Roadway supporting method for passing through weak phyllite thrust fault

A technology of roadway support and phyllite, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of serious bottom sag, large cement consumption of anchor-injection-net-spraying combined support, complex construction technology, etc., and achieve extension Long service life, good on-site support effect, and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

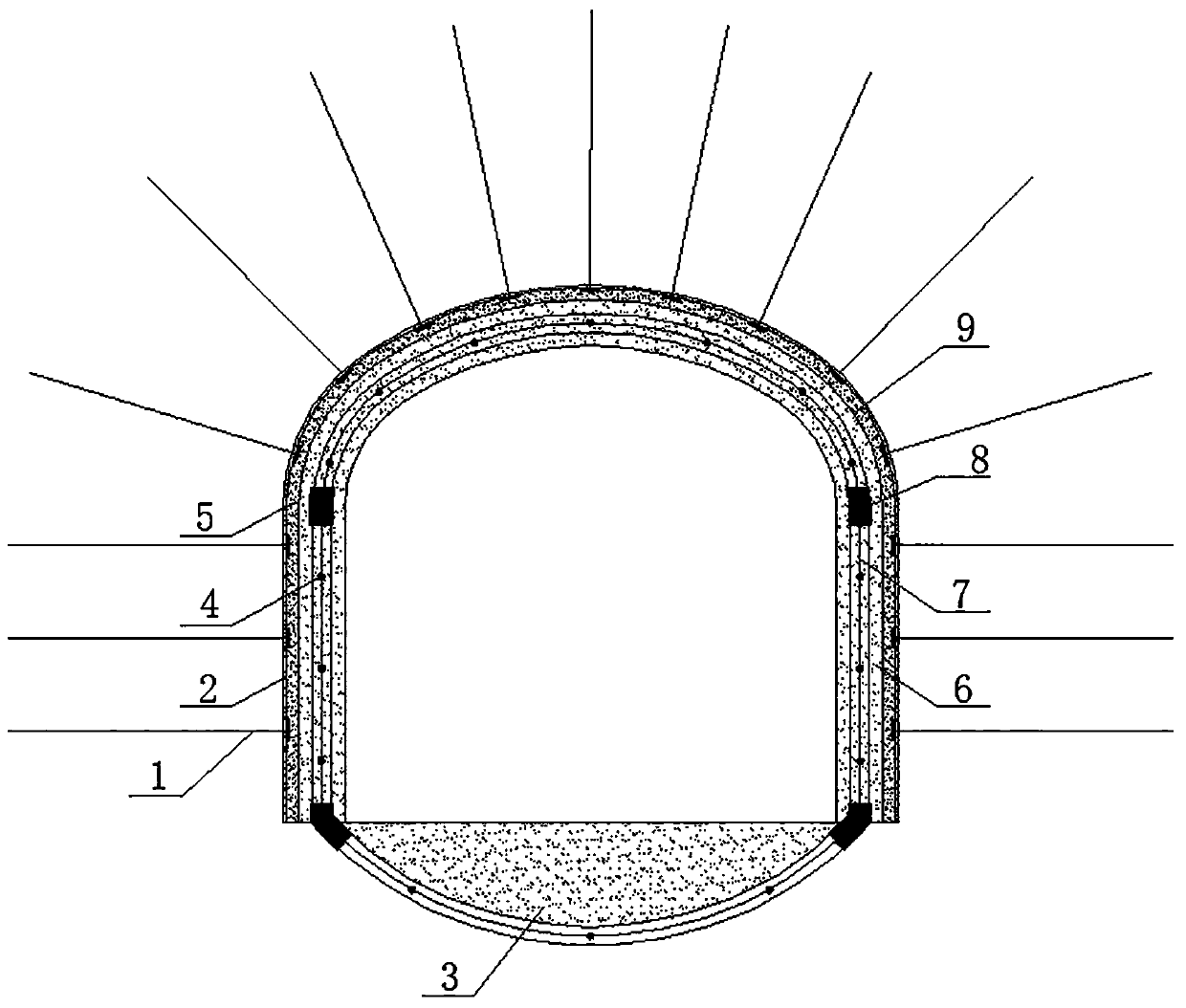

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The geological engineering conditions of a lead-zinc mine are consistent with the technical background of the present invention. The mine design adopts the main slope development method. The surface elevation of the crossing F2 fault area is 675m, the elevation of the main slope is about 535m, and the buried depth is 140m; crossing the F4 fault The surface elevation of the area is 640m, the elevation of the main ramp is about 530m, and the buried depth is 110m. The designed section of the main ramp is a 1 / 3 three-core arch with a net section of 3.2m×3.1m above the floor, and a circle with a height of 0.8m below the floor. Arc arch, on-site construction steps are as follows:

[0028] Such as figure 1 As shown, this includes the following steps:

[0029] Step 1), before excavating the roadway, use double-layer advanced bolts for advanced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com