Patents

Literature

42results about How to "Assembly applicable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

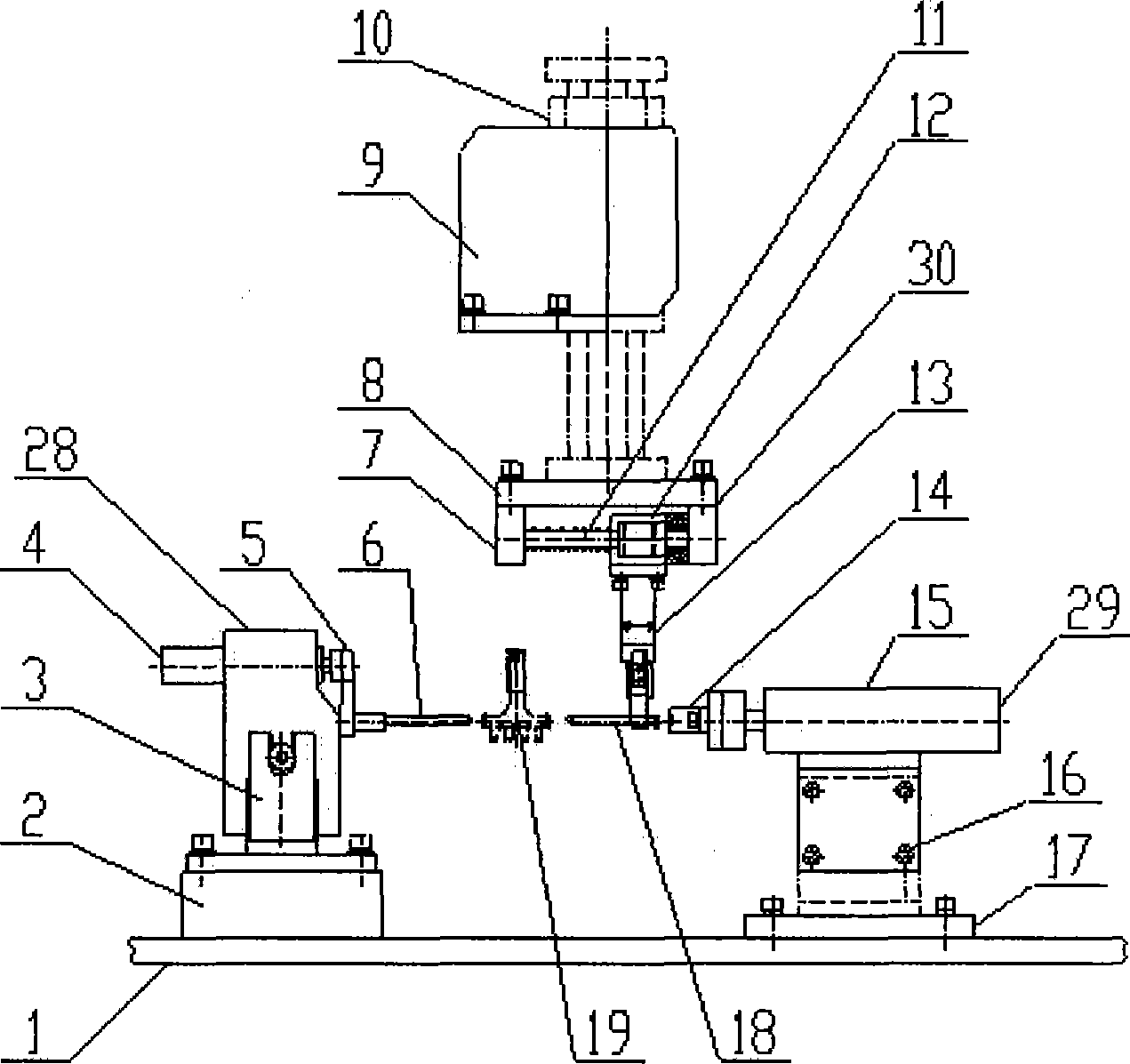

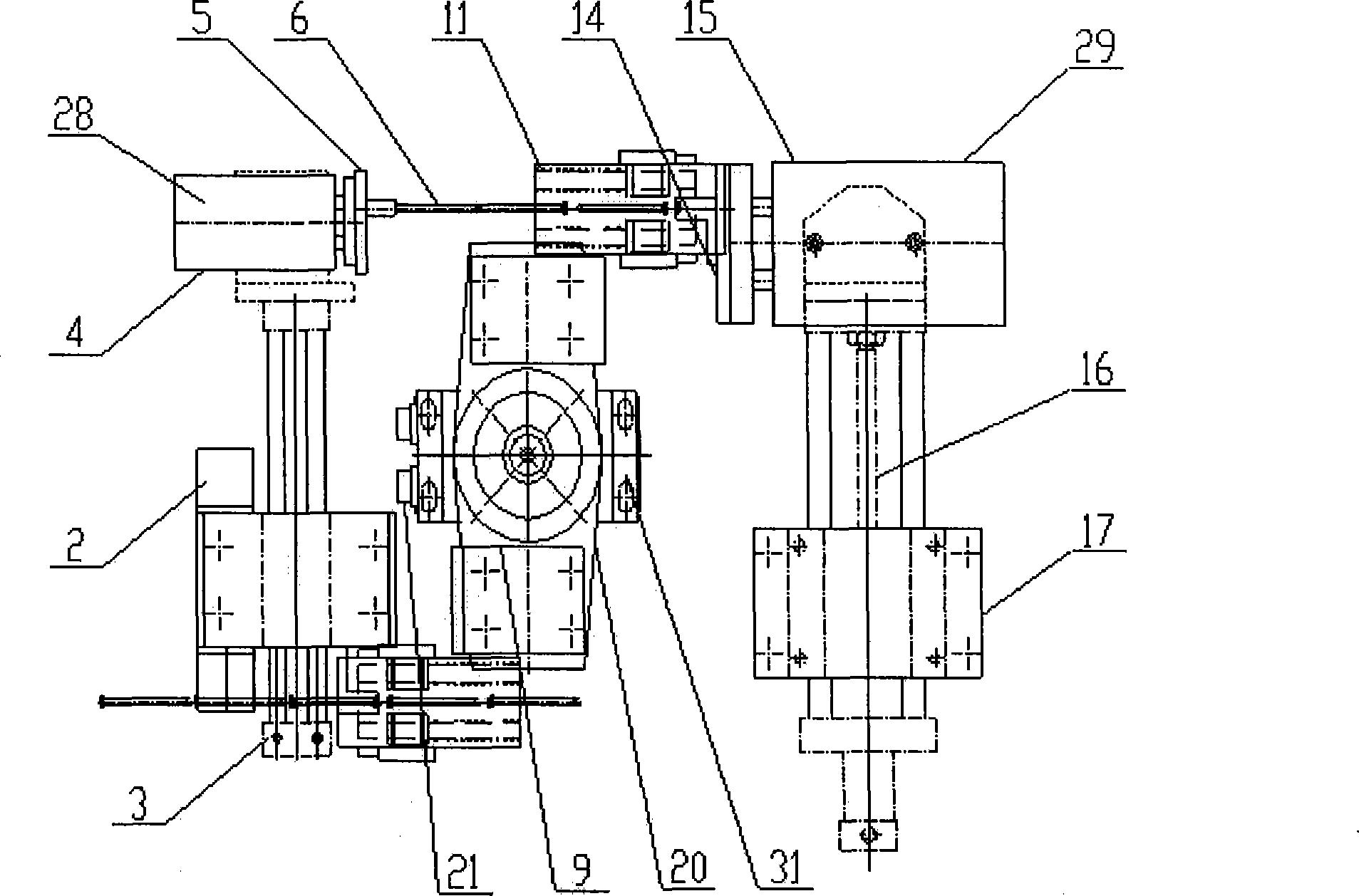

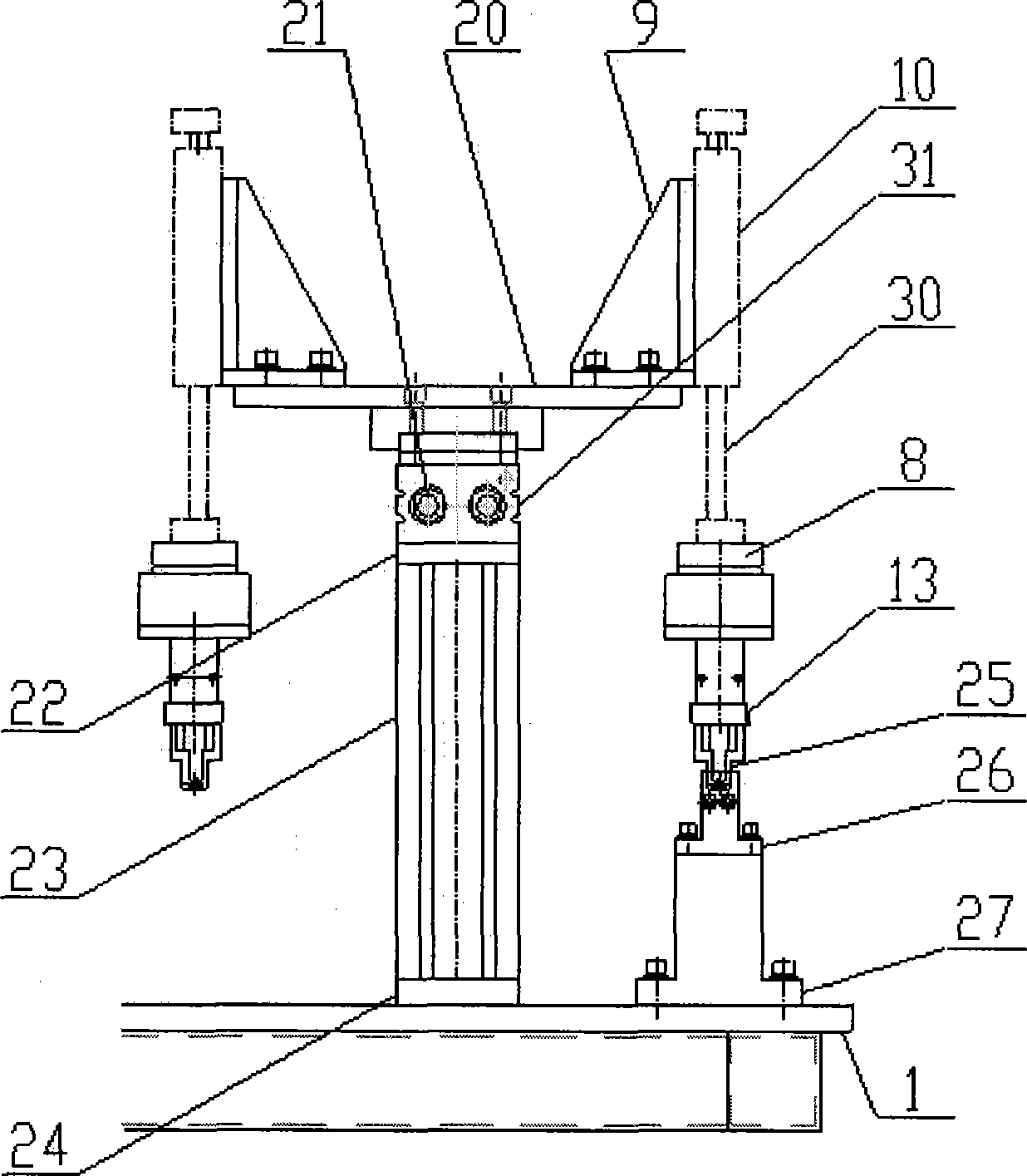

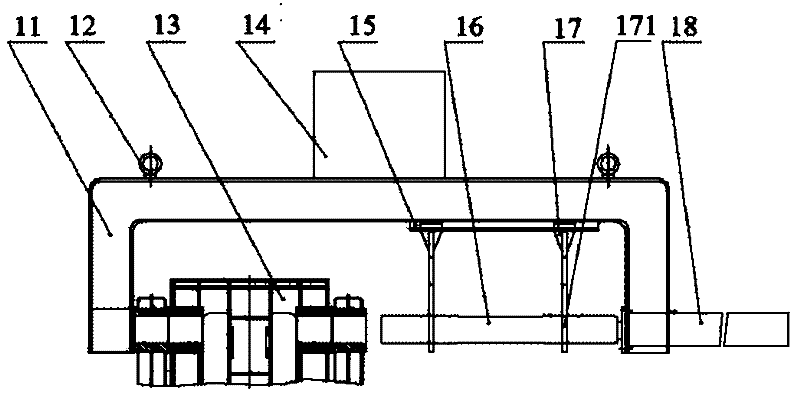

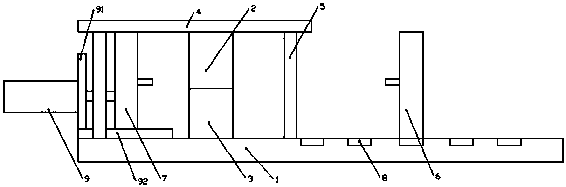

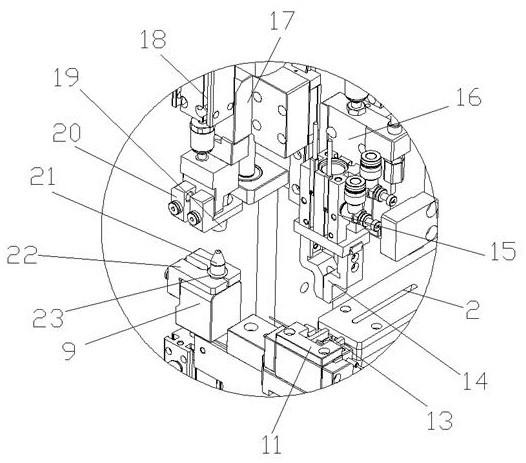

Slender pin horizontal automatic assembly device

The invention relates to an elongated pin horizontal auto assembling device, comprising a horizontal mounting panel, an elongated pin mounting base for a workpiece disposed above the mounting panel and an elongated pin. A pin inserting guiding unit for guiding location of the elongated pin mounting base is secured on the upper surface at the left side of the mounting panel, and an inserted pin location assembling unit for aligning the elongated pin with the elongated pin mounting base is secured on the upper surface at the right side of the mounting panel; an inserted pin catching unit is disposed on the mounting panel, and a pawl for catching the elongated pin is provided with the inserted pin catching unit; a rotating shift unit is provided at the center of the mounting panel, and is connected fixedly to the inserted pin catching unit to rotatingly shift the inserted pin catching unit so as to transport the elongated pin onto the inserted pin location assembling unit. The invented device is suitable for auto assembly of horizontal elongated pins on automated production assembly lines.

