Tool fixture for permanent magnetic high field intensity magnetic filter magnetic system and assembly process thereof

A tooling fixture and assembly process technology, which is applied in the field of magnetic separation, can solve the problems of complex assembly, uneven distribution, and low field strength in the sorting area, and achieve the effects of improving assembly efficiency, high magnetic field strength, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

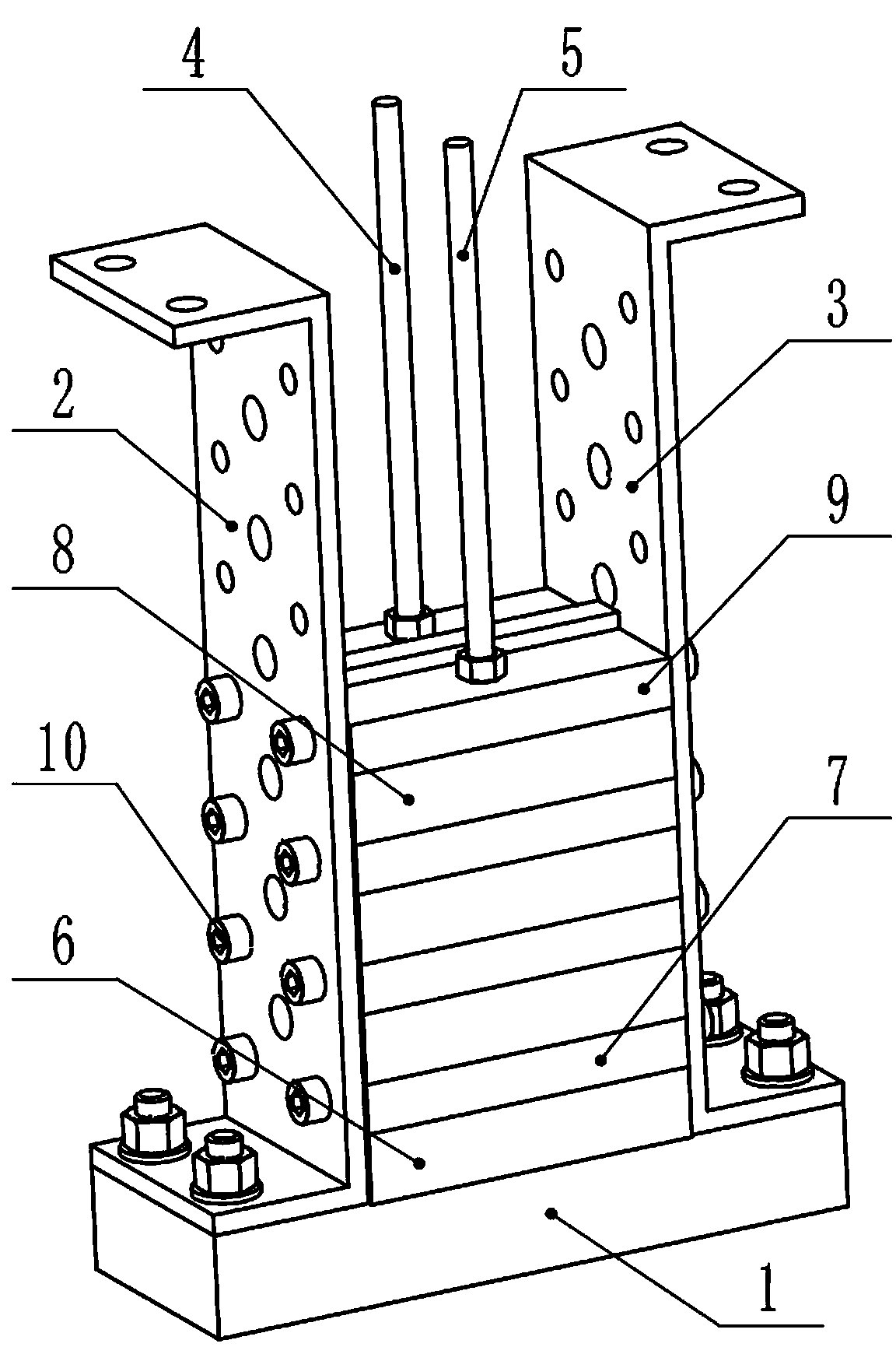

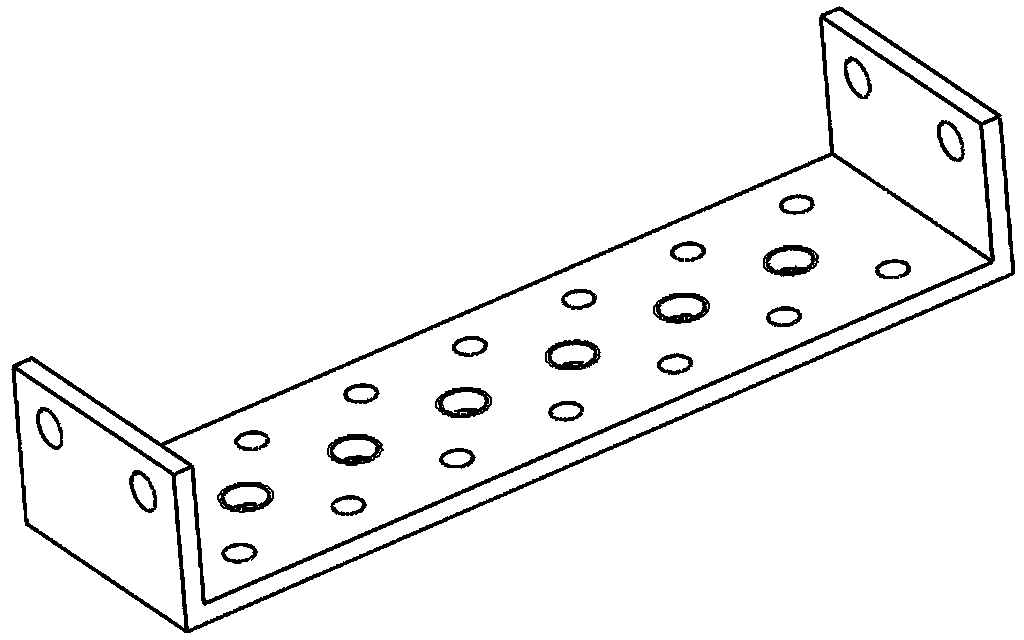

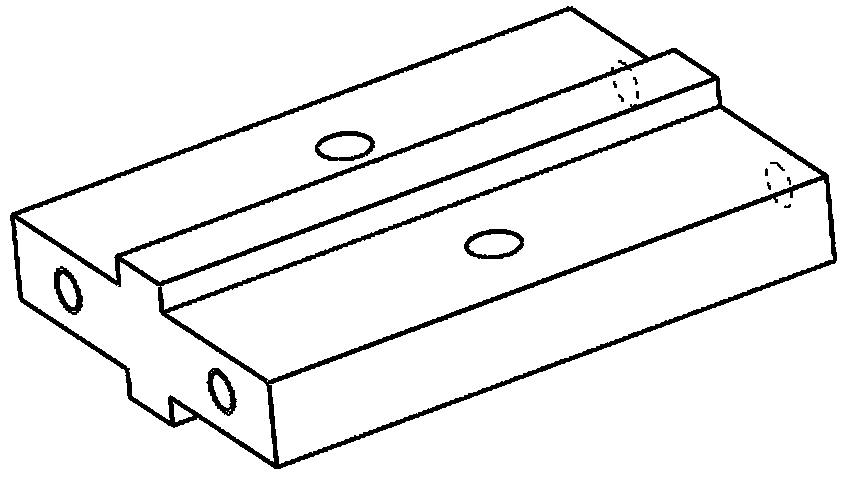

[0028] Such as figure 1 As shown, a tooling fixture for the magnetic system of a permanent magnet high-field magnetic filter includes two magnetic system end plates 1, and a parallel magnetic system armor plate I2 and a magnetic system are fixed between the two magnetic system end plates 1 System armor plate Ⅱ3, between the two magnetic system end plates 1, there are also screw I4 and screw II5, the screw I4 and screw II5 are located between the magnetic system armor plate I2 and the magnetic system armor plate II3. This fixture is for permanent magnets The magnetic block 8 and the magnetic yoke of the high-field magnetic filter are designed for the particularity of the magnetic system. Such as image 3 with Figure 4 For the cross yoke and T-shaped yoke of the permanent magnet high-field magnetic filter magnetic system, the matching method of the magnetic block and the yoke in this application ensures that the uniform background magnetic induction intensity of each sorting spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com