Shaft workpiece alignment device and alignment method thereof

A technology for shaft workpieces and components, which is applied in the field of aligning devices for shaft workpieces, can solve the problems of easy deviation, low precision, troublesome operation, etc., and achieve the effects of convenient alignment, high precision, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

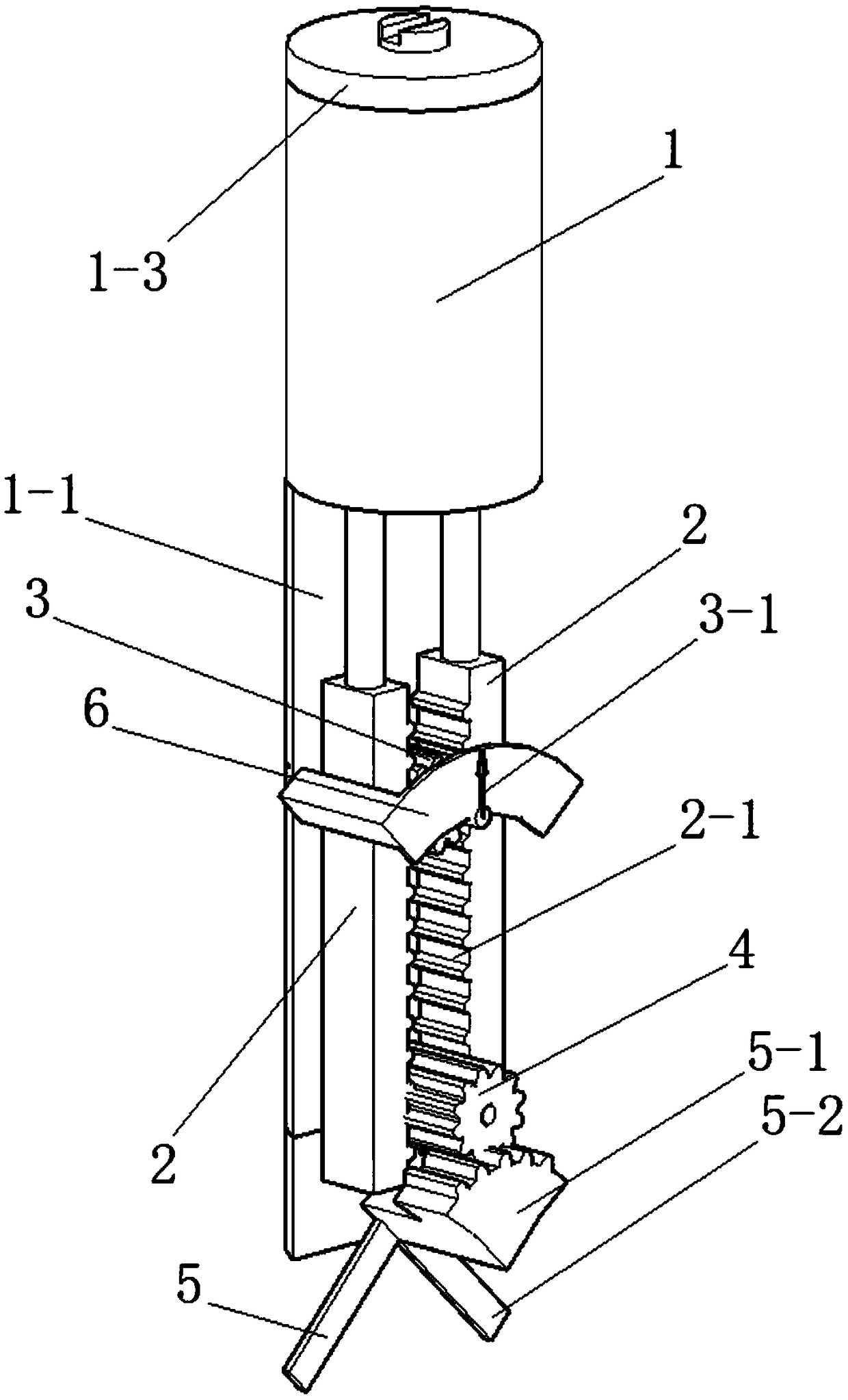

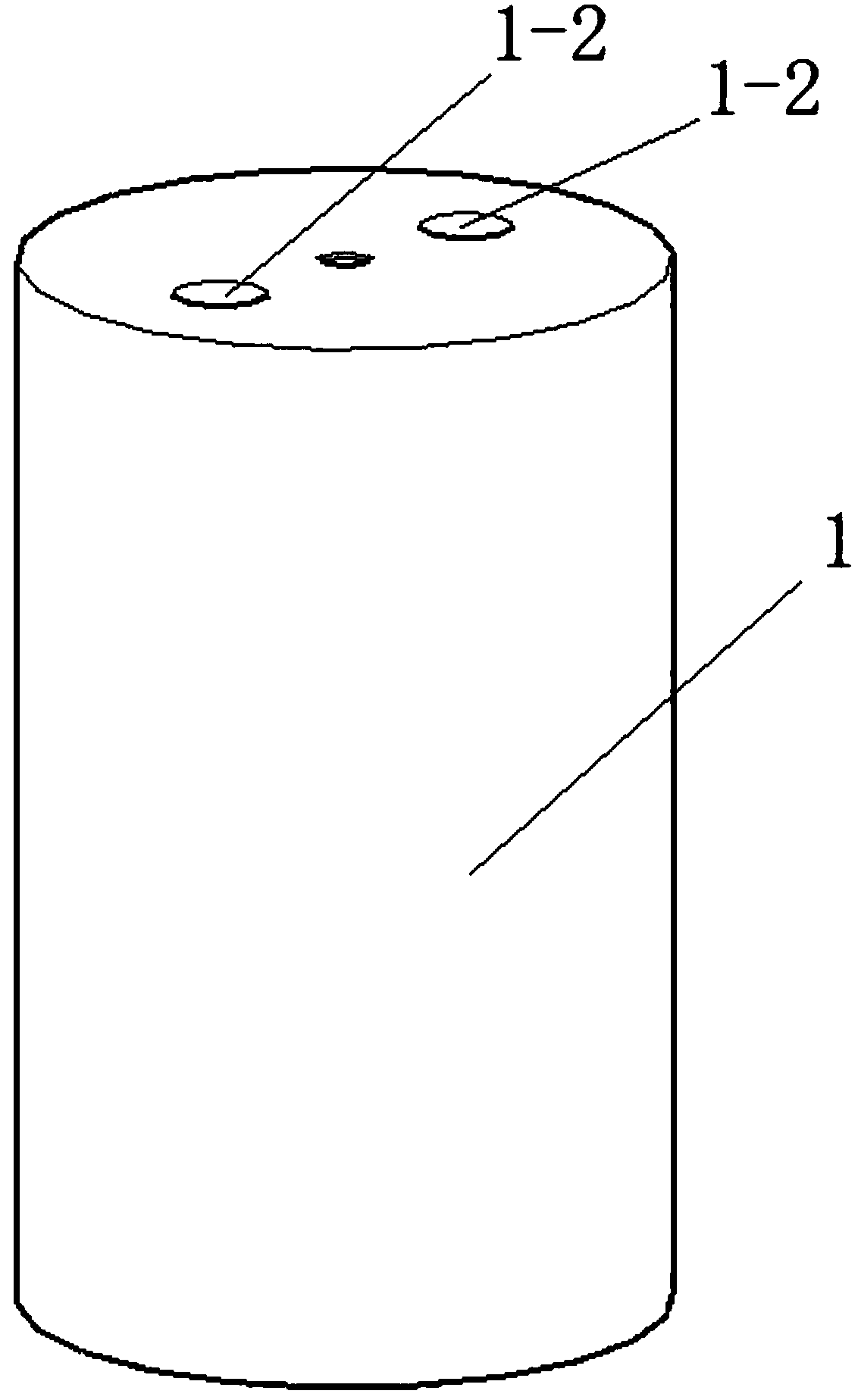

[0033] See Figure 1 to Figure 4 , The alignment device for shaft workpieces in this embodiment includes a fixed seat 1, a balance bar 2, a pointer gear 3, an input gear 4, a measuring claw assembly 5 and a scale plate 6.

