Foundation pit supporting structure and construction method

A technology of support structure and construction method, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as long cycle, achieve good support, improve overall stability, and reduce lateral pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

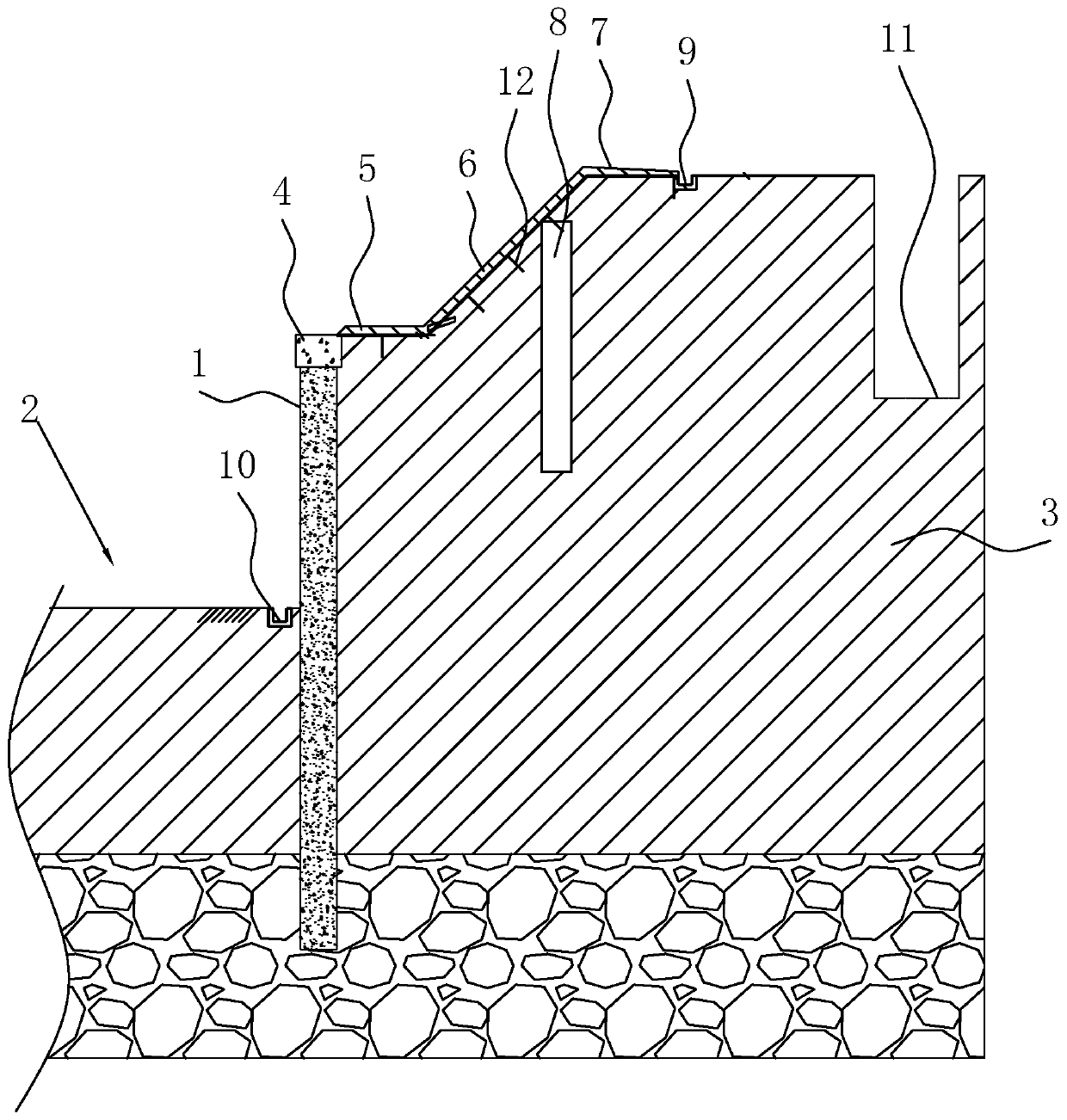

[0027] A support structure for a foundation pit 2, comprising a plurality of rows of piles 1 evenly arranged in a circle around the foundation pit 2, the top of the pile row 1 is provided with a slope reinforcement area, and the slope reinforcement area includes a horizontal connecting section 5, The inclined slope section 6 and the slope top hardening section 7, the angle between the inclined slope section 6 and the horizontal is 45°, and a vertical reinforcement pile 8 located inside the soil 3 is arranged below the inclined slope section 6 to reinforce A plurality of piles 8 are evenly spaced around the foundation pit 2 and are all parallel to the row of piles 1 .

[0028] One side of the row of piles 1 is in contact with the soil 3 below the slope reinforcement area, the other side of the row of piles 1 faces the foundation pit 2, and the bottom of the row of piles 1 is inserted into the soil 3 and the end is lower than the foundation pit. The bottom of pit 2. A horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com