Assembling device for nose cowl of rocket launcher

An assembly device and launcher technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as inaccurate clamp ring positioning, affecting launch tube assembly, difficult launch hole position accuracy, etc., to achieve convenient operation and solve problems The effect of launch hole position accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

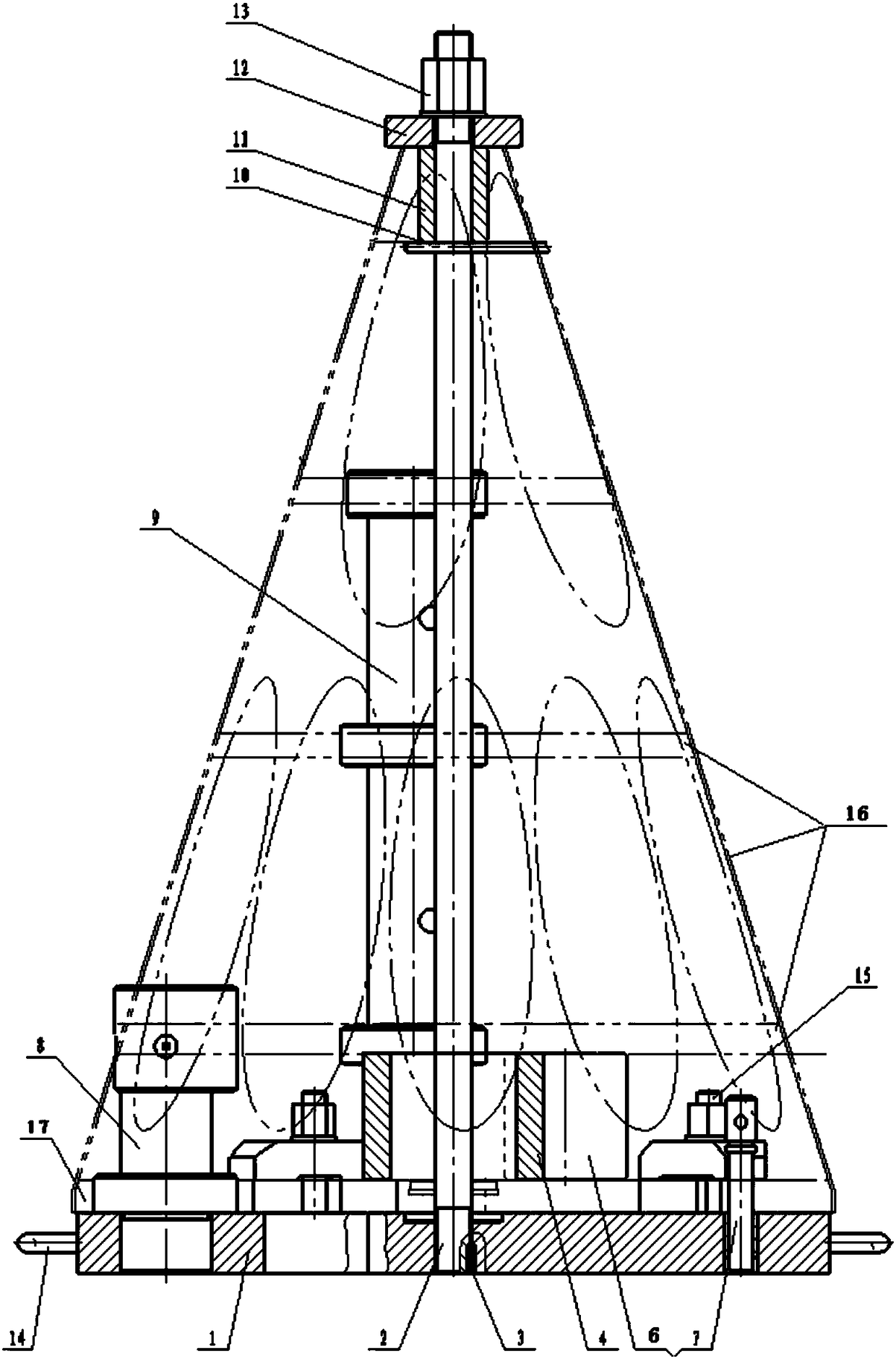

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

[0019] An assembly device for a pre-ignition fairing, comprising the following components: a base 1, a threaded rod 2, a stop screw 3, a limit bush 4, a limit block 5, a positioning pin 6, a bush 7, and a small positioning shaft 8. Positioning shaft 9, latch 10, pad 11, pressure plate 12, step nut 13, handle 14, pressure plate assembly 15, skin assembly; pressure plate assembly 15 includes flat pressure plate, screw, stud bolt, nut; skin assembly is Manufactured by pre-installing the center clip and rear clip assemblies and the front clip and front cone assemblies within the skin.

[0020] The main implementation process: first place the base of the device on the working platform, start to guide the center hole in the disc through the threaded rod 2, and use a positioning shaft 9 and a small positioning shaft 8 to position it, and stick to the upper surface of the base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com