High-performance sealant for building assembling and preparation method thereof

A sealant, high-performance technology, used in chemical instruments and methods, adhesives, transportation and packaging, etc., can solve the problems of mildew resistance and adhesion with concrete, not environmentally friendly, affecting colloid performance, etc., to reduce Colloidal tensile modulus, good aging resistance, and the effect of improving bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A high-performance sealant for building assembly, comprising the following components:

[0039] Element Weight (kg) Silane modified polyether 30000T 30 Polyether polyol PPG 5616 8 Hydrogenated bisphenol A diglycidyl ether 2 Nano Light Calcium Carbonate 40 BYK-W 985 1 γ-Aminopropyltriethoxysilane 1.5 Fumed silica R202 1.5 anti aging agent 0.9 Antifungal agent SZ99P 0.2 coupling agent 0.3 Bis(acetylacetonate) dibutyltin 0.1

[0040] Among them, the anti-aging agent is composed of β-(4-hydroxyphenyl-3,5-di-tert-butyl) propanoic acid n-octadecyl alcohol: 2'-(2'-hydroxy-3'-tert-butyl-5' -Methylphenyl)-5-chlorobenzotriazole: bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate mixed at a weight ratio of 3:2:2 . The coupling agent is prepared by mixing N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane:bis(acetoacetate ethyl)di-n-butoxy titanate in a weight ratio of 1:1.

[0041] The preparation method o...

Embodiment 2

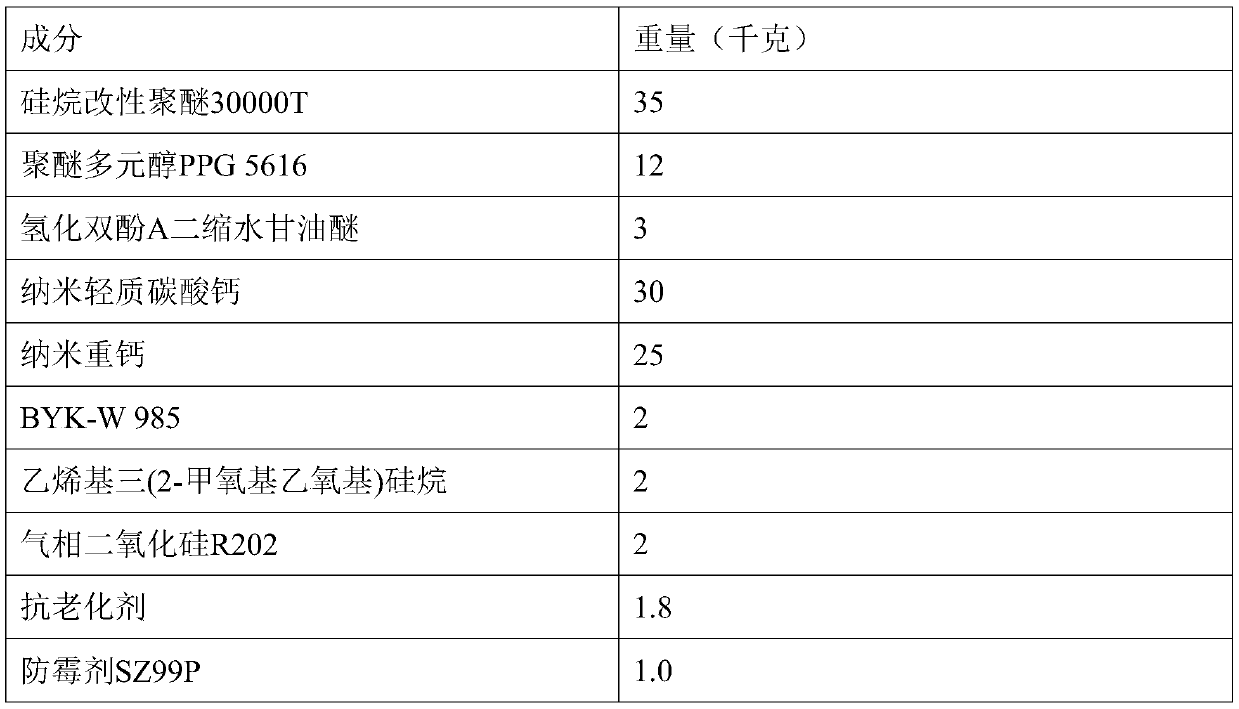

[0047] A high-performance sealant for building assembly, comprising the following components:

[0048]

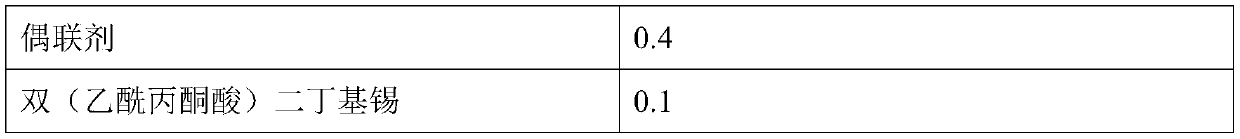

[0049]

[0050] Among them, the anti-aging agent is composed of β-(4-hydroxyphenyl-3,5-di-tert-butyl) propanoic acid n-octadecyl alcohol: 2'-(2'-hydroxy-3'-tert-butyl-5' -Methylphenyl)-5-chlorobenzotriazole: bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate mixed at a weight ratio of 3:2:2 . The coupling agent is prepared by mixing N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane:bis(acetoacetate ethyl)di-n-butoxy titanate in a weight ratio of 1:1.

