Slotting equipment used before production of preserved kumquats

A technology of candied fruit and kumquat, which is applied in the field of slotting equipment before the production of kumquat candied fruit, which can solve the problems of laboriousness and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

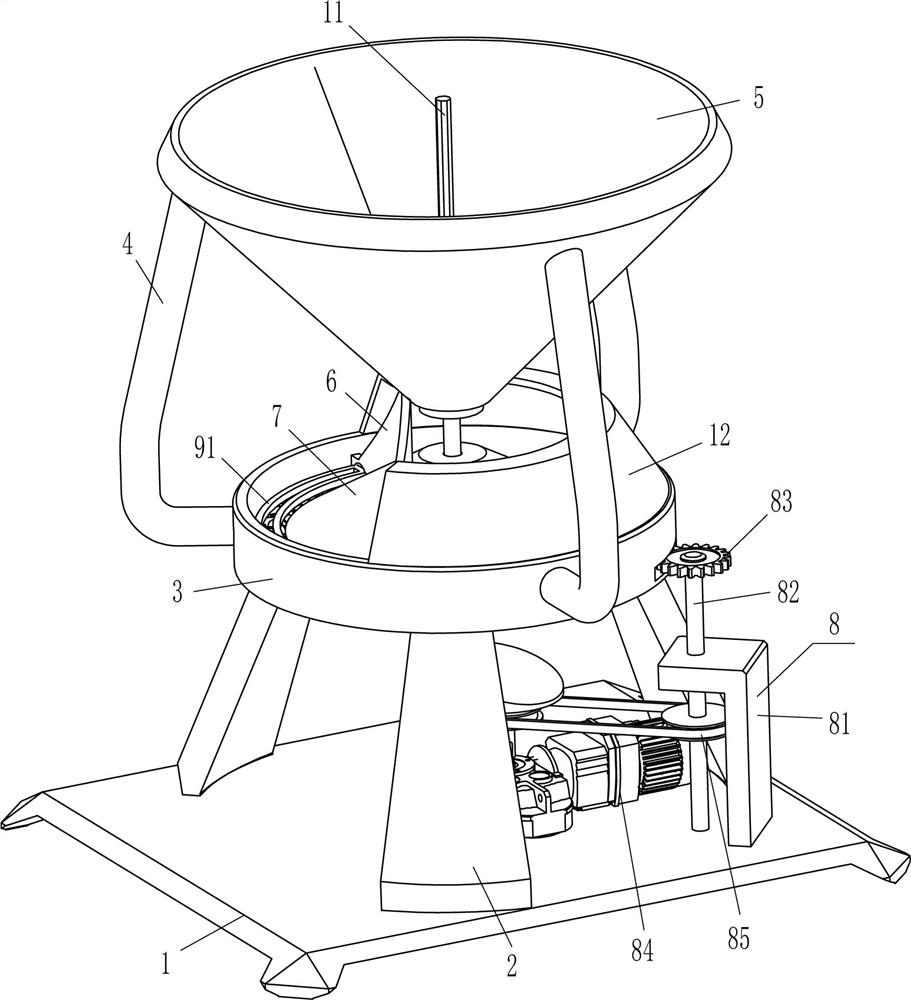

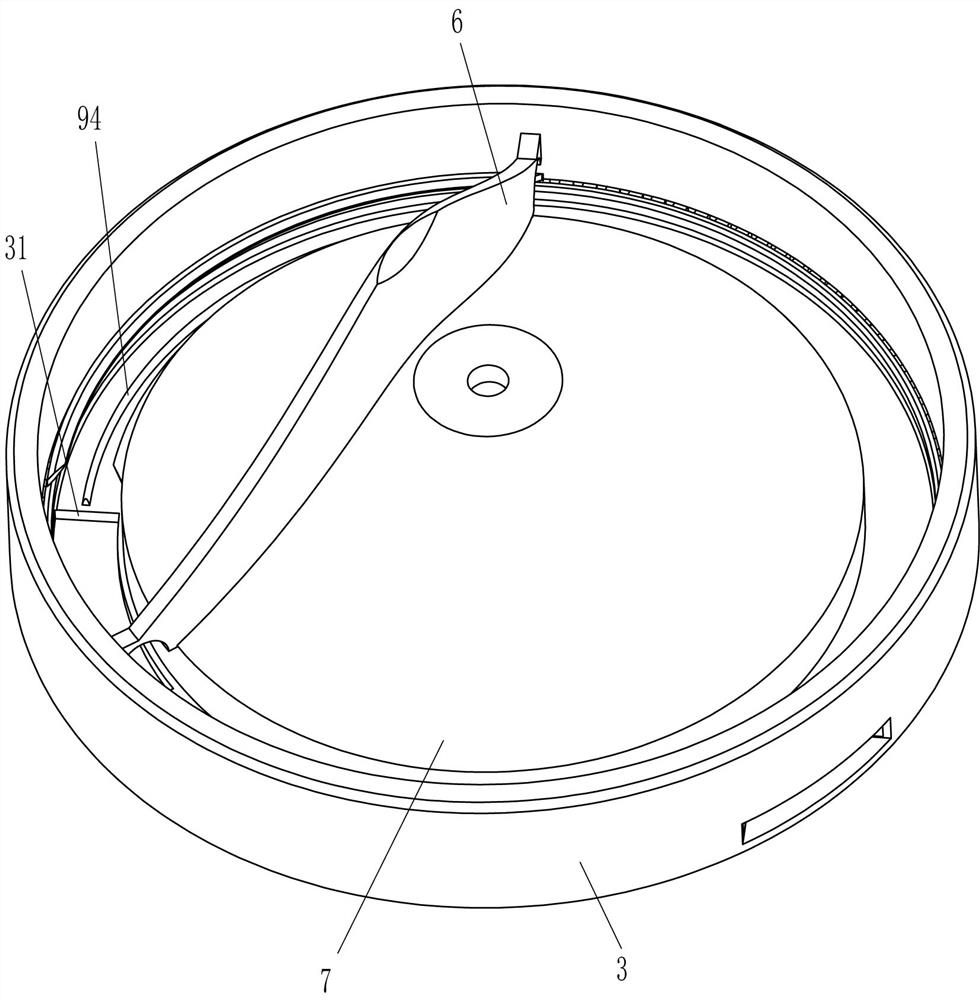

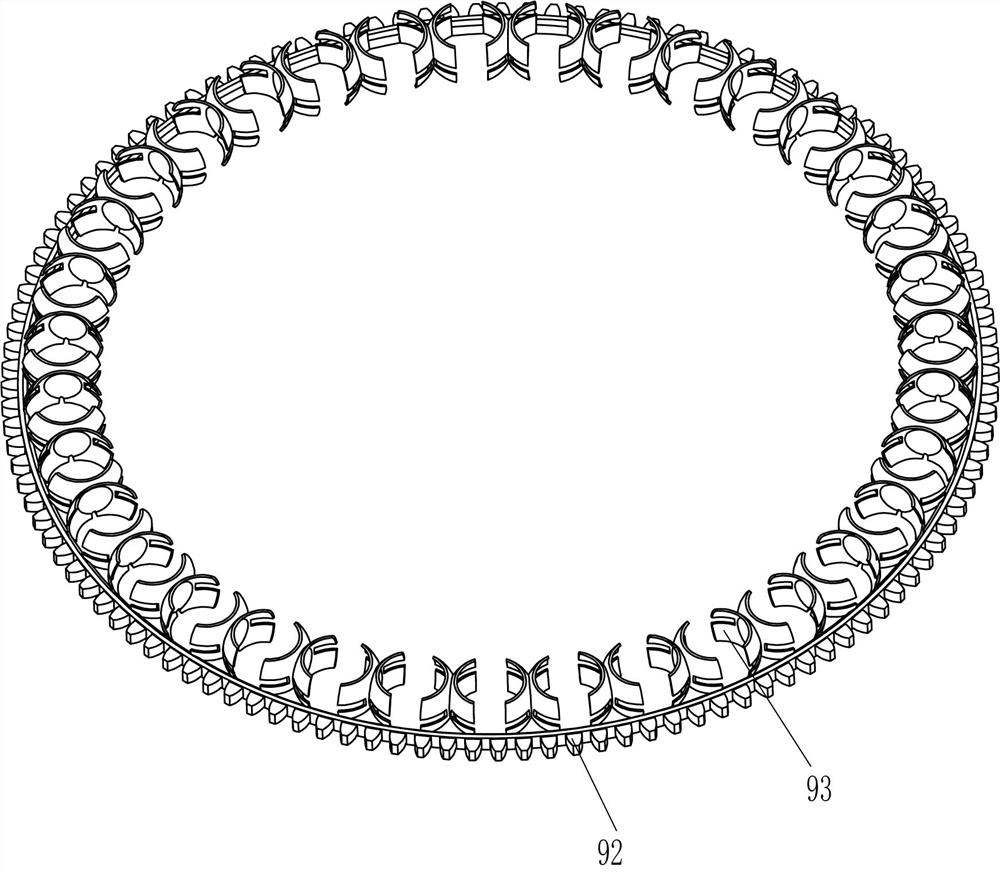

[0024] A kind of slotting equipment before the production of kumquat candied fruit, such as Figure 1-Figure 4 As shown, it includes a base 1, a support plate 2, a round frame 3, an L-shaped rod 4, a lower hopper 5, an arc-shaped baffle 6, a cone 7, a driving mechanism 8 and a cutting mechanism 9, and the top of the base 1 is evenly spaced. There are three supporting plates 2 fixedly connected, and a round frame 3 is fixedly connected between the tops of the three supporting plates 2, and three L-shaped rods 4 are fixedly connected to the outer circumference of the round frame 3 at uniform intervals, and the tops of the three L-shaped rods 4 are fixedly connected to each other. A lower hopper 5 is connected, and the