Main arch support structure of overpass bridge and installation method

A technology of support structure and flyover bridge, applied in the direction of bridge, bridge parts, bridge construction, etc., to achieve good support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

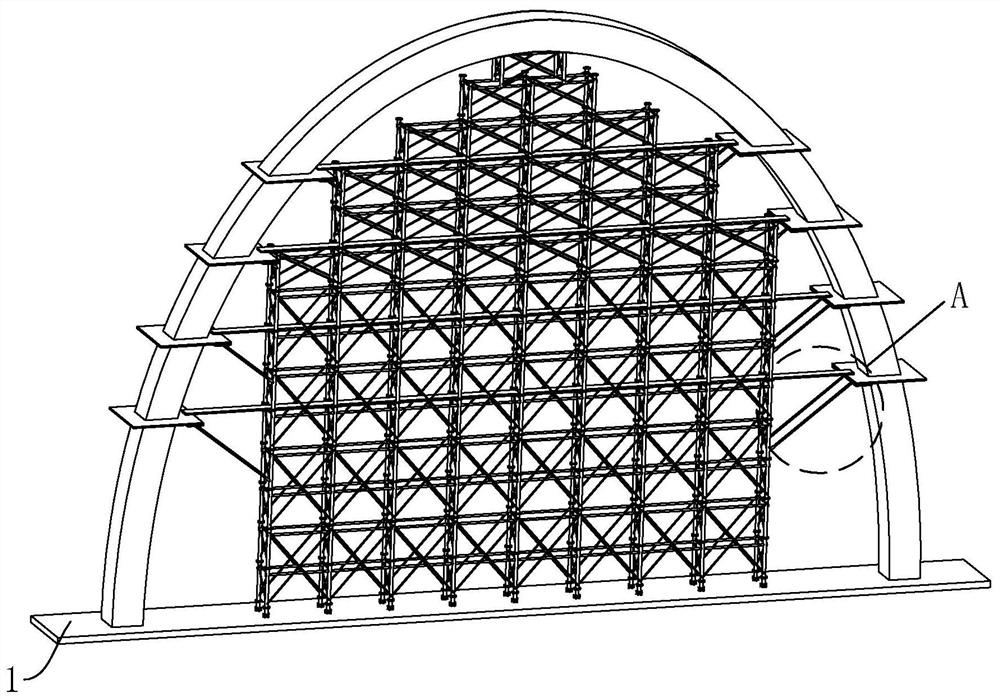

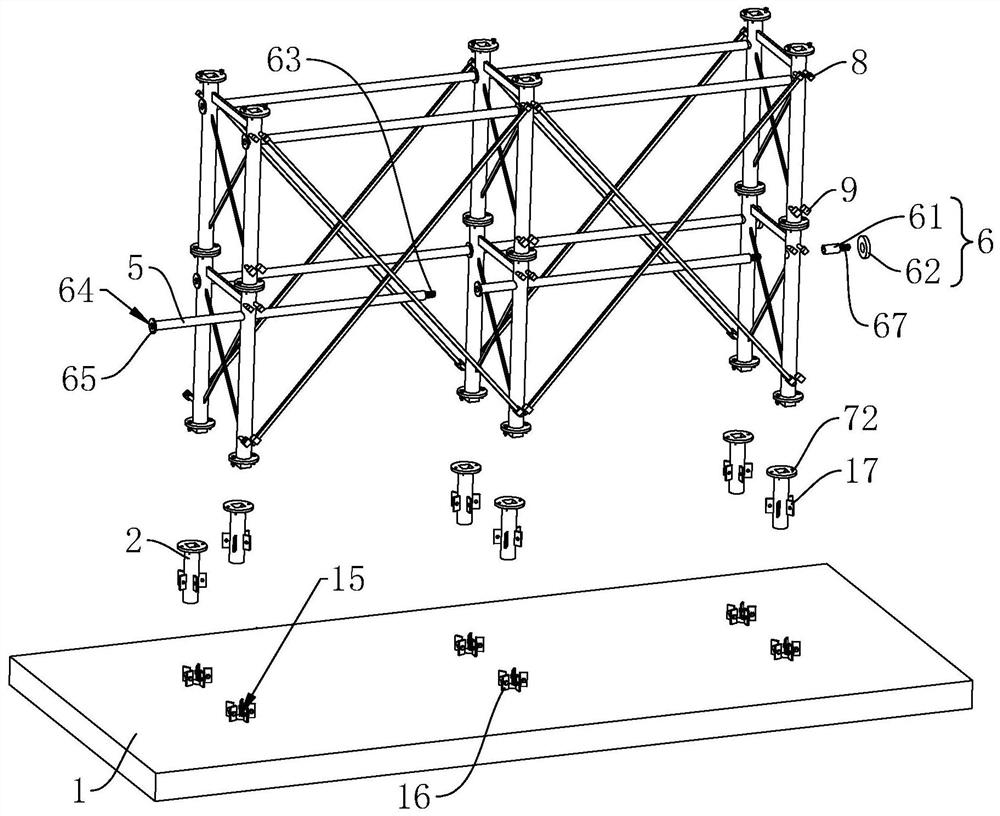

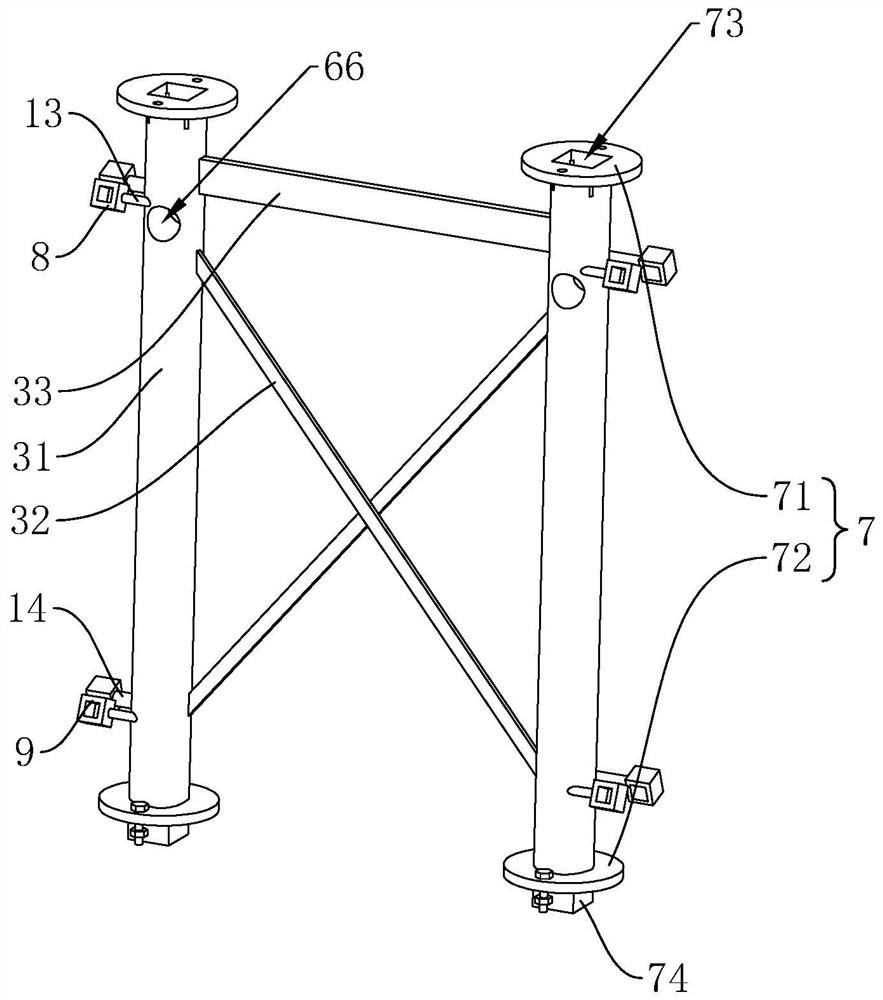

[0045] refer to figure 1 and figure 2 , a main arch support structure of a flyover bridge includes a support base plate 1 and several piles 2, the main arch is spliced by several main arch splits, and the two main arches at the bottom of the main arch are separately fixed on the ground , the bracket bottom plate 1 is laid between the two main arch splits at the bottommost end of the main arch. The top of the support bottom plate 1 is provided with several installation grooves 15, and several installation grooves 15 are divided into two groups, and the two groups of installation grooves 15 are arranged at intervals along the width direction of the support bottom plate 1, and several installation grooves 15 in the same group are arranged along the width direction of the support bottom plate 1. The longitudinal direction of the support bottom plate 1 is evenly distributed. Several first limiting plates 16 are vertically arranged on the support bottom plate 1, and each mounti...

Embodiment 2

[0051] A method for installing a main arch support of a flyover bridge, comprising the steps of:

[0052] Fix the pile 2: place the support base plate 1 and fix the stake 2 on the support base plate 1.

[0053] Install the bracket split 3: fix the bracket split 3 on the pile 2, and use the horizontal clamp column 5 to connect the bracket split 3 adjacent in the horizontal direction; the vertical height of the bracket split 3 is based on the existing height of the main arch. Depending on the building height, the building height of the support split body 3 is always lower than the building height of the main arch. According to the height of the main arch, more support split bodies 3 are connected at the top of the support split body 3 so as to facilitate pouring of the main arch.

[0054] The first inclined rod connected between the bracket splits 3 in the same horizontal direction is determined according to the angle between the main arch splits:

[0055] The four ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com