Punching device

A punching device and plate placement technology, which is applied to the feeding device, positioning device, storage device, etc., can solve the problems of poor clamping effect of parts, affecting the size of punching holes, etc., so as to achieve simple and efficient clamping process and extended use. The effect of longevity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

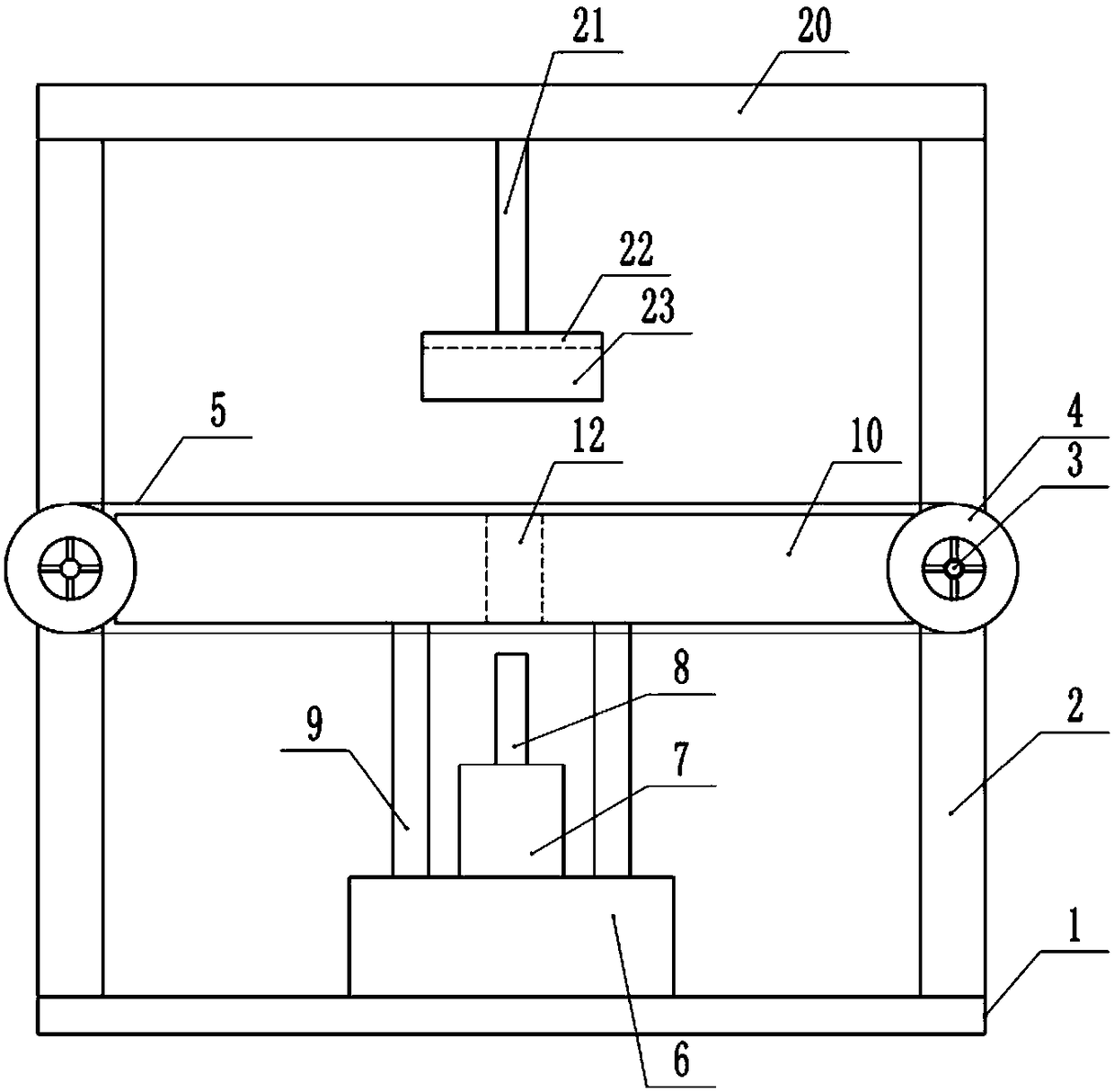

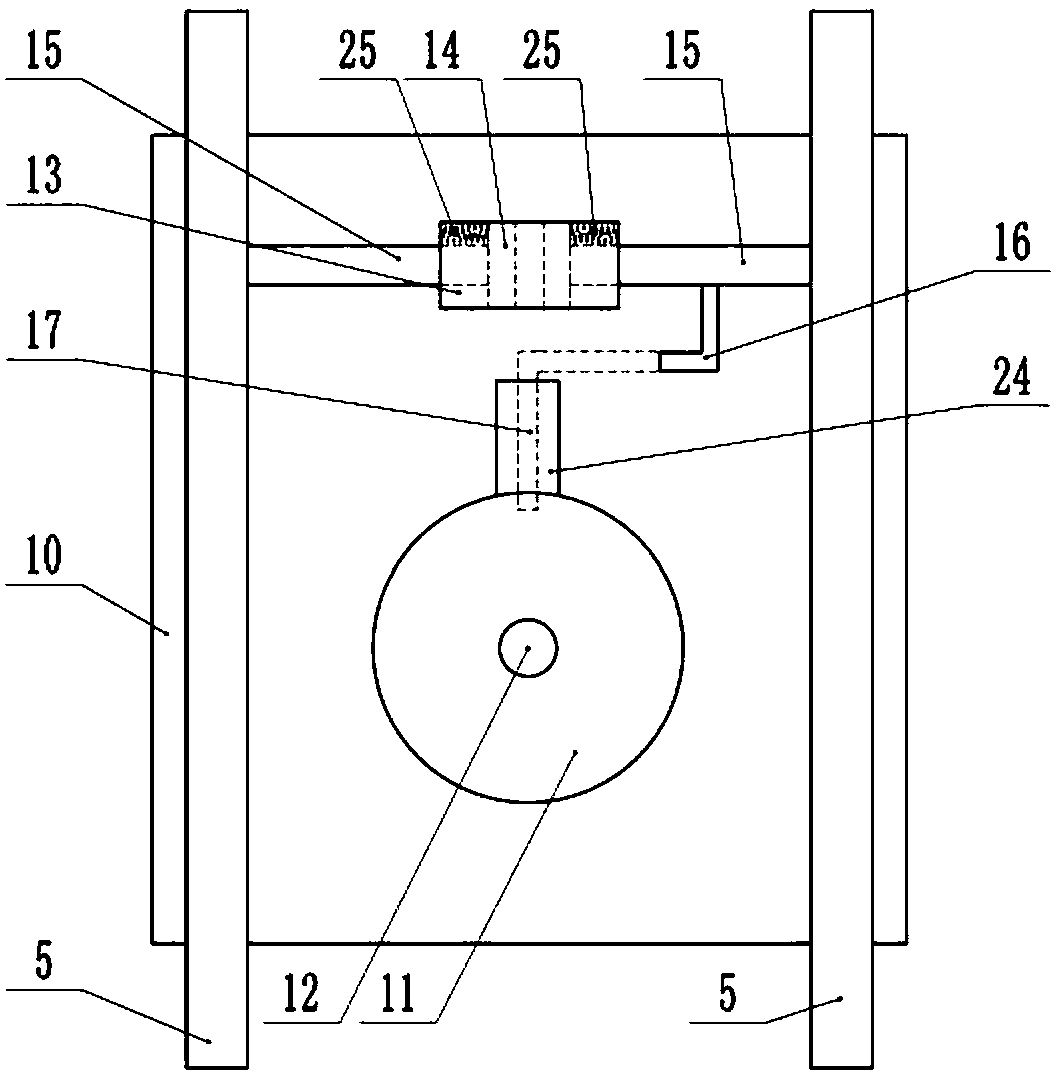

