Positioning and press fitting fixture

A technology for pressing jigs and jigs, which is used in manufacturing tools, assembly machines, metal processing equipment, etc. to reduce production costs and expand the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

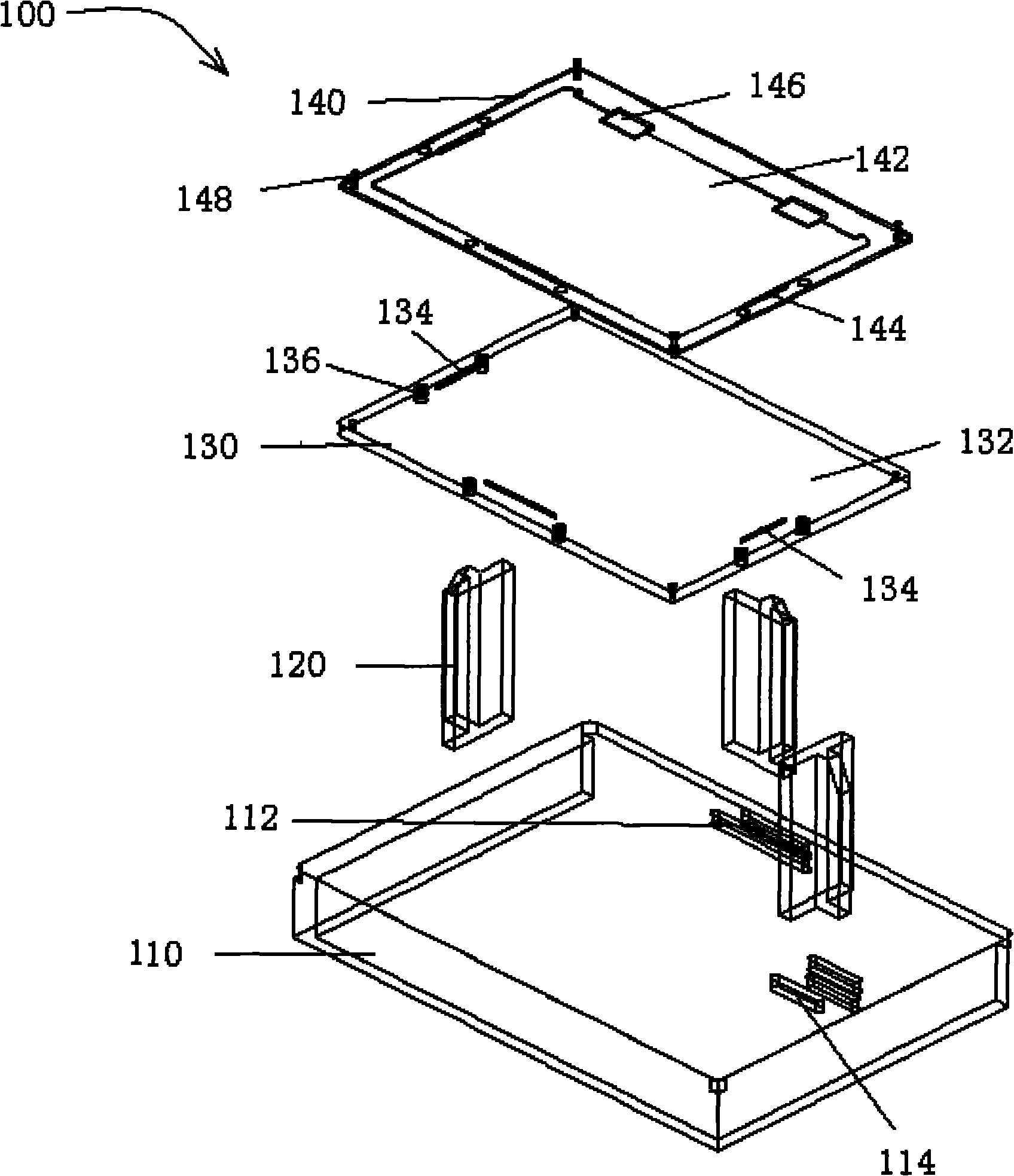

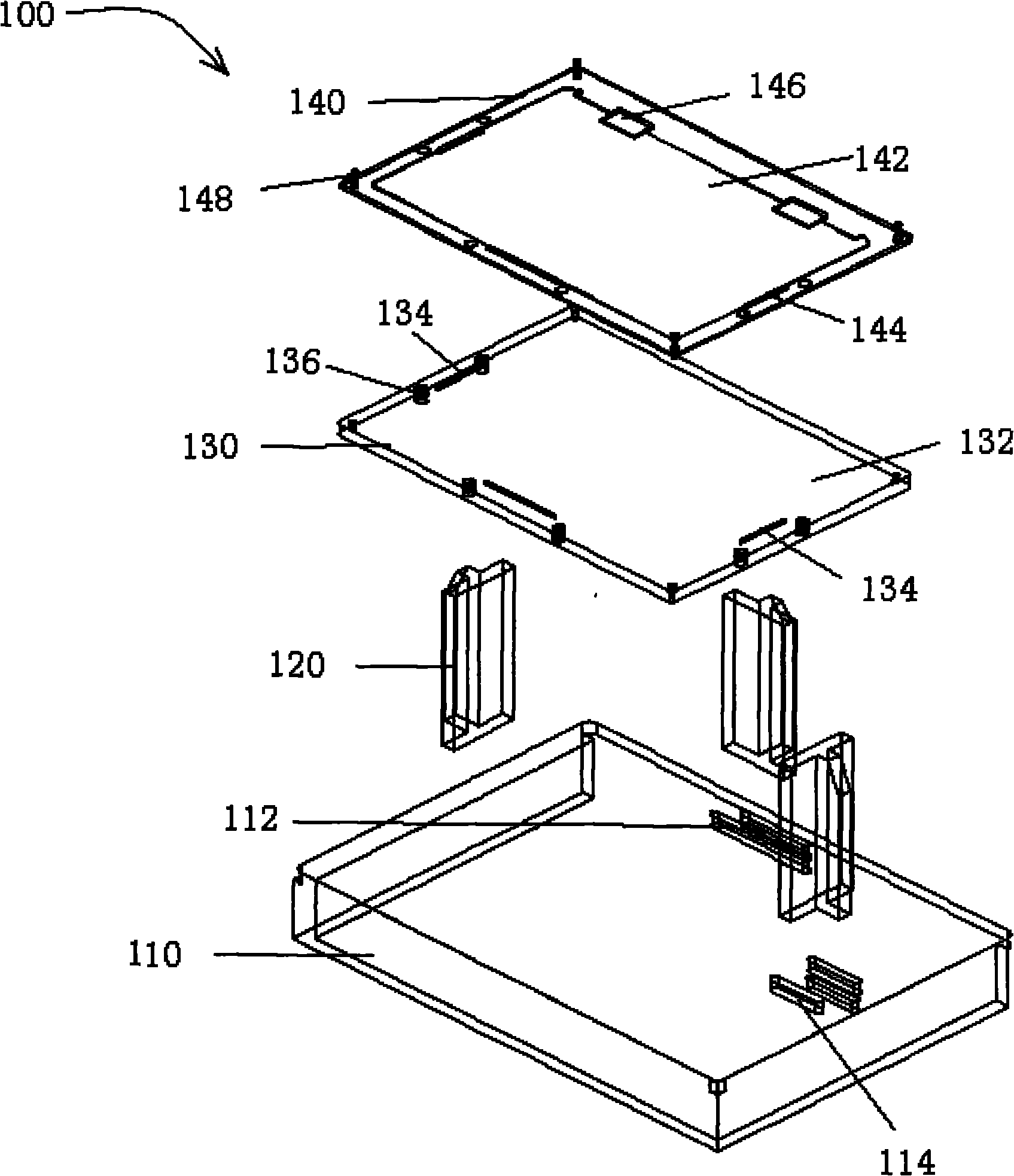

[0016] see figure 1 As shown, the present invention relates to a positioning and bonding jig 100 , which includes a worktable 110 . A positioning column 120 is disposed on the workbench 110 , and a working area thereon is defined by the positioning column 120 . Further, the positioning and bonding jig 100 also includes a lower jig 130 and an upper jig 140 .

[0017] Further, the workbench 110 is also provided with a number of size adjustment slots 112 , 114 for installing the positioning column 120 . The positioning column 120 can change the size of the working area defined by it on the workbench by being installed in different size adjusting grooves 112 , 114 . In this way, the workbench 110 can be used for assembling notebook computers of various sizes.

[0018] Wherein the lower jig 130 includes a plate-like body 132 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com