Slender pin horizontal automatic assembly device

An automatic assembly device, slender technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that the vertical assembly method of slender pins is not applicable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

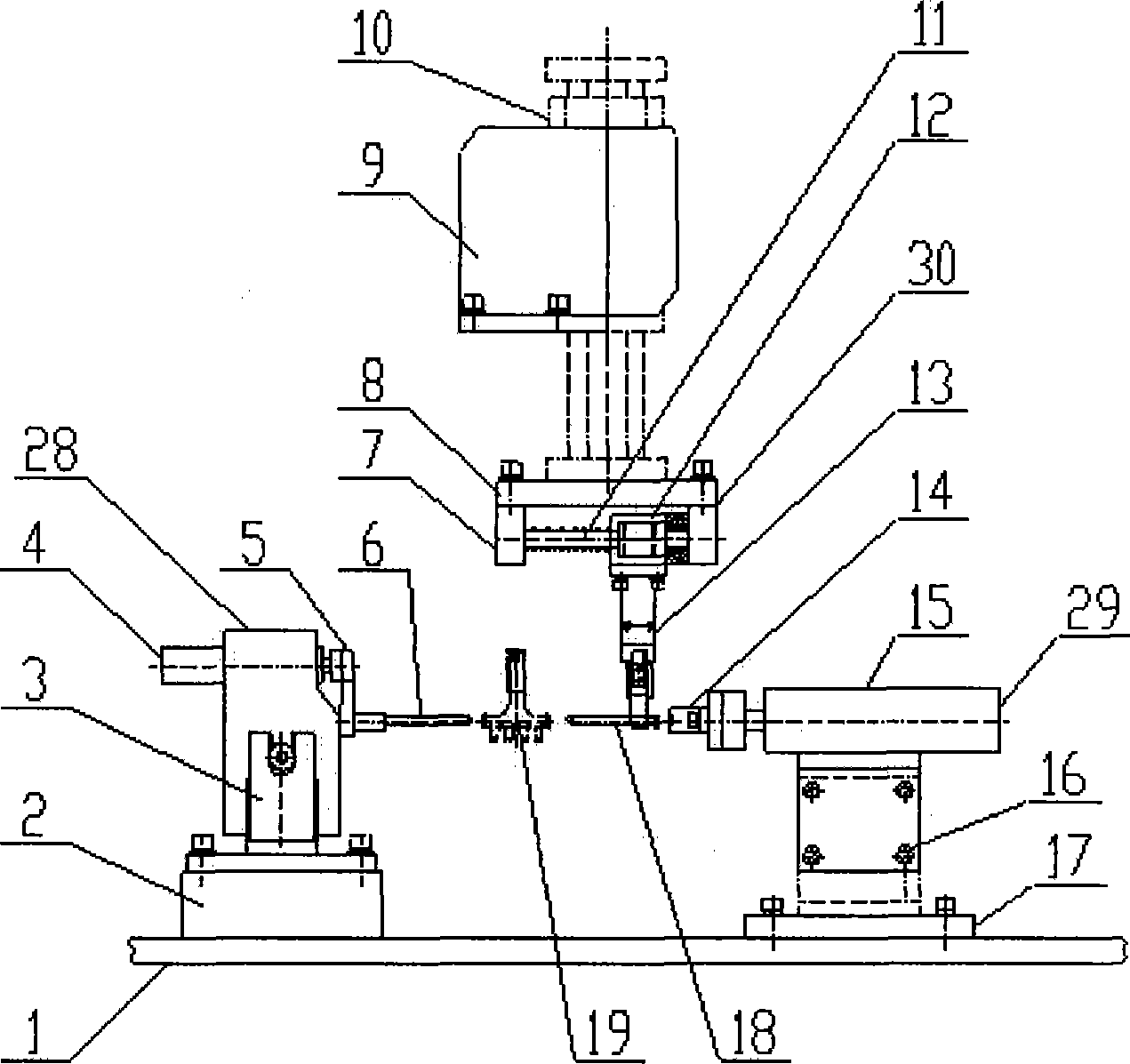

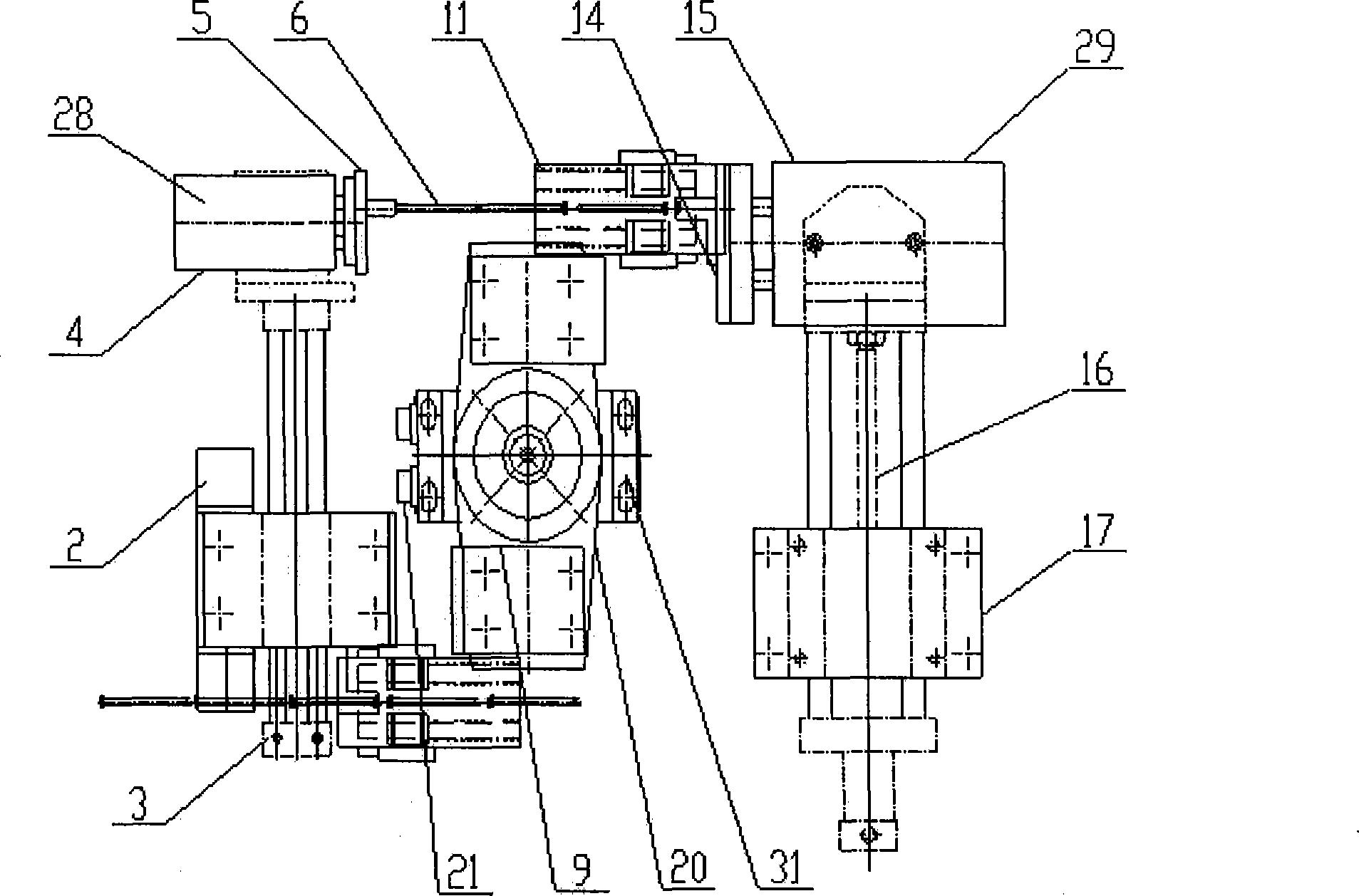

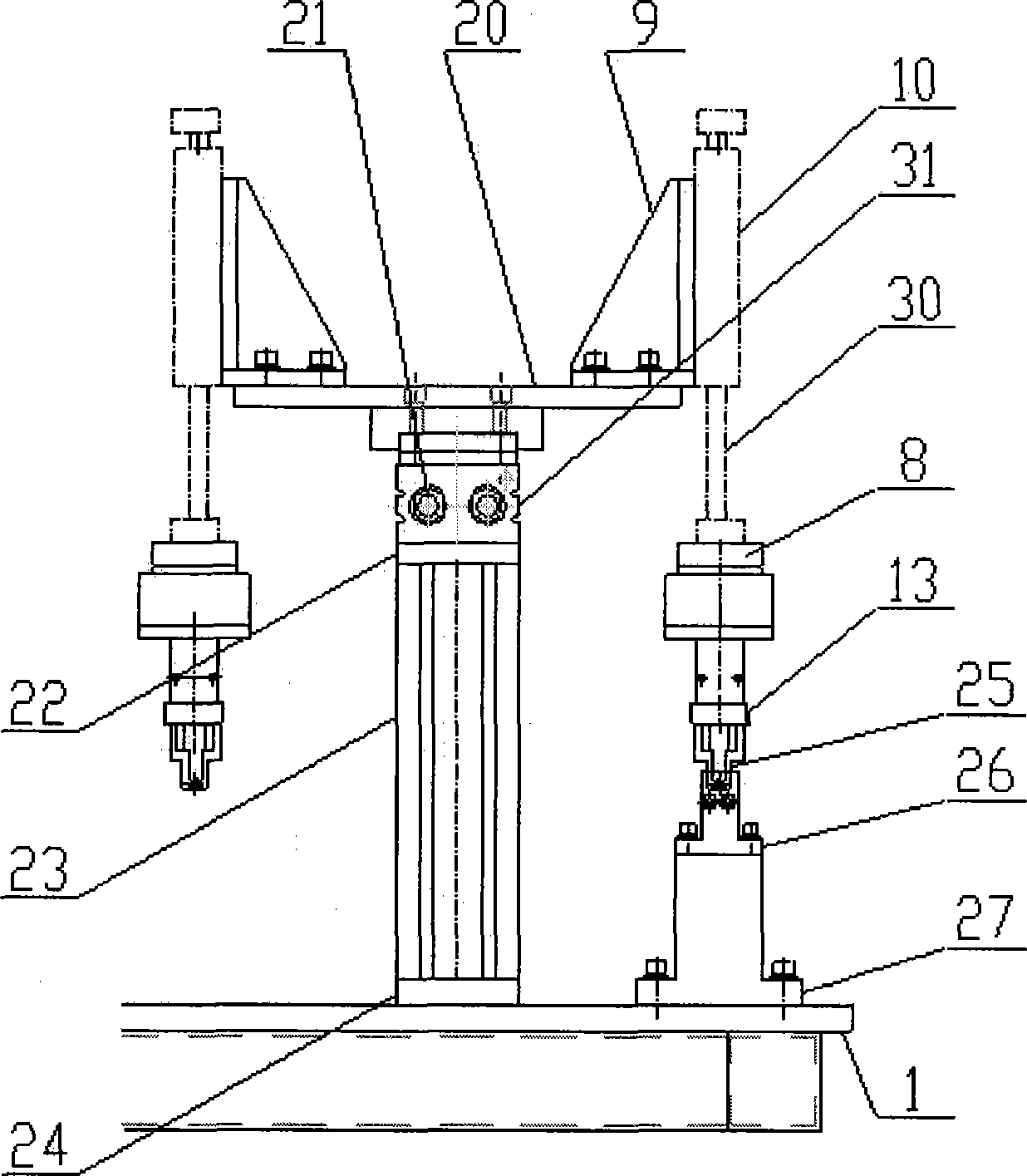

[0015] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

[0016] see figure 1 , figure 2 and image 3 , the elongated pin horizontal automatic assembly device includes a horizontal installation panel 1 , an elongated pin mounting seat 19 and an elongated pin 18 for the workpiece above the installation panel 1 . On the upper surface on the left side of the installation panel 1, a bolt guide mechanism 28 is fixedly installed to guide the positioning of the elongated pin mounting seat 19, and on the upper surface on the right side of the installation panel 1, a latch positioning assembly mechanism 29 is fixedly installed to make the elongated pin 18 Align with the slender pin mounting seat 19; a latch grabbing mechanism 30 is installed above the installation panel 1, and the claw 25 on it grabs the slender pin 18 horizontally; a rotating transposition mechanism is fixedly installed at the center of the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com