Owner:SHANGHAI UNIV +1

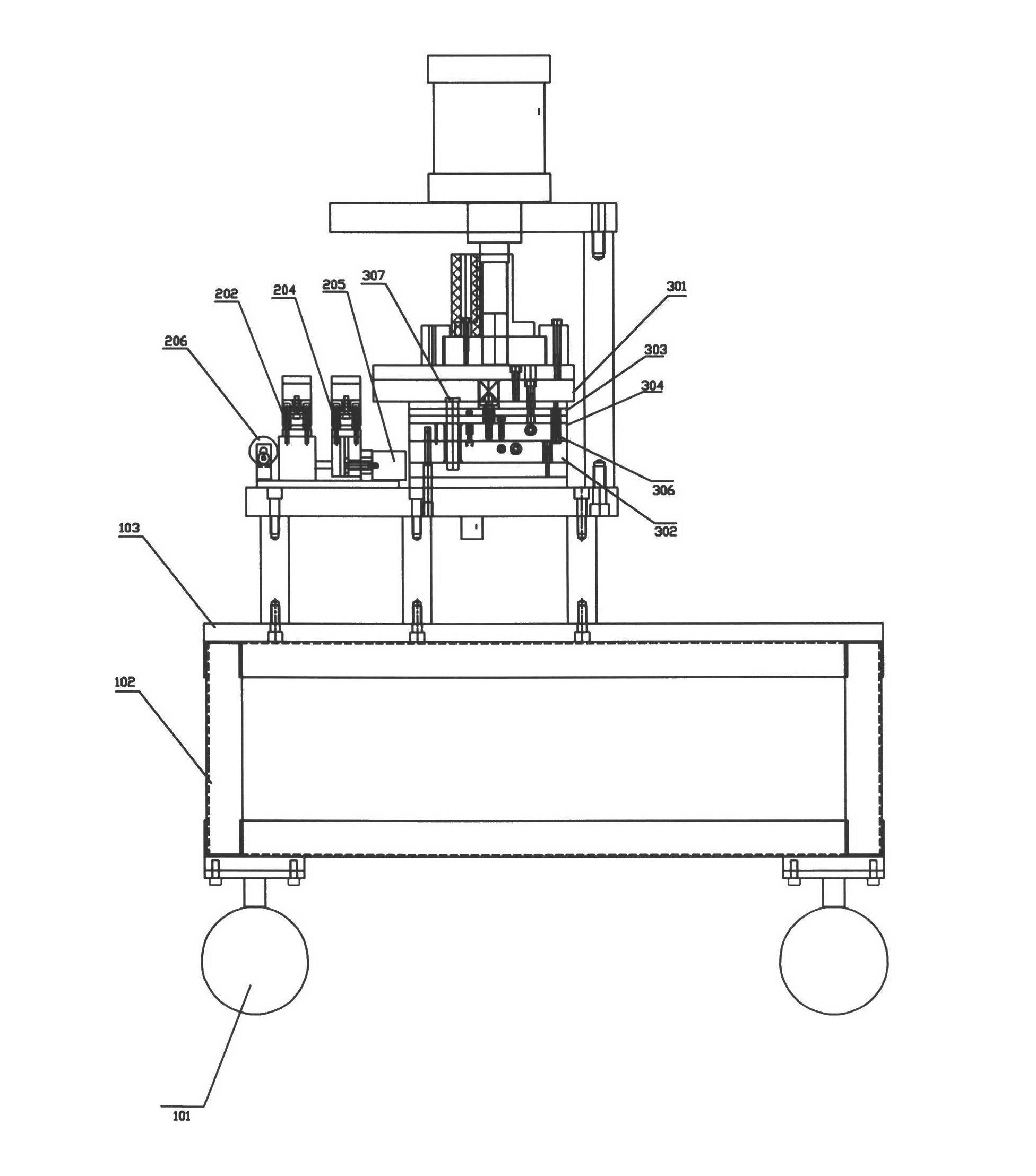

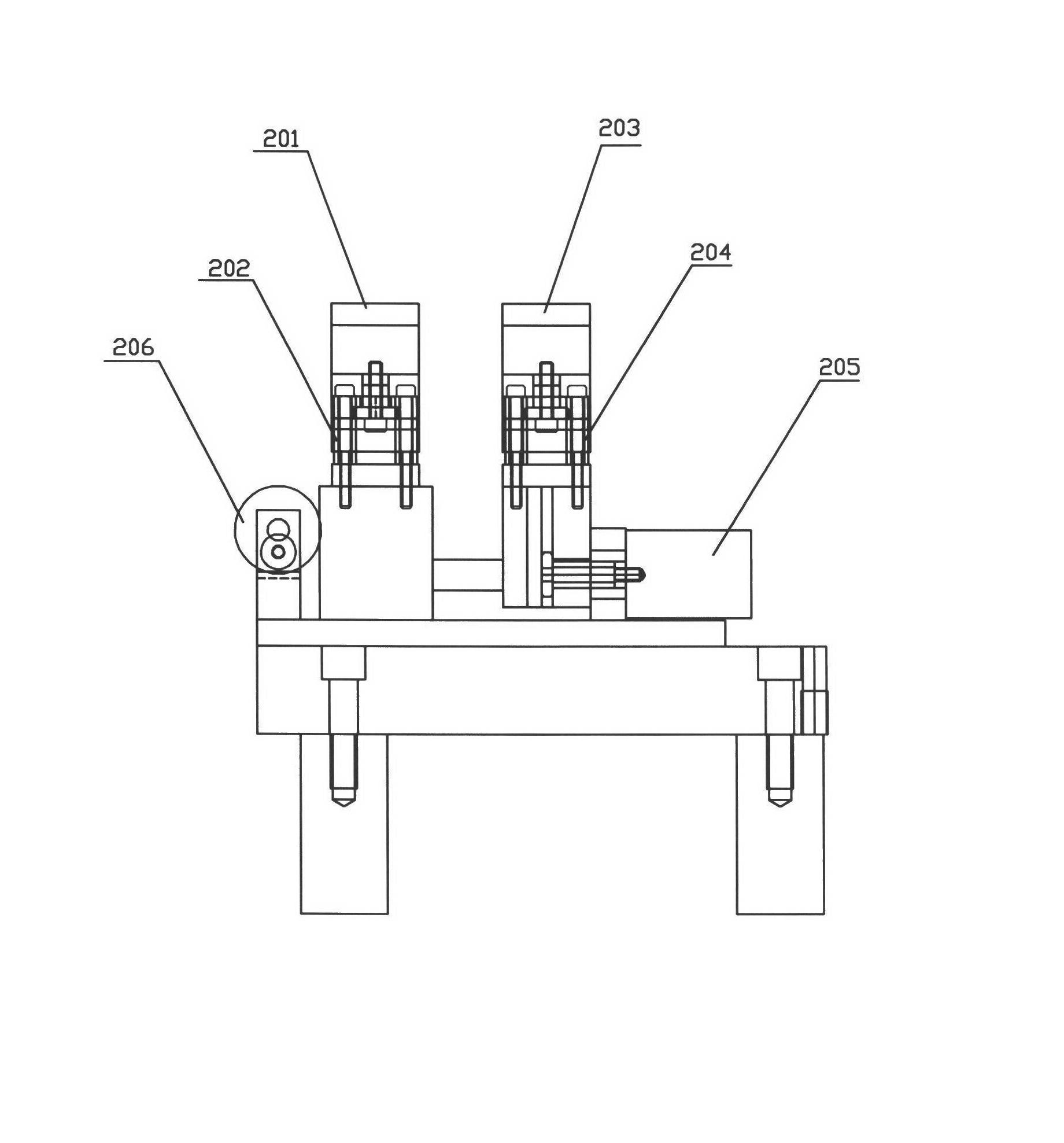

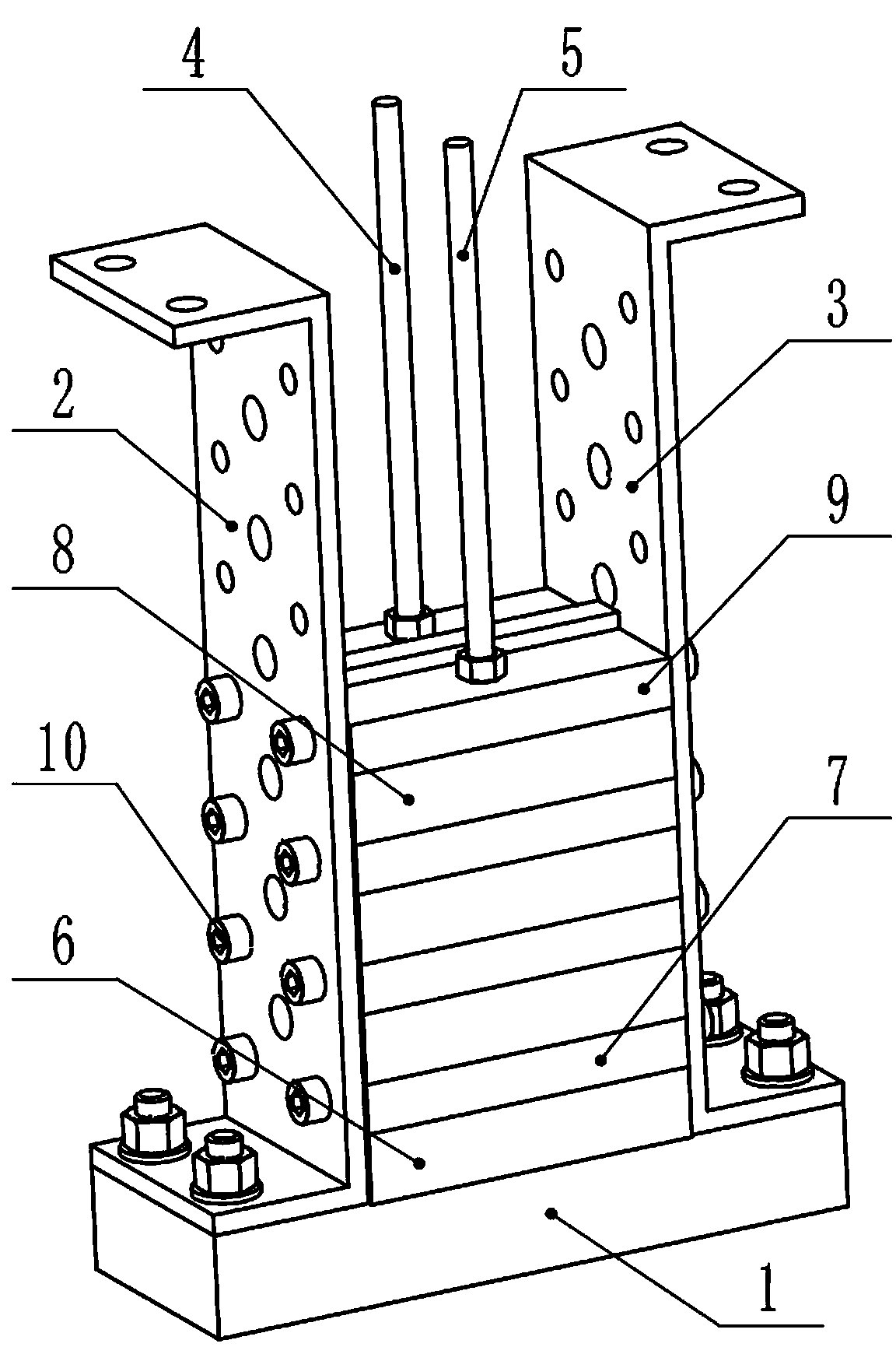

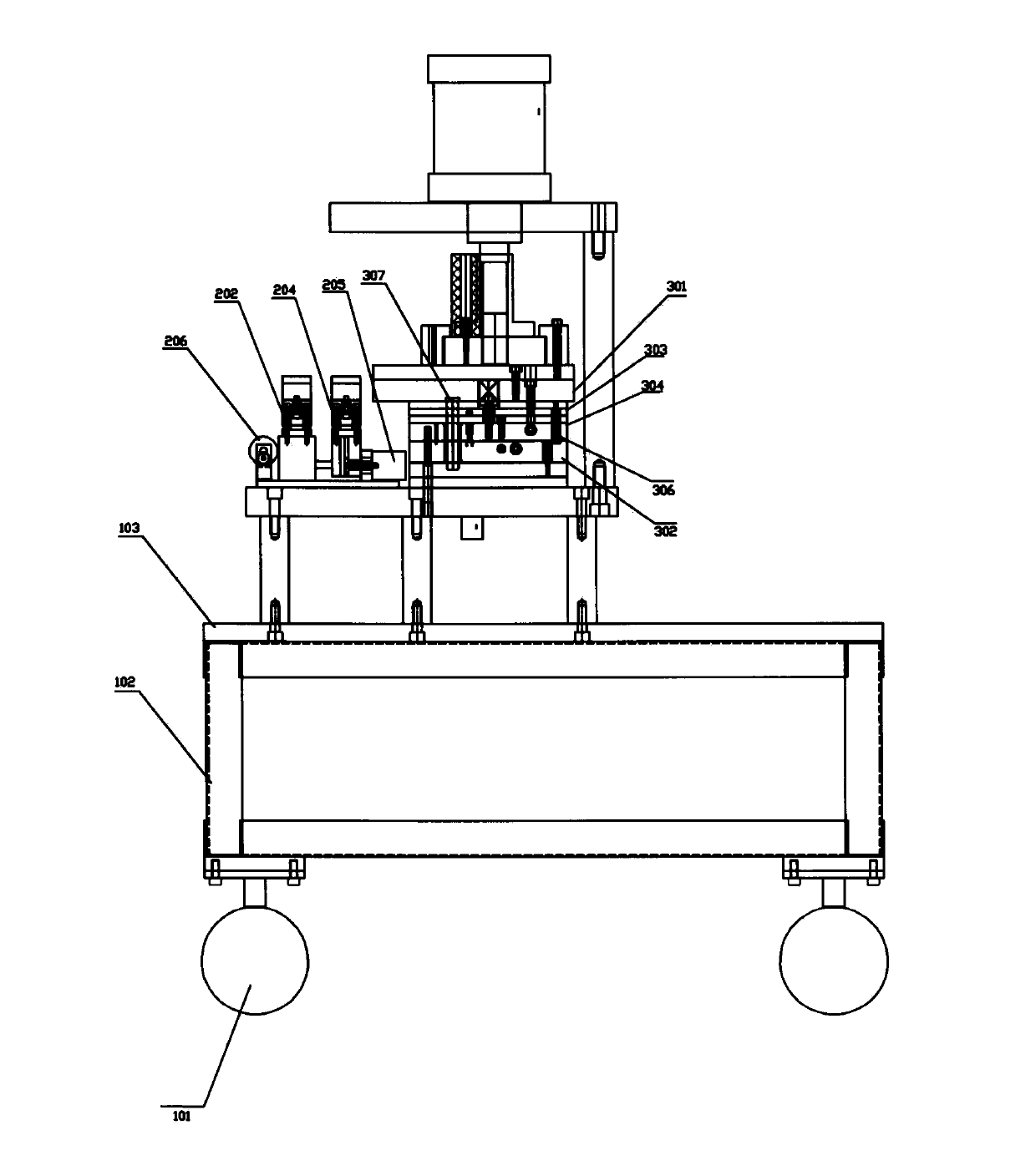

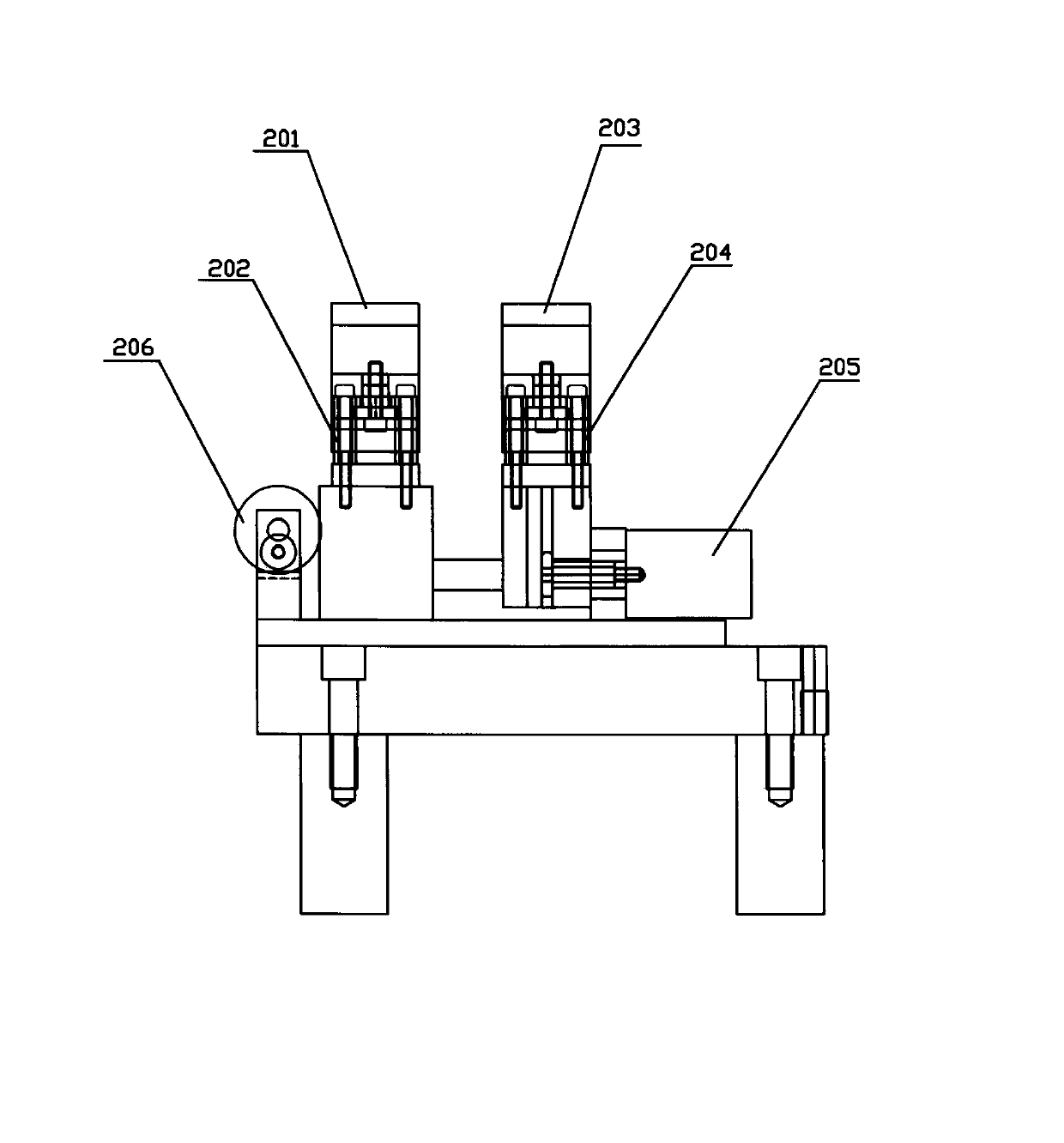

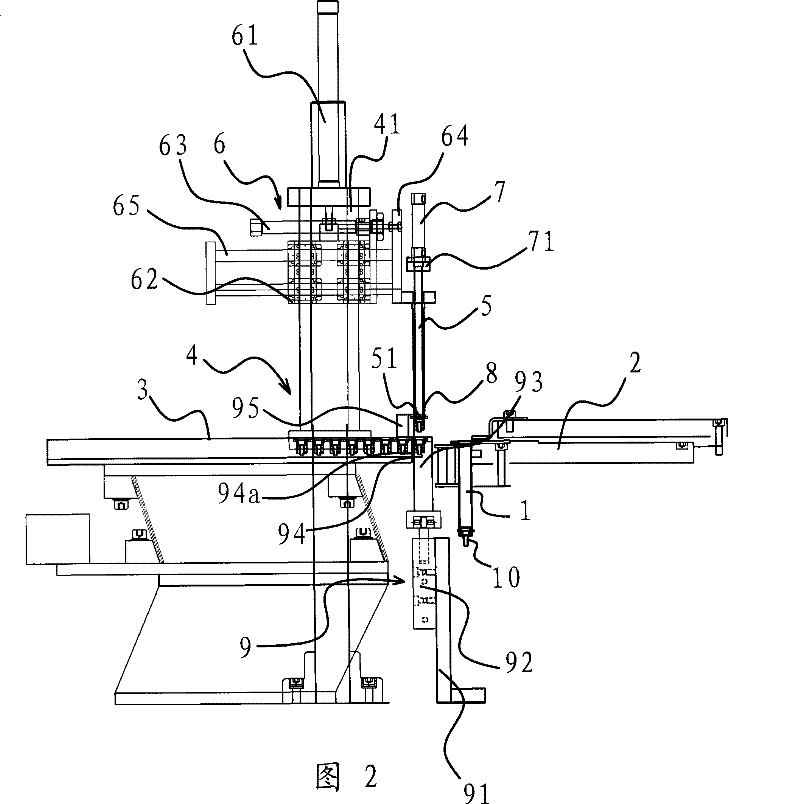

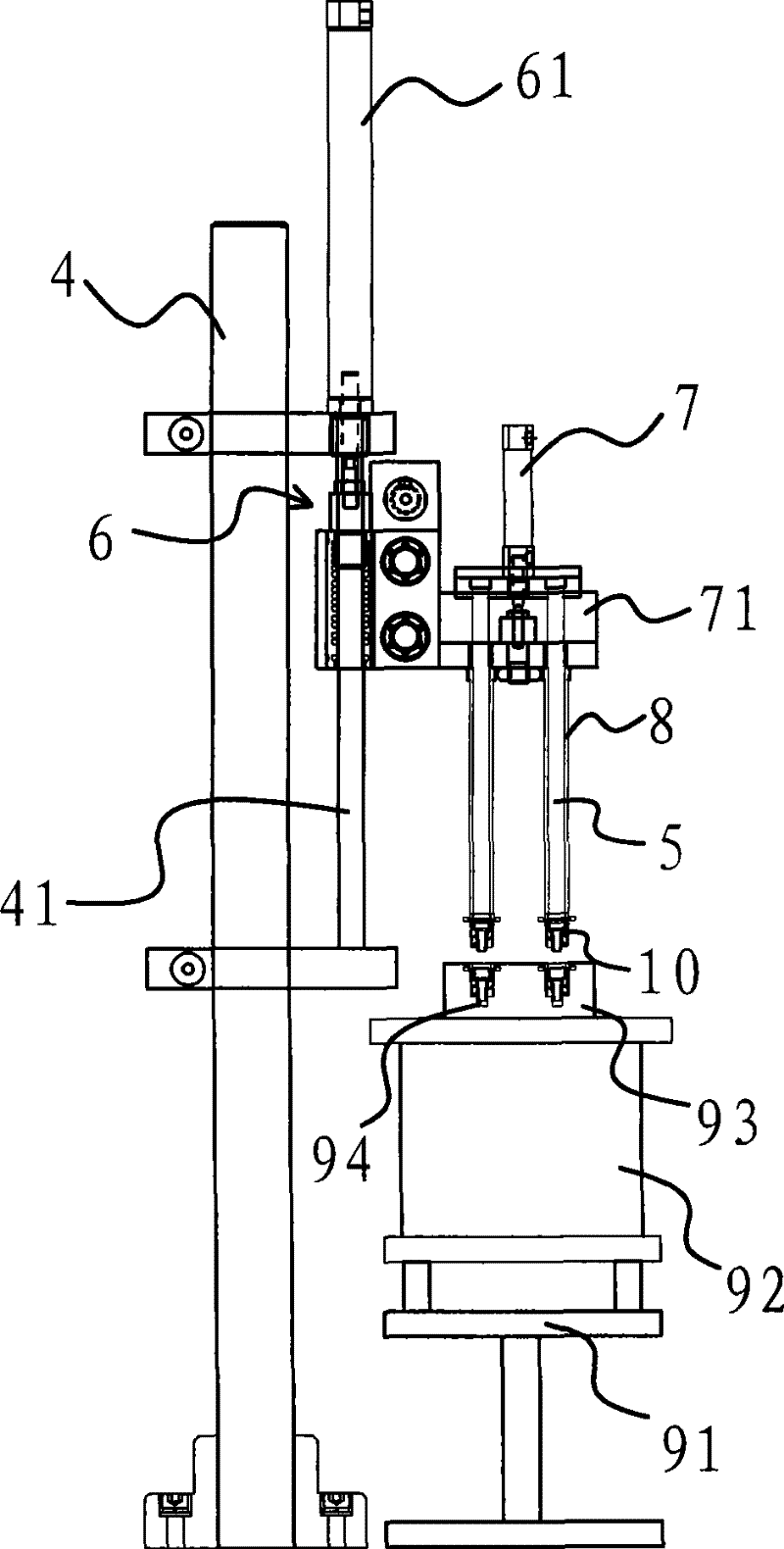

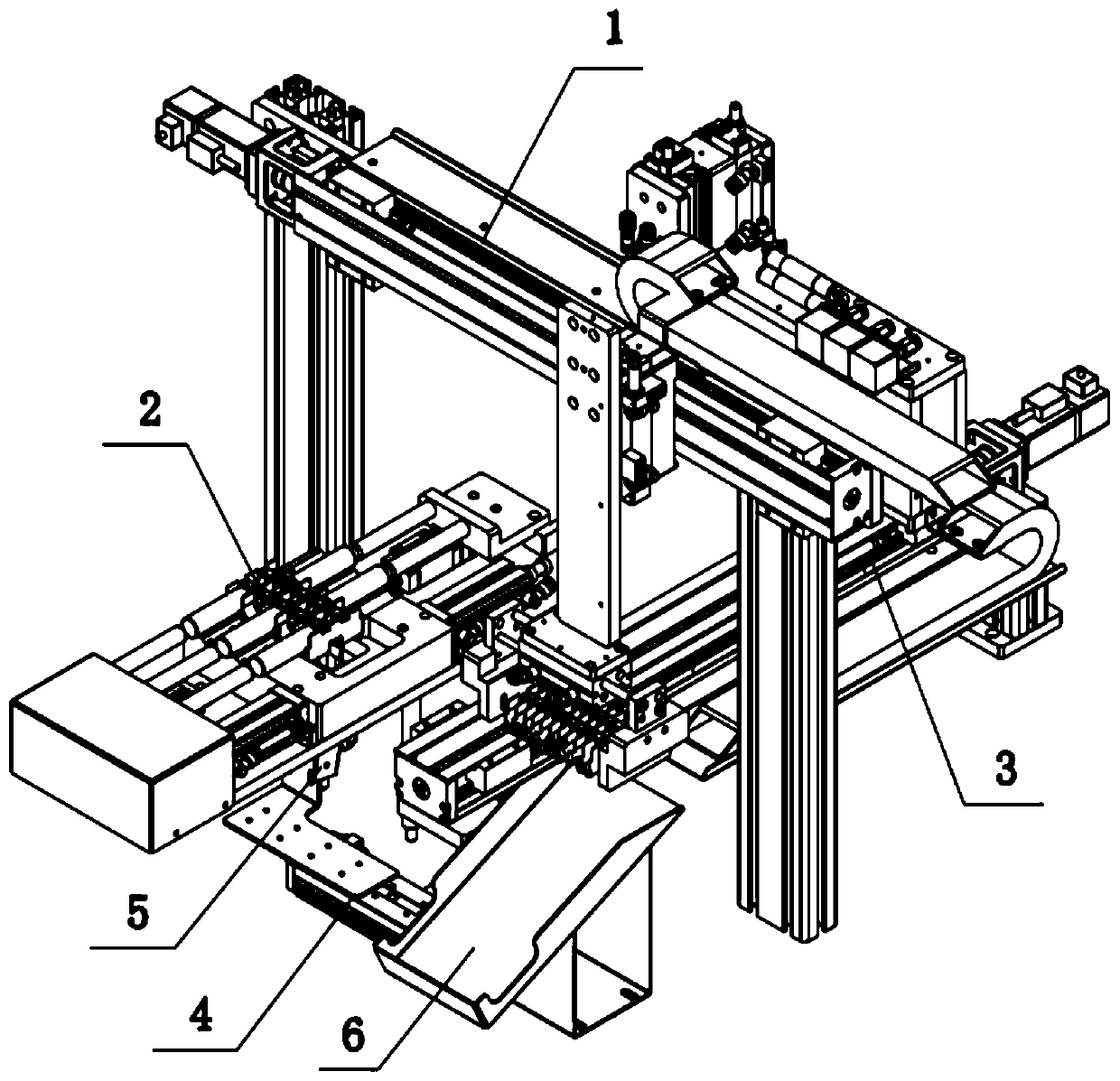

Automatic assembly device of captive nut

InactiveCN102430656AReduce labor costsIncrease productivityShaping toolsMetal-working feeding devicesEngineeringAssembly machine

The invention relates to the field of automatic assembly machines, and discloses an automatic assembly device of a captive nut, which comprises an assembly frame platform, a stamping die, a feeding device and a nut-feeding mechanism, wherein the assembly frame platform realizes fixation and movement of the whole device, the stamping device is positioned above the assembly frame platform, the pressing die comprises a pre-bending punch, a bending slanted sliding block, an upper die assembly jacking the punch, and a lower die assembly comprising a bottom plate, the feeding mechanism comprise a feeding mechanism fixing device driven by a first cylinder, a feeding mechanism movable device driven by a second cylinder, and a third cylinder in a horizontal direction, the third cylinder is connected with the feeding mechanism movable device, a nut-feeding mechanism comprises a fifth cylinder, a square push rod and a nut sliding chute, the push rod is driven to move in the nut sliding chute, and an output of the nut sliding nut extends into the stamping die. The invention realizes automatic assembly of the captive nut, has capabilities of effectively saving labor cost and increasing production efficiency, and is suitable for production of massive captive nuts.

