Anti-explosion structure of downhole polling robot

A technology of inspection robots and explosion-proof structures, which is applied in the field of inspection robots, can solve problems such as increased maintenance costs, impact on moving speed, long distance, etc., to improve the ability to resist explosions, avoid blocking the movement of rollers, and increase the speed of movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

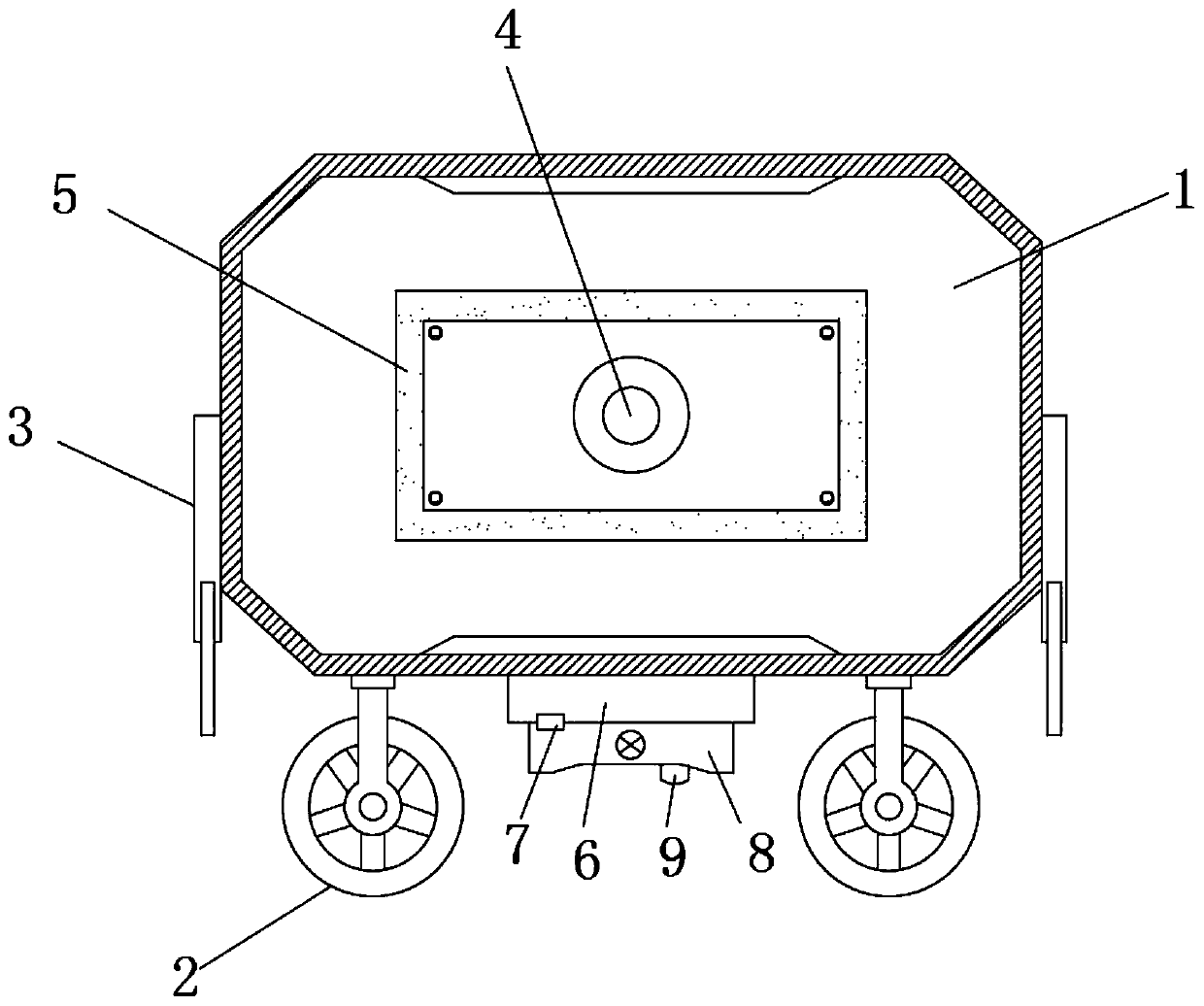

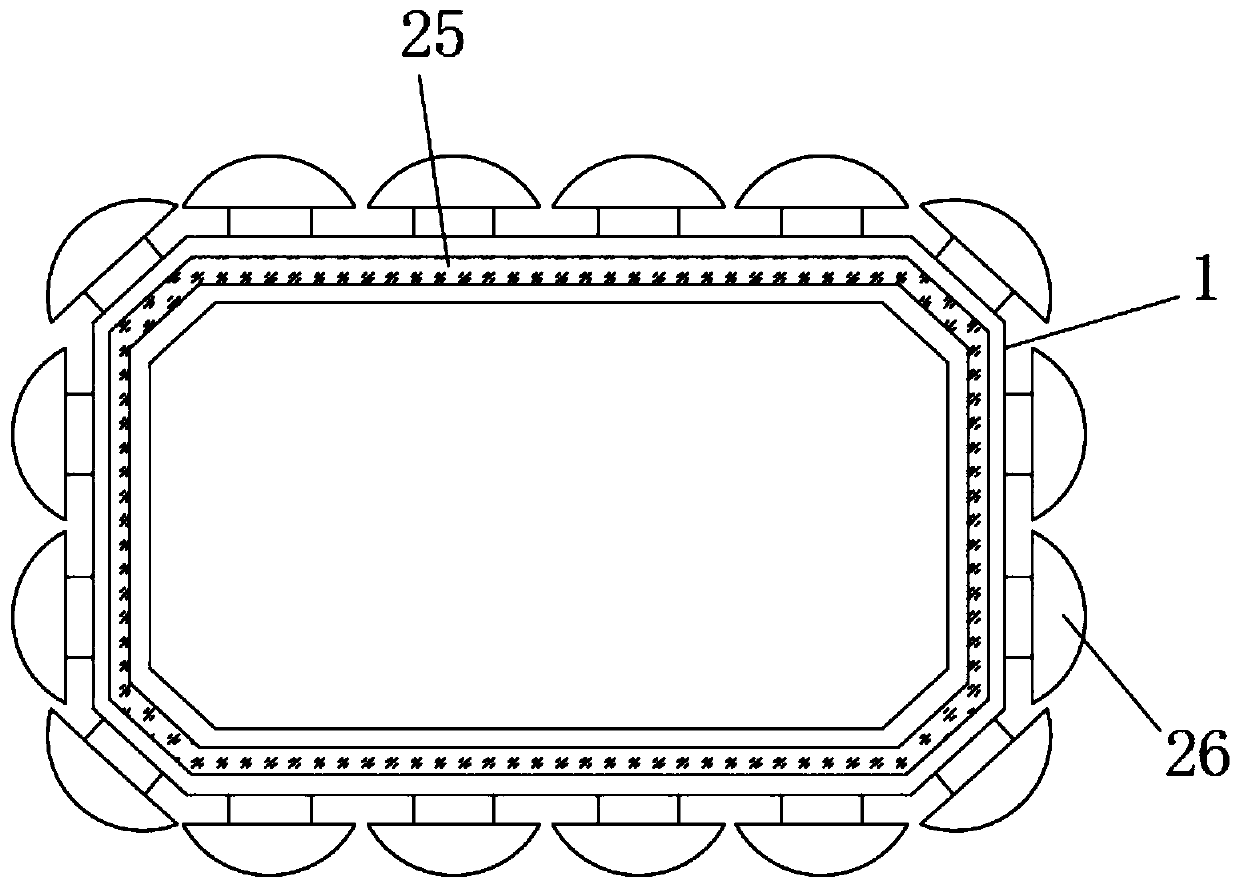

[0028] Such as figure 1 , figure 2 with Figure 4 As shown, an explosion-proof structure of an underground inspection robot includes an inspection robot housing 1, a roller 2 and an infrared camera 4. The roller 2 is located at the bottom of the inspection robot housing 1, and the infrared camera 4 is located on the surface of the inspection robot housing 1. On one side, an explosion-proof box 3 is welded on the bottom side of the inspection robot shell 1. The explosion-proof box 3 is equipped with four groups. The explosion-proof box 3 is equipped with a metal explosion-proof plate 15 inside. The metal explosion-proof plate 15 is equipped with pulleys 16 on both sides. 3 Slide rails 17 are welded on both sides of the inner wall, and the metal explosion-proof plate 15 is slidably connected to the slide rail 17 through pulleys 16. The inspection robot housing 1 is filled with an explosion-proof metal material layer 25. The inspection robot housing 1 A nickel-based alloy semicirc...