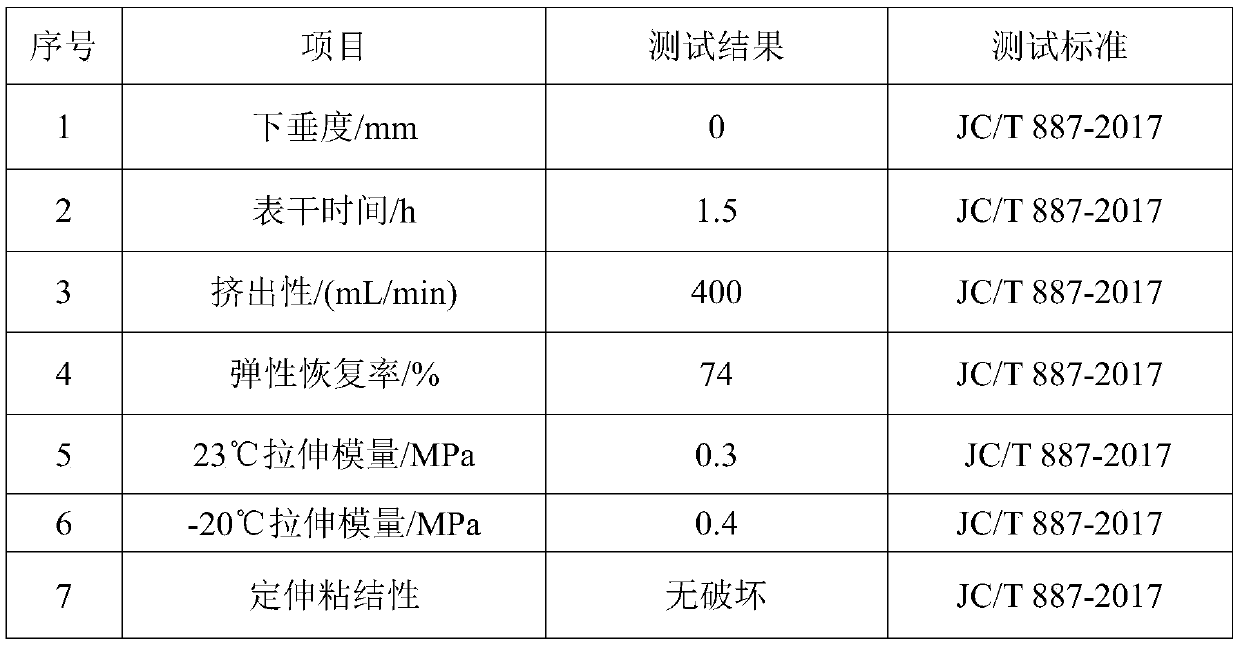

[0051] The preparation method of above-mentioned sealant is as follows:

[0052] First add silane-modified polyether 30000T, polyether polyol PPG 5616, hydrogenated bisphenol A diglycidyl ether, BYK-W985, and fumed silica R202 into the twin-shaft power mixer, stir and rotate at 10r / min, and disperse Rotate at 200r / min, stir for 15min; then add anti-aging agent, SZ99P antifungal agent, stir for 5min; then add nano-light cal...

Embodiment 3

[0058] A high-performance sealant for building assembly, comprising the following components:

[0059] Element Weight (kg) Silane modified polyether 30000T 50 Polyether polyol PPG 5616 11.2 Hydrogenated bisphenol A diglycidyl ether 2.8 Nano Heavy Calcium 35 BYK-W 985 1.2 Vinyltris(2-methoxyethoxy)silane 1 Fumed silica R202 3 anti aging agent 2.4 Antifungal agent SZ99P 1.5 coupling agent 0.8 Bis(acetylacetonate) dibutyltin 0.2

[0060] Among them, the anti-aging agent is composed of β-(4-hydroxyphenyl-3,5-di-tert-butyl) propanoic acid n-octadecyl alcohol: 2'-(2'-hydroxy-3'-tert-butyl-5' -Methylphenyl)-5-chlorobenzotriazole: bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate mixed at a weight ratio of 3:2:2 . The coupling agent is prepared by mixing N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane:bis(acetoacetate ethyl)di-n-butoxy titanate in a weight ratio of 1:1.

[0061] The preparation method of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com