Owner:苏州瑞玛精密工业股份有限公司

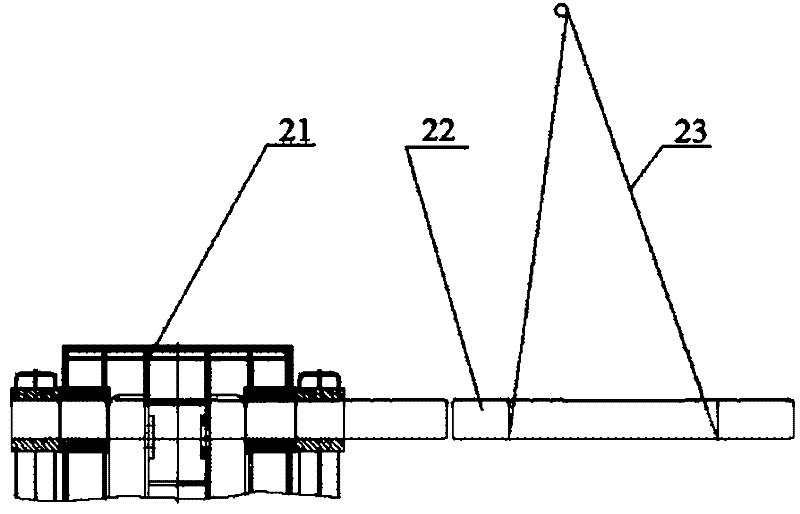

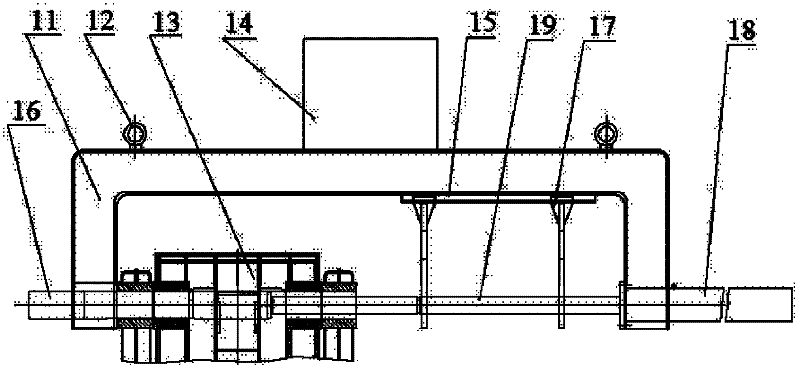

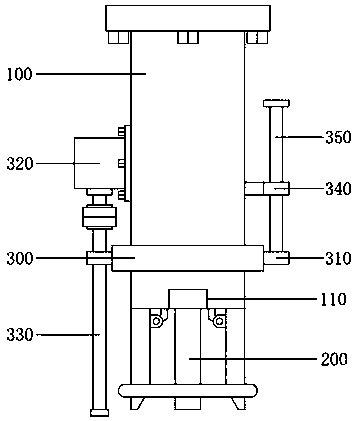

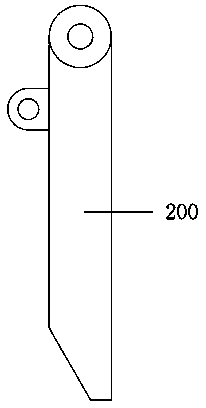

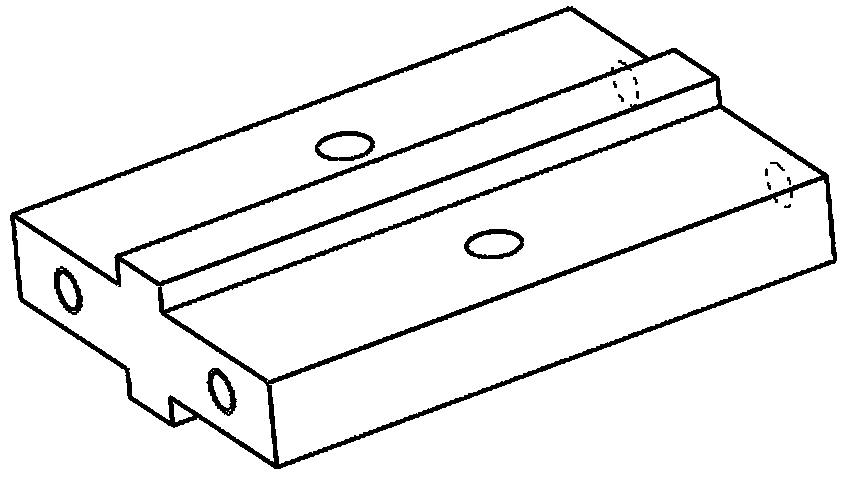

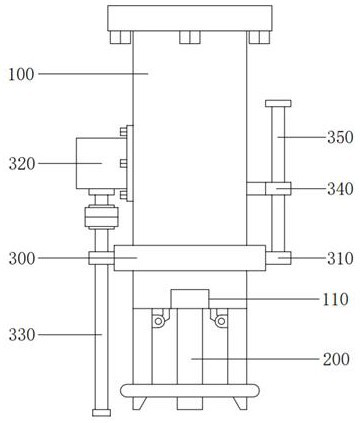

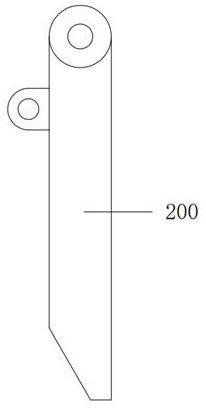

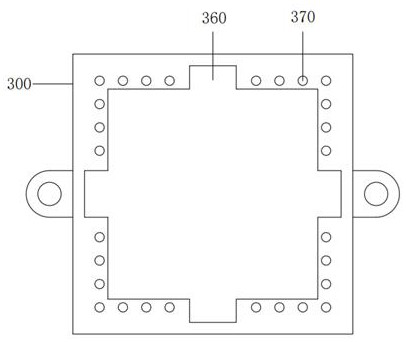

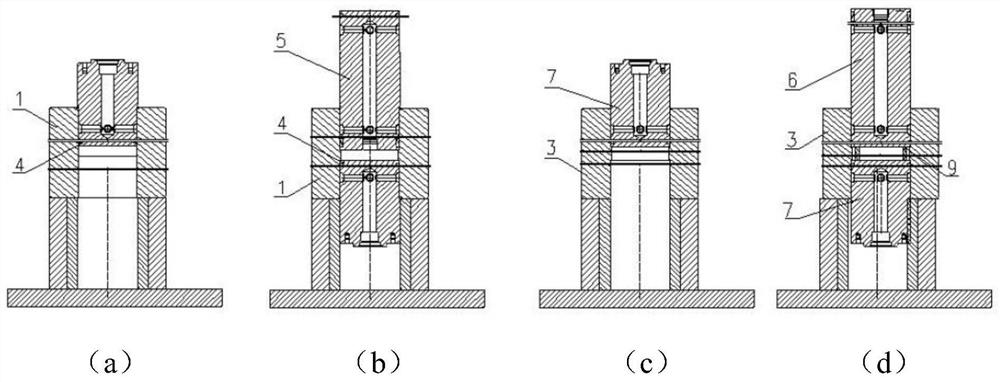

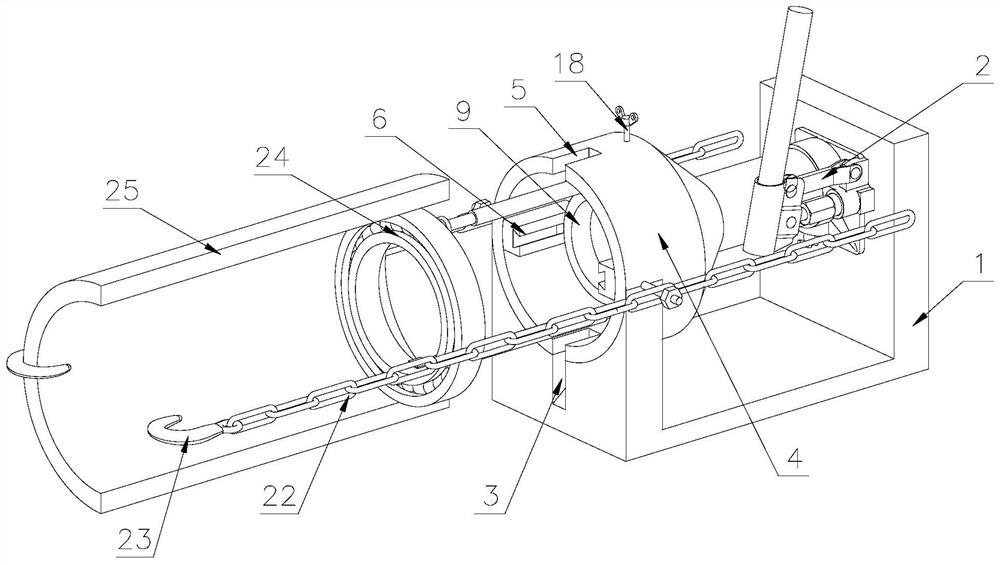

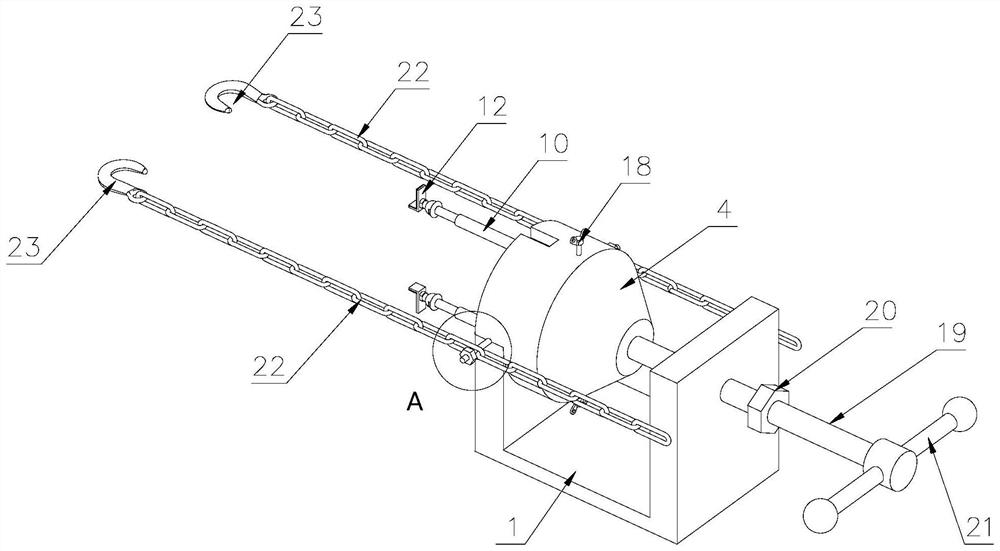

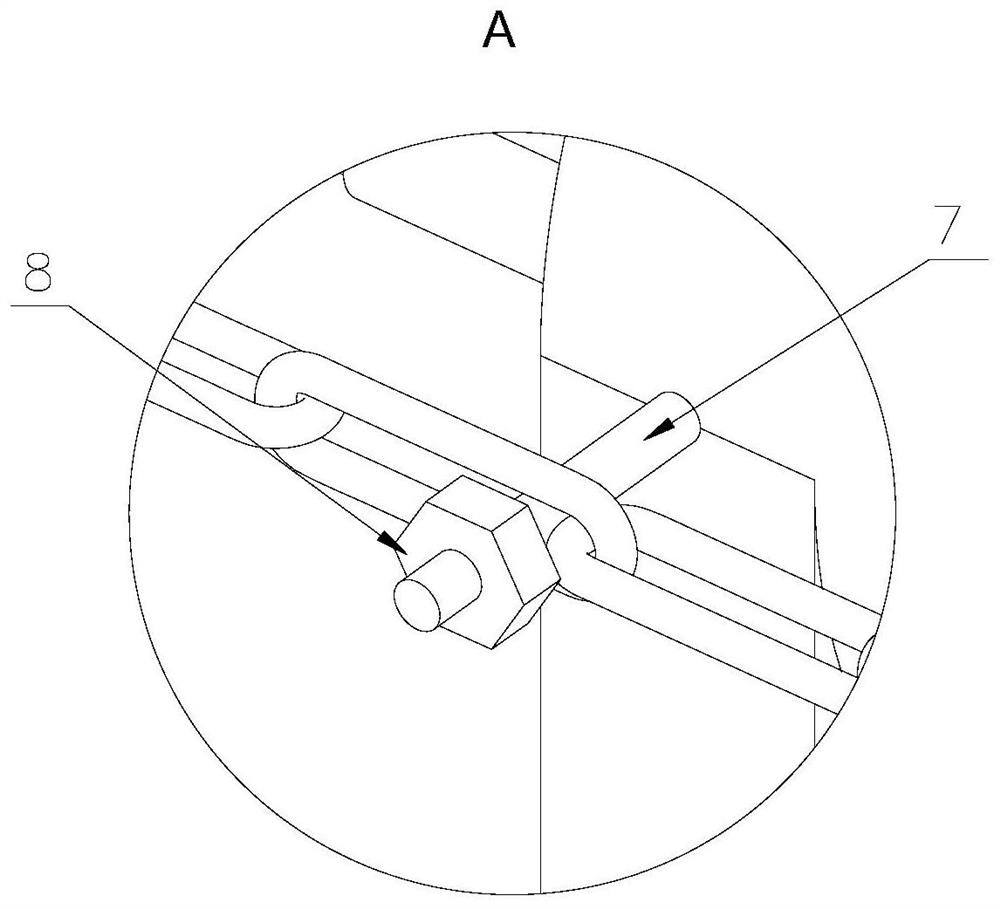

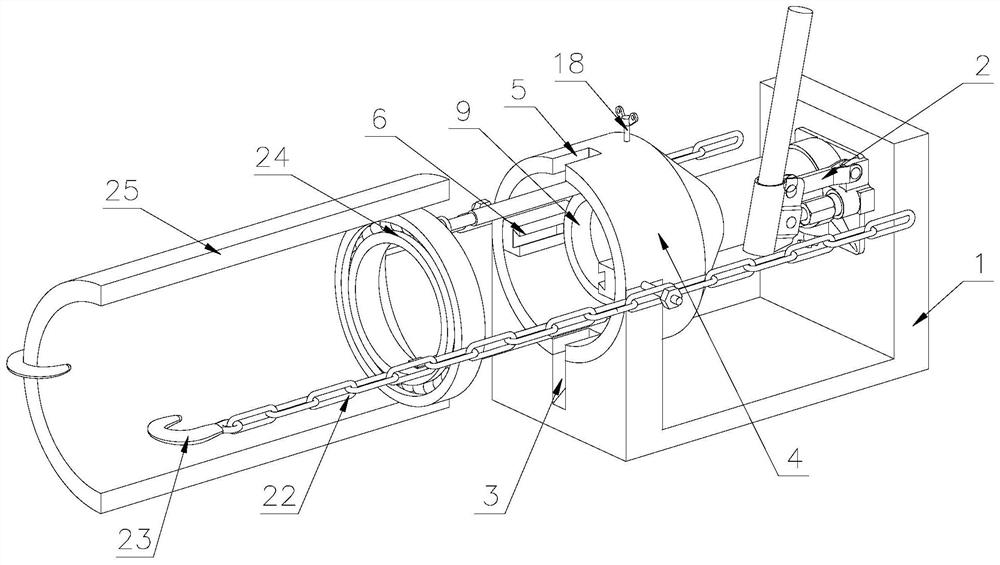

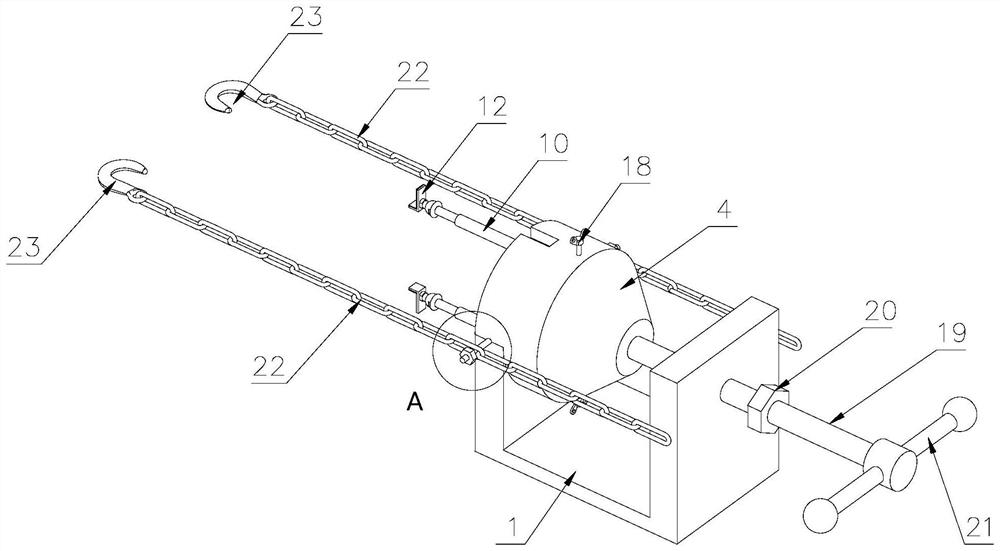

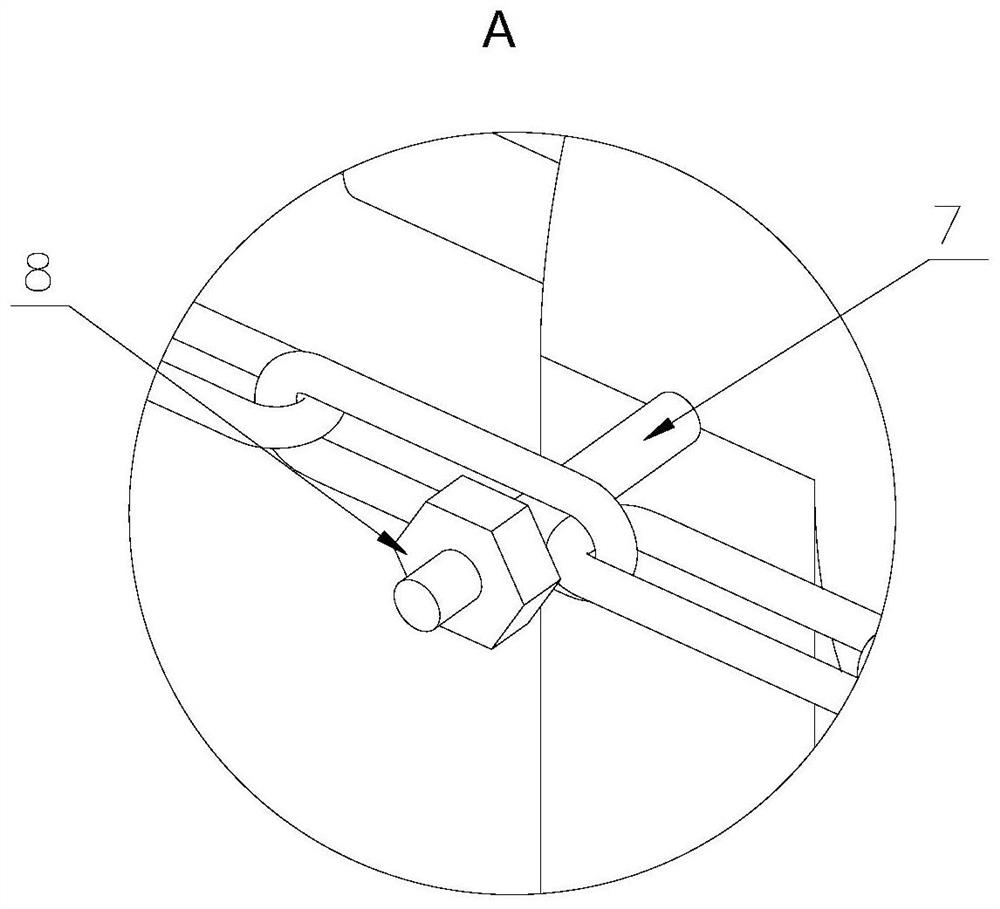

Pin assembling and disassembling device

InactiveCN102501056AAssembly applicableApplicable for disassemblyMetal working apparatusHydraulic cylinderEngineering

The invention provides a pin assembling and dissembling device, which comprises a gantry, a support and a hydraulic cylinder. The support is connected below the gantry and provided with a lifting portion used for lifting a pin, and the hydraulic cylinder is fixedly connected to the gantry and is provided with a piston which is retractably connected with the pin in a driving manner. The pin assembling and disassembling device has the advantages that assembling and disassembling of the pin are integrated, stable transmission is realized by using power of a pump station, and the pin assembling and disassembling device is compact in structure, fine in universality and applicable to assembling and dissembling of various pins of cranes.

Owner:ZOOMLION HEAVY IND CO LTD

Bonding and sealing method of proton exchange membrane fuel cell stack

ActiveCN108550886ASimple processSimplify the assembly processFinal product manufactureFuel cellsEngineeringProton exchange membrane fuel cell

The invention discloses a bonding and sealing method of a proton exchange membrane fuel cell stack and belongs to the technical field of fuel cell fabrication. The method particularly comprises the following steps of: I, preparing bipolar plates, and fixing flow channel carbon paper, anode carbon paper and the bipolar plates on a glue dispensing disk, II, setting a program of a dispenser for gluedispensing along the edges of anode plates, III, laying membrane electrodes and cathode carbon paper on the anode plates of the bipolar plates after the glue dispensing, and assembling into monocells,IV, stacking the assembled monocells into cell packs, and putting the stacked cell packs between two cell pack end plates for pressing and solidification, and V, fastening and assembling the solidified cell packs through electric collecting plates, stack end plates and screw rods into the stack. A proton exchange membrane fuel cell sealing technology and a stack assembly technology are simplified; and the method has the characteristics of simple technology, practicality, simplicity in operation and low cost and is applicable to the sealing and assembly of various fuel cells.

Owner:锋源新创科技(北京)有限公司

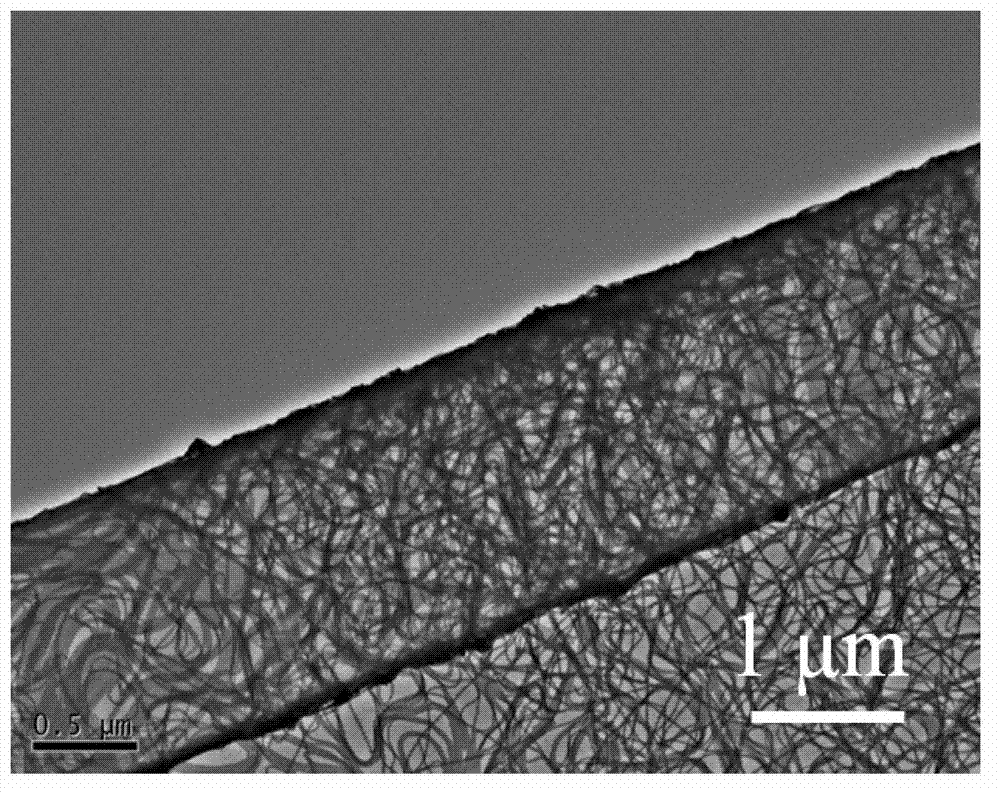

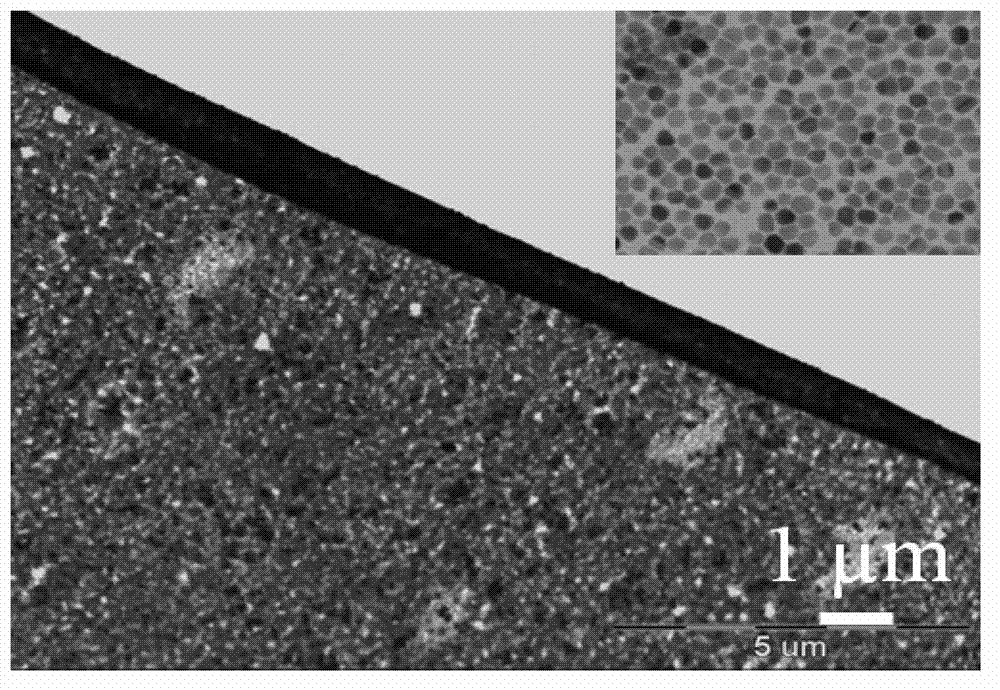

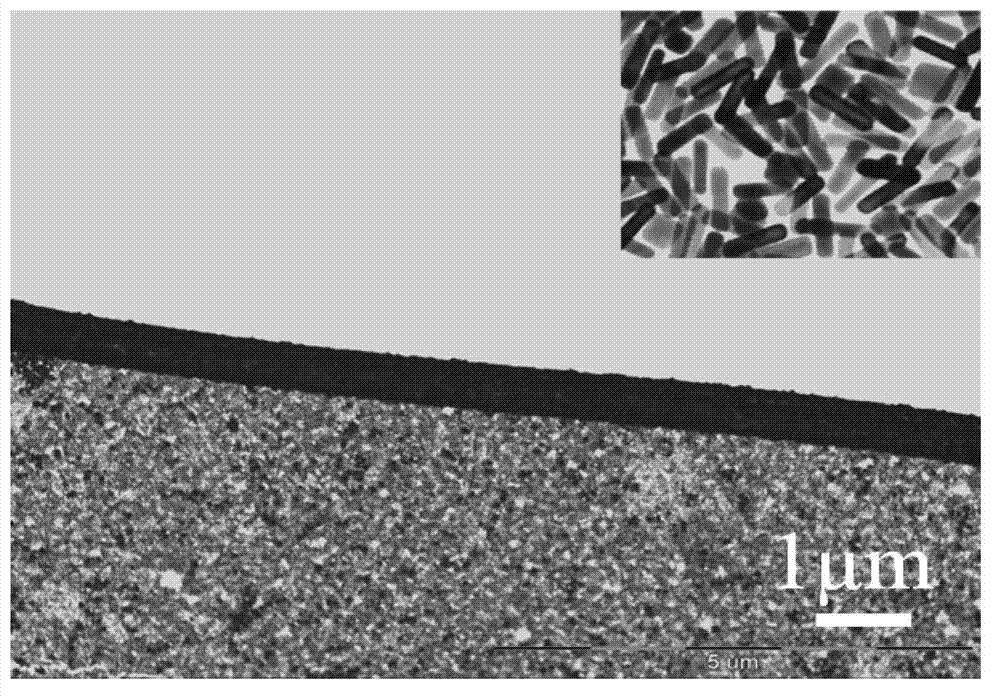

Method for manufacturing nano pipes

InactiveCN102874749AAssembly applicableLow requirements for preparation conditionsNanostructure manufactureCarbon filmElectron

The invention provides a method for manufacturing nano pipes. The method comprises the following steps of: dripping nano materials or an assembly of the nano materials to a support covered with a carbon film to obtain a compound carbon film; cracking the compound carbon film to obtain a cracked compound carbon film; and illuminating the cracked compound carbon film by using electron beams for crimping to obtain the nano pipe. By the method, the nano pipe can be obtained only through 3 steps, the manufacturing requirement is relatively low, and an expensive instrument is not required; the method is simple; and the nano pipe is formed by the carbon film crimped cladding nano materials or the assembly of the nano materials, and the method does not have limits on the nano materials or the assembly of the nano materials, so that the method is suitable for assembling a plurality of kinds of nano materials.

