An injection mold without draft and an injection molding method using the same

A technology of injection mold and draft angle, which is applied in the direction of coating, etc., can solve the problems of enlargement, mold cost and injection molding cost, and long mold production cycle, so as to shorten the manufacturing cycle, simple and reasonable structure, and shrink the mold effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

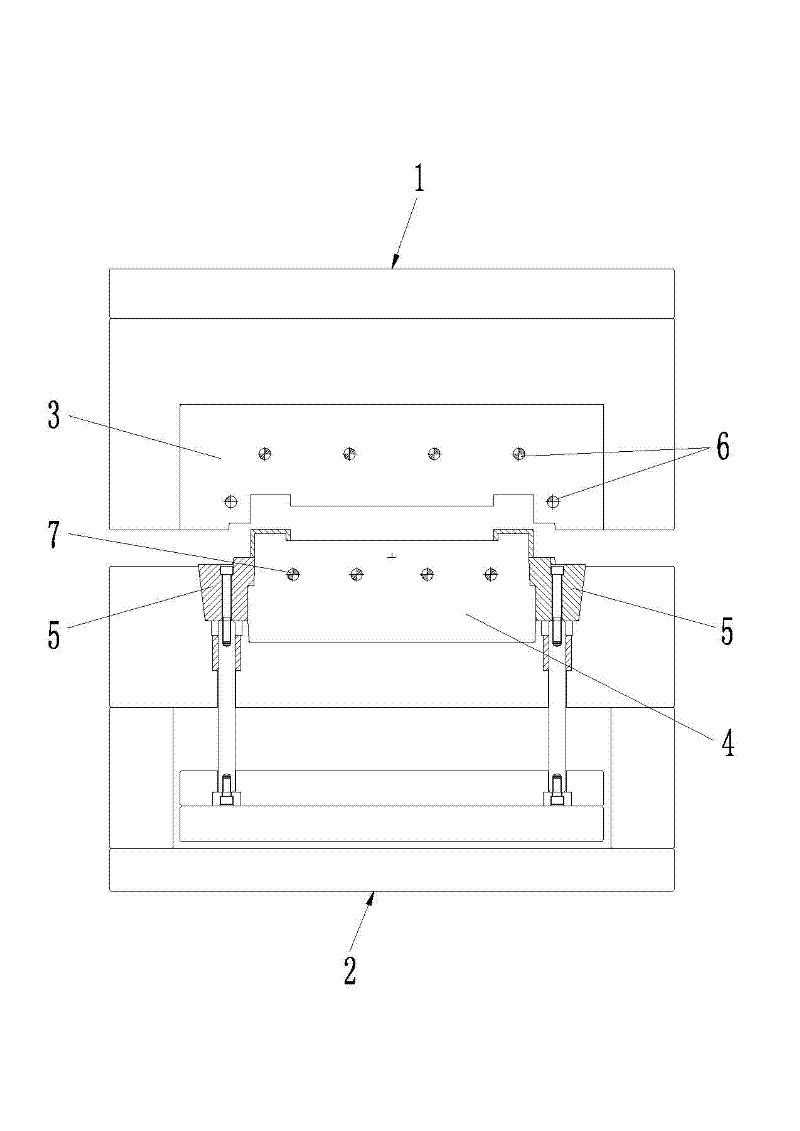

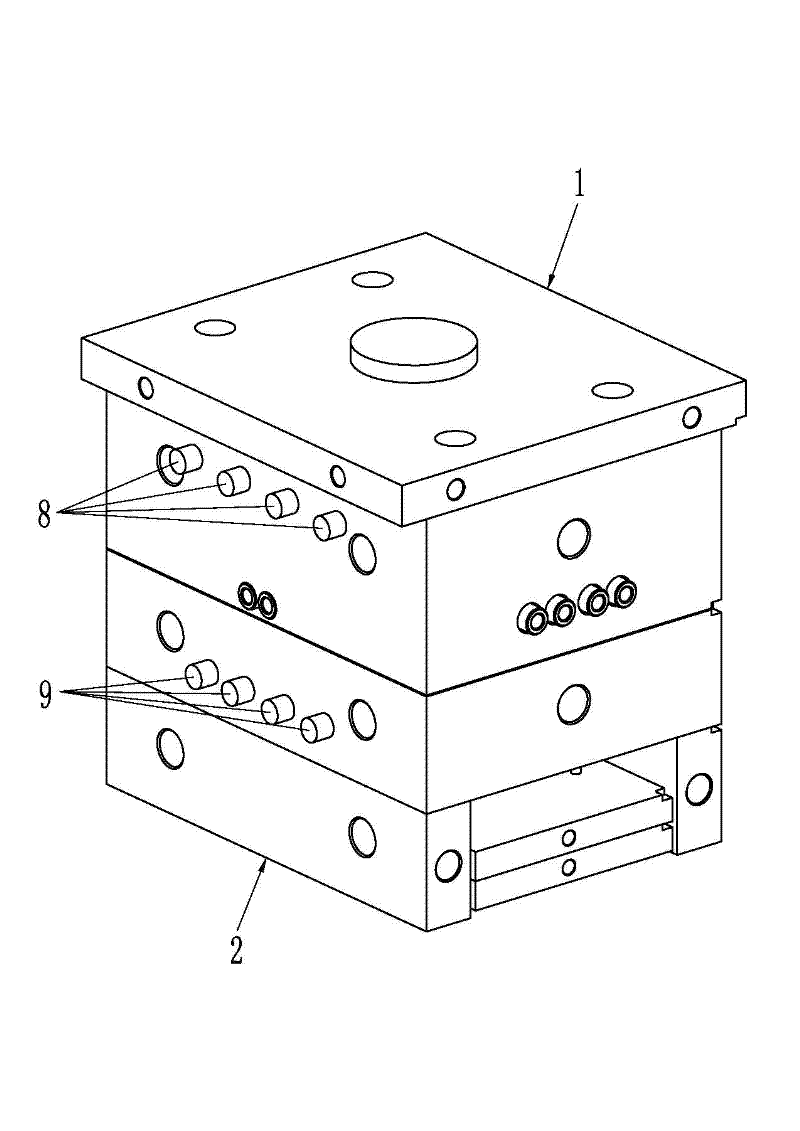

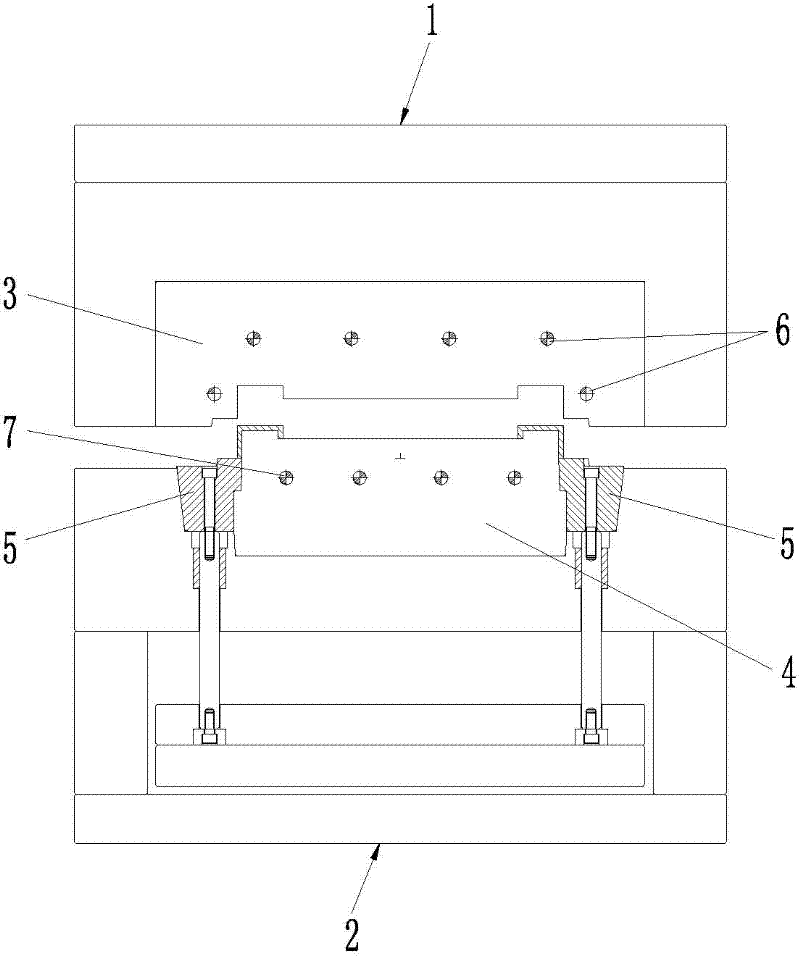

[0029] Such as figure 1 with figure 2 As shown, in this embodiment, an injection mold without draft angle includes a fixed mold overall 1 and a movable mold overall 2, and the fixed mold overall 1 includes a fixed template and a fixed mold cavity 3, and the fixed mold cavity 3 is set on the fixed template, and the fixed template is provided with guide post holes, and the movable mold overall 2 includes a movable template, a movable mold core 4 and an ejection system, and the movable mold core 4 is set on the movable template Above, the movable template is provided with a guide post, and the guide post is matched with the guide post hole, and the ejection system includes a push block 5 that can push out the product as a whole in a balanced manner, and the fixed mold cavity 3 and Steam flow passages are provided around the movable mold core 4, and the steam flow passages can transfer heat to the movable mold core 4 and the fixed mold cavity 3, so that the products in the cavit...

Embodiment 2

[0035] Embodiment two, such as figure 1 with figure 2 Shown, a kind of injection molding method of the injection mold without draft, comprises the following steps:

[0036] a. Mold closing: make the movable mold core 4 and the fixed mold cavity 3 close the mold, that is, for the product with the straight extension position, the straight extension movable mold core 4 and the straight extension fixed mold cavity 3 matching the straight extension position are set, and then the straight extension movable mold Core 4 and straight stretch fixed mold cavity 3 are closed;

[0037] b. Glue injection: inject glue into the mold cavity after mold closing, that is, inject glue into the mold cavity after the mold closing of the straight-stretching movable mold core 4 and the straight-stretch fixed mold cavity 3;

[0038] c. Heating: While injecting glue into the mold cavity after closing the mold, inject steam into the fixed mold cavity 3 and the movable mold core 4 to heat rapidly, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com