Good-stiffness and good-hardness cotton cloth pleating chiffon fabric

A wrinkle and hardness technology, applied in clothing, layered products, applications, etc., can solve the problems of inability to meet multi-directional needs, lack of three-dimensional appearance, poor clothing firmness and ease of handling, etc., to increase stiffness and The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

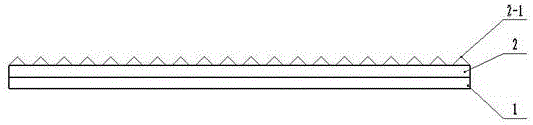

[0013] see figure 1 , a cotton pleated chiffon fabric with good rigidity and hardness, comprising a pleated layer 2 and an inner layer 1, the pleated layer 2 is fixed on the inner layer 1 by sewing, the pleated layer 2 is made of cotton cloth, and is hot-pressed In the shape of pleats, the pleats 2-1 are evenly distributed, the distance between the pleats 2-1 is 3 mm, and the inner layer 1 is made of chiffon.

[0014] A lining fabric layer is provided on the back of the inner layer, and the lining fabric layer is made of braided fabric, and the braided fabric may include a plurality of warp threads and at least one weft thread coupled with the plurality of warp threads. The braid may also include a plurality of bonding fibers. The joining fibers may be positioned parallel to the warp threads and / or parallel to the weft threads. Additionally, the bonding fibers may be formed of a material having a melting point temperature lower than that of the material used to form the warp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com