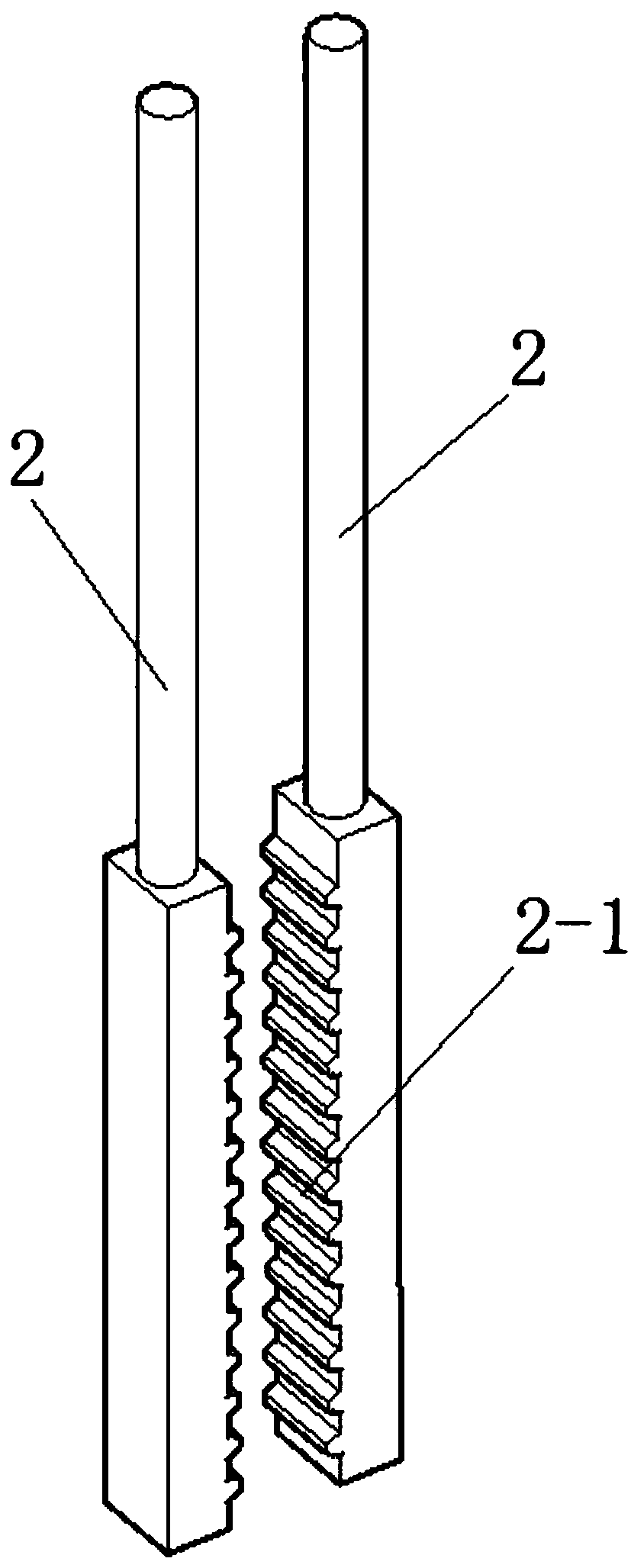

[0034] A back plate 1-1 extending downward is provided on the fixing base 1 . Two balance poles 2 are arranged in parallel. The tops of the two balance poles 2 protrude into the fixed seat 1 and are slidably connected with the fixed seat 1 . The bottoms of the two balance bars 2 are fixed with racks 2-1 with opposite tooth surfaces. Both the pointer gear 3 and the input gear 4 are rotatably arranged on the back plate 1-1, and are both meshed with the two racks 2-1. The input gear 4 is located below the pointer gear 3 . The diameter and modulus of the pointer gear 3 and the input gear 4 are consistent. A pointer 3-1 is fixed at the center of the front end of the pointer gear 3. The measuring jaw assembly 5 drives the input gear 4 to rotate. The scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com