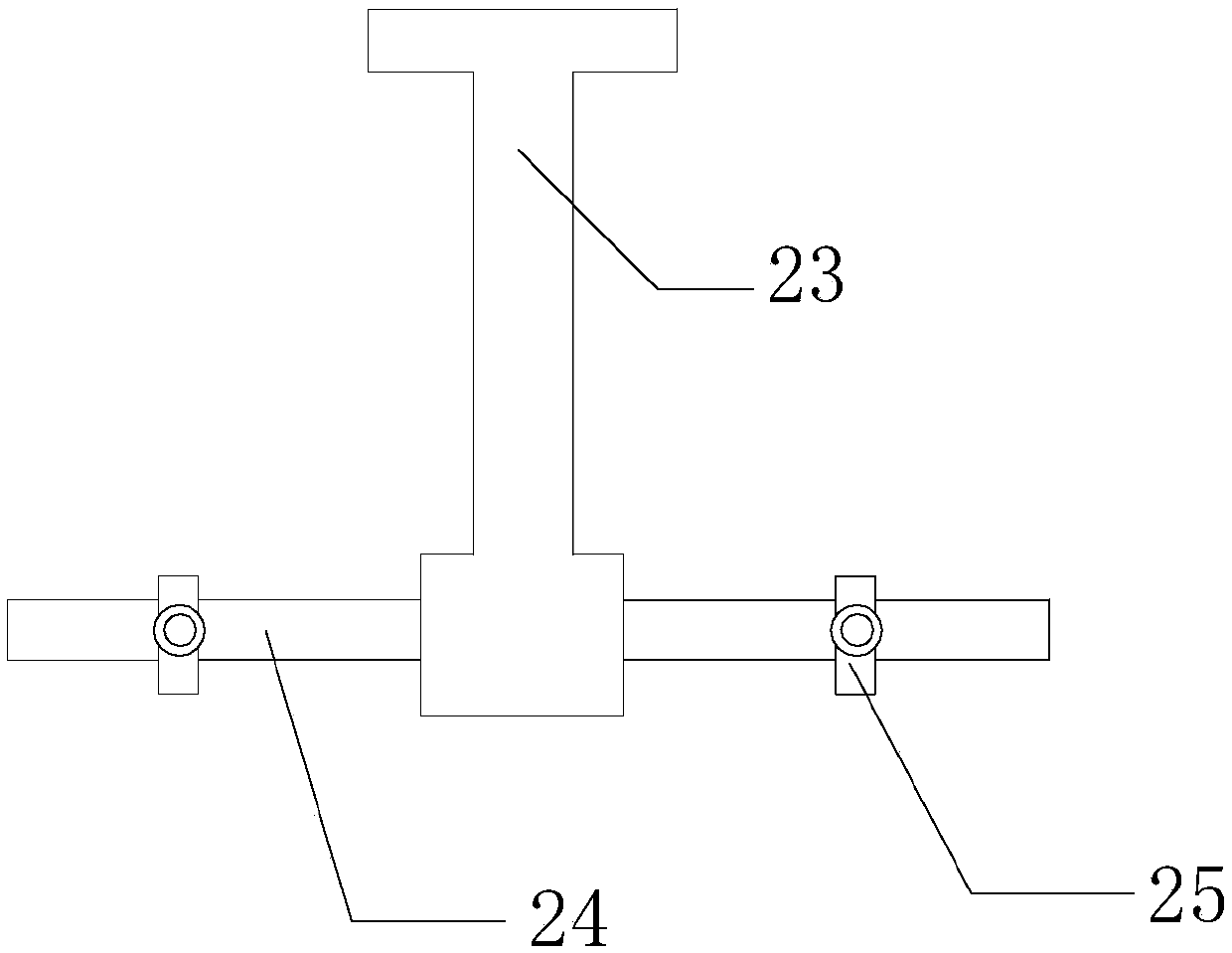

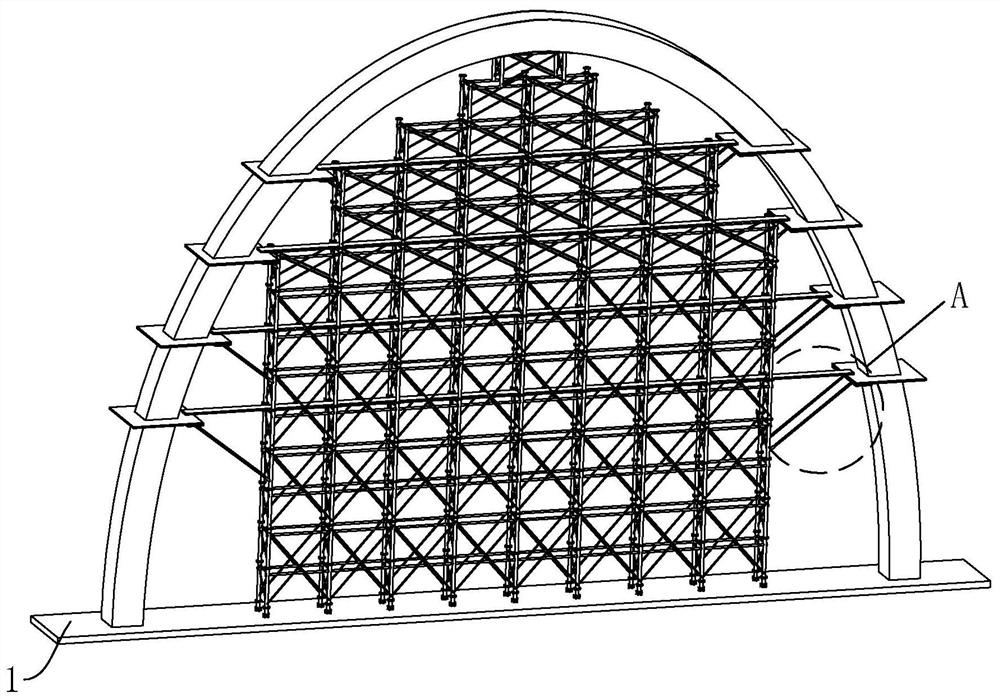

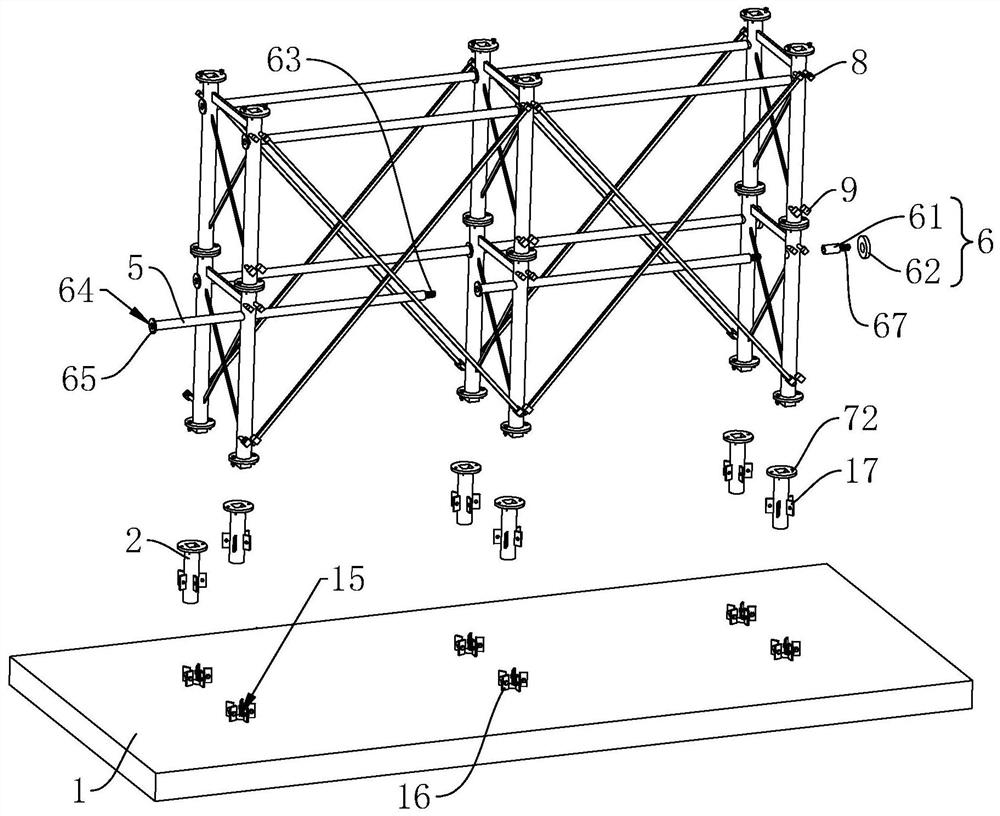

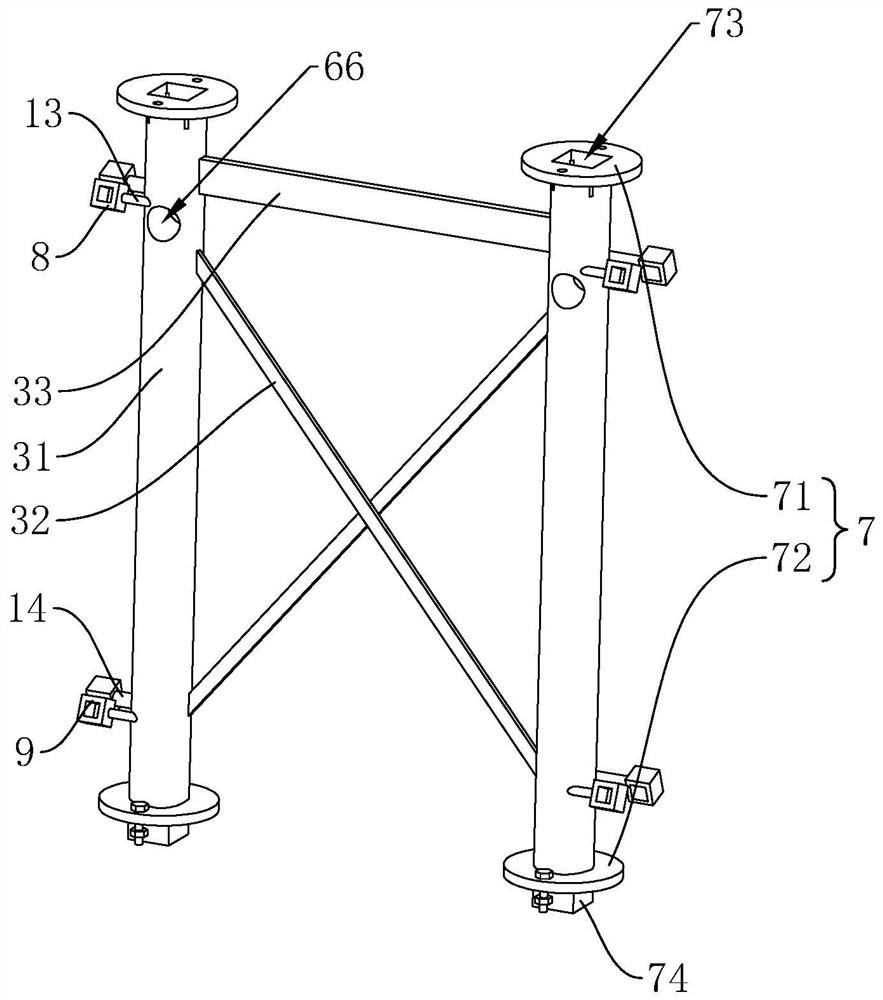

Main arch support structure of overpass bridge and installation method

PendingCN113774796AGood support effectAvoid affecting movementBridge structural detailsBridge erection/assemblyCross overArch supports

The invention relates to a main arch support structure of an overpass bridge and an installation method, wherein the main arch support structure comprises a support bottom plate, a plurality of piles and a plurality of support split bodies, the piles are vertically arranged at the top end of the support bottom plate, every two piles correspond to one support split body, and the top ends of the two piles are fixedly connected with the bottom ends of the support split bodies; the two first inclined clamping rods are arranged between the adjacent support split bodies in the same horizontal direction, the two first inclined clamping rods are arranged in a crossed mode, a horizontal clamping column is arranged between the adjacent support split bodies in the same horizontal direction in a penetrating mode, a fastening assembly is arranged on the horizontal clamping column, and a connecting assembly is arranged between the adjacent support split bodies in the same vertical direction. In the application, the main arch support is built according to the built height of a main arch, the horizontal clamping columns enable the support in the horizontal direction to be detachably installed in a split mode through the fastening assemblies, and the connecting assemblies enable the support in the vertical direction to be detachably installed in a split mode; therefore, the main arch support is prevented from influencing the effect that the crane moves the hoisted main arch split body to the installed main arch split body.