Owner:UNIV OF SCI & TECH OF CHINA

Automatic assembly device of O-type sealing ring

The invention discloses an automatic assembly device of an O-type sealing ring, and belongs to the technical field of sealing ring assembly. The automatic assembly device of the O-type sealing ring comprises a sliding platform connecting cylinder, wherein a reversing claw clamping groove is formed in the lower part of the outer wall of the sliding platform connecting cylinder; a reversing claw ishinged to an inner cavity of the reversing claw clamping groove; L-shaped connecting rods are connected to the inner wall of the reversing claw in a pin-joint mode; a connecting plate is connected tothe top ends of the L-shaped connecting rods in the pin-joint mode; a first threaded rod is connected to the top wall of the connecting plate in a threaded mode; an output shaft of a first driving motor is connected to one end of the first threaded rod through a coupler; the outer wall of the sliding platform connecting cylinder is sleeved with a sealing ring releasing ring sleeving plate; a second driving motor is connected to the left wall of the sliding platform connecting cylinder in the threaded mode; a second threaded rod is installed on an output shaft of the second driving motor through a coupler; a reversing claw containing groove is formed in the middle part of the inner wall of the sealing ring releasing ring sleeving plate; and balls are evenly connected to the bottom wall of the sealing ring releasing ring sleeving plate in a clamping mode. According to the automatic assembly device of the O-type sealing ring, the structure is simple, the usage is convenient, the automaticassembly operation of the O-type sealing ring can be realized, and the device is suitable for the assembly of O-type sealing rings with various diameters.

Owner:安徽沃尔顶密封工业股份有限公司

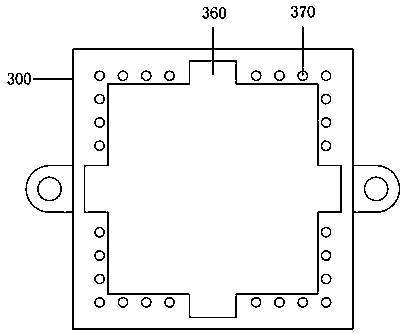

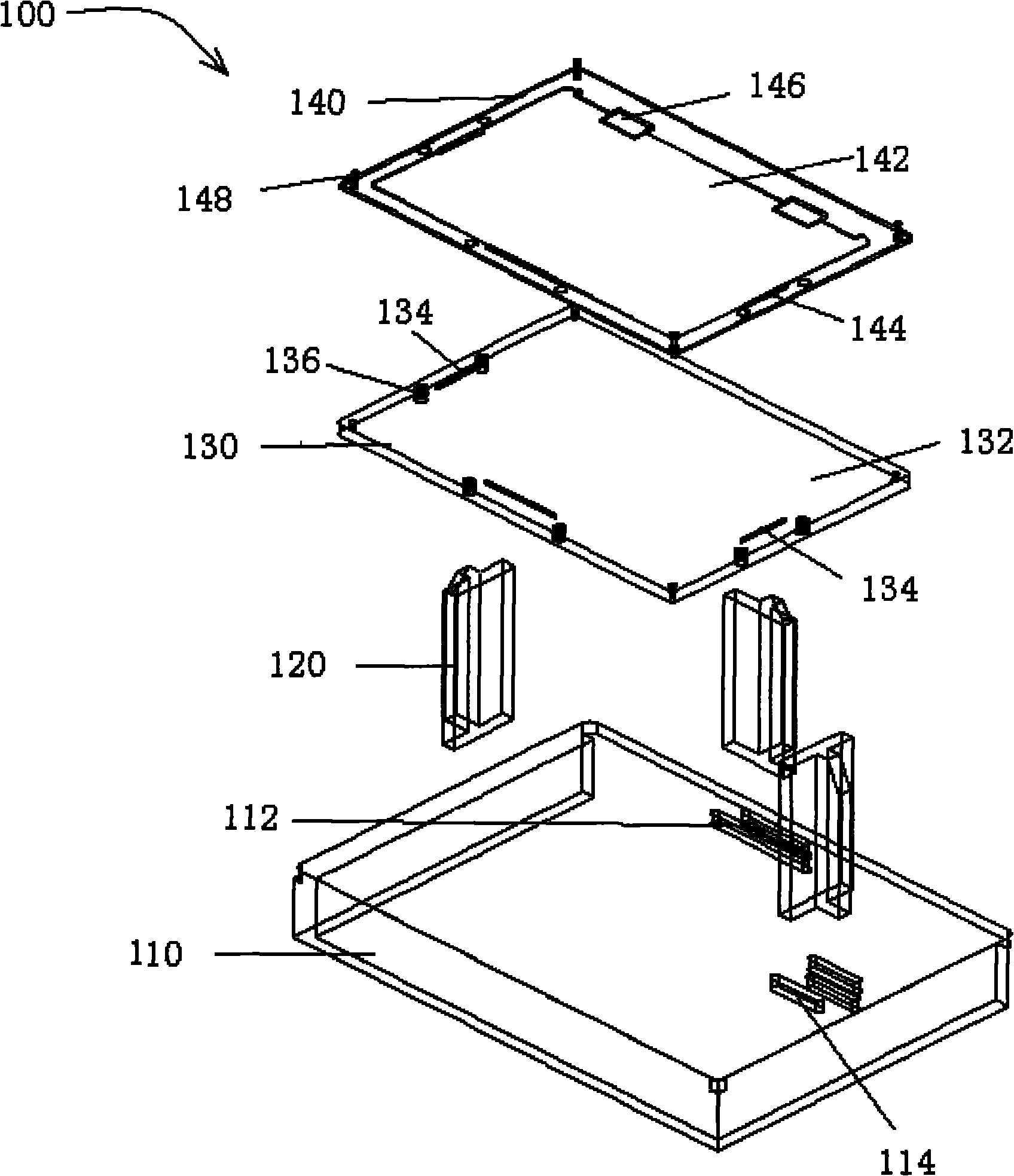

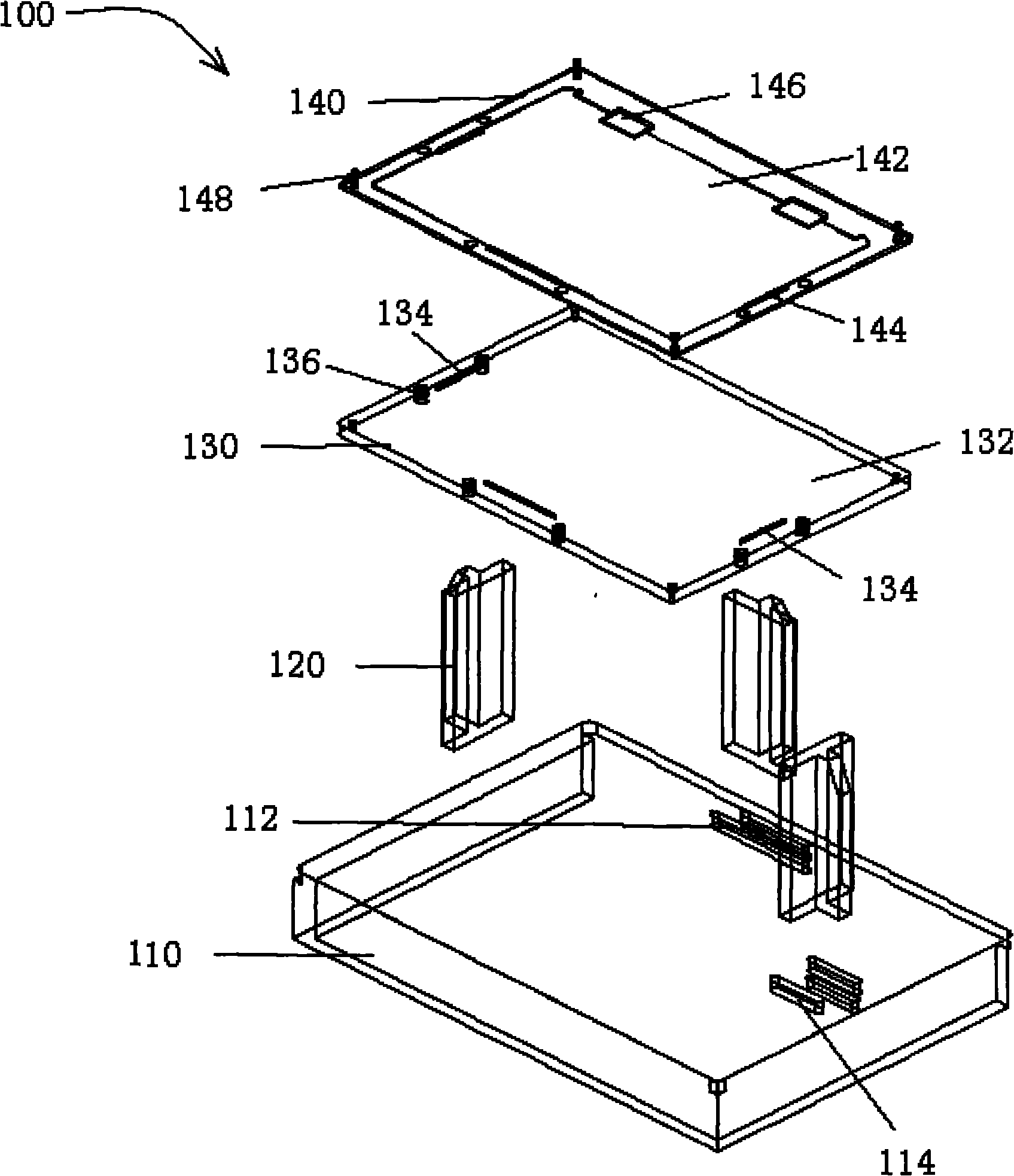

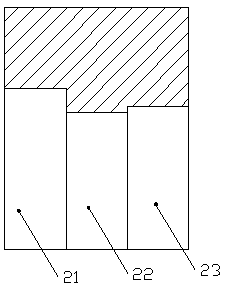

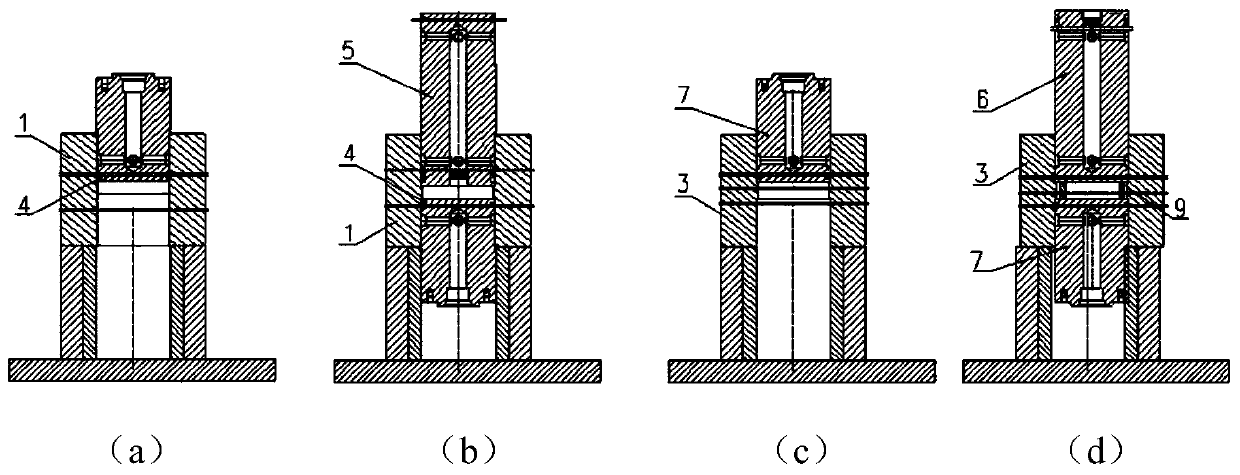

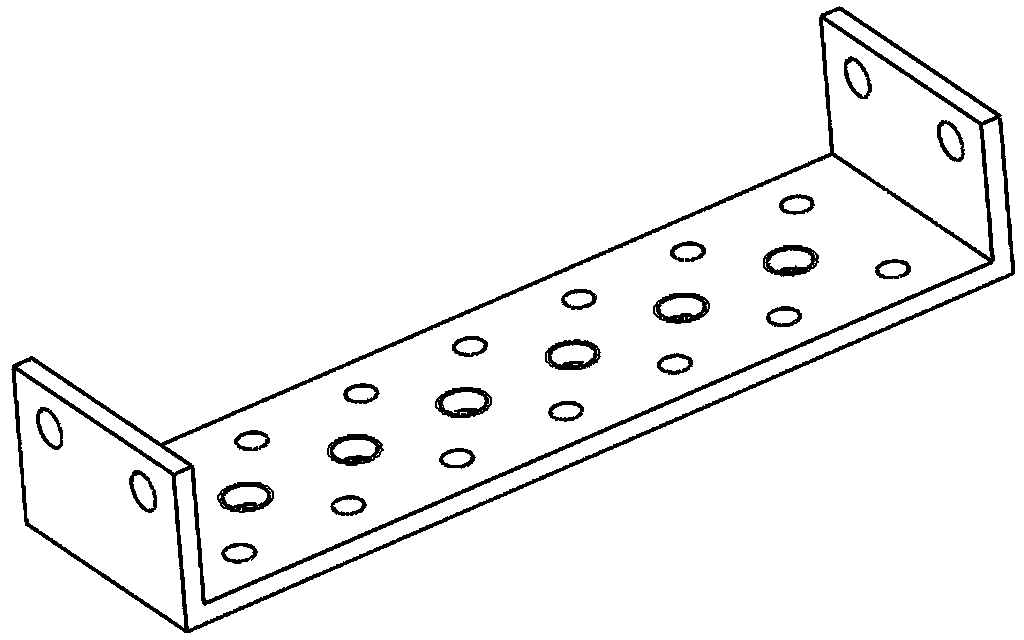

Positioning and press fitting fixture

ActiveCN101966648AExpand the scope of useReduce manufacturing costAssembly machinesSize adjustmentEngineering

The invention relates to a positioning and press fitting fixture which comprises a workbench, a plurality of positioning columns are arranged on the workbench, and the positioning columns are provided with a work area on the workbench. Furthermore, a plurality of size adjustment slots are also arranged on the workbench, the positioning columns are installed on the size adjustment slots, and the size of the work area set by the positioning columns can be changed by installing the positioning columns in different size adjustment slots. The positioning and press fitting fixture can be used for assembling various notebook computers with different sizes.

Owner:KUNSHAN HUAGUAN TRADEMARK PRINTING

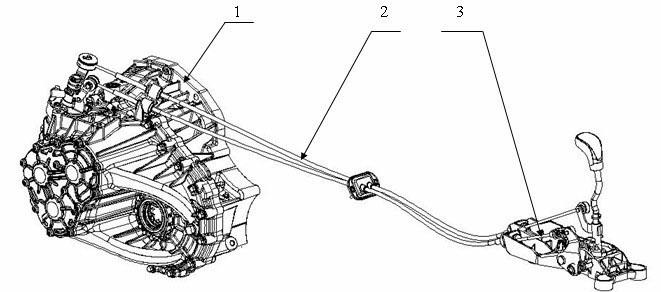

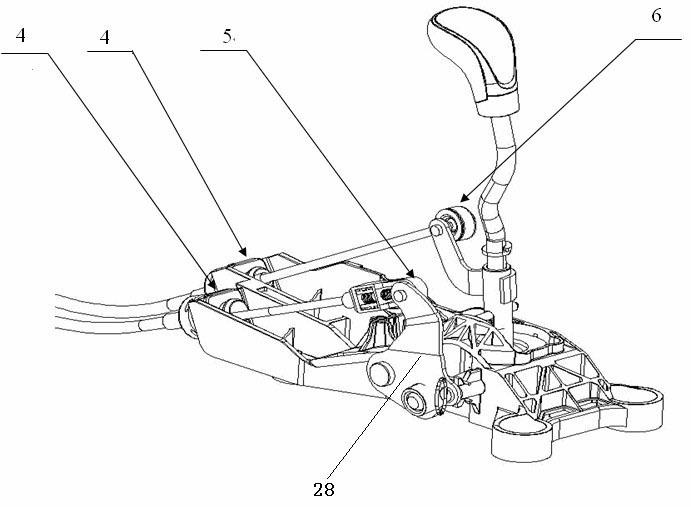

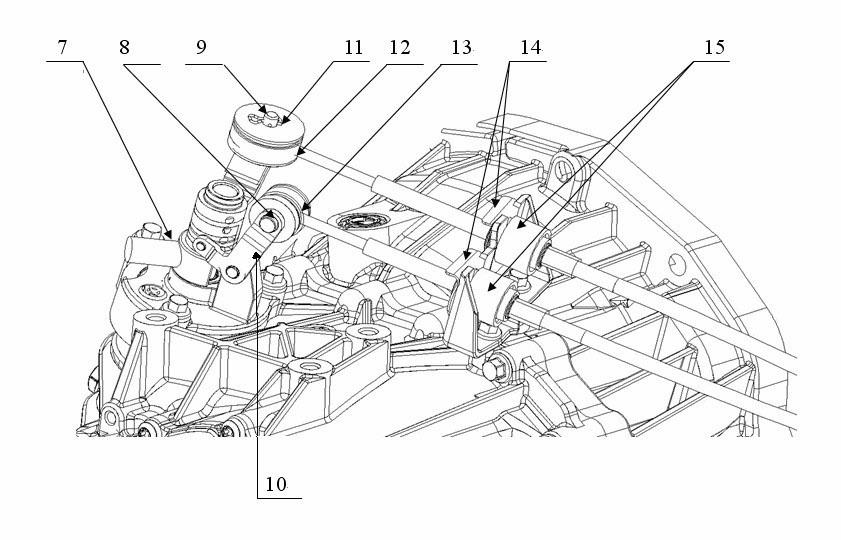

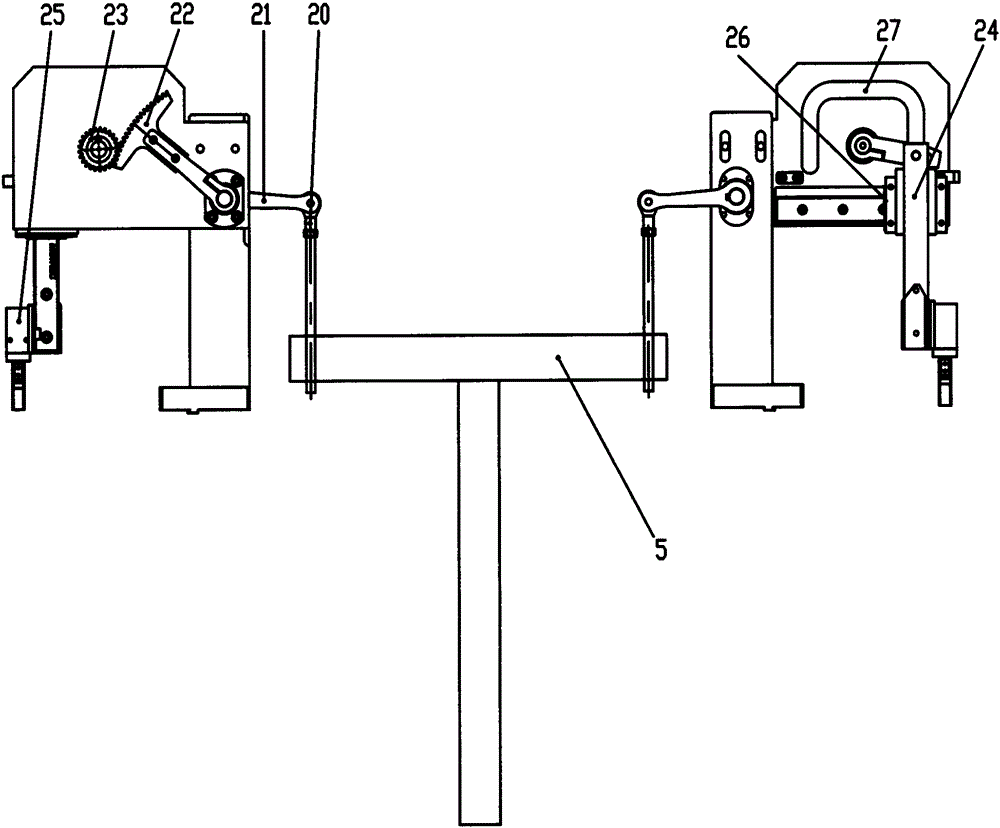

Device and method for assembling six-speed manual gear-changing control system

ActiveCN102635686AAssembly applicableSolve the difficulty of shifting gearsGearing controlControl systemPush pull

The invention discloses a device and a method for assembling a six-speed manual gear-changing control system. The device comprises a 1 / 2 gear assembling process fork and a 1 / 2 gear assembling process pin. The method comprises the steps of: firstly, controlling a six-speed manual gear-changing control assembly to a 1 / 2 gear position by using the 1 / 2 gear assembling process pin, then arranging a first gear-changing joint of a flexible shaft push-pull cable on the six-speed manual gear-changing control assembly, respectively installing a second gear-changing joint and a second position-changing joint of the flexible shaft push-pull shaft on the six-speed manual gearbox assembly, fixing a gear of the six-speed manual gearbox assembly on a 1 / 2 gear by using the 1 / 2 gear assembling process fork, and finally installing a first position-changing joint of the flexible shaft push-pull cable on the six-speed manual gear-changing control assembly. According to the method, the problem that a vehicle is difficult to change the gear or a driver can not normally change the gear for driving the vehicle due to mismatching from a neutral position to a 1 / 2 position-changing journey is effectively solved; and the device is simple in structure, is convenient for operation, and is suitable for assembling the six-speed manual gear-changing control system.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Flange assembling device for hollow composite insulator

The invention relates to a flange assembling device for a hollow composite insulator. The flange assembling device comprises an assembling base; an insulator positioning assembly arranged on the assembling base, wherein the insulator positioning assembly comprises an insulator positioning upper die and an insulator positioning lower die, a first positioning cavity is formed in the lower end of theinsulator positioning upper die, a second positioning cavity is formed in the upper end of the insulator positioning lower die, and the first cavity and the second cavity are jointly matched to forma positioning cavity for installing an insulator; and a flange positioning assembly which comprises a pair of flange positioning plates which are respectively positioned at two sides of the insulatorpositioning assembly. The device has the advantages that the assembling base, the insulator positioning assembly and the flange positioning assembly are matched, so the flanges at the two ends of an insulator can be assembled only through one assembling oil cylinder; the structure is simple, the whole assembling process is very convenient, and the device is suitable for assembling flanges of insulators of different sizes.

