Magnetic memory detection device for cross manifold weld

A detection device and cross-pipe technology, applied in the direction of material magnetic variables, etc., can solve the problems of poor measurement repeatability, low accuracy of measurement results, and low measurement efficiency, so as to ensure measurement accuracy, good stability, and measurement efficiency Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

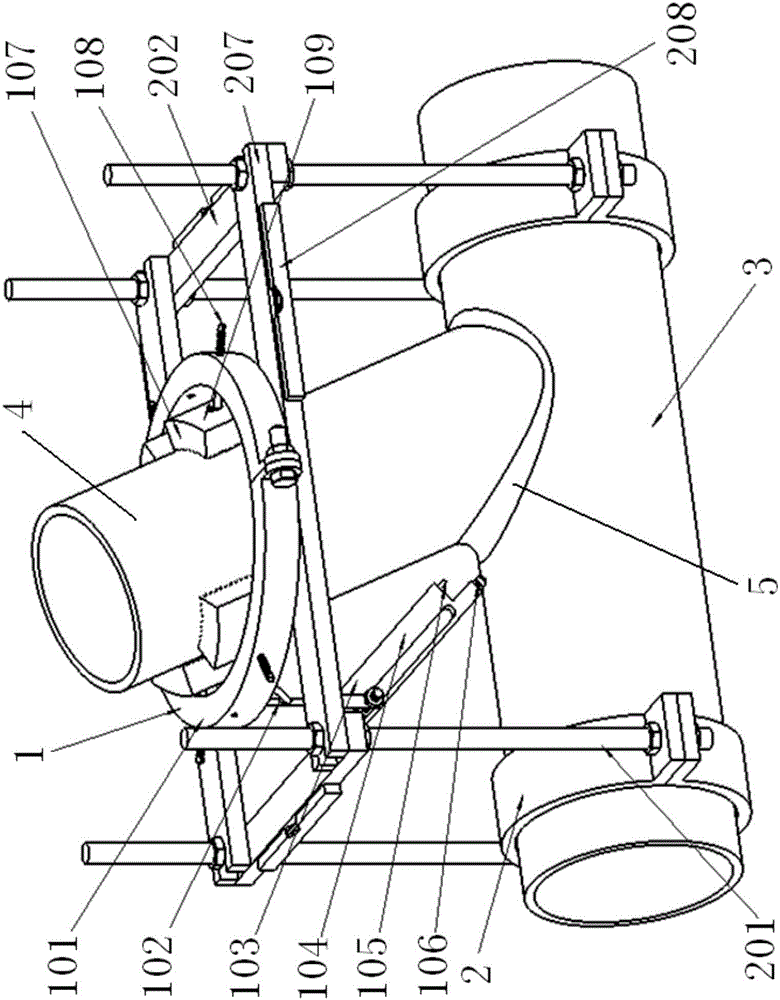

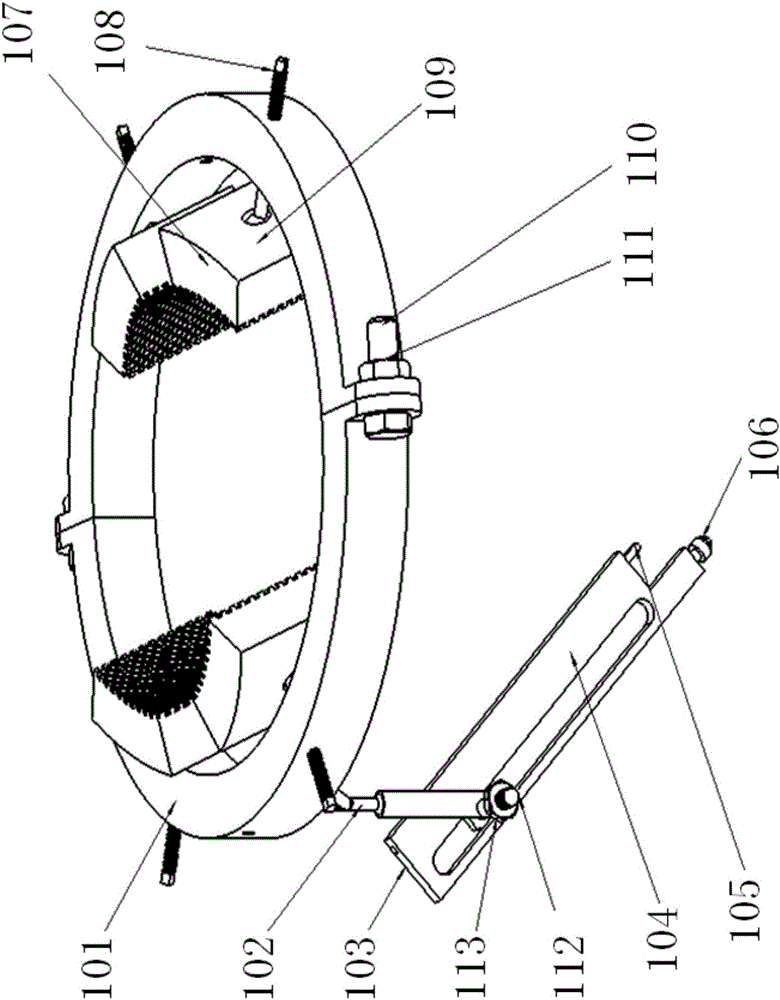

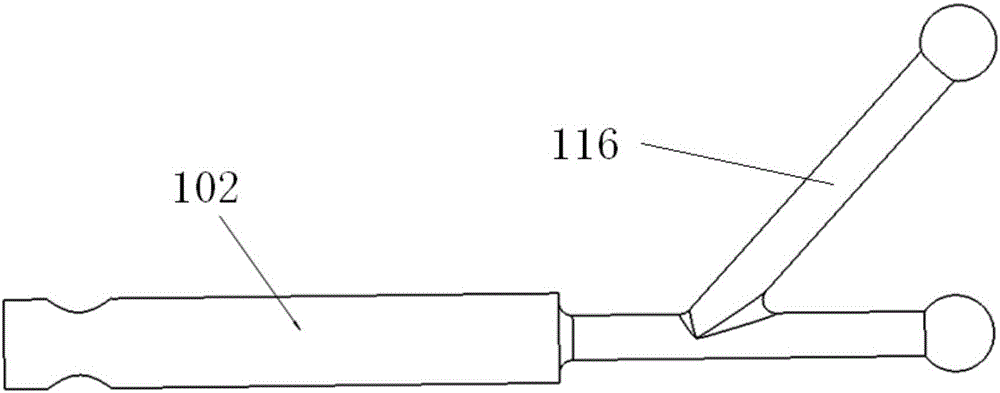

[0037] A magnetic memory detection device for cross pipeline welds, which can be used to detect the weld 5 between straight pipes 3 and inclined pipes 4, the magnetic memory detection device for cross pipeline welds includes a magnetic memory sensor to detect drive Mechanism 1 and auxiliary adjustment bracket 2, the magnetic memory sensor detection drive mechanism 1 includes a detection unit 103 and a circular track 115 that can be sleeved outside the inclined tube 4, the detection unit 103 is connected to the circular track 115, and the detection unit 103 can move along the The detection weld 5 is detected during the movement of the circular track 115; the auxiliary adjustment bracket 2 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com