Owner:CHINA FIRST HIGHWAY ENG

Processing device for six-blade flat milling cutter of multi-axis linkage machining center

InactiveCN110340414AEasy to fixEasy to adjustMilling cuttersPositioning apparatusMilling cutterEngineering

The invention discloses a processing device for a six-blade flat milling cutter of a multi-axis linkage machining center, and relates to the technical field of mechanical equipment. The processing device comprises a vertical plate, supporting plates are fixedly connected to the upper surface and the lower surface of the vertical plate, sliding grooves are formed in the opposite surfaces of the twosupporting plates, and sliding blocks are connected in the two sliding grooves in a sliding mode. The processing device for the six-blade flat milling cutter of the multi-axis linkage machining center is characterized in that a first hydraulic push rod, a second hydraulic push rod and a motor are arranged, people utilize the four second hydraulic push rods to extend to drive the four extrusion plates to fix a workpiece in the clamping groove, and then rotate through the output shaft of the motor to drive the movable plate to rotate, so that the angle of the workpiece is adjusted, when the angle of the workpiece is adjusted, the two first hydraulic push rods are controlled to extend to drive the two sliders to move leftwards, the two sliding blocks drive the workpiece to move leftwards through the fixing plate, so that the workpiece can be processed by the cutting mechanism, so that people can conveniently fix and adjust the workpiece.

Owner:马鞍山正复安电子科技有限公司

Constant-speed transfer structure of stamping parts based on intelligent manufacturing of auto parts

ActiveCN113319182BRealize automatic progressLower control costsMetal-working feeding devicesPositioning devicesManufacturing technologyElectric machine

The invention discloses a fixed-speed transfer structure based on the intelligent manufacturing of stamping parts of auto parts, relates to the technical field of auto parts manufacturing, and solves the problem that the currently used transfer structure is mainly controlled by a motor, and cannot realize the automatic control effect through the mechanical structure according to the steps of stamping , to control the problem of high cost. The constant-speed transmission structure based on the intelligent manufacturing of stamping parts of auto parts includes a long bottom plate. The top right rear side of the top of the long bottom plate is fixed with an output row by a bracket. The output row is a wedge-shaped channel structure. The output row The outer side of the inner side is inclined downwards. By setting the driven shaft A and the rack B, it provides an automatic control effect for the transmission structure, which can extend the power when the stamping is reset, provide the power for the workpiece to advance, and realize the one-time station. Automatic progress, compared with the current commonly used transfer structure, greatly saves the control cost, and is more stable than the electronic control method, and there will be no asynchronous dislocation and other phenomena.

Owner:NANTONG SUHE LAMP PARTS

Floating roller mechanism and bill processing device

The invention provides a floating roller mechanism and a bill processing device and relates to the technical field of financial machinery. The floating roller mechanism comprises a machine frame, a drive assembly, a supporting assembly, a first floating roller and a second floating roller. The first floating roller and the second floating roller are supported by the supporting assembly, the firstfloating roller and the second floating roller are arranged in parallel in a spaced manner and both can freely rotate around own axes. The supporting assembly is movably connected with the machine frame. The drive assembly is in transmission connection with the supporting assembly. The drive assembly is configured to drive the supporting assembly to be located at a first position or a second position relative to the machine frame. When the supporting assembly is located at the first position, the first floating roller and the second floating roller conduct downward press at the same time. Whenthe supporting assembly is located at the second position, the first floating roller and the second floating roller rise at the same time. The floating roller mechanism relieves the technical problemthat in a relevant technology, since the position of the floating roller is fixed, bill deviation correcting by a deviation correcting mechanism is influenced.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

Agricultural machinery threshing machine

ActiveCN114223404AAvoid threshingSwipe to avoid impactThreshersSaving energy measuresElectric machineryAgricultural engineering

The invention belongs to the technical field of agricultural machinery, and particularly relates to an agricultural machinery threshing machine which comprises a base, rollers are arranged at the front end and the rear end of the base, a threshing groove is formed in the top end of the base, holding rods are arranged at the front end and the rear end of the left side of the threshing groove, a through hole is formed in a side plate of the front end face of the threshing groove, and a rotating motor is arranged in the through hole. A rotating shaft of the rotating motor extends into an inner cavity of the threshing groove, four sets of threshing fan blades are arranged on the outer side of the rotating shaft of the rotating motor, limiting supporting blocks are arranged on the front side and the rear side of the top end of the threshing groove correspondingly, a grain seedling clamping plate is arranged on the left side of the top end of the threshing groove, and the grain seedling clamping plate comprises a rotating cover plate; the bottom end of the rotating cover plate is connected with the threshing groove through a second connecting rotating shaft, four sets of material inserting holes are formed in the left side and the right side of the rotating cover plate in total, the threshing machine is simple in structure, and people do not need to hold food crops in hands to put the food crops into the threshing groove for threshing.

