A method of connection structure between square steel tube concrete column with lug plate and prefabricated shear wall

A concrete column and prefabricated technology, which is applied to building structures, walls, building components, etc., can solve the problems of complex construction methods and low bearing capacity at the joints of prefabricated structures, so as to facilitate transportation, facilitate assembly efficiency, and improve performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments.

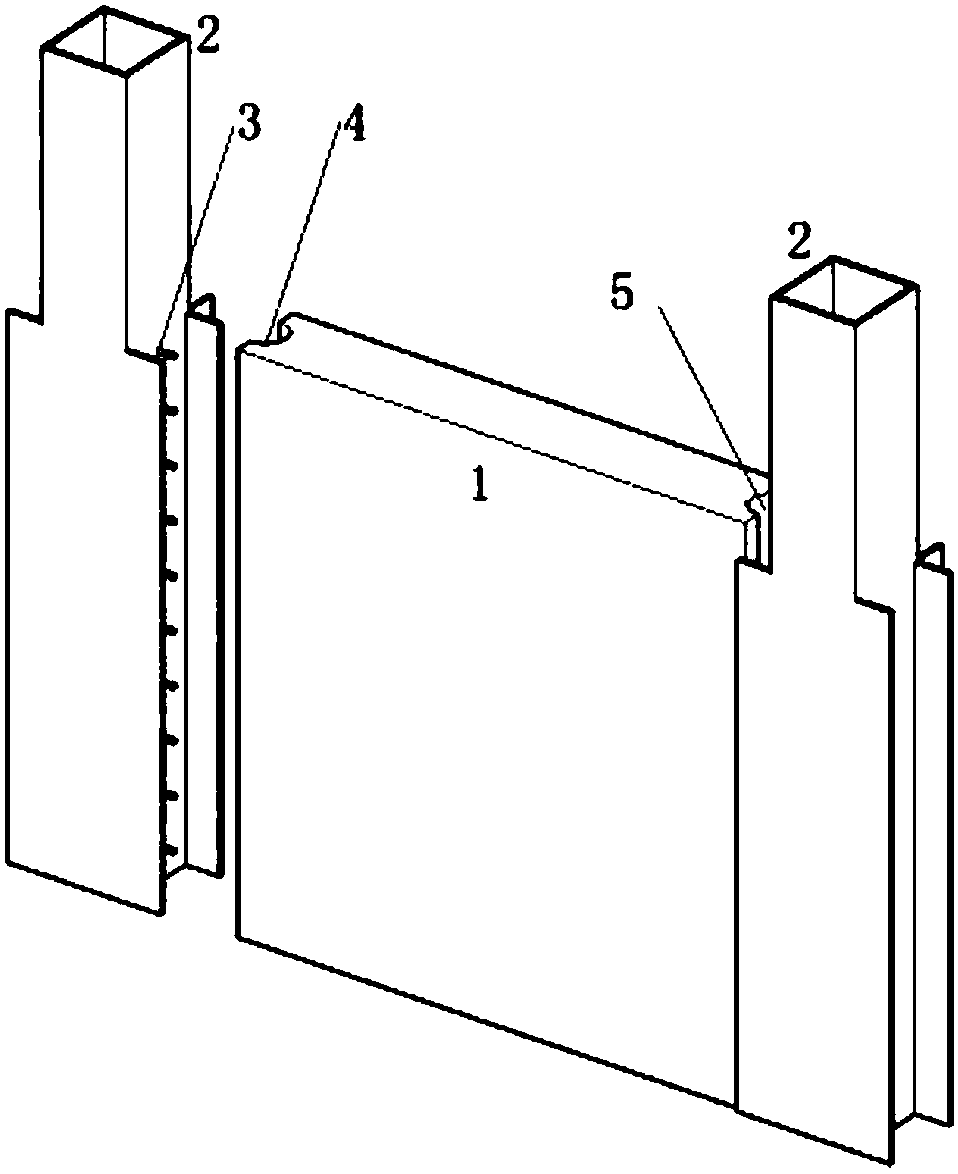

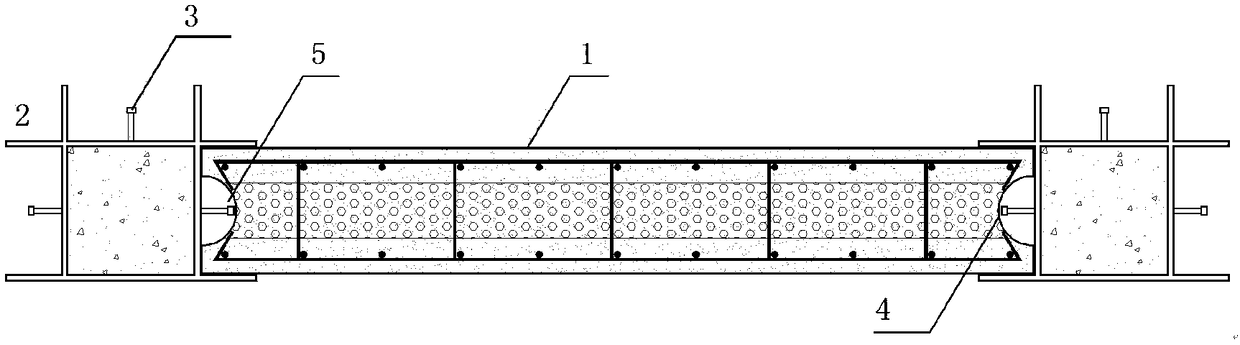

[0027] Such as Figure 1-2 As shown, a connection structure between a prefabricated concrete-filled steel tube column and a prefabricated shear wall mainly consists of a prefabricated composite thermal insulation module shear wall (1), a square concrete-filled steel tube column with ear plates (2), and studs on the side of the column (3), the semicircular ribbed groove (4) on the side of the prefabricated shear wall, and the high-strength grouting material (5). It is characterized in that: the polystyrene particles in the shear wall of the assembled composite thermal insulation module can be designed based on the thermal insulation performance. The bulk density of the prefabricated composite thermal insulation module shear wall with inner layer of polystyrene particle board, outer layer of foamed concrete surface layer and double-layer high-strength steel wire mesh can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com