Bonding and sealing method of proton exchange membrane fuel cell stack

A fuel cell stack and proton exchange membrane technology, applied in the directions of fuel cells, circuits, electrical components, etc., can solve the problems of unpractical production of fuel cells, difficult operation, and cumbersome process, so as to simplify the sealing and stack assembly process and operation. Simple, easy-to-craft effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] This embodiment takes room temperature curing silica gel sealed cathode open-type air-cooled stack as an example

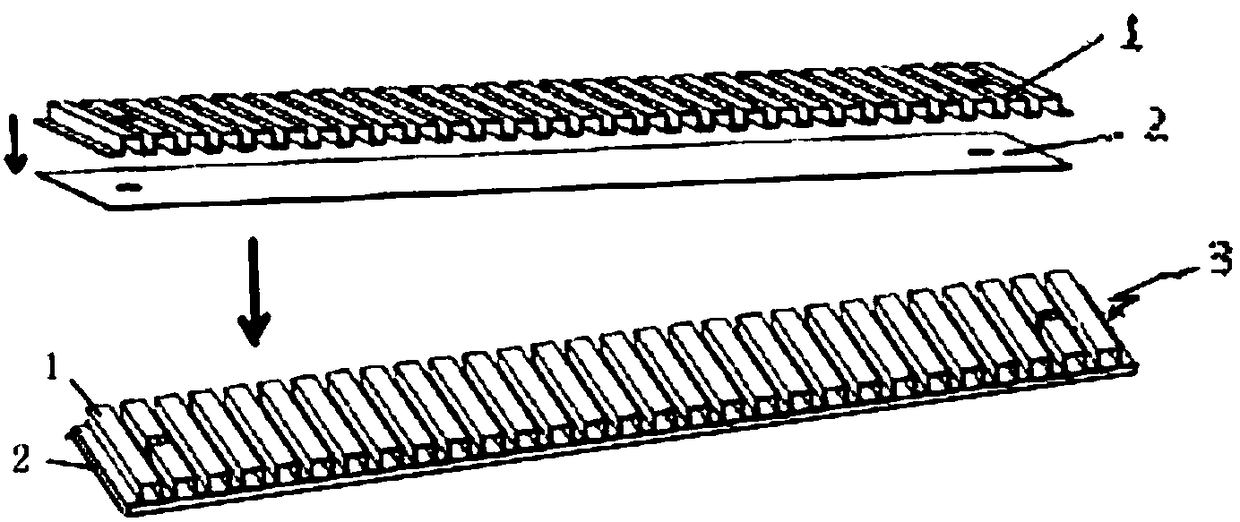

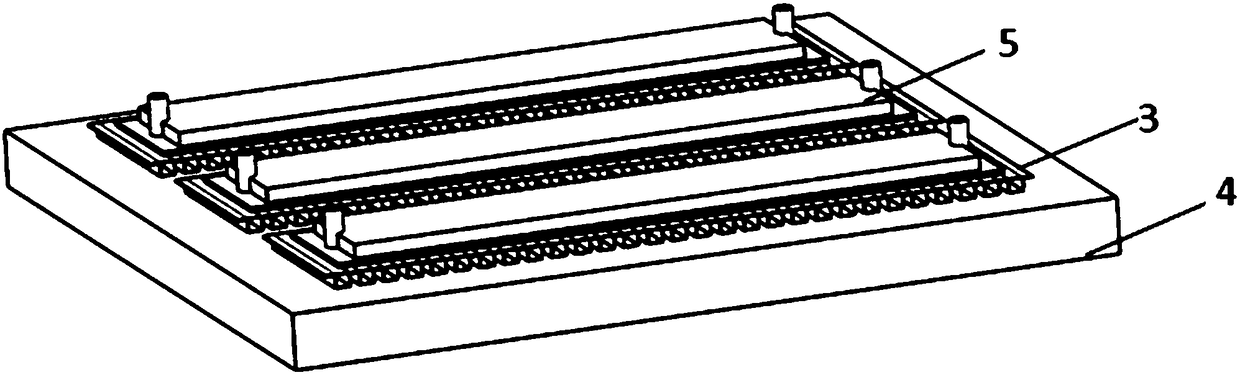

[0031] Step 1. Prepare 3 pieces of bipolar plates, fix the anode plate of the bipolar plate upwards on the dispensing disc 4, spread the flow channel carbon paper 7 and the anode carbon paper 8 on the anode plate, and the flow channel The size of carbon paper 7 and anode carbon paper 8 is smaller than that of bipolar plate 3 and membrane electrode 9, and form a dispensing line 6 of 6mm. Use pressure plate 5 to fix bipolar plate 3, channel carbon paper 7 and anode carbon paper 8 To flatten.

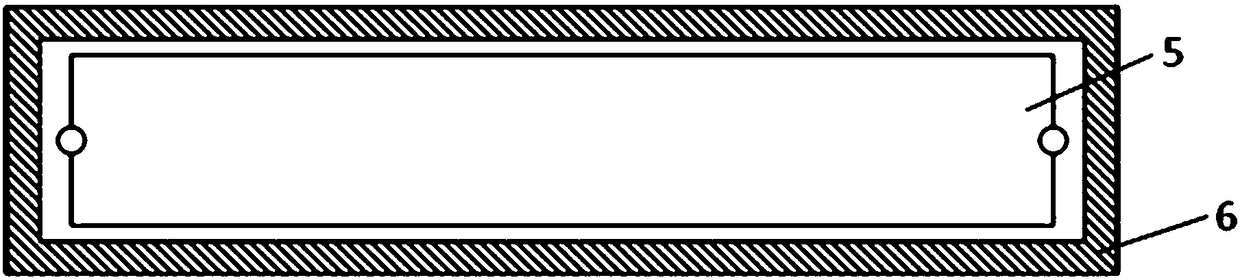

[0032] Step 2. Set the program of the dispenser and the dispensing route 6 of the dispenser, and start dispensing along the edge of the anode carbon paper 8; the height of the dispensing at the edge of the anode plate of the bipolar plate is 4mm, and the dispensing width 7mm,. Among them, any one of AB glue, epoxy glue and silica gel is used; dealcoholization and degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com