Owner:武威职业学院

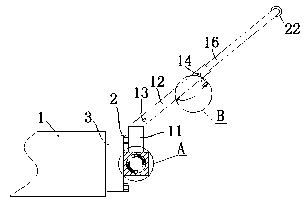

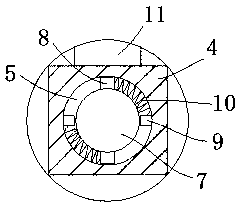

Magnetic memory detection device for welding seam of intersecting pipeline

ActiveCN106645383BGuaranteed accuracyAvoid analysis errorsMaterial magnetic variablesFillet weldStraight tube

The invention provides a magnetic memory detection device for a cross manifold weld, used for detecting a weld (5) between a straight pipe (3) and an inclined pipe (4), wherein the magnetic memory detection device for the cross manifold weld comprises a magnetic memory sensor detection driving mechanism (1) and an assistant adjusting support (2), the magnetic memory sensor detection driving mechanism (1) comprises a detection unit (103) and a circular rail (115) capable of sleeving the outside of the inclined pipe (4), and the detection unit (103) can detect the detected weld (5) during the process of moving along the circular rail (115); the magnetic memory detection device for the cross manifold weld can perform omni-directional barrier-free detection on oblique crossing pipe intersecting line fillet welds with small angle areas. The error caused by manual operation during measuring can be greatly reduced, the smooth and stable detection process and accurate measuring result are ensured, and the measuring efficiency is greatly improved.

Owner:PETROCHINA CO LTD +1

a shower

InactiveCN109701766BPrevent splashGuaranteed negative pressureSpray nozzlesSewageMechanical engineering

The invention relates to a sprinkler. The sprinkler comprises a sprinkler seat and a water outlet panel, and is characterized in that water outlet channels and sewage recovery channels are arranged inthe sprinkler seat; a water outlet area and an anti-splashing area are separately arranged on the surface, away from the sprinkler seat, of the water outlet panel, and the anti-splashing area is located at the edge of the water outlet panel; at least one water outlet hole communicating with the water outlet channels is formed in the water outlet area; at least two first protruding parts are arranged in the anti-splashing area, the at least two first protruding parts are arranged at intervals, and anti-splashing absorbing holes communicating with the sewage recovery channels are formed in theend surfaces of the ends, away from the water outlet panel, of the first protruding parts. According to the sprinkler, the first protruding parts are arranged on the anti-splashing area outside the water outlet area, the anti-splashing absorbing holes are formed in the first protruding parts, so that splashing is prevented while recovering sewage.