Embodiment 2

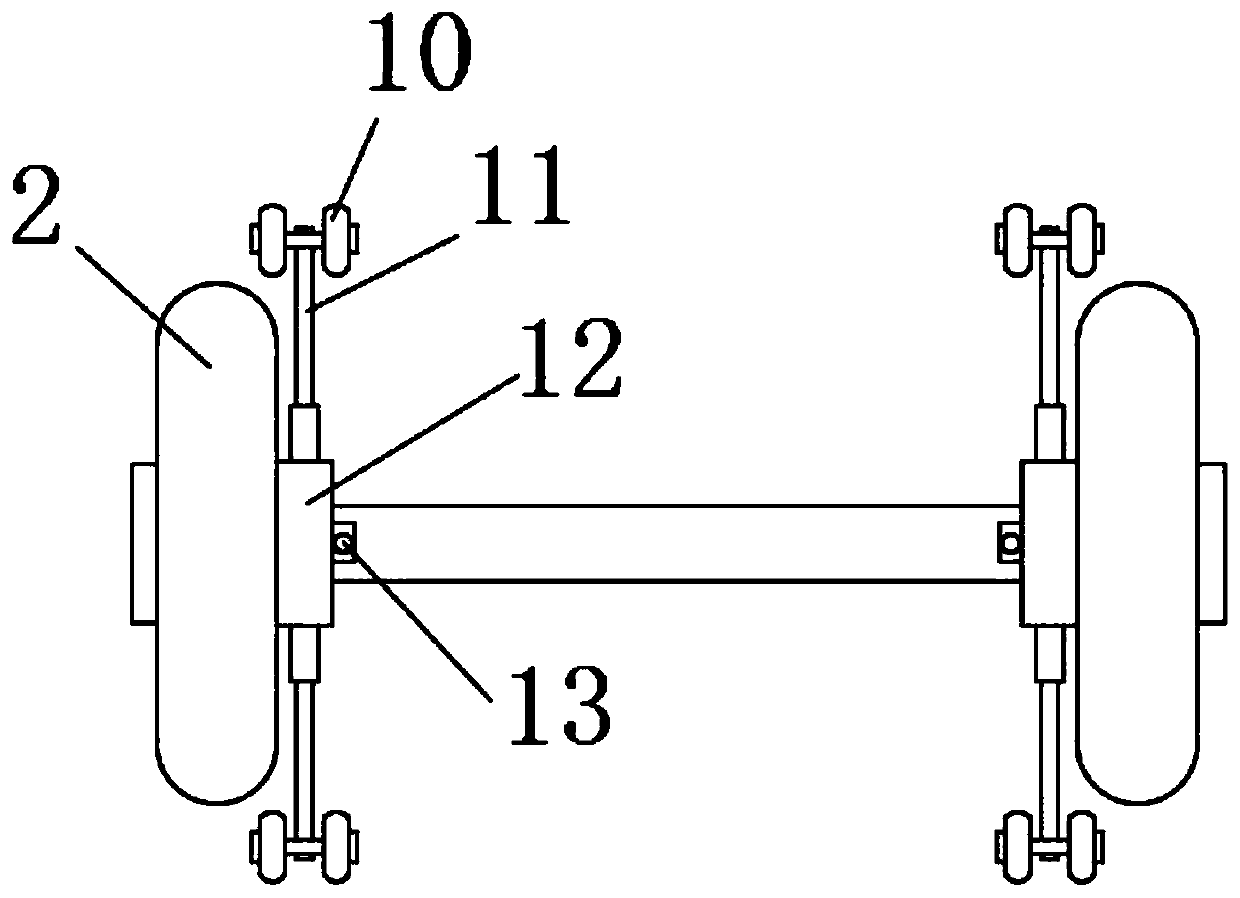

[0031] Such as figure 1 with image 3 As shown, the infrared camera 4 is provided with explosion-proof glass 5, which is fixedly connected to the inspection robot shell 1, and the bottom of the inspection robot shell 1 is fixedly connected to the sampling box 6, and the bottom of the sampling box 6 is equipped with an air pump 8 to pump One end of the air pump 8 is fixedly connected to the check valve 7, and the other end of the air pump 8 is fixedly connected to the air inlet 9. The air pump 8 communicates with the sampling box 6 through the check valve 7 and a bearing 12 is installed on one side of the roller 2, outside of the bearing 12 The ring is provided with an electric telescopic rod 11, the electric telescopic rod 11 is provided with nine groups, and one end of the electric telescopic rod 11 is equipped with an explosion-proof wheel 10, and the bearing 12 side is provided with a remote control switch 13, an air pump 8, an electric telescopic rod 11 and The electromagnet...

Embodiment 3

[0034] Such as Figure 5 As shown, the outer sides of the inspection robot casing 1 are inlaid with gas springs 19, one end of the gas spring 19 is fixedly connected with an explosion-proof partition 20, and the outer ends of the inspection robot casing 1 are installed with folding fireproof pads 22, which are folded for fire protection. One side of the cushion 22 is fixedly connected to the second explosion-proof partition 21, the inside of the folding fireproof cushion 22 is filled with a laminated rubber shock isolation support 23, and the outer surface of the laminated rubber shock isolation support 23 is bonded with a fireproof cloth 24.

[0035] In this embodiment, the gas spring 19 and the laminated rubber shock isolation support 23 are provided to effectively reduce the vibration generated by the inspection robot housing 1 when an explosion occurs.

[0036] It should be noted that the present invention is an explosion-proof structure of a downhole inspection robot. When wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com