lower hopper 5 is located directly above the round frame 3. A conical cylinder 7 is fixedly connected in the middle of the inner bottom of the circular frame 3. An arc-shaped baffle plate 6 is fixedly connected to the outer circumference of the conical cylinder 7 to...

Embodiment 2

[0031] On the basis of Example 1, such as figure 2 and Figure 5 As shown, it also includes a discharge mechanism 10, the discharge mechanism 10 includes a slide bar 101, a first spring 102, a disc cam 103, a rubber cone block 104 and a second spring 105, and the top end of the rotating rod 86 is fixedly connected with a disc Shaped cam 103, slide bar 101 is connected between the center of circle position at the bottom of circular frame 3 and the center of circle position at the top of tapered tube 7 in a sliding manner. A first spring 102 is wound around the outer bottom of the frame 3, and the top of the slide bar 101 is slidably covered with a rubber conical block 104. The rubber conical block 104 contacts and cooperates with the discharge end of the lower hopper 5, and the rubber conical block 104 A second spring 105 is connected between the inner top and the top of the slide bar 101 .

[0032] Initially, the first spring 102 is in a compressed state. At first the opera...

Embodiment 3

[0034] On the basis of embodiment 1 and embodiment 2, such as figure 1 As shown, a poking rod 11 is also included, and the poking rod 11 is fixedly connected to the middle of the outer top of the rubber cone block 104 , and the poking rod 11 is located in the lower hopper 5 .

[0035] It also includes an arc-shaped stop frame 12, and the right side of the top of the round frame 3 is fixedly connected with an arc-shaped stop frame 12.

[0036] When the rubber cone block 104 moved up and down, the rubber cone block 104 also drove the poking bar 11 to move up and down, and the poking bar 11 moved up and down to stir the kumquats in the lower hopper 5 . When the rubber cone block 104 stopped moving up and down, the poking bar 11 also stopped moving up and down. Like this, can avoid kumquat to be stuck in lower hopper 5 and cause be difficult to drop out.

[0037] When kumquats fell on the conical tube 7, the kumquats slid down into the round frame 3, and the arc-shaped retaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com