Owner:XIAMEN COMFORT SCIENCE & TECHNOLOGY GROUP CO LTD +1

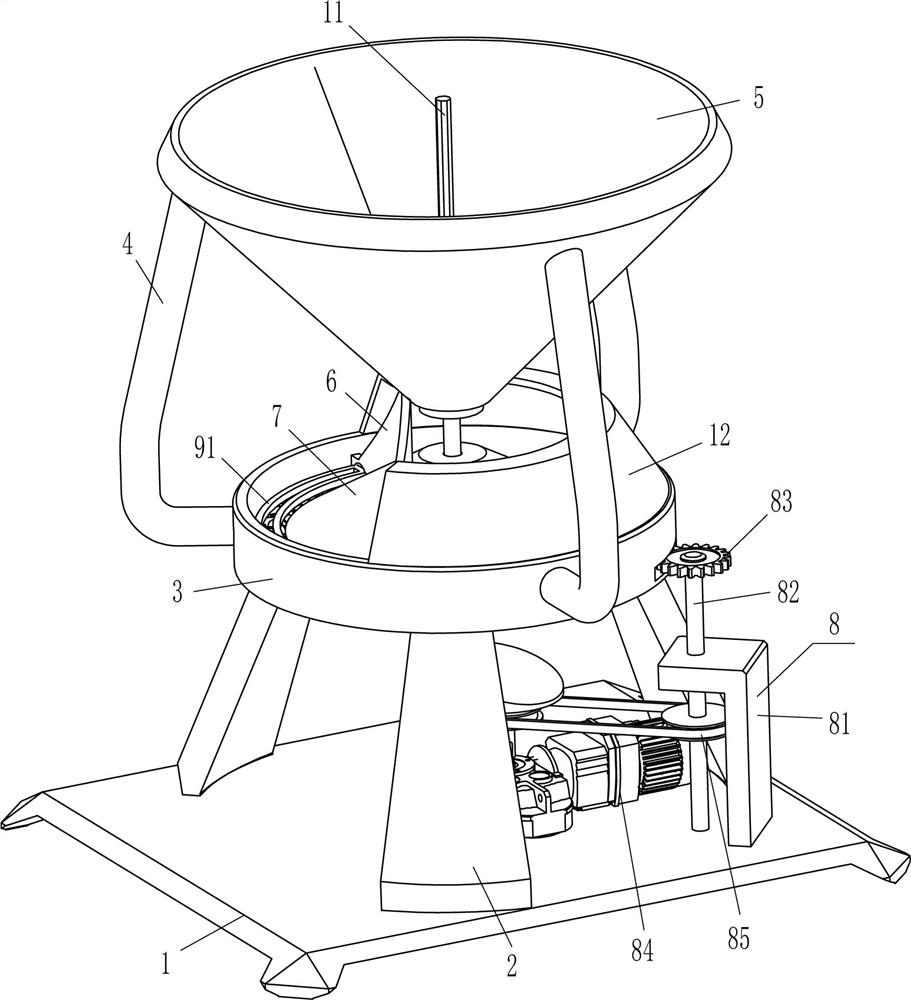

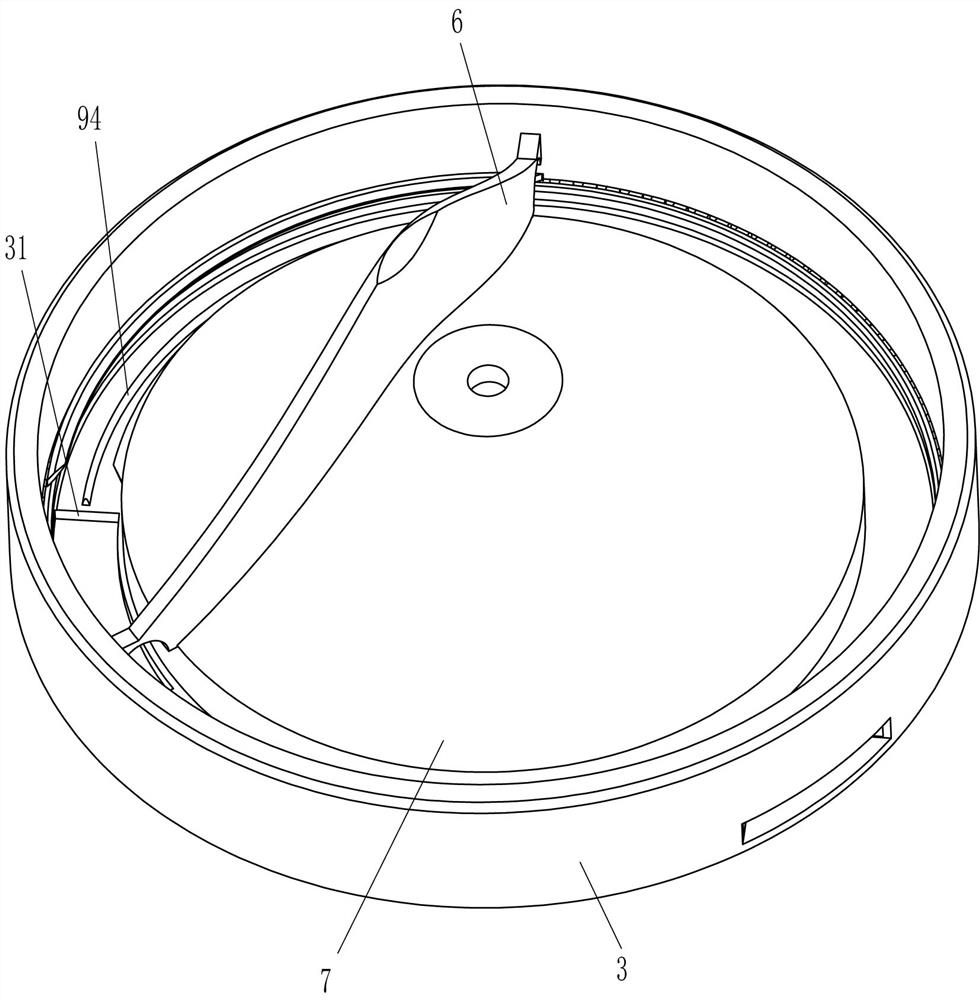

Automatic discharging device for counting beads

PendingCN111731798AOrderly rowsIncrease productivityConveyorsControl devices for conveyorsControl theoryMechanical engineering

