An automatic feeding and assembling system for light guide body in automobile interior decoration

A technology for automatic material feeding and automobile interior decoration, applied in the field of machinery, it can solve the problems of difficult assembly quality control, small size of light guide body, unsuitable for mass production, etc., and achieves saving assembly time, compact structure and stable assembly quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below according to the accompanying drawings.

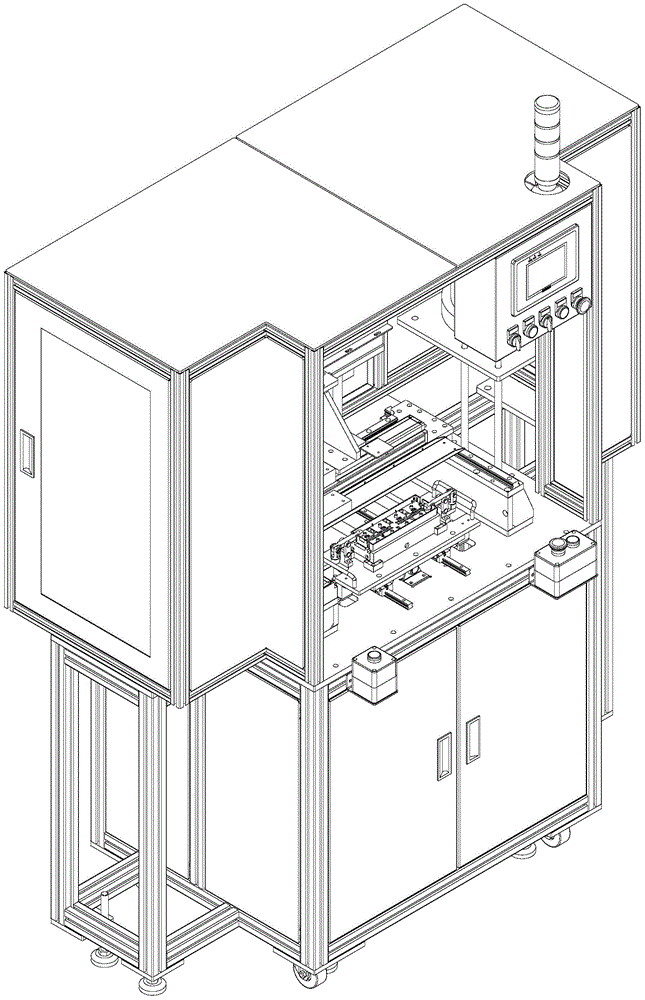

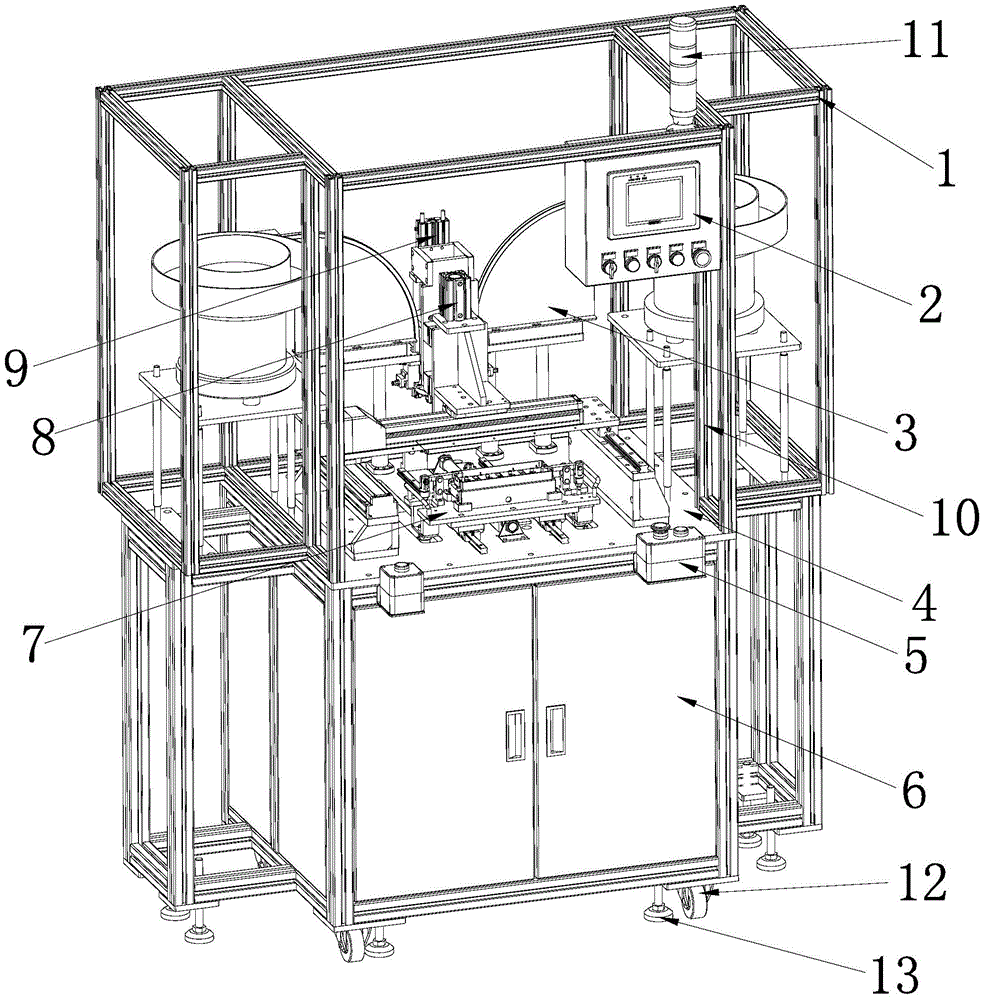

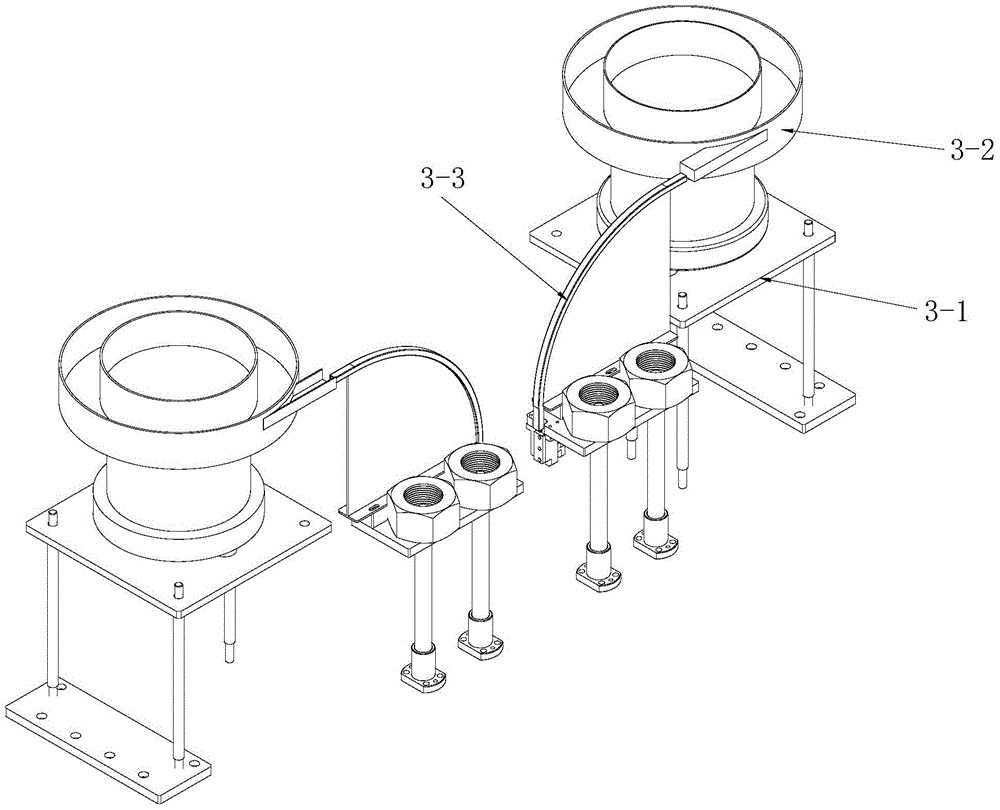

[0026] Such as figure 1 , figure 2 As shown, the middle part of the frame 1 is horizontally provided with a workbench 4, the workbench 4 is provided with a profiling mold structure 7, and the top of the profiling mold structure 7 is provided with a disk loading mechanism 9, which is located at the left and right sides of the disk loading mechanism 9. A feeding mechanism 3 is connected to the frame 1 on the side;

[0027] Control switches 5 are respectively arranged at the left and right ends of the front of the workbench 4 .

[0028] What the workbench 4 used is the control switch 5 of the two-hand start mode, which can effectively prevent the employee from accidentally pressing the start button to start the system because of distraction.

[0029] The rack 1 below the workbench 4 is provided with an industrial computer placement position 6 .

[0030] The design of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com