Rapid-releasing sleeving tool

A tool and unsleeve technology, which is applied in the field of quick-release socket tools, can solve the problems of loose sliding parts and inability to slide smoothly, and achieves the best support effect, and the effect of improving smoothness and structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

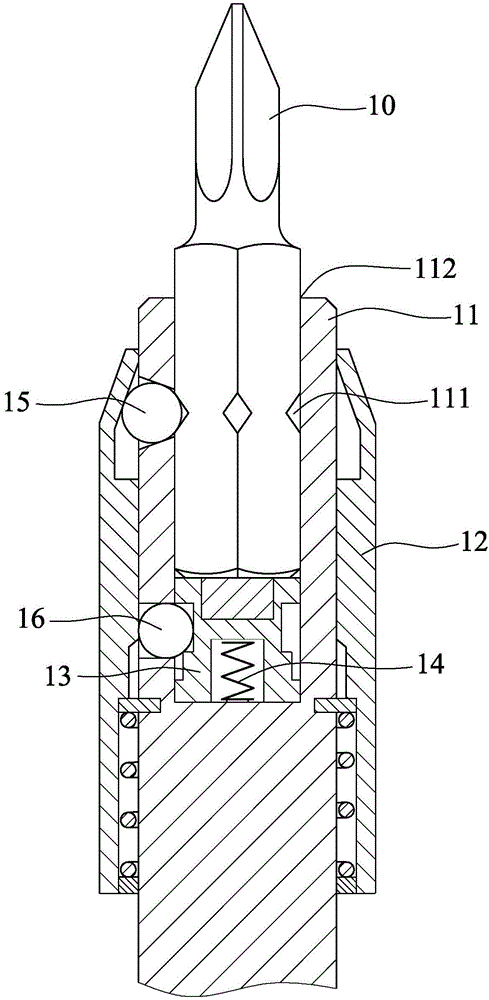

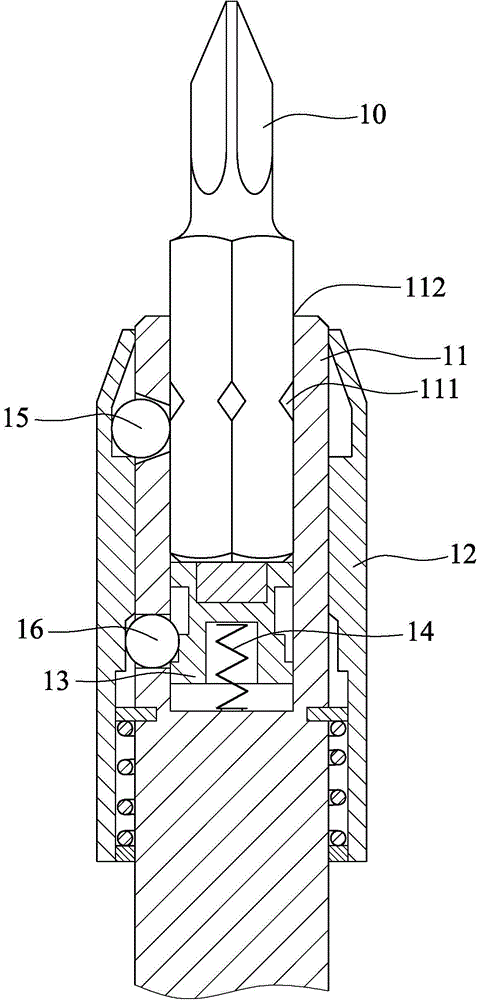

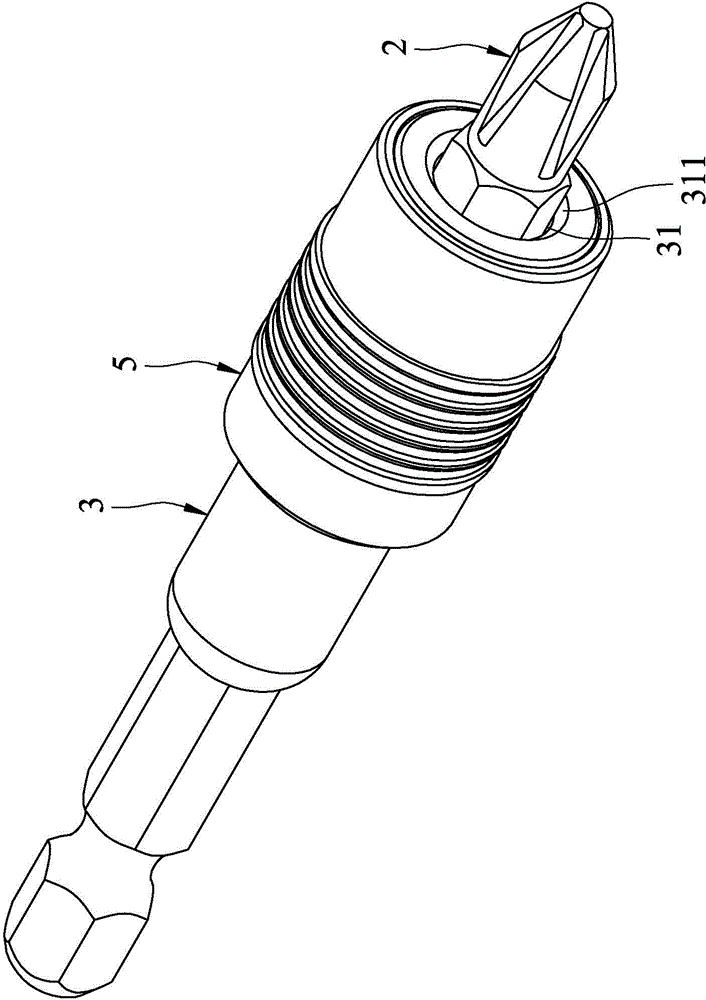

[0027] Such as image 3 and Figure 4 As shown, the embodiment of the quick release socket tool of the present invention can be used for installing and dismounting a subhead 2, and includes a rod body 3, an interlocking device 4, and a fastening device 5.

[0028] The rod body 3 includes a slotted hole 31 arranged axially and having a port 311, a fastening hole 32 adjacent to the port 311, a slotted hole 33 away from the port 311, and a slotted hole 33 adjacent to the port 311 and along the The front side edge 34 of the rod body 3 extends radially outward.

[0029] In this embodiment, the slot hole 31 also has a slot section 312 adjacent to the port 311 and capable of inserting the screwdriver bit 2 , and a guide slot section 313 away from the port 311 . The cross-sectional shape of the slot section 312 corresponds to the shape of the screwdriver b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com