The invention discloses an automatic discharging device for counting beads. A feeding hopper is driven to swing back and forth through a swing driving mechanism, so that the counting beads located atthe bottommost are arranged along a feeding guide rail in order; the feeding hopper is swung until the tail end of the feeding guide rail communicates with the top end of a guide groove, an outlet ofthe feeding hopper is opened through a stopping mechanism, and due to the fact that a guide plate and the feeding hopper are both obliquely arranged, and a discharging plate is at the initial positionof the first position, the counting beads at the bottommost end of the feeding hopper slide downwards along the guide groove until the counting beads fall into a discharging groove; and finally, thedischarging plate is driven to move to the second position through a discharging driver, so that the next step of stringing the counting beads on an inserting rod is carried out. According to the automatic discharging device for the counting beads, the plurality of counting beads can be automatically arranged in a row in order to wait for string together without manual string one by one, so that the production efficiency is greatly improved, the labor cost is reduced, the error rate of the string is low, and the rework rate is low.

Owner:HUAQIAO UNIVERSITY

A lightweight multi-joint module for a robot

The invention discloses a lightweight multi-joint module for a robot, which includes a housing, a frameless moment motor and a base. An overload protector is installed on the inner bottom of the base through bolts, and an anti-electromagnetic A jammer, the inner top of the base is equipped with a vibration alarm through the installation groove, the top of the base is connected to the housing through a rotating shaft, a frameless torque motor is installed in the housing through a connecting frame, and the frameless torque motor A brake is installed on one side, and a harmonic reducer is installed on the other side of the frameless torque motor through a mounting frame. A refrigeration box is arranged on the top of the housing. The invention integrates robot joints, is convenient for installation, can be installed on a small robot, and can realize multi-angle movement, and is suitable for being widely popularized and used.

Owner:东莞市本润机器人科技股份有限公司

Explosion-proof structure of an underground inspection robot

ActiveCN109866234BBarrier explosion suppressionImprove the ability to resist explosionWithdrawing sample devicesManipulatorAir springAir pump

The invention discloses an anti-explosion structure of a downhole polling robot. The anti-explosion structure comprises a polling robot shell, rollers and an infrared camera. The rollers are located at the bottom of the polling robot shell, the infrared camera is located on one side of the surface of the polling robot shell, and anti-explosion boxes are welded to the side faces of the bottom of the polling robot shell. Through the arrangement of a blocking anti-explosion metal material layer and nickel-based alloy semicircular blocks, the hardness and the rigidity of the polling robot shell are improved; through the arrangement of the anti-explosion boxes and metal anti-explosion plates, the anti-explosion performance of the polling robot shell is improved, and damage of downhole emergencies to the polling robot shell is reduced; through the arrangement of a sucking pump and a check valve, downhole air is sampled, and the downhole air can be conveniently detected; through the arrangement of electric telescopic rods and first anti-explosion wheels, the situation that barriers block movement of the rollers is effectively avoided; and through the arrangement of air springs and a laminated rubber shock insulating support, vibration generated by the polling robot shell is effectively reduced when explosions happen.

Owner:安徽玄离智能科技股份有限公司

Sprinkler

The invention relates to a sprinkler. The sprinkler comprises a sprinkler seat and a water outlet panel, and is characterized in that water outlet channels and sewage recovery channels are arranged inthe sprinkler seat; a water outlet area and an anti-splashing area are separately arranged on the surface, away from the sprinkler seat, of the water outlet panel, and the anti-splashing area is located at the edge of the water outlet panel; at least one water outlet hole communicating with the water outlet channels is formed in the water outlet area; at least two first protruding parts are arranged in the anti-splashing area, the at least two first protruding parts are arranged at intervals, and anti-splashing absorbing holes communicating with the sewage recovery channels are formed in theend surfaces of the ends, away from the water outlet panel, of the first protruding parts. According to the sprinkler, the first protruding parts are arranged on the anti-splashing area outside the water outlet area, the anti-splashing absorbing holes are formed in the first protruding parts, so that splashing is prevented while recovering sewage.