Owner:JIANGSU XIANGYUAN ELECTRIC EQUIP

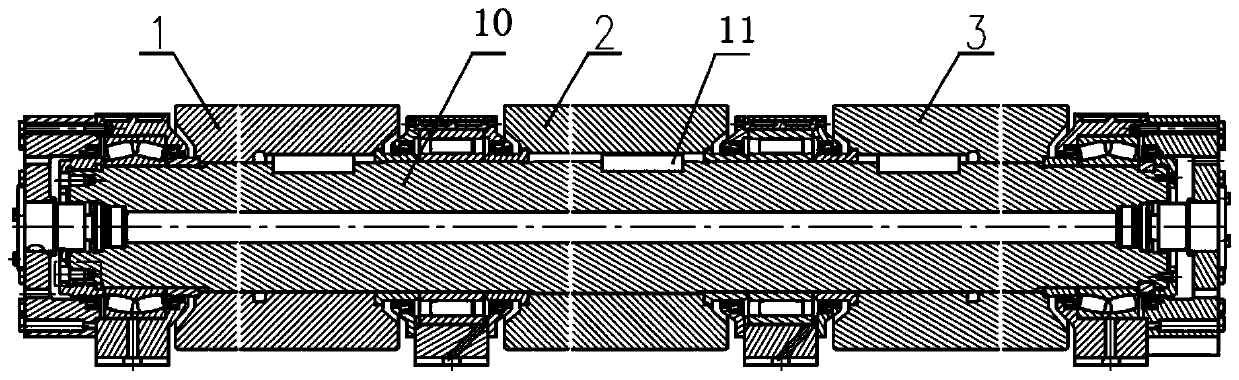

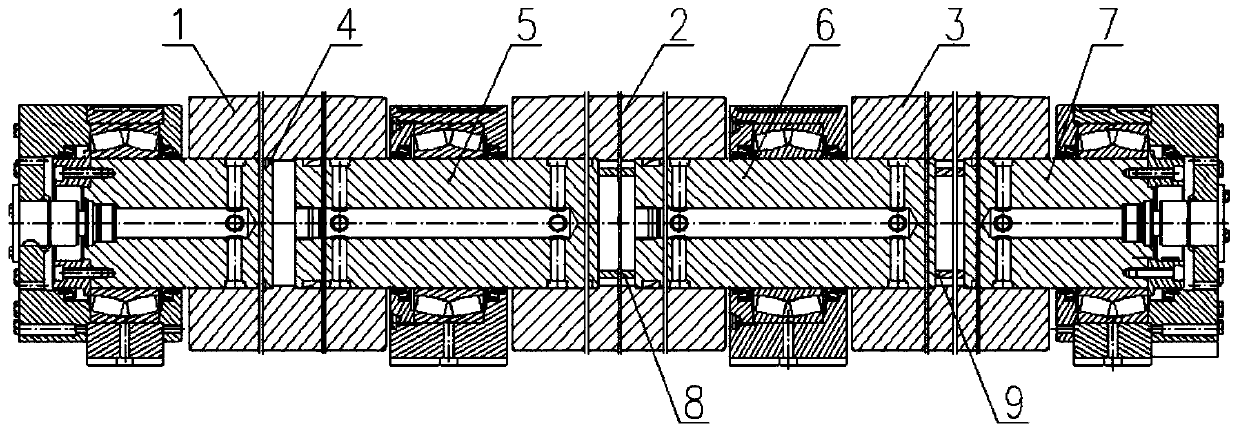

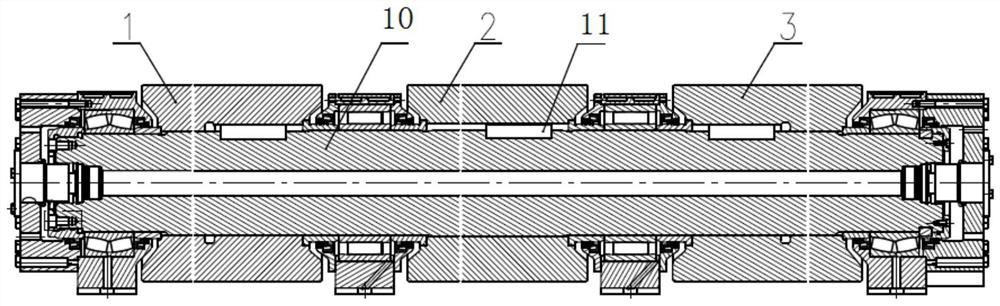

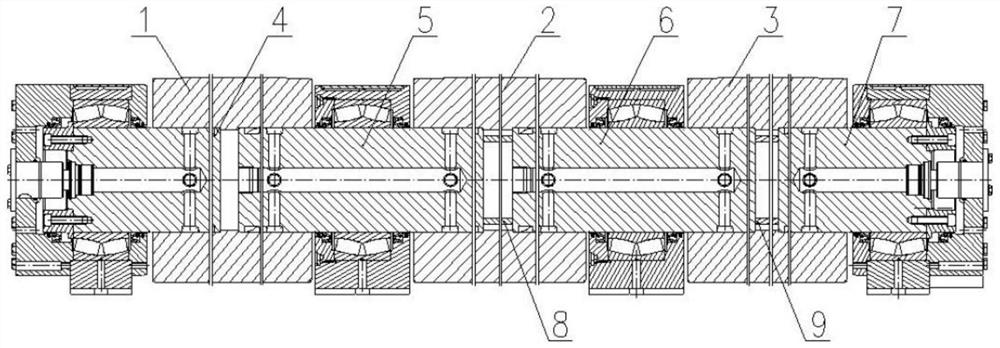

Installation method for short mandrel continuous casting rolls adopting interference fit

The invention provides an installation method for short mandrel continuous casting rolls adopting interference fit. Since the installation between roller sleeves and mandrels of the short mandrel continuous casting rolls adopts interference fit, the assembly is realized by utilizing the principle of thermal expansion and cold contraction of materials, namely the roller sleeves are assembled with the mandrels at normal temperature after being heated to a set temperature, or the roller sleeves are assembled with the cooled mandrels after being heated to the set temperature, so that the requirement on interference fit of the short mandrel continuous casting rolls can be realized. The installation method is suitable for installation of the short mandrel continuous casting rolls.

Owner:SINOSTEEL XIAN MACHINERY

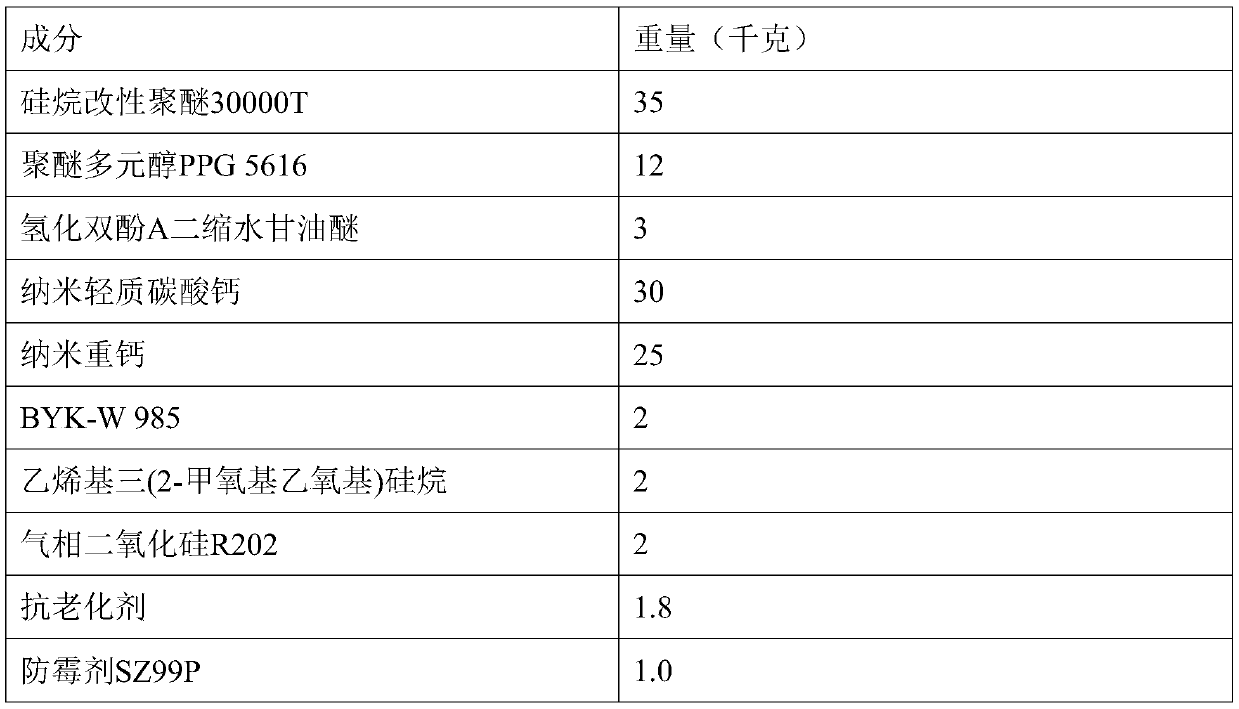

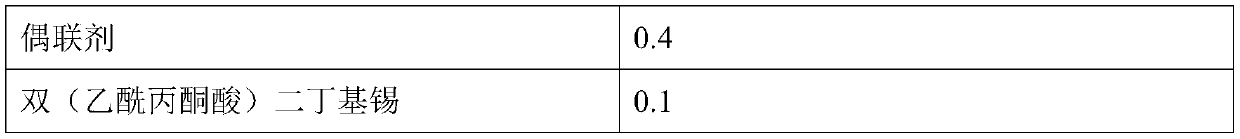

High-performance sealant for building assembling and preparation method thereof

InactiveCN110484183AGood adhesionLow modulusNon-macromolecular adhesive additivesRotary stirring mixersEnvironmental resistanceProduct testing

The invention relates to the technical field of building materials, and discloses a high-performance sealant for building assembling, which comprises the following components by weight: 30-50 parts ofsilane modified polyether, 10-15 parts of a viscosity reducer, 35-55 parts of a wetting dispersant, 1-2 parts of a filler, 1-2 parts of a water removal agent, 1.5-3 parts of a thixotropic agent, 0.9-2.4 parts of an anti-aging agent, 0.2-1.5 parts of a mildew inhibitor, 0.3-0.8 part of a coupling agent and 0.1-0.2 part of catalyst. The performance of the sealant meets the standard requirements oflow-modulus glue in JC / T 887-2017 Building Sealant for Concrete Joints, and primer coating is not used in a product testing process. Meanwhile, the mildew-proof performance meets the requirements of the mildew-proof grade in GB / T 1741-2007 Paint Film Mould Resistance Test Method. The sealant provided by the invention has the characteristics of low modulus, good elasticity, strong binding power, good aging resistance, good paintability, environmental protection and the like on a concrete base material, and can be widely applied to sealing and waterproofing of concrete and concrete joints.

Owner:SUZHOU RES INST OF ARCHITECTURE SCI

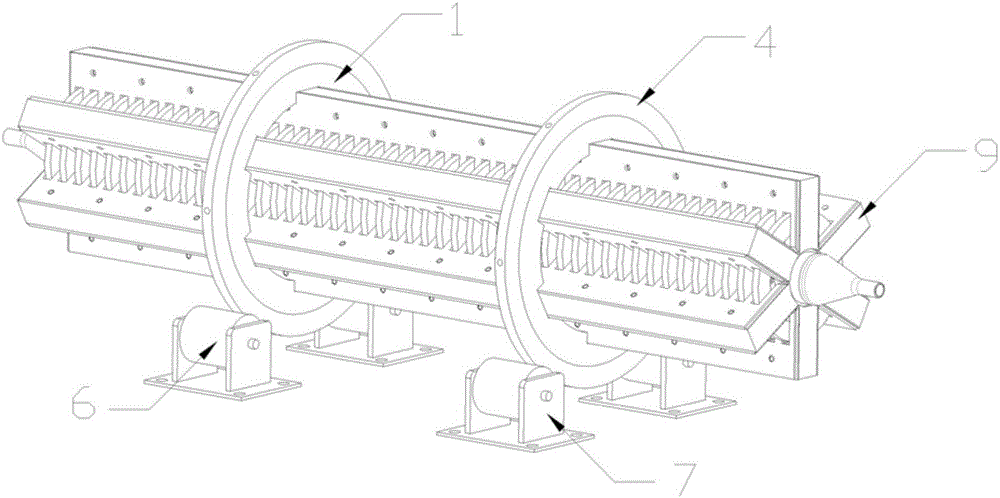

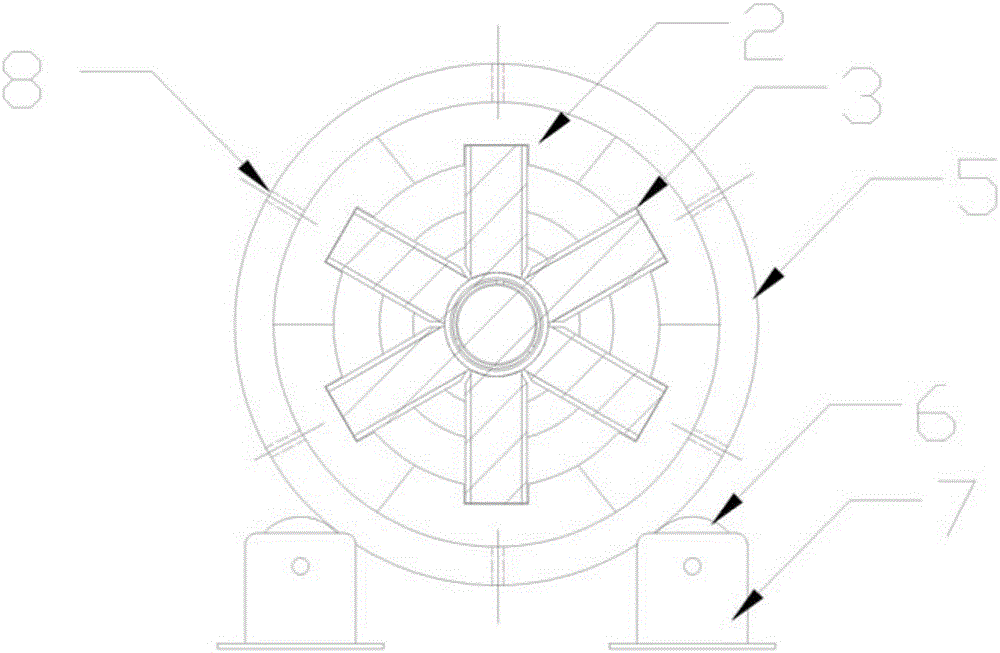

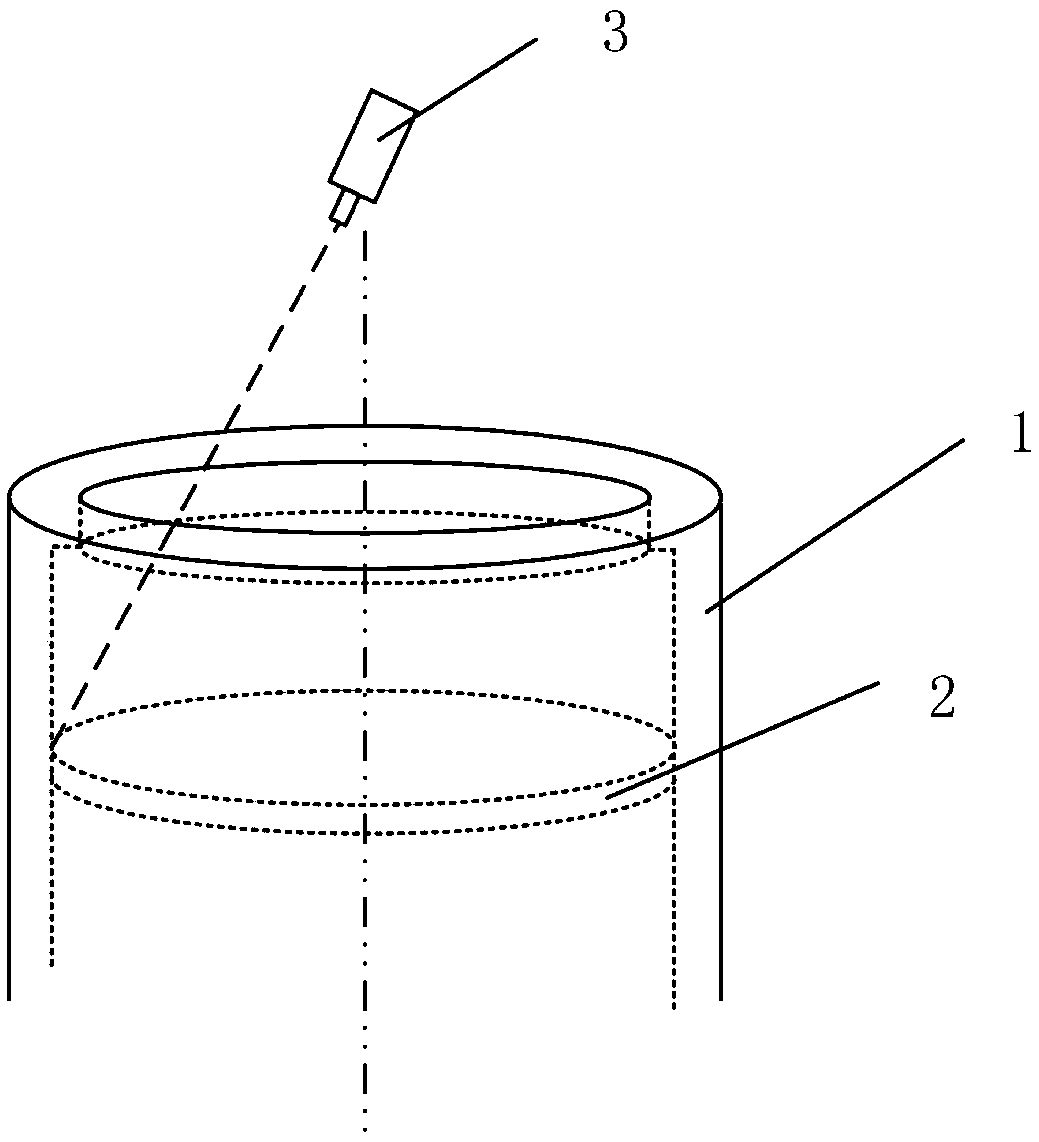

Assembly tooling of large electromagnetic pump

The invention relates to an assembly tooling of equipment, and provides an assembly tooling of a large electromagnetic pump, which aims at solving the problem of difficulty in assembly of large electromagnetic pumps. The assembly tooling comprises an inner fixing ring, an outer fixing ring and a roller, wherein the inner fixing ring consists of a plurality of inner fixing ring clamp blocks in an annular way, and the inner surface of the inner fixing ring is provided with a clamp groove; the outer fixing ring consists of a plurality of outer fixing ring clamp blocks in an annular way, and the inner diameter of the outer fixing ring is the same with the outer diameter of the inner fixing ring. The assembly tooling of the large electromagnetic pump has the advantages that by adopting the block type structure, the transverse assembly which is usually difficult to realize can be realized, and the rotation in the assembly process is easily realized; actual application shows that the assembly of the large electromagnetic pump by the assembly tooling is convenient, the assembly efficiency is obviously improved, the labor intensity of an operator is obviously decreased, and the good effect is obtained.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Assembling device for nose cowl of rocket launcher

PendingCN109420898ASolve the location accuracy of launch holesGuaranteed distance and parallelismAssembly machinesRocket

The invention belongs to the technical field of machinery manufacturing and particularly relates to an assembling device for the nose cowl of a rocket launcher. An assembling device for the nose cowlof a rocket launcher comprises a base, a threaded connecting rod, cylindrical pins for press plate assemblies, stop screws, a bushing, a cushion block, a step nut, a bolt, a limit bushing, limit blocks, a small positioning shaft, positioning shafts, a press plate and handles, wherein each press plate assembly comprises a flat pressure plate, a stop screw, a stud and a nut. The assembling device provided by the invention is simple in structure and convenient to operate, well solves the problem about ensuring the position accuracy of a launching hole between clamping rings, ensures the distanceand parallelism between a rear clamping ring in a skin assembly and a disc and does not need to repair or file a skin. The structure applies to the assembling of devices similar to the nose cowl of the rocket launcher.

Owner:GUIZHOU FENGLEI AVIATION ORDNANCE CO LTD

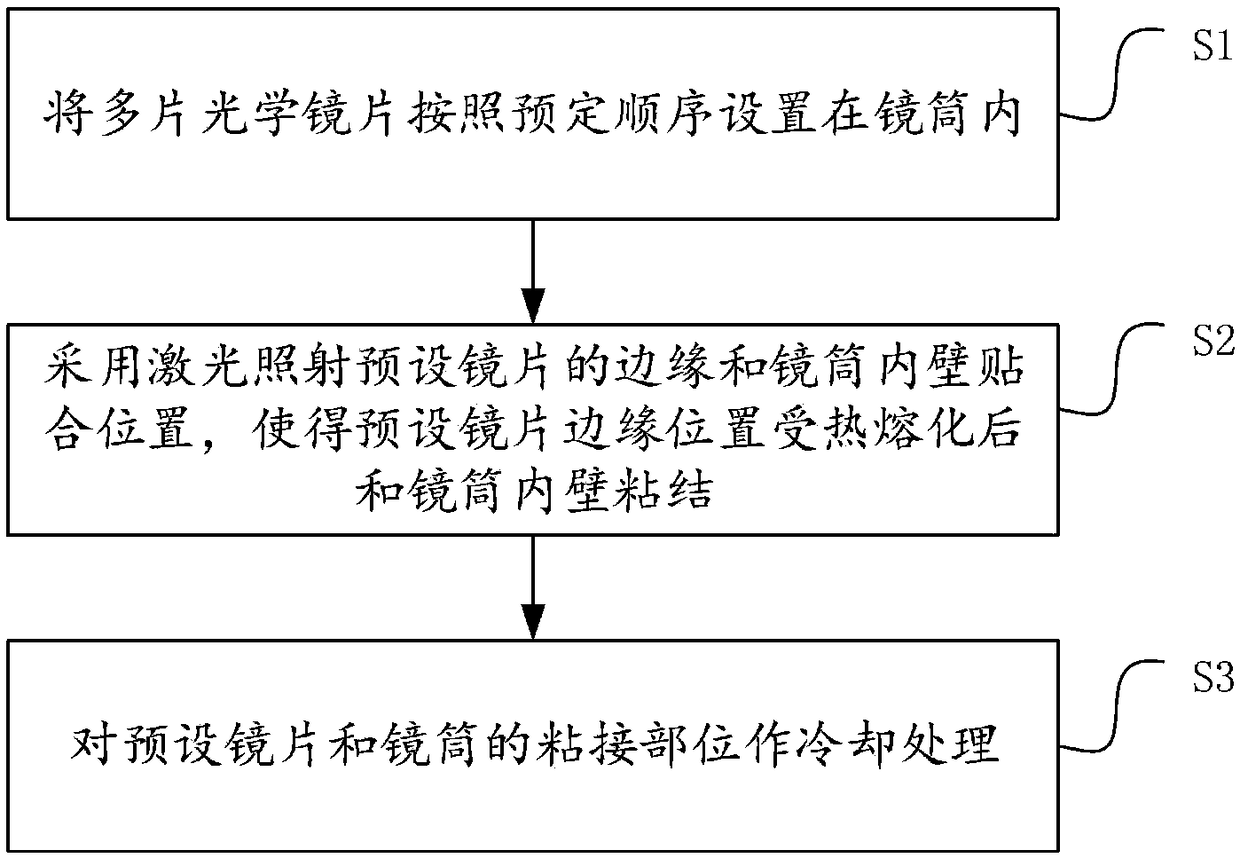

Assembly method of optical lens

InactiveCN109085689AAssembly applicableReduce the difficulty of production assemblyMountingsCamera lensLaser

The invention discloses an assembly method of an optical lens. The method comprises the following steps: arranging a plurality of optical lenses in a lens cone according to a preset order; irradiatingthe joint position of the edge of a preset lens and the inner wall of the lens cone by a laser, so that the edge of the preset lens is stuck to the inner wall of the lens cone after melted by heat, wherein the preset lens is an optical lens which is finally arranged in the lens cone; and performing cooling treatment on the stuck portion of the preset lens and the lens cone. According to the assembly method of the optical lens, the method is simple to operate, can be applied to assemble optical lenses of various sizes, the production assembly difficulty of the optical lenses is reduced, and the product quality is improved.

