A plastic faucet spool assembly device

A technology for assembling devices and faucets, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of unfavorable production and development of enterprises, long time consumption, large manpower and other problems, so as to reduce the time for replacing the faucet, reduce Manpower consumption and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

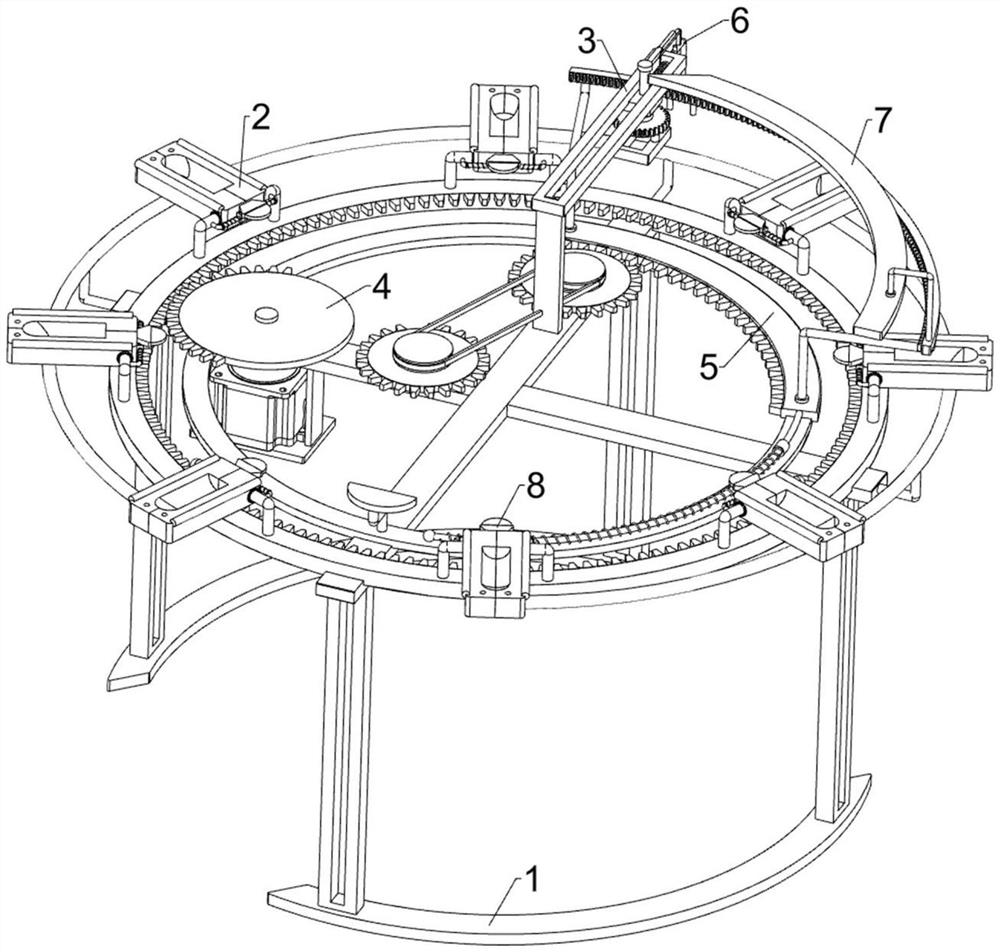