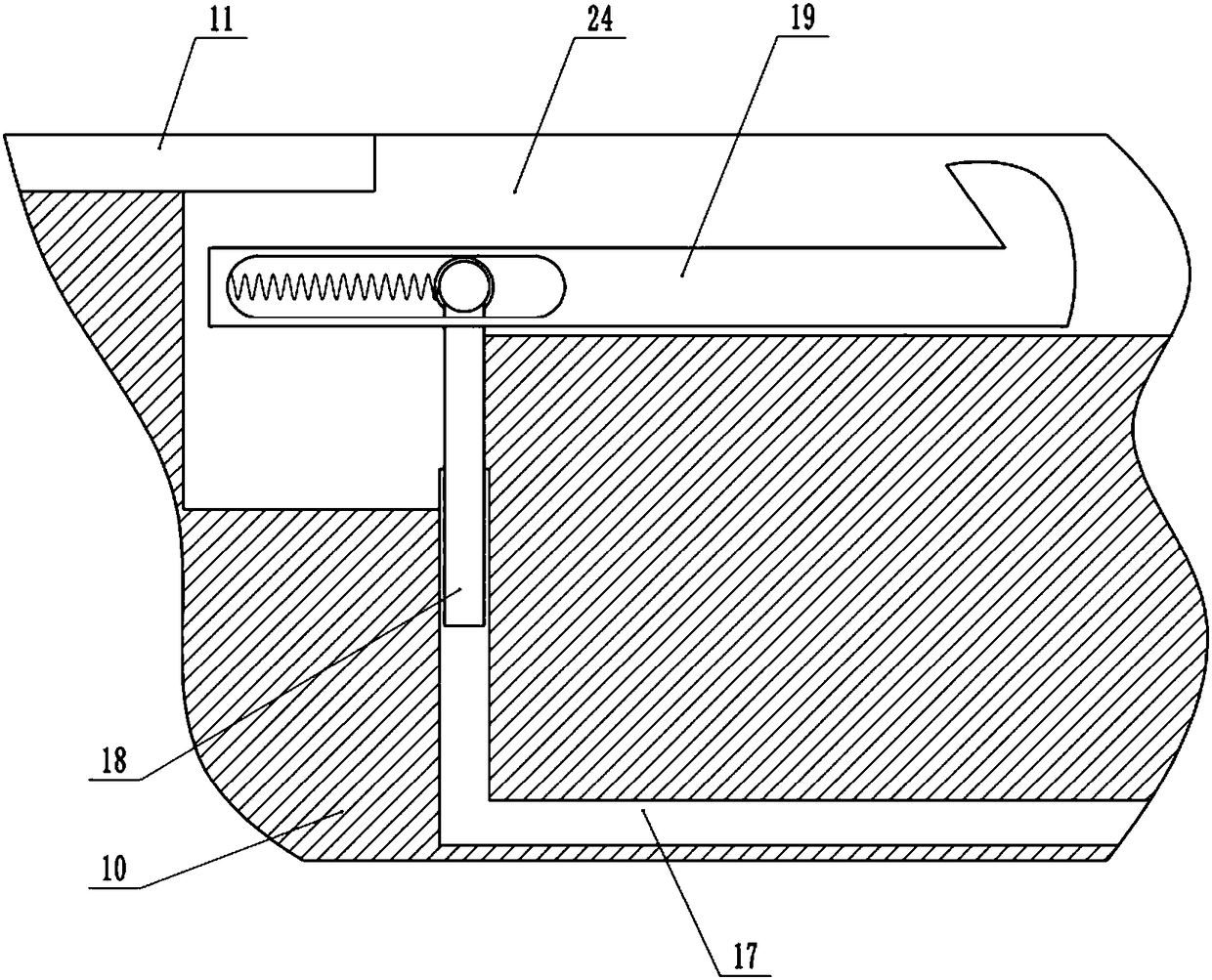

[0021] The reference signs in the drawings of the description include: base 1, pillar 2, transverse shaft 3, pulley 4, conveyor belt 5, support table 6, cylinder 7, punch 8, support rod 9, placement plate 10, placement slot 11, through Hole 12, sleeve 13, first electromagnet 14, ejector rod 15, push rod 16, cavity structure 17, slider 18, buckle rod 19, beam 20, pole 21, second electromagnet 22, collection box 23, the first groove 24, the first spring 25.

[0022] Such as figure 1 As shown, the punching device includes a base 1 and a motor that rotates intermittently. The motor is controlled by a controller to rotate intermittently. The middle part of each pillar 2 is provided with a shaft hole respectively, bearing housings are installed on both sides of the shaft hole, a bearing is installed in the bearing housing, and a horizontal shaft 3 is installed in the bearing;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com