Owner:TRULY OPTO ELECTRONICS

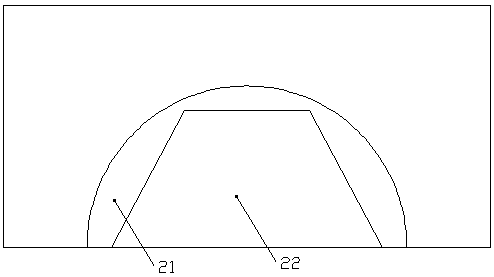

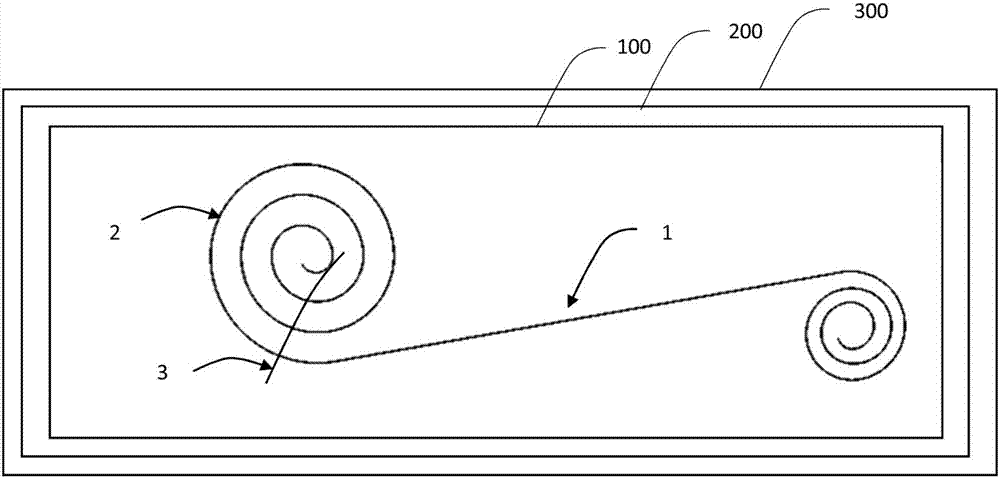

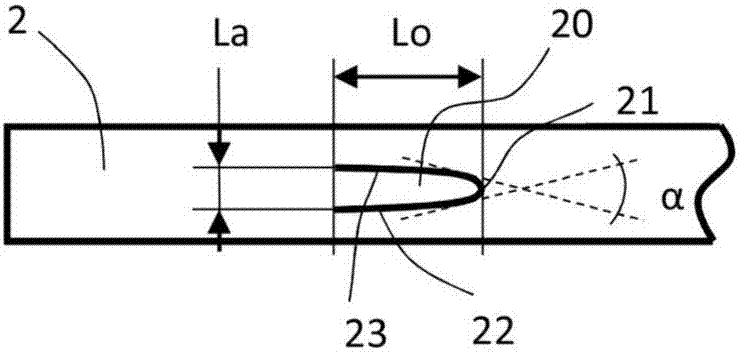

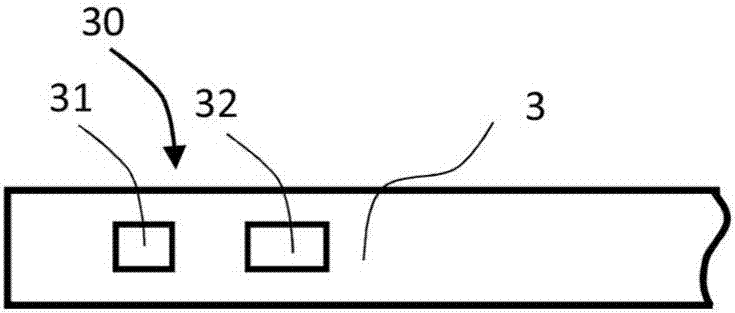

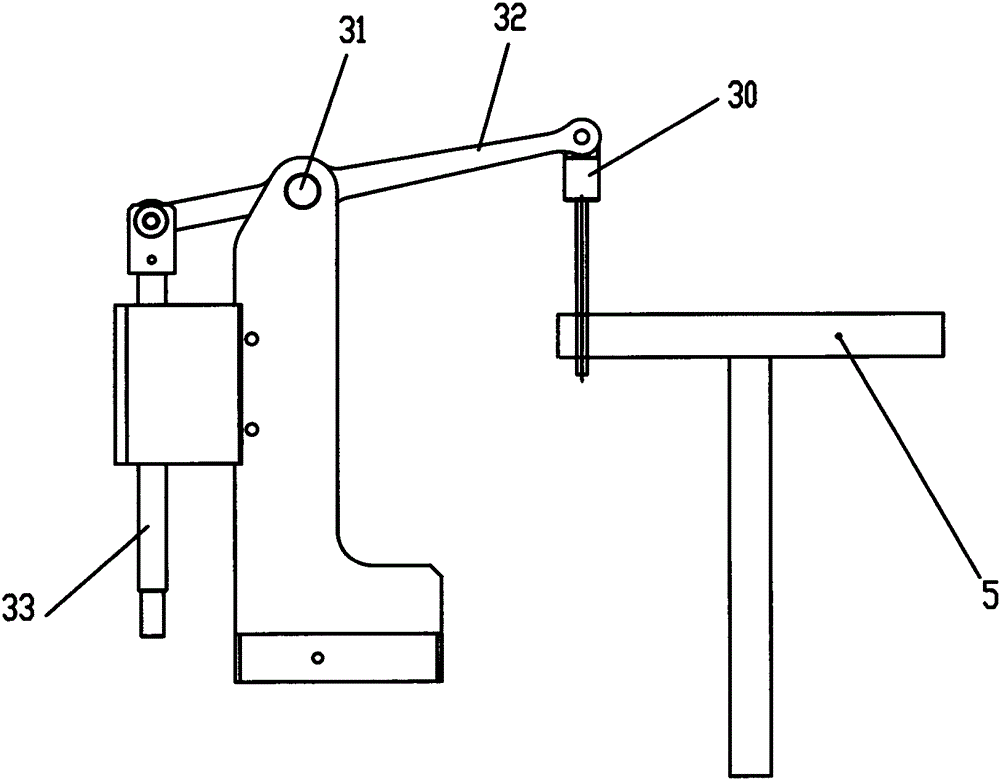

Method for production of a horology assembly, and horology assembly thus obtained

PendingCN107577133AEasy to assembleAssembly applicableClock driving mechanismsMechanical engineeringMouth opening

A method for production of a horology assembly of two components, comprising (i) supplying a first component (2) being a spring, and comprising at least one element made of elastic material provided with a tongue (20); supplying a second component (3) provided with at least one cut-out or opening (31, 32); permanently assembling the two components. The two components cooperate by means of an obstacle such as to create the assembly, and in particular the tongue is accommodated in the at least one cut-out or opening (31, 32).

Owner:ROLEX SA

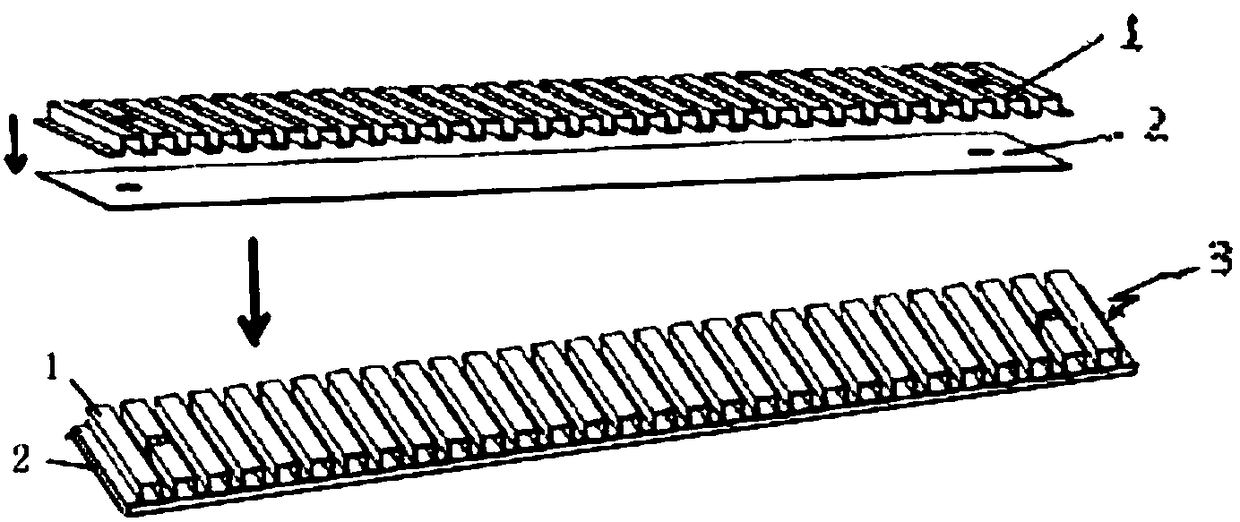

Assembly method of meter movements

InactiveCN103100841AImprove assembly accuracyImprove assembly efficiencyMetal working apparatusEngineeringMechanical engineering

The invention discloses an assembly method of meter movements. Firstly, sequencing plates are arranged on a vibration platform, then a plurality of identical components are arranged on the sequencing plates, and the vibration platform vibrates to enable the components to fall in and be clamped in profiled through holes in the same shape with the components. A corresponding number of the sequencing plates are sequentially stacked according to the number of the components, after each layer of sequencing plate is stacked, the corresponding components are arranged on the sequencing plates until all the profiled through holes in the sequencing plates contain the corresponding components, and the assembly positions of the components on the sequencing plates correspond to each other up and down. Lastly, all the sequencing plates are arranged into a riveting machine for pressing combination, so that a large number of products are assembled at one time. When the assembly method of the meter movements is used for assembling the meter movements such as pressure meters, a large number of components can be sequenced rapidly, a plurality of the movements can be pressed and formed on the pressing-combination riveting machine at one time, assembly accuracy and efficiency are high, and labor cost is low.

Owner:苏州千仓精密电子有限公司

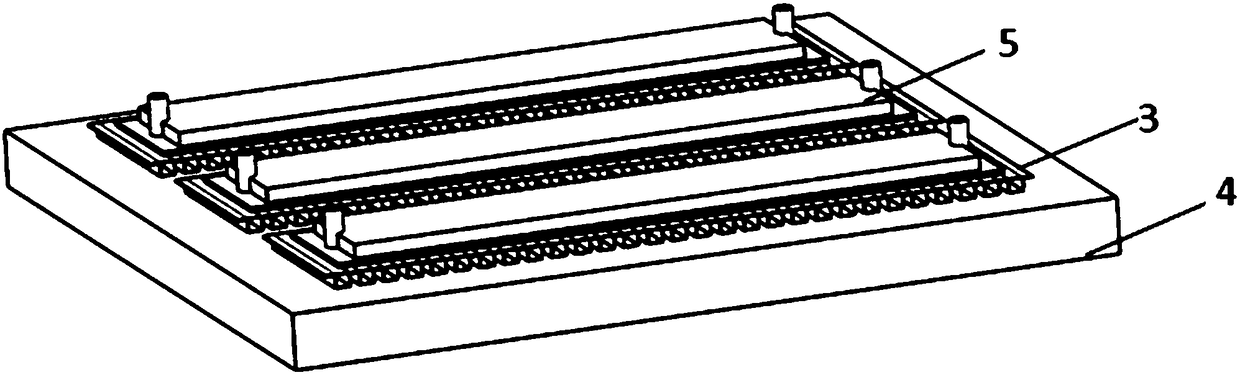

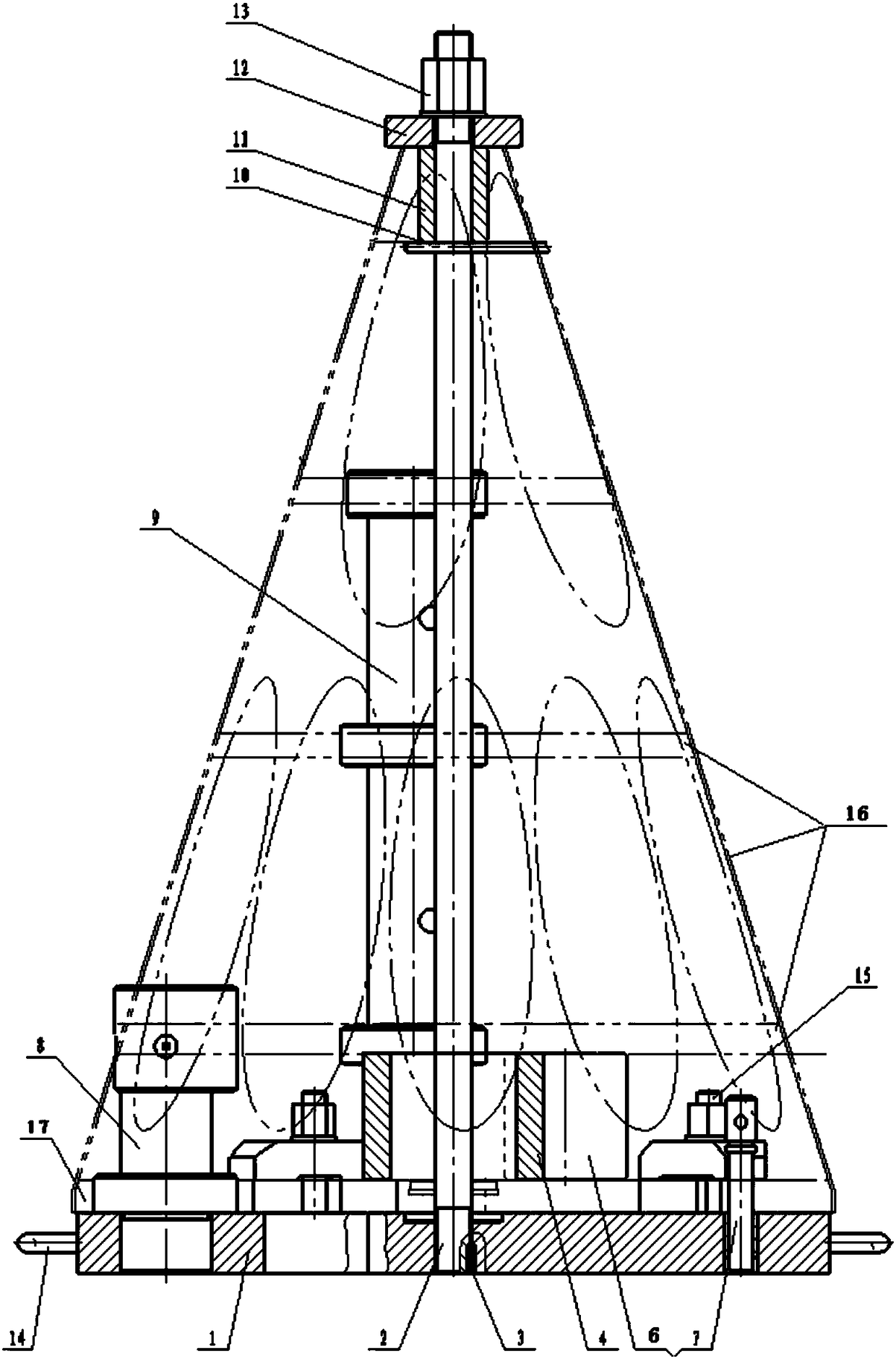

Tool fixture for permanent magnetic high field intensity magnetic filter magnetic system and assembly process thereof

InactiveCN104015147AEasy assemblyEasy to assembleWork holdersMagnetic separationMagnetic separatorMagnetic field magnitude

The invention discloses a tool fixture for a permanent magnetic high field intensity magnetic filter magnetic system and an assembly process thereof, and particularly relates to a permanent magnetic high field intensity magnetic system, wherein the even background magnetic induction intensity of each sorting space can reach more than 1.5 T. The tool fixture for the permanent magnetic high field intensity magnetic filter magnetic system and the assembly process thereof aim to solve the technical problems that the field intensity of the sorting area of a magnetic separator is low and uneven in distribution, and assembling is complex in the prior art. The tool fixture for the permanent magnetic high field intensity magnetic filter magnetic system comprises two magnetic system end plates, a magnetic system armor plate I and a magnetic system armor plate II which are parallel are fixed between the two magnetic system end plates, a screw rod I and a screw rod II are further arranged between the two magnetic system end plates, and the screw rod I and the screw rod II are located between the magnetic system armor plate I and the magnetic system armor plate II. By the adoption of the technical scheme, the tool fixture is simple, easy to assemble, convenient to operate and easy to achieve. Although permanent magnet materials with high performance are adopted, assembling is achieved with the help of manpower and auxiliary tool fixtures skillfully, the assembling is complete in a one-off mode, assembling quality is high, magnetic field intensity is high, a magnetic pole is intact in shape, and assembling quality is guaranteed.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

