Novel derusting device for design and processing of fabricated steel structure

A prefabricated, steel structure technology, applied in the direction of metal processing equipment, grinding/polishing safety devices, manufacturing tools, etc., can solve the problems affecting the quality of the project, the impact of the service life of the steel, and the shortening of the service life of the steel, so as to increase the brush movement Area, the effect of enhancing the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

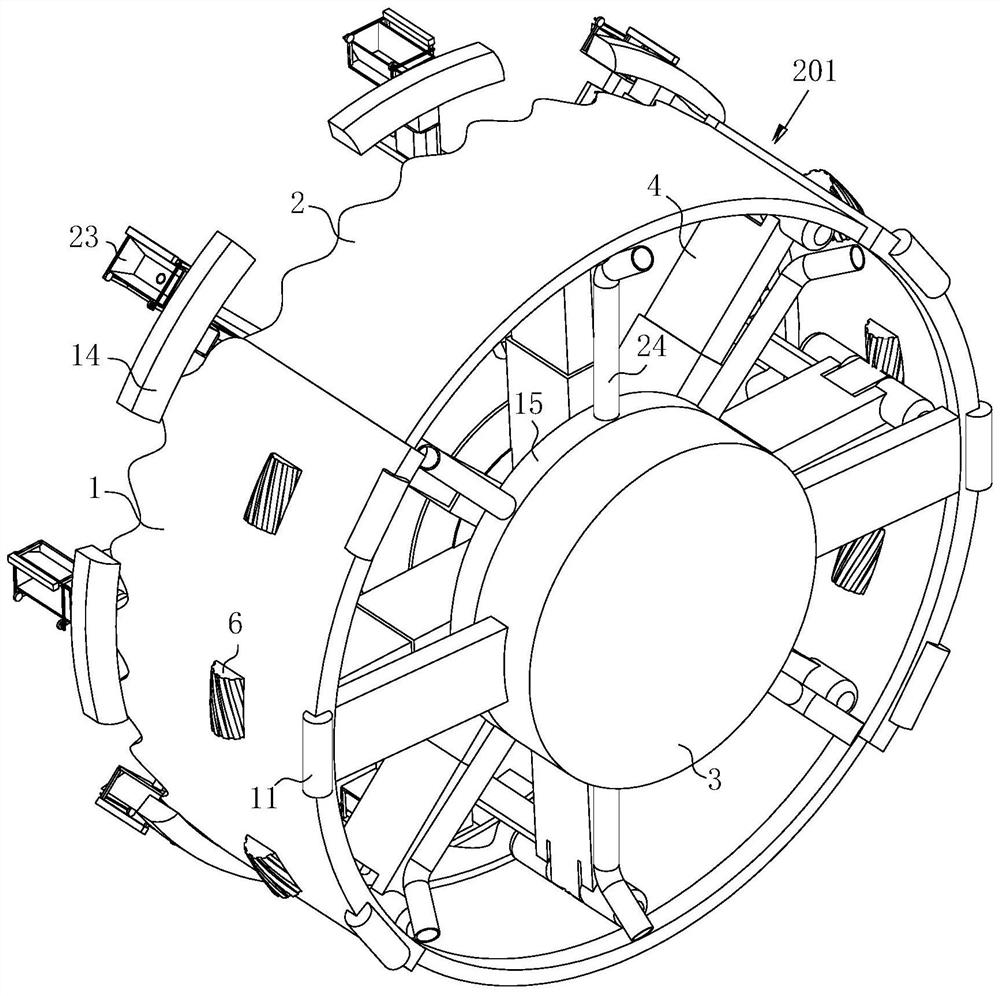

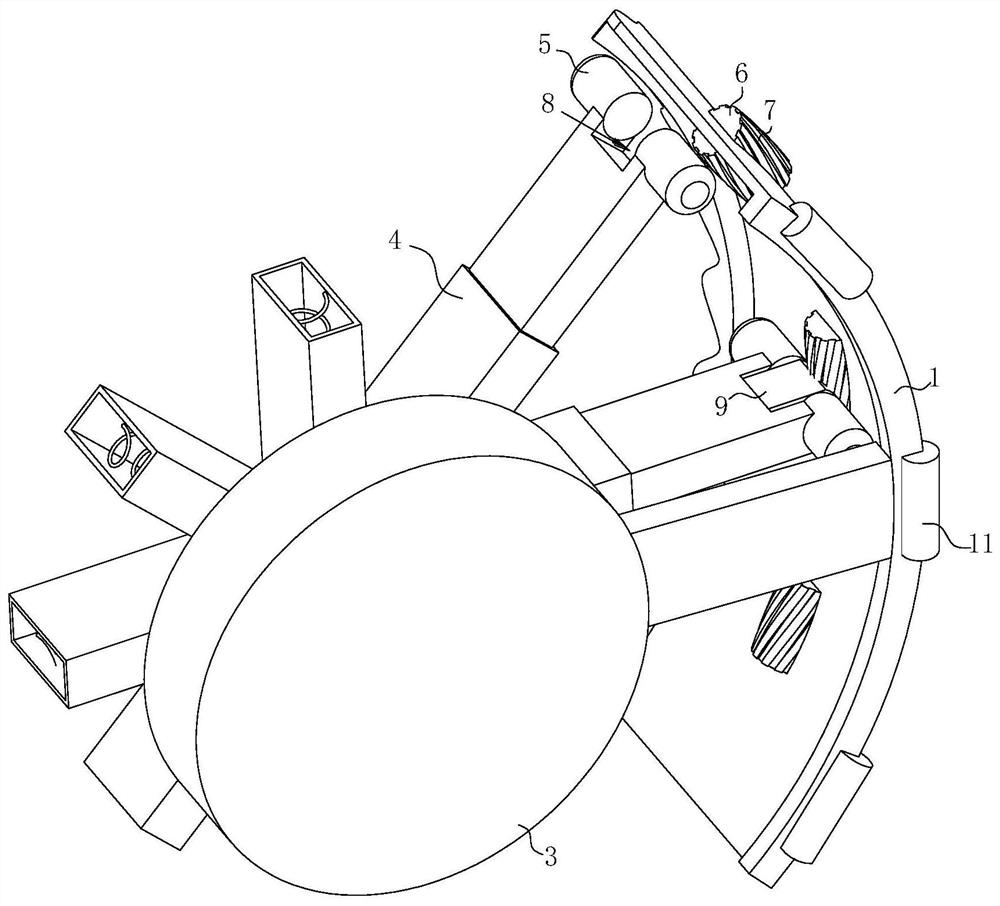

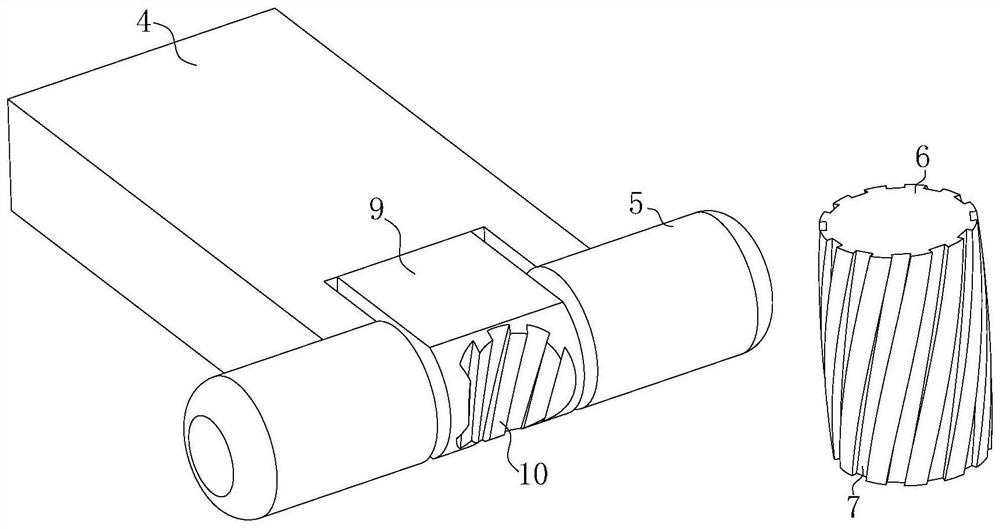

[0030] see Figure 1-10 , the present invention provides a technical solution: a novel assembly-type derusting device for steel structure design and processing, including two arc-shaped support plates 1 and two elastic arc-shaped connecting plates 2, two arc-shaped support plates 1 and Two arc-shaped connecting plates 2 form a circular moving frame 201, and the two arc-shaped connecting plates 2 slide on the inner sides of the two arc-shaped support plates 1, and a drive motor 3 is fixedly connected between the inner walls of the two arc-shaped support plates 1, The output shaft of the driving motor 3 extends backward to the inside of the mobile frame 201, and the surface of the output shaft of the driving motor 3 is fixedly connected with a plurality of equiangularly arranged and telescopic support rods 4, and the ends of the support rods 4 are rotatably connected with a rotating roller 5, The rotating rollers 5 roll on the inner wall of the two arc-shaped support plates 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com