Method for production of a horology assembly, and horology assembly thus obtained

A technology for clock components and components, applied in the field of manufacturing elastic clock components, clockwork barrels, clock components, clockwork devices, manufacturing two-part clock components, movements or clock parts, clock barrel spring flanges, It can solve the problems that the outer end of the mainspring is not allowed to slide, the mainspring is broken, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

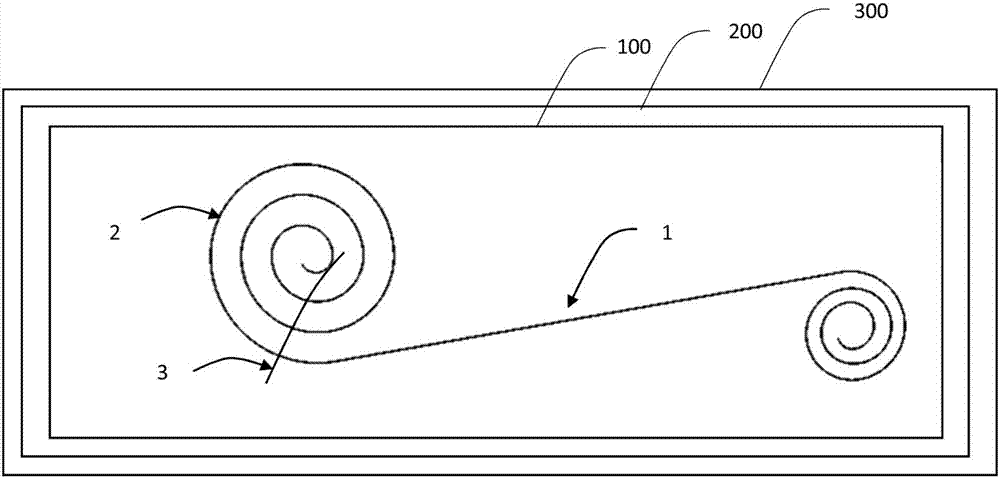

[0030] Reference below Figure 1 to Figure 10 A first embodiment of the timepiece part 300 will now be described. For example, the horological item is a watch, especially a watch. The timepiece includes a timepiece movement 200 , in particular a mechanical movement.

[0031] The movement can be self-winding or manually wound. The movement includes a barrel 100 .

[0032] As for the parts of the barrel, it consists of an assembled barrel spring 1 .

[0033] The assembled barrel-shaped clockwork device 1 includes:

[0034] - barrel spring 2;

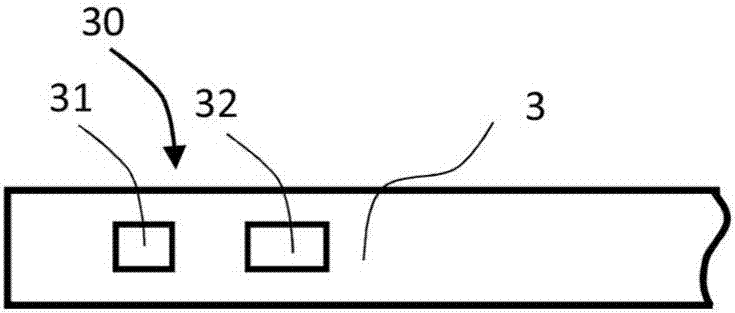

[0035] - flange 3;

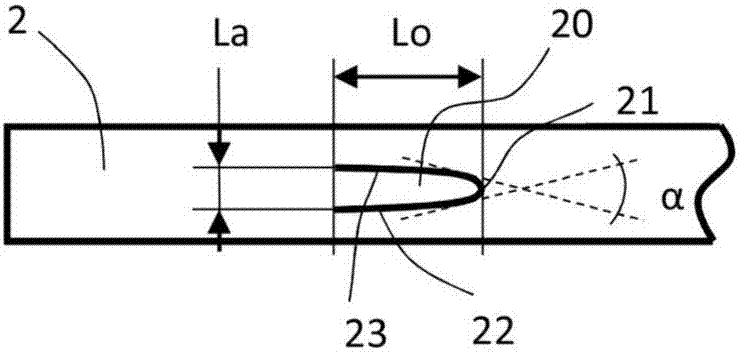

[0036] - the first structure 20 on the clockwork; and

[0037] - a second structure 30 on the flange,

[0038] The first structure and the second structure are designed to cooperate to assemble the spring and the flange, in particular to assemble them by means of obstacles.

[0039] For connecting the barrel spring and the flange, the barrel spring-flange assembly is advantageously produced without a further t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com