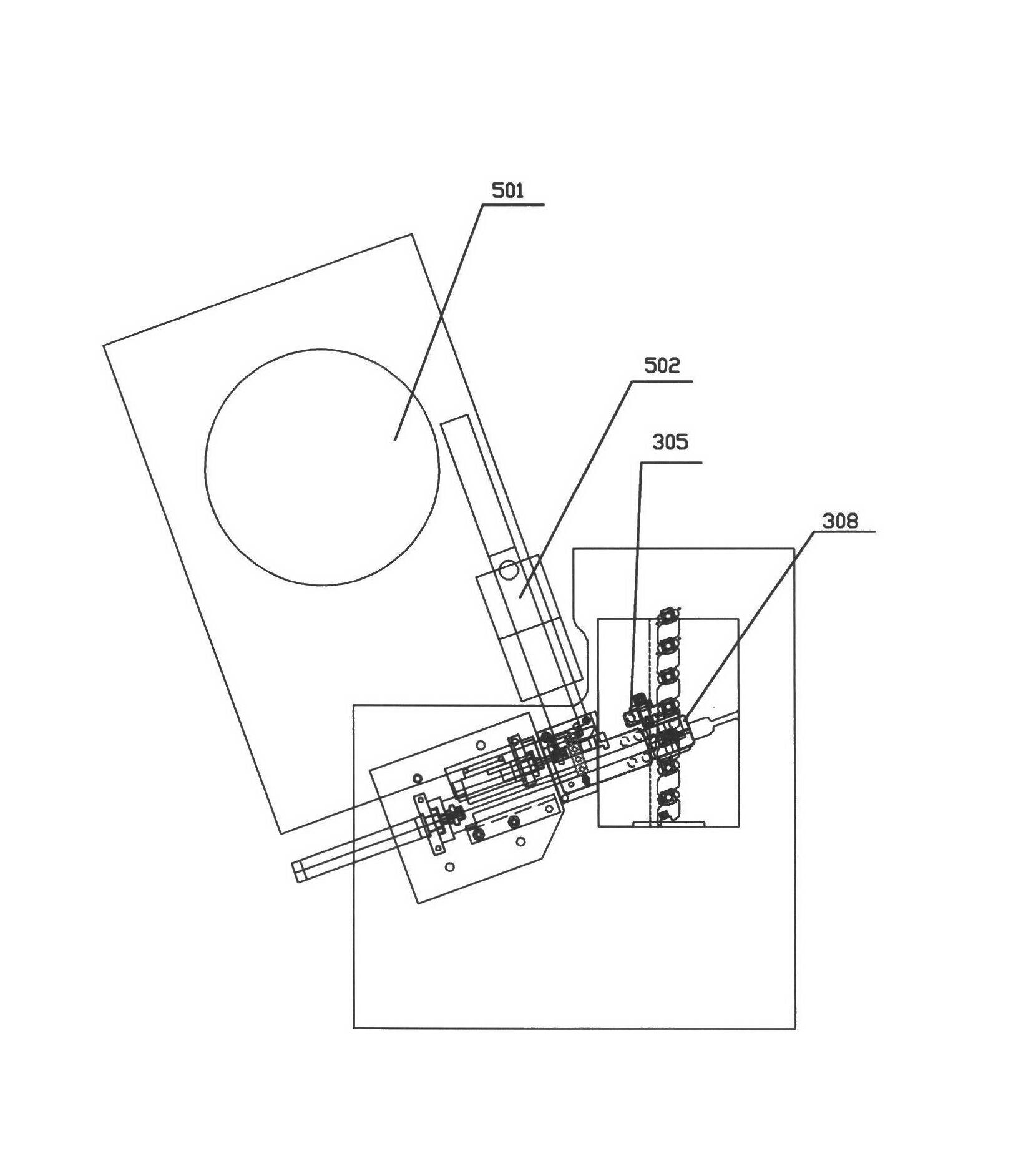

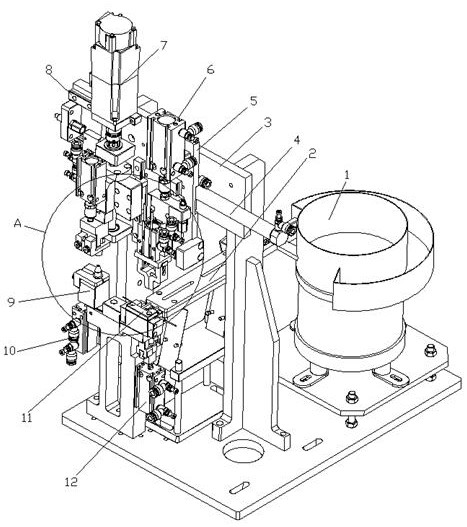

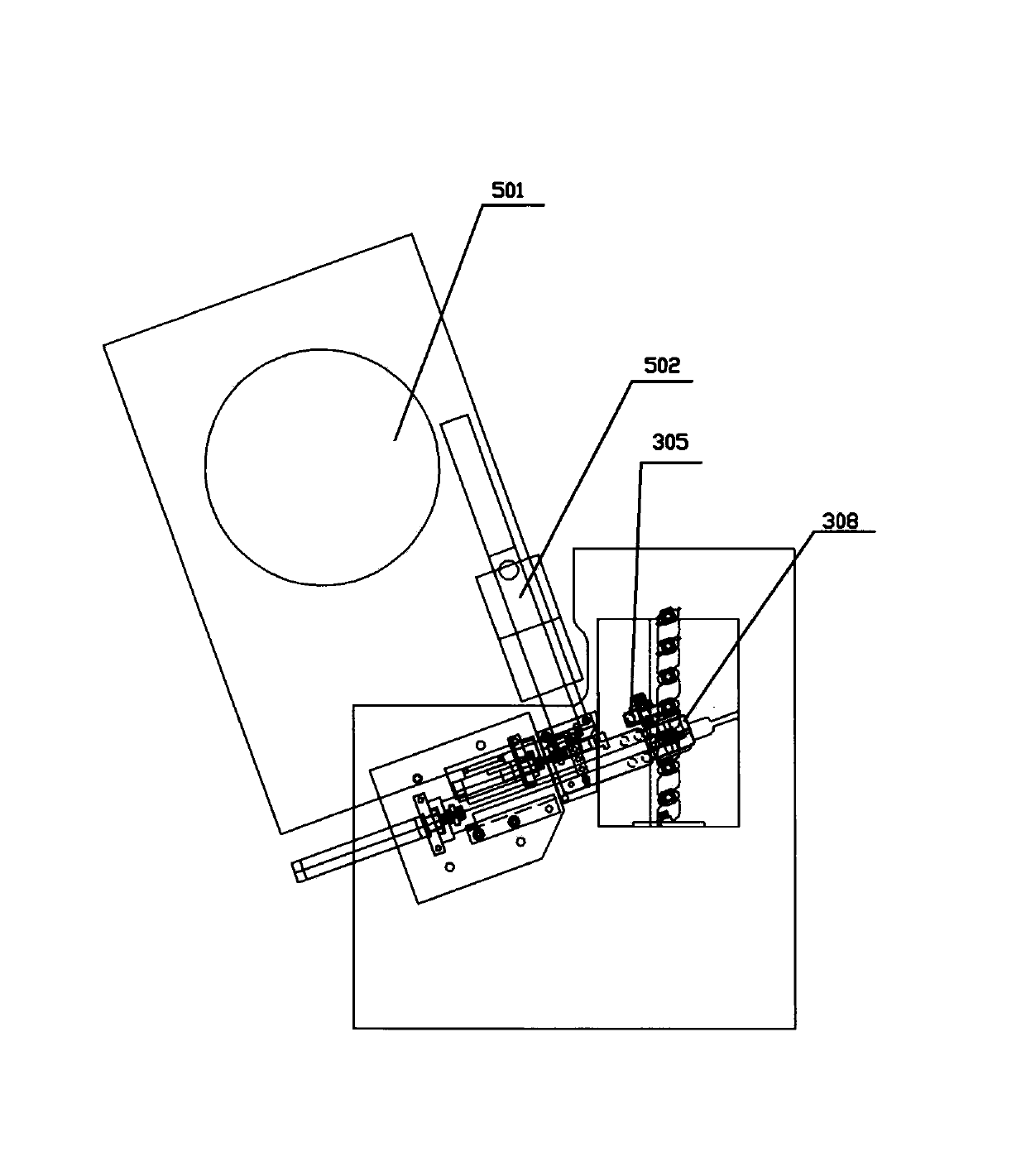

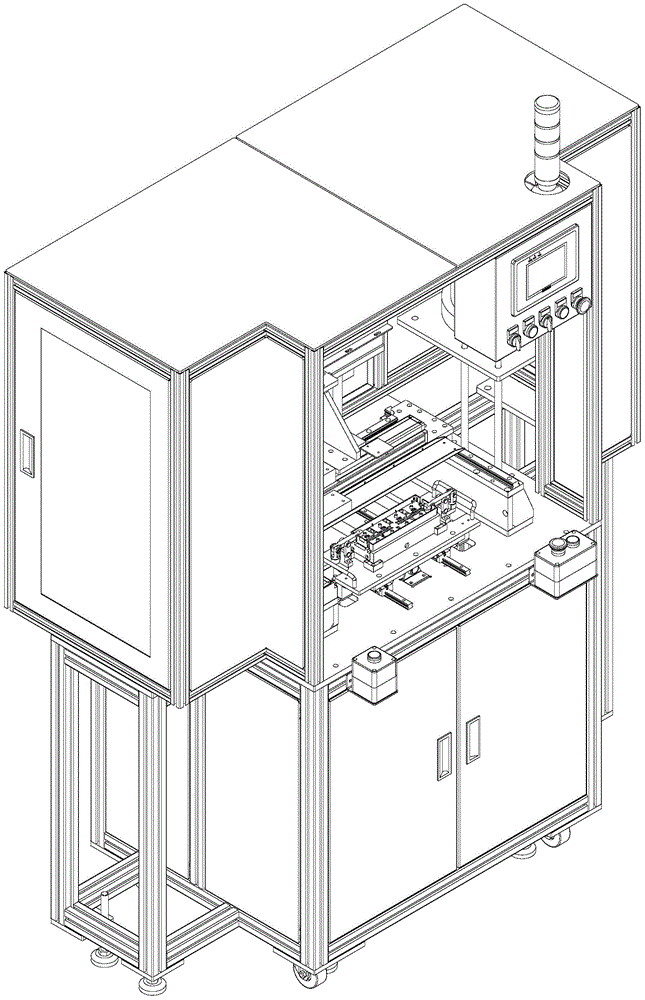

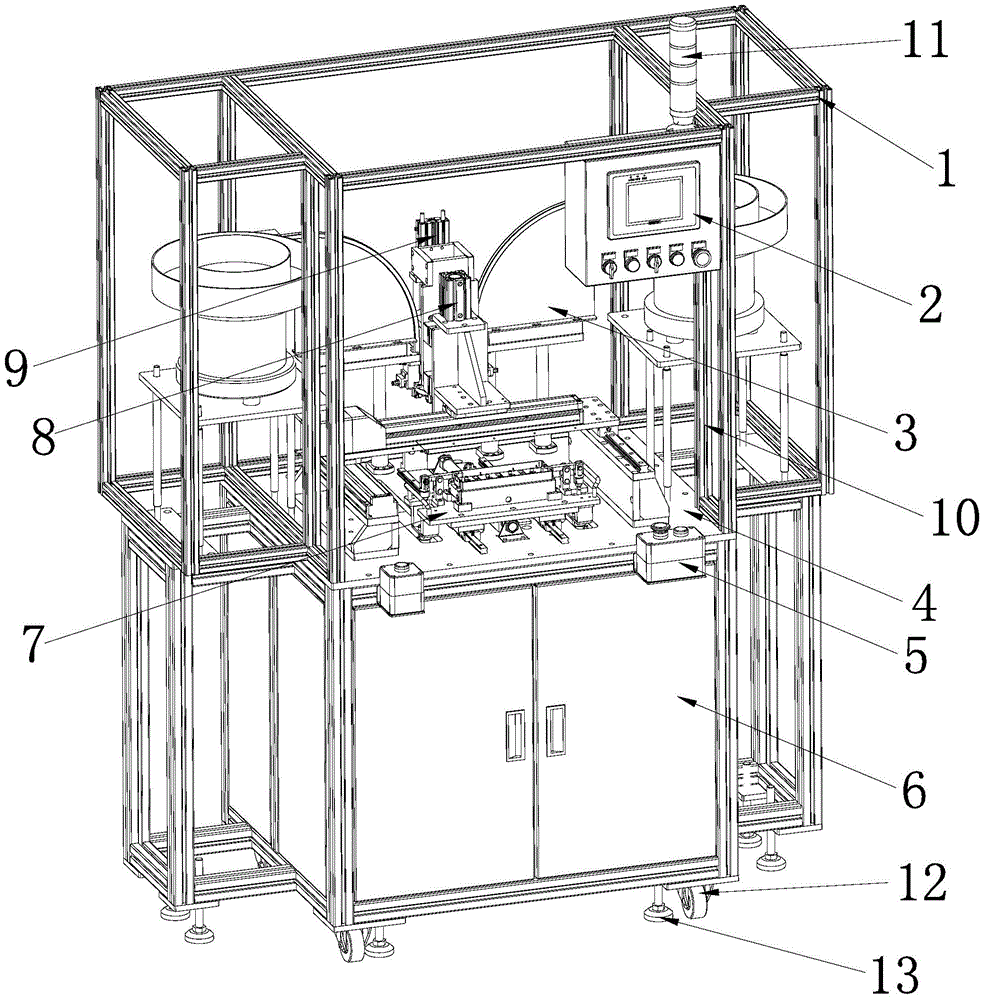

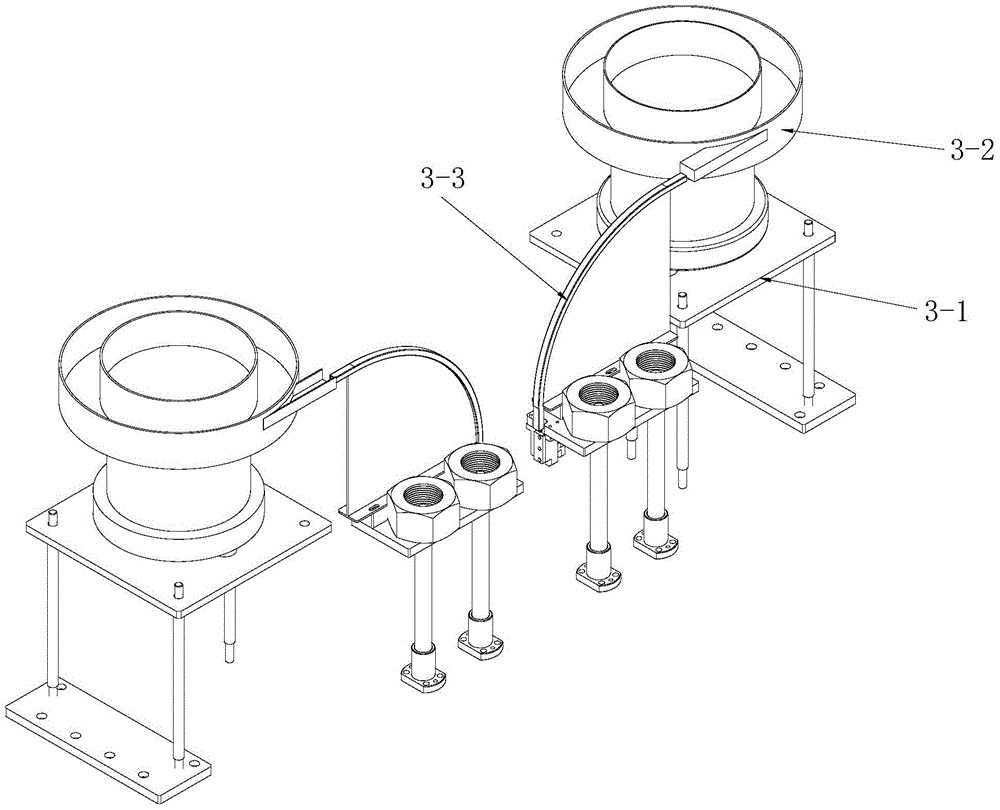

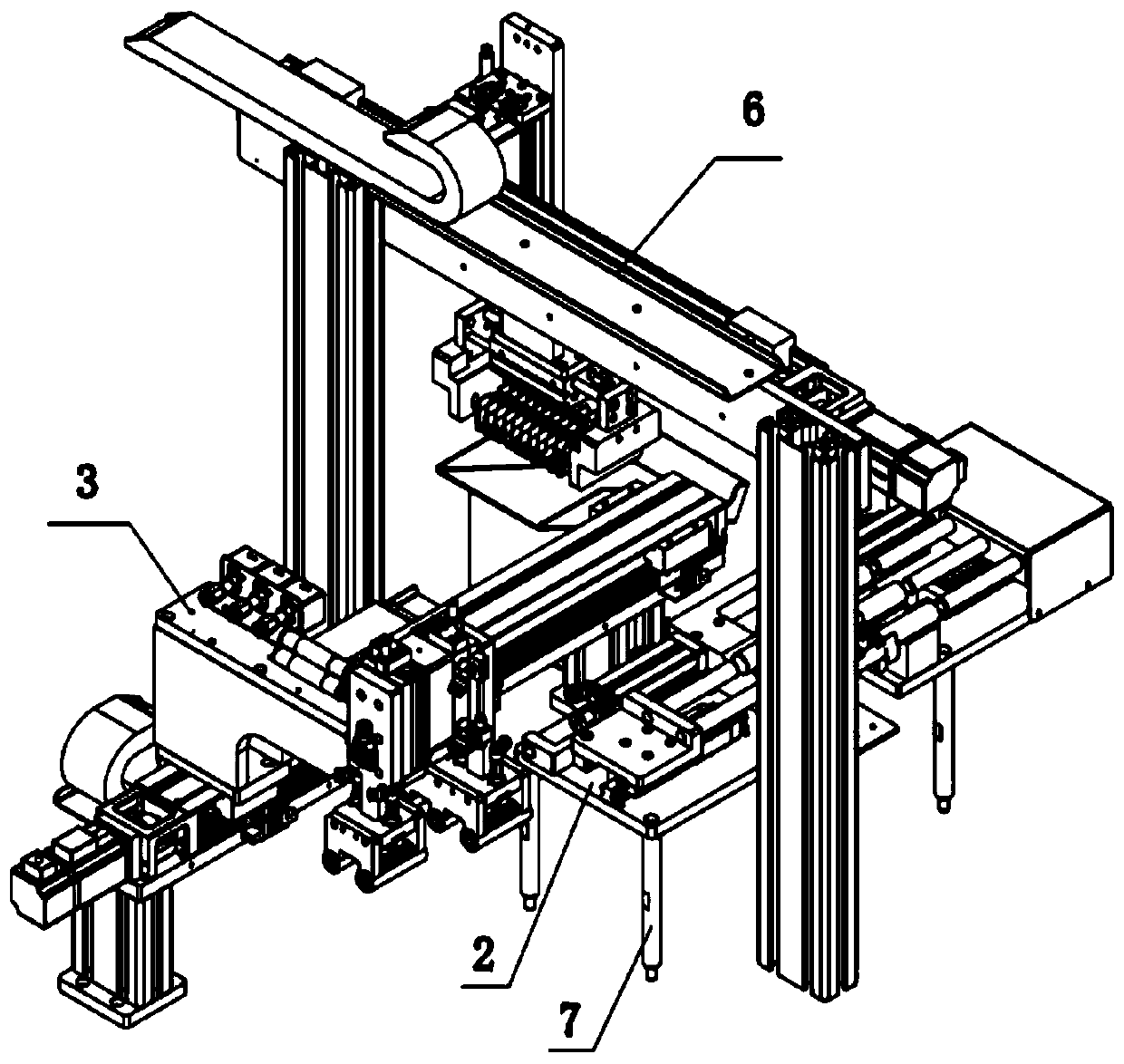

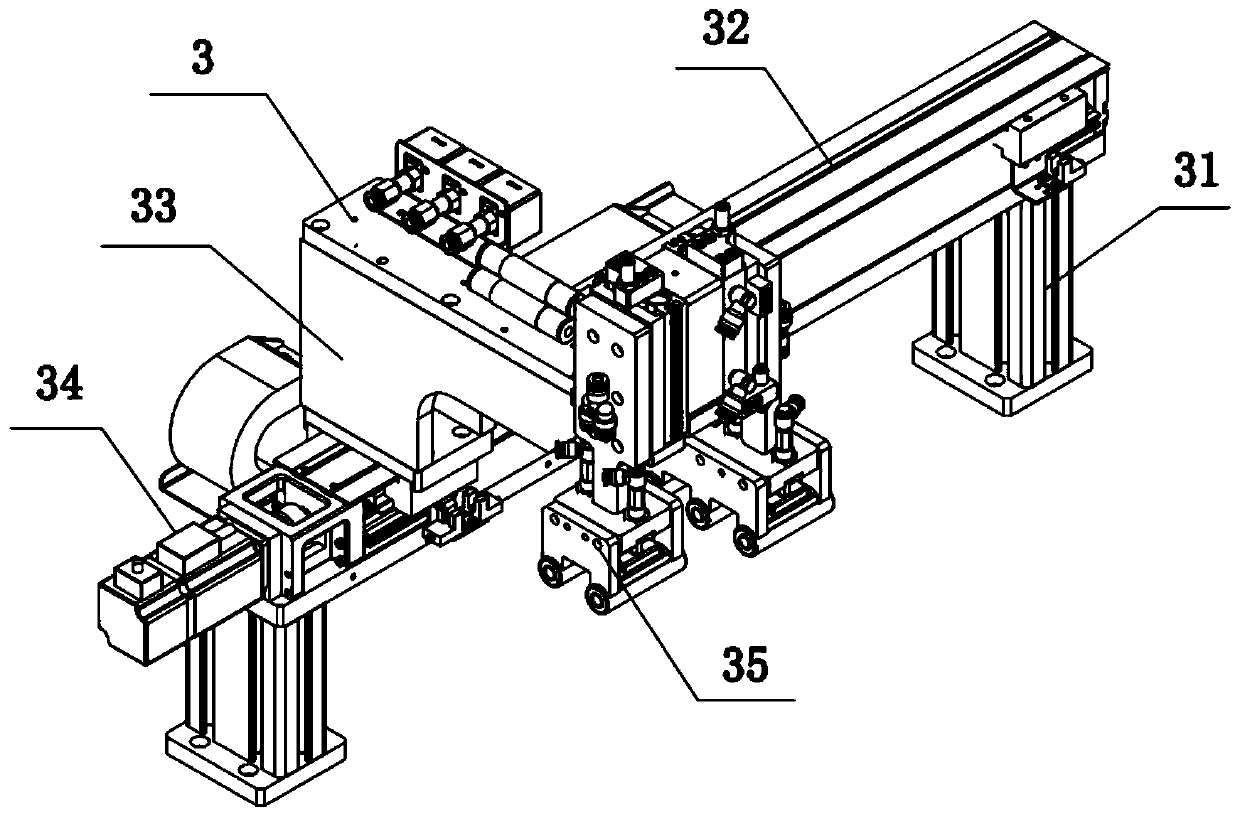

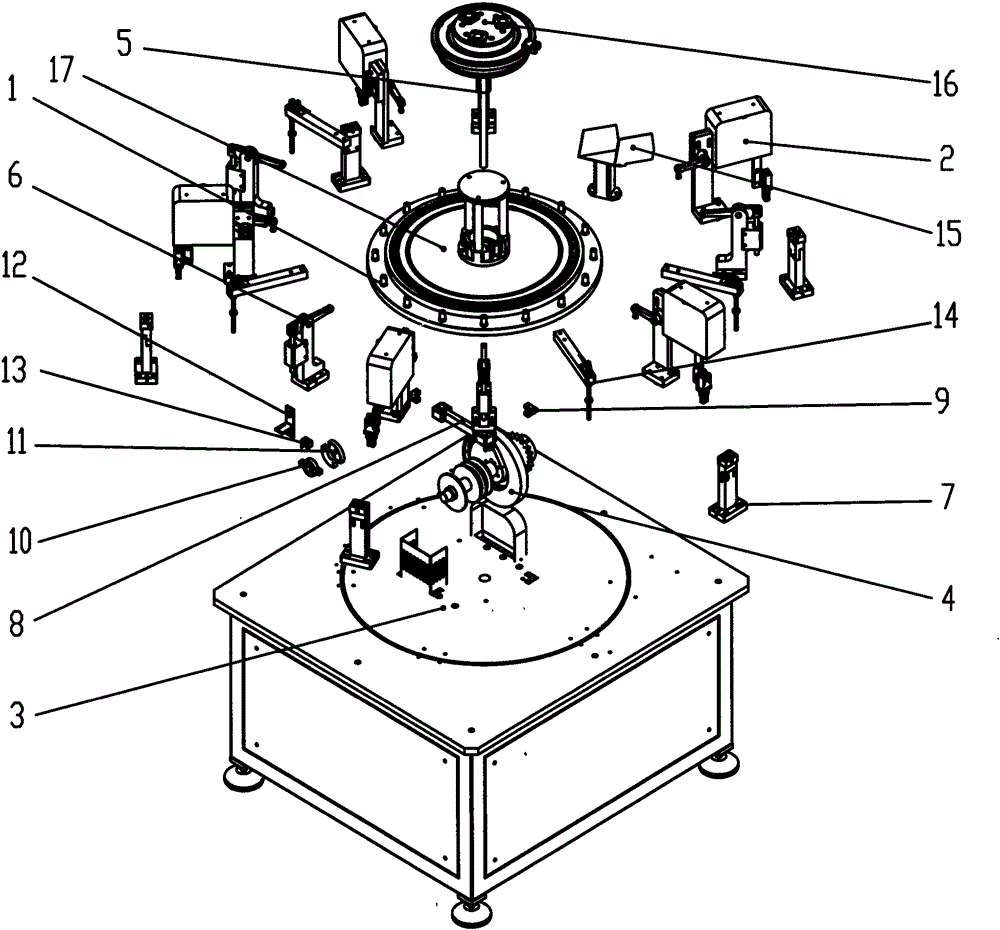

Automatic sealing ring assembling system

PendingCN112692550AAssembly applicableHigh degree of automationMetal working apparatusAutomationPhysics

The invention discloses an automatic sealing ring assembling system. The system comprises a sealing ring vibration feeding disc, a sealing ring direct vibration conveying groove body, a sealing ring positioning and separating assembly, a sealing ring carrying assembly, a sealing ring transferring assembly and a sealing ring installing assembly. By means of the mode, according to the automatic sealing ring assembling system, sealing rings are output to the sealing ring direct vibration conveying groove body one by one through the sealing ring vibration feeding disc, are arrayed in the sealing ring direct vibration conveying groove body and then are conveyed to the sealing ring positioning and separating assembly, and positioning and lifting separation of the single sealing ring are conducted. Then the sealing rings are transferred to the sealing ring transferring assembly through the sealing ring carrying assembly, finally the sealing rings are mounted on a one-way valve body on one side through the sealing ring installing assembly, so that the automation degree is high, and the mounting precision and efficiency are ensured.

Owner:JIANGSU COWAIN AUTOMATION TECH

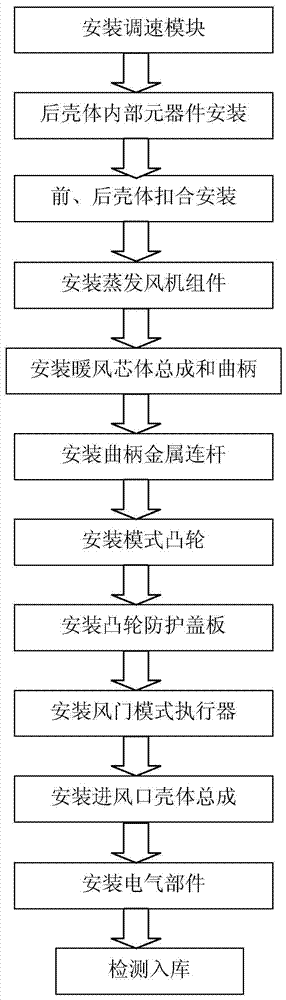

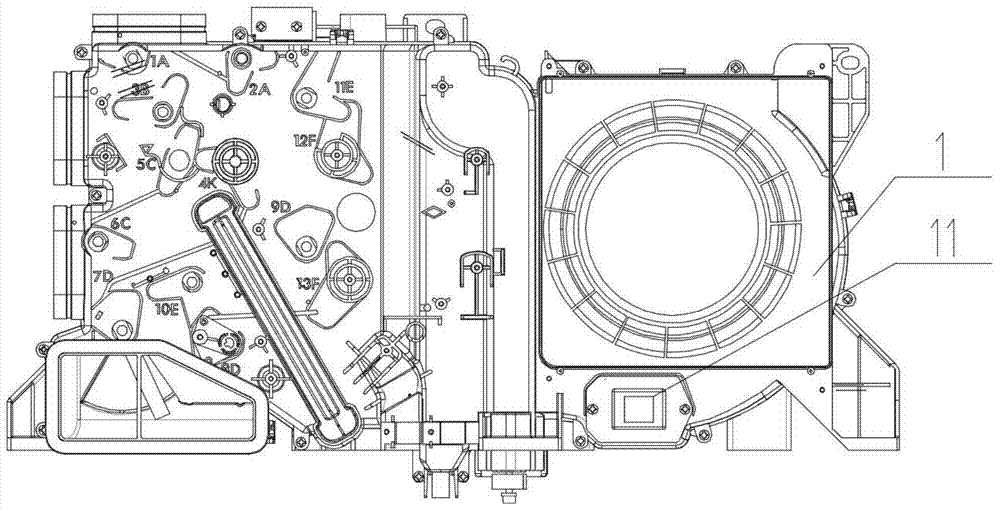

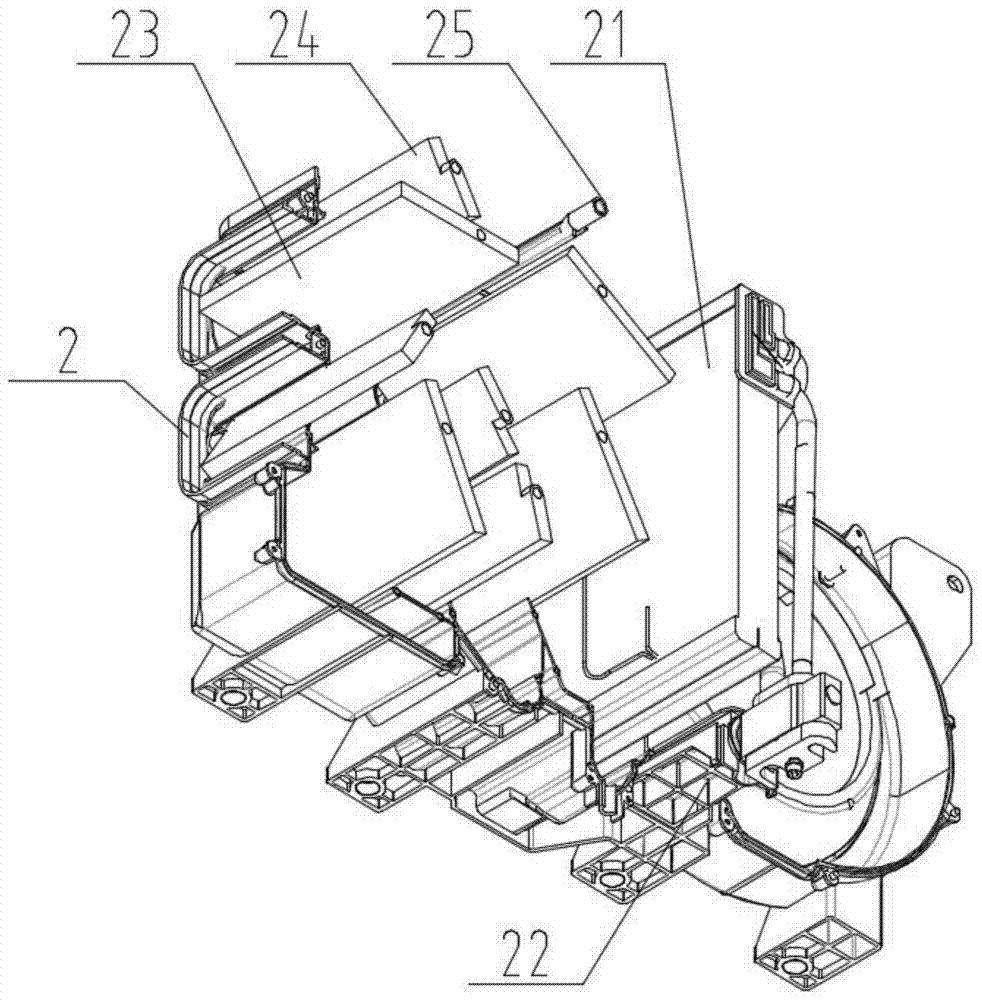

An assembly method of an excavator air conditioner indoor unit

ActiveCN105222423BAssembly applicableEasy snap-fit installationMechanical apparatusSpace heating and ventilation detailsAgricultural engineeringAir conditioning

The invention discloses an assembly method of an air conditioner indoor unit of an excavator, comprising the following steps: installing a speed regulating module (11); installing internal components of the rear casing (2); fastening and installing the front and rear casings; installing an evaporation fan Assembly (3); install heater core assembly (4) and crank; install crank metal connecting rod (5); install mode cam (6); install cam protection cover (7); install damper mode actuator (8 ); install the air inlet shell assembly (9); install electrical components; detect and put into storage. The method for assembling the air-conditioning indoor unit of the excavator does not need to make a special damper installation guide tool when installing the indoor air-conditioning unit of the excavator. Assembly of excavator air conditioner indoor unit.

Owner:徐州天一红点车用空调有限公司

Automatic assembly device of captive nut

InactiveCN102430656BRealize the assemblyAssembly applicableShaping toolsMetal-working feeding devicesAssembly machineEngineering

The invention relates to the field of automatic assembly machines, and discloses an automatic assembly device of a captive nut, which comprises an assembly frame platform, a stamping die, a feeding device and a nut-feeding mechanism, wherein the assembly frame platform realizes fixation and movement of the whole device, the stamping device is positioned above the assembly frame platform, the pressing die comprises a pre-bending punch, a bending slanted sliding block, an upper die assembly jacking the punch, and a lower die assembly comprising a bottom plate, the feeding mechanism comprise a feeding mechanism fixing device driven by a first cylinder, a feeding mechanism movable device driven by a second cylinder, and a third cylinder in a horizontal direction, the third cylinder is connected with the feeding mechanism movable device, a nut-feeding mechanism comprises a fifth cylinder, a square push rod and a nut sliding chute, the push rod is driven to move in the nut sliding chute, and an output of the nut sliding nut extends into the stamping die. The invention realizes automatic assembly of the captive nut, has capabilities of effectively saving labor cost and increasing production efficiency, and is suitable for production of massive captive nuts.