Owner:XIAMEN COMFORT SCIENCE & TECHNOLOGY GROUP CO LTD +1

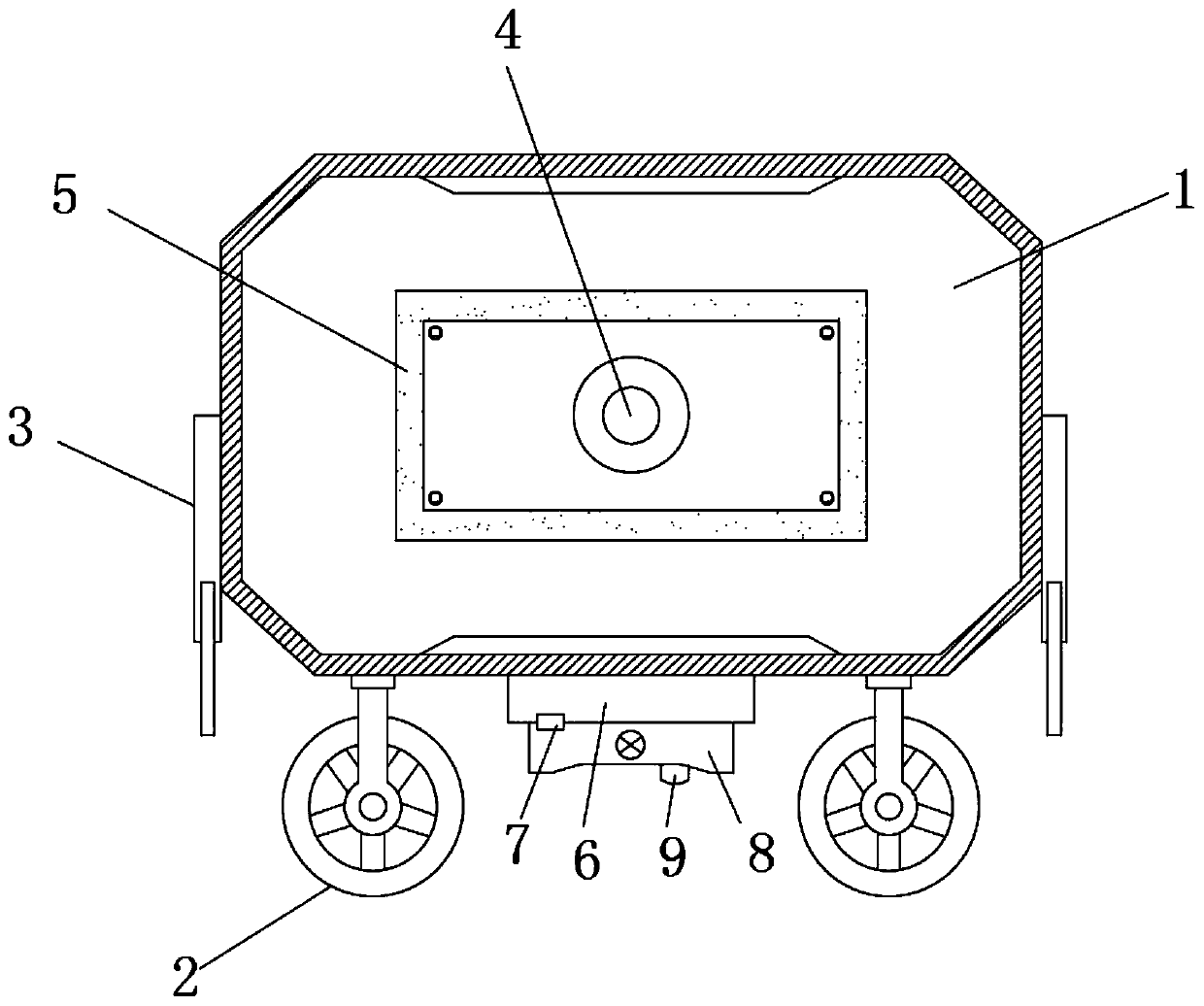

Self-cleaning logistics vehicle

InactiveCN111731734AAvoid affecting movementAvoid affecting recognitionConveyorsCleaning using toolsLogistics managementAgricultural engineering

Owner:安徽匠桥财务咨询服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com