Ventilation fabric with high rigidity and high hardness

A breathable fabric and hardness technology, which is applied in the field of fabrics and textile fabrics, can solve the problems of poor air permeability, good air permeability of reticulated fabric, and failure to meet the requirements of use, and achieve the effect of increasing stiffness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

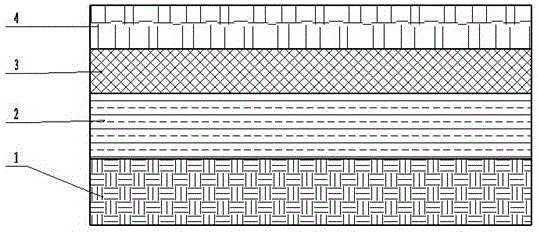

[0014] see figure 1 , a breathable fabric with good stiffness and hardness, comprising a bottom layer, a moisture-absorbing layer, a breathable layer and an outer layer are sequentially arranged outside the bottom layer, the bottom layer and the moisture-absorbing layer are fixed by sewing, and the breathable layer, the moisture-absorbing layer and the outer layer are made of The polyurethane glue is fixed; the bottom layer includes a first warp yarn and a first weft yarn, the first warp yarn is made of long-staple cotton, and the first weft yarn is made of milk protein fiber; the moisture-absorbing layer includes a second warp yarn and a first weft yarn Two weft yarns, the second warp yarn is made of polyvinyl formal fiber, the second weft yarn is made of memory fiber polyester silk; the air-permeable layer is made of spandex fiber, and the outer layer includes the third warp yarn and The third weft yarn, the third warp yarn is woven with flax fiber, and the third weft yarn i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com