Owner:苏州瑞玛精密工业股份有限公司

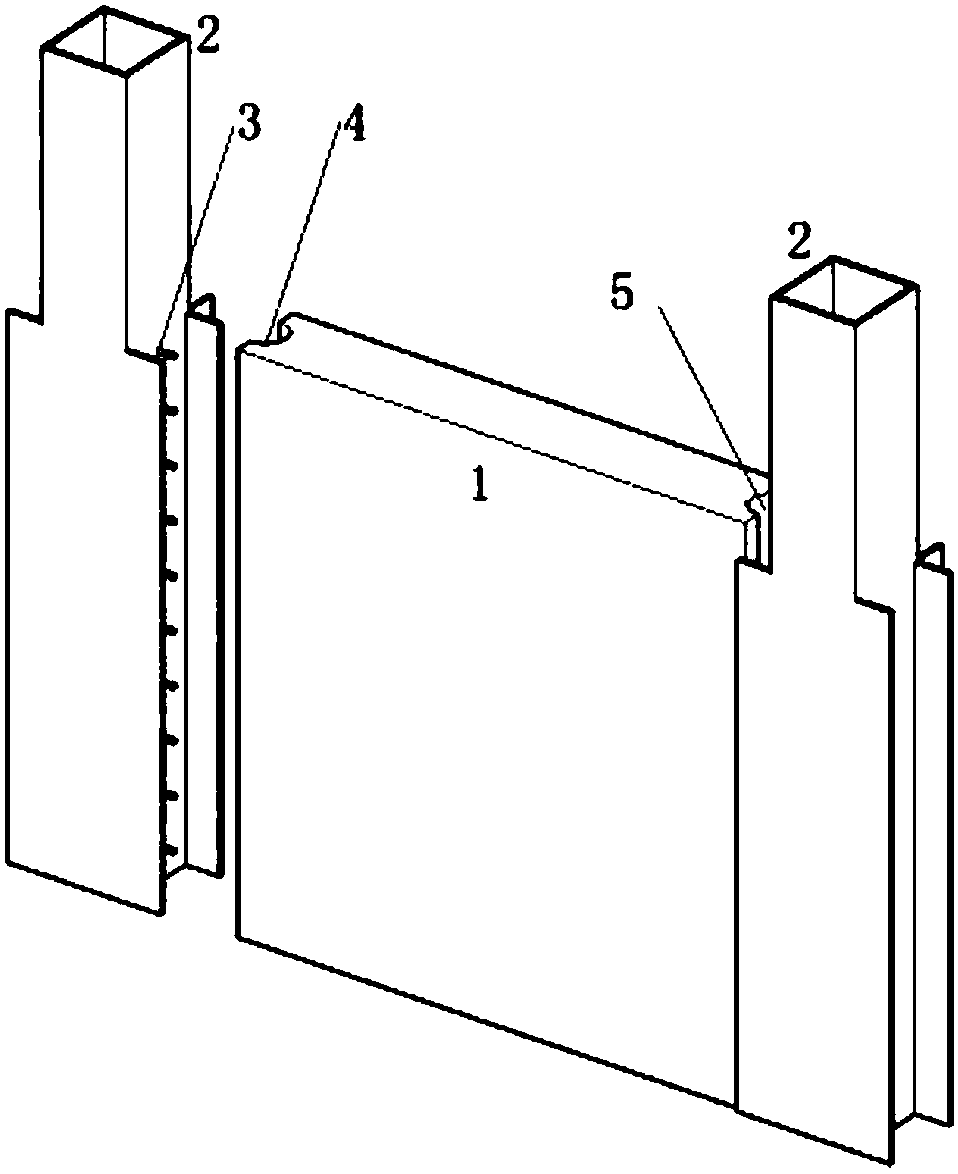

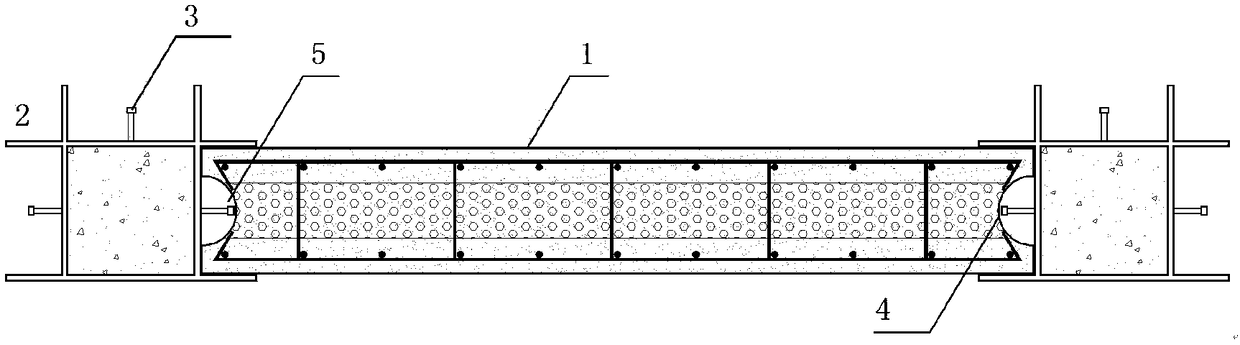

A method of connection structure between square steel tube concrete column with lug plate and prefabricated shear wall

InactiveCN106121086BAssembly applicableImprove the level of industrializationWallsSteel frameSeismic resistance

The invention provides a connection structure of assembly type steel pipe concrete columns and an assembly type shear wall and a construction method of the connection structure. The connection structure comprises the assembly type composite heat insulation module shear wall, the assembly type square steel pipe concrete columns with anchorage plates, column side studs, semicircular ribbed grooves in the side faces of the shear wall, and a high-strength grouting material. The structure is superior to ordinary rural dwelling structures in anti-seismic property, and a system with two seismic fortification lines is formed. In addition, the final damage belongs to ductile failures, and the situation that due to the fact that part of the structure or part of members are damaged, the whole system is collapsed is avoided. According to the square steel pipe concrete columns with the anchorage plates and the short studs arranged on the side faces and the shear wall with the semicircular ribbed grooves, the assembly type shear wall and a light steel frame are connected firmly, the integrity is good, assembly is easy, the construction period is short, no new building waste is generated during construction, the requirements for energy saving and environmental friendliness are met, the requirements of dwellings for industrialization and scale production are also met, and the connection structure is a novel wall connection structure suitable for seismic resistance, energy saving and assembly integration of current rural low-rise buildings.

Owner:BEIJING UNIV OF TECH +1

An O-ring automatic assembly device

ActiveCN109693093BAssembly applicableAvoid scratchesMetal working apparatusCouplingElectric machinery

The invention discloses an automatic assembly device for an O-shaped sealing ring in the technical field of sealing ring assembly. The inner wall of the turning claw is pinned with an L-shaped connecting rod, the top of the L-shaped connecting rod is pinned with a connecting plate, the top wall of the connecting plate is screwed with a first screw, and one end of the first screw is connected with a second screw through a coupling. The output shaft of a driving motor, the outer wall of the sliding table connecting cylinder is sleeved with a sealing ring and the ring sleeve plate, the left wall of the sliding table connecting cylinder is screwed with a second driving motor, and the output shaft of the second driving motor is installed through a coupling. The second screw, the middle part of the inner wall of the sealing ring stripping plate is provided with a turning claw accommodation groove, and the bottom wall of the sealing ring stripping plate is evenly clamped with balls. This device has a simple structure and is easy to use, and can realize the automatic assembly of the O-ring. Operation, suitable for the assembly of various diameter O-rings.

Owner:安徽沃尔顶密封工业股份有限公司

An automatic feeding and assembling system for light guide body in automobile interior decoration

The invention relates to the field of mechanical technology, in particular to an automatic feeding and assembling system for light guides in automobile interior decoration. An automatic feeding and assembling system for light guides in automobile interior decoration, including a frame, a workbench, and a control panel, characterized in that: a workbench is horizontally arranged in the middle of the frame, and a profiling mold structure is arranged on the workbench. A plate loading mechanism is arranged above the profiling mold structure, and a feeding mechanism is connected to the racks located on the left and right sides of the plate loading mechanism; the front of the plate loading mechanism is provided with a downward pressure cylinder. Compared with the existing technology, the structure is simple and compact, the cost is low, the maintenance and repair are simple, the operation is simple, the assembly is easy, and it is suitable for mass production; the labor intensity of workers is reduced, the assembly quality is stable, the assembly efficiency is greatly improved, and assembly man-hours are saved.

Owner:SHANGHAI KEY AUTOMOTIVE PLASTIC COMPONENT

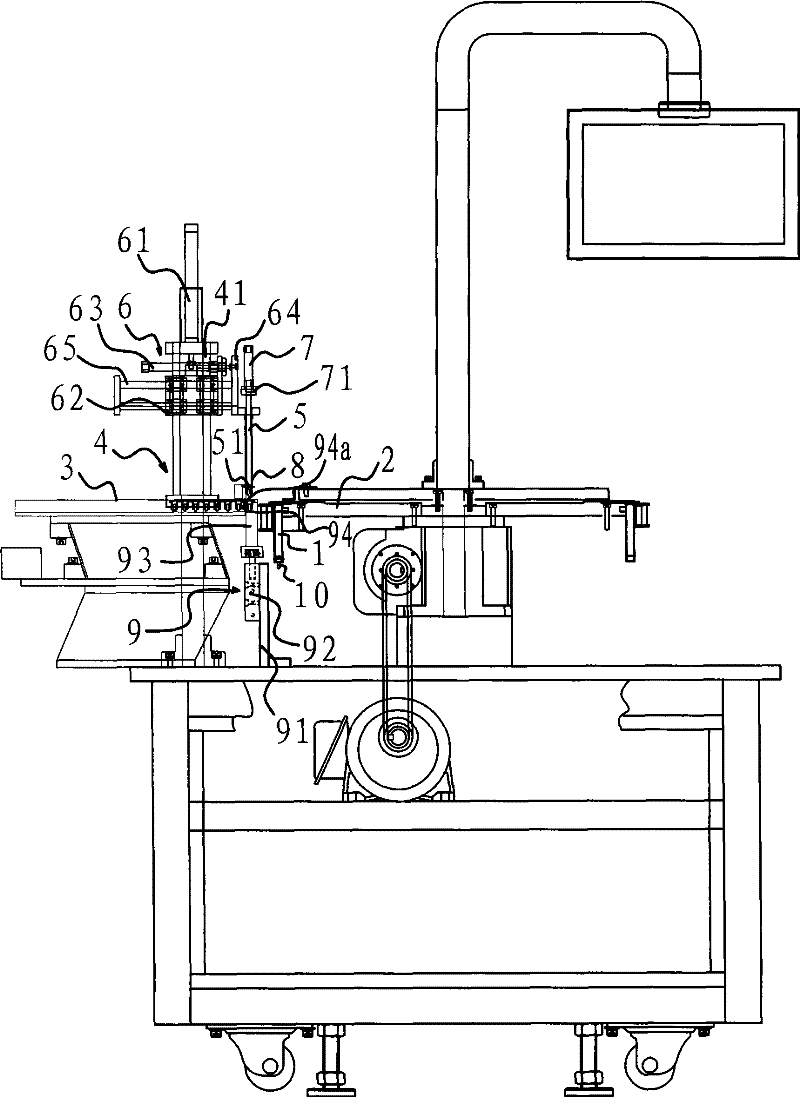

Syringe fitting assembling device for safety self-destructing syringe assembling machine

InactiveCN101104086BImprove work efficiencyReduce man-made pollutionMetal working apparatusEngineeringTransfer mechanism

The invention provides a needle fitting assembly device of a safety self-destruction syringe assembly machine, which belongs to medical device production apparatus technical field. The invention solves the problems that the current needle fitting assembly device of the safety self-destruction syringe assembly machine has unqualified sanitation request, and the working stability is low. The needle fitting assembly device of the safety self-destruction syringe assembly machine includes a frame, an assembly rod that can be attached with the needle fittings at the lower end part thereof is arranged on the frame, a transfer mechanism that can be used to move the assembly rod and insert the lower end part thereof into the needle is arranged between the frame and the assembly rod, and a separation mechanism that can separate the needle fittings attached to the lower end part thereof is arranged on the assembly rod. The needle fitting assembly device of the safety self-destruction syringe assembly machine has advantages of high working efficiency, safety and health, broad application range, availability for being used on the assembling of a plurality of syringes, and stable and reliable operation.

Owner:王兴章

A method for installing continuous casting rolls with interference fit short mandrels

Owner:SINOSTEEL XIAN MACHINERY

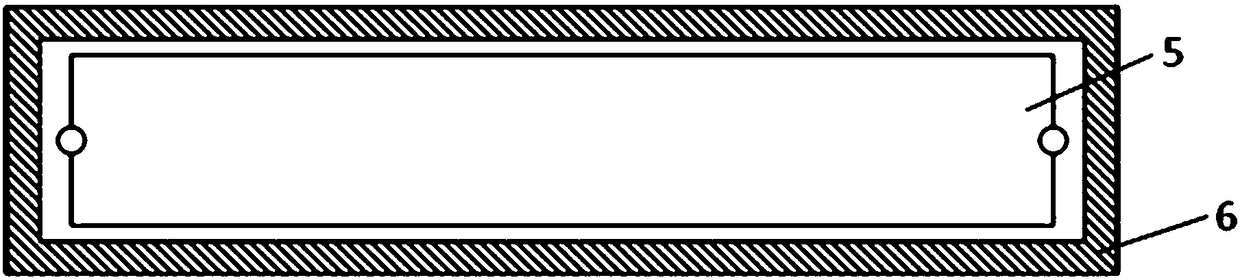

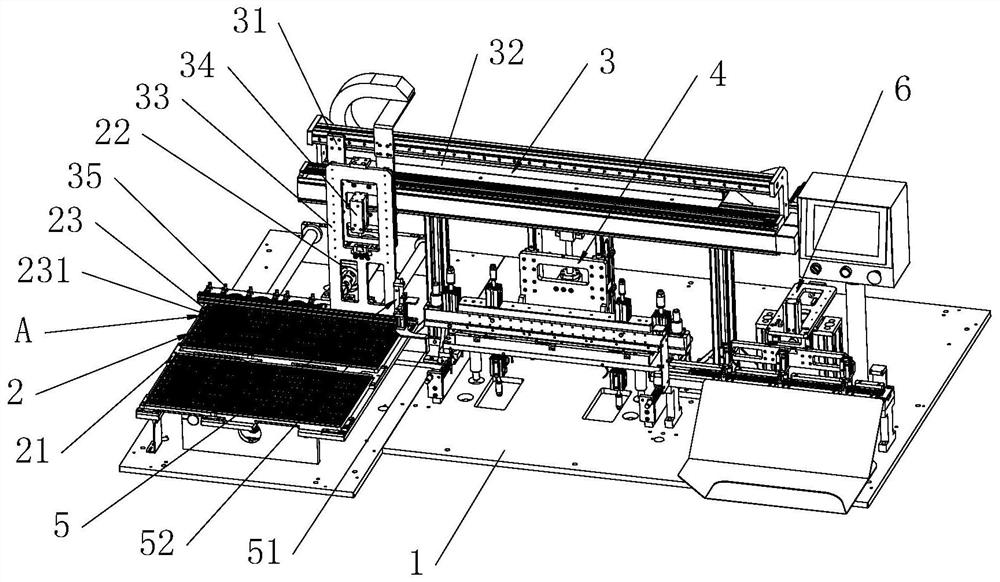

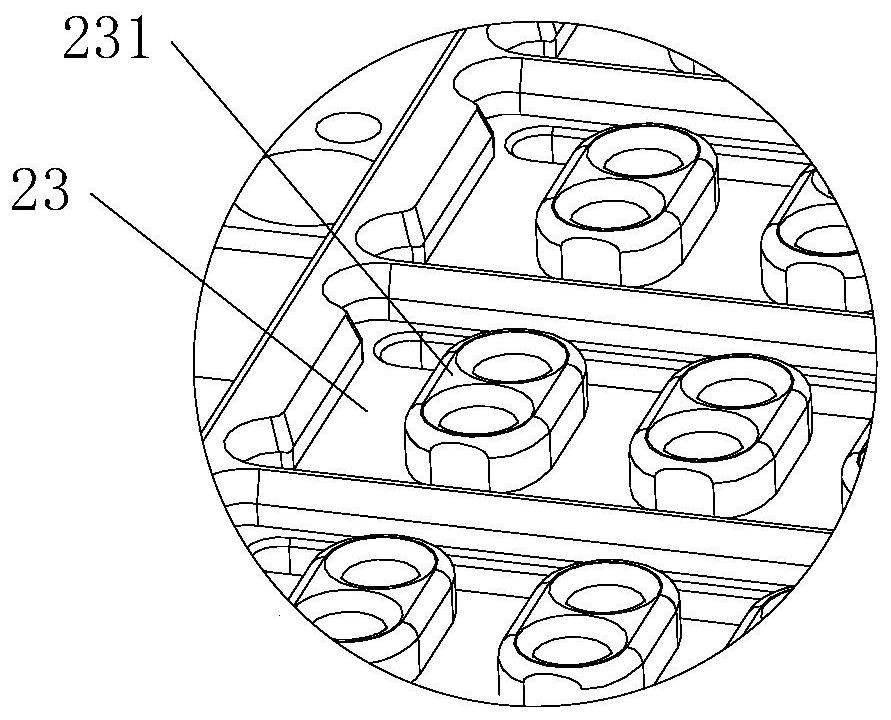

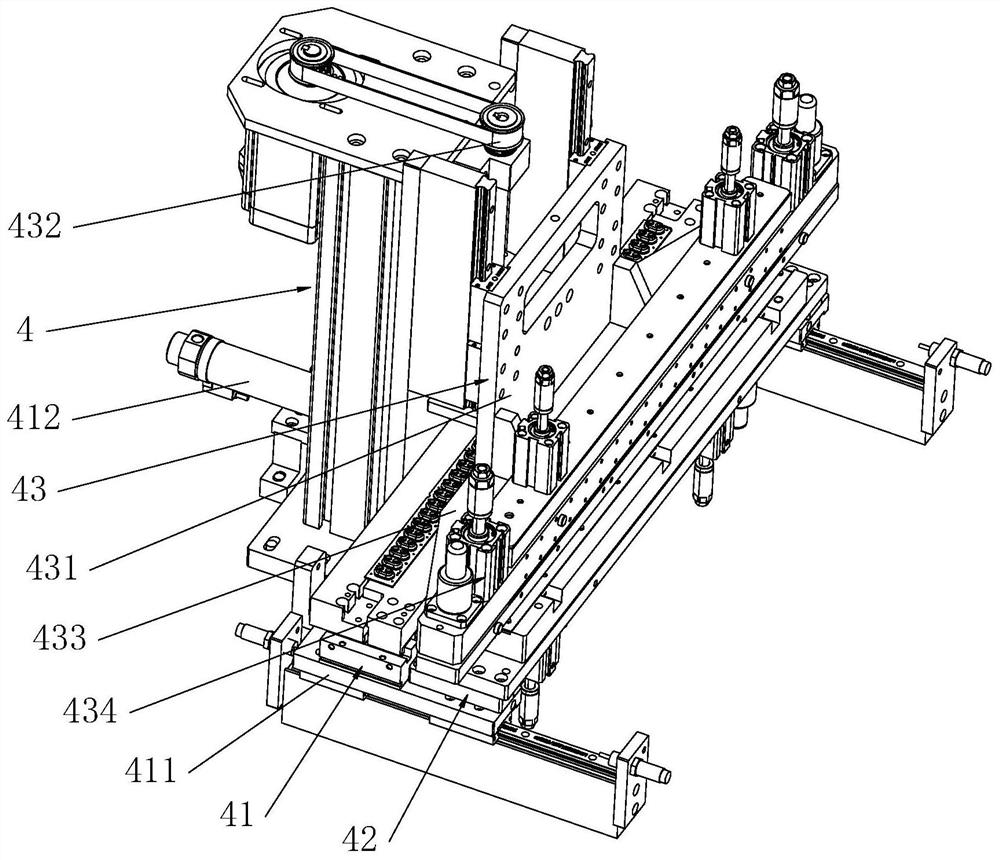

Keyboard plate and silicone key automatic assembly machine

ActiveCN113414571BRealize automatic assemblyAssembly applicableMetal working apparatusComputer hardwareKey pressing

The invention relates to the technical field of electronic pianos, in particular to an automatic assembly machine for piano key boards and silicone keys, including a workbench, which is provided with a silicone key feeding device, a transfer manipulator, an assembly unit, a feeding device, and a finished product unloading device. device; the transfer manipulator is used to send the silicone button to be assembled in the silicone button feeding device to the assembly unit for assembly; the feeding device is used to send the assembled finished product in the assembly unit to the finished product In the blanking device; the present invention can replace the manual way to insert the silicone keys into the keyboard, which can reduce a lot of workload of the operator, improve the assembly efficiency of the keyboard and the silicone keys, and can be well applied to large batches The assembly of the key board and the silicone keys.

Owner:DONGGUAN LONGJOIN ELECTRONICS

Code scanning device for battery separation and assembly

ActiveCN111129532AImprove assembly efficiencyAssembly applicablePrimary cell manufactureAssembling battery machinesProcess engineeringBattery cell

The invention discloses a code scanning device for battery separation and assembly in the technical field of battery assembly and detection. The device comprises a finished product taking and placingmechanism, and a battery assembling mechanism is arranged at the bottom of the finished product taking and placing mechanism; a battery separation module is arranged on the right side of the battery assembly mechanism; a code scanning gun is arranged at the bottom of the battery assembling mechanism; the code scanning gun is fixed on a moving station of the sliding table cylinder; a finished product box is arranged on the right side of the sliding table cylinder; the batteries on the conveying belt are taken out through the battery separation module, and the positive and negative batteries areseparated out; the sliding table cylinder drives the code scanning gun to move to the code scanning position for code scanning, and the assembled battery pack is taken out through the finished product taking and placing mechanism. According to the invention, the space is effectively utilized, assembling and code scanning can be conducted at the same time, the battery assembling efficiency is improved, and the device is suitable for assembling of four-core and five-core battery packs.

Owner:荣旗工业科技(苏州)股份有限公司

Bearing mounting tool

The invention discloses a bearing mounting tool. The bearing mounting tool comprises a U-shaped base, an ejection mechanism and a fixed cylinder, wherein the fixed cylinder is fixedly mounted at one end of the U-shaped base; a top base is arranged in the fixed cylinder; one end of the ejection mechanism is fixedly mounted on the side wall of the U-shaped base, and the other end is fixedly connected with the top base; the ejection mechanism is a hydraulic jack or a screw rod; when the ejection mechanism is the hydraulic jack, the ejection mechanism is fixedly connected with one end of the fixedcylinder; when the ejection mechanism is the screw rod, the ejection mechanism is in threaded connection with one end of the fixed cylinder, and a handle is arranged at one end of the screw rod; anda plurality of ejector rods are symmetrically arranged on one side of the top base, and at least two ejector rods are provided. The ejection mechanism is arranged on one side of the top base, and themultiple ejector rods are symmetrically arranged on the other side of the top base; the ejection mechanism is used for driving the top base to slide to transfer acting force to the ejector rods; and the ejector rods press bearings into parts to be assembled, so that the bearing mounting tool is specifically suitable for assembly of the bearings in shaft sleeve parts.

Owner:冠县恒祥轴承制造有限公司

Machine tool for product assembling

The invention discloses a machine tool for product assembling. The machine tool for product assembling comprises a rack, wherein the upper part of the rack is equipped with a discharging bucket; a speed reducer is mounted in the rack; an indexing mechanism, indexing plates, a sensor plate and a sensor are horizontally mounted at the upper part of the rack; the speed reducer is connected with a lifting plate assembly through a cam assembly; a first indexing plate, a second indexing plate and an indexing top plate are mounted on the indexing mechanism; a manipulator assembly, a riveting pressing assembly and a detecting assembly are connected to the indexing top plate; a lifting top plate is arranged at the upper part of the lifting plate assembly, and a directional arm assembly is connected to the lower part of the lifting plate assembly; a connecting part, a connecting rod, a sector gear and a rotating gear are mounted between the lifting plate assembly and the manipulator assembly; a clamping claw mechanism is mounted on the manipulator assembly; the lifting plate assembly is connected with a big arm set through a connecting shaft, a rotating arm, a grooved plate and a cross slide block. The machine tool for the product assembling has the beneficial effects that the production cost is low; the use is convenient; the product assembling can be automatically carried out; the assembling of various products applies, so that the generality is high.

Owner:余姚市爱佟塑料制品厂

A bearing installation tool

ActiveCN112264961BAssembly applicableEasy fine-tuningMetal-working hand toolsJackscrewIndustrial engineering

The invention discloses a bearing installation tool, which comprises a U-shaped seat, an ejection mechanism, and a fixing cylinder. The fixed cylinder is fixedly installed on one end of the U-shaped seat. It is installed on the side wall of the U-shaped seat, and the other end is fixedly connected with the top seat. The ejection mechanism is a hydraulic jack or a screw. When the mechanism is a screw, the ejector mechanism is threadedly connected to one end of the fixed cylinder, and a handle is provided at one end of the screw; one side of the top seat is symmetrically provided with a plurality of ejector rods, and at least two ejector rods are provided. In the present invention, an ejection mechanism is arranged on one side of the top seat, and a plurality of symmetrical ejector rods are arranged on the other side of the top seat, and the ejector mechanism is used to drive the top seat to slide, thereby transmitting the active force to the ejector rod, and the ejector rod presses the bearing Into the interior of parts to be assembled, especially suitable for the assembly of bearings in shaft sleeve parts.

Owner:冠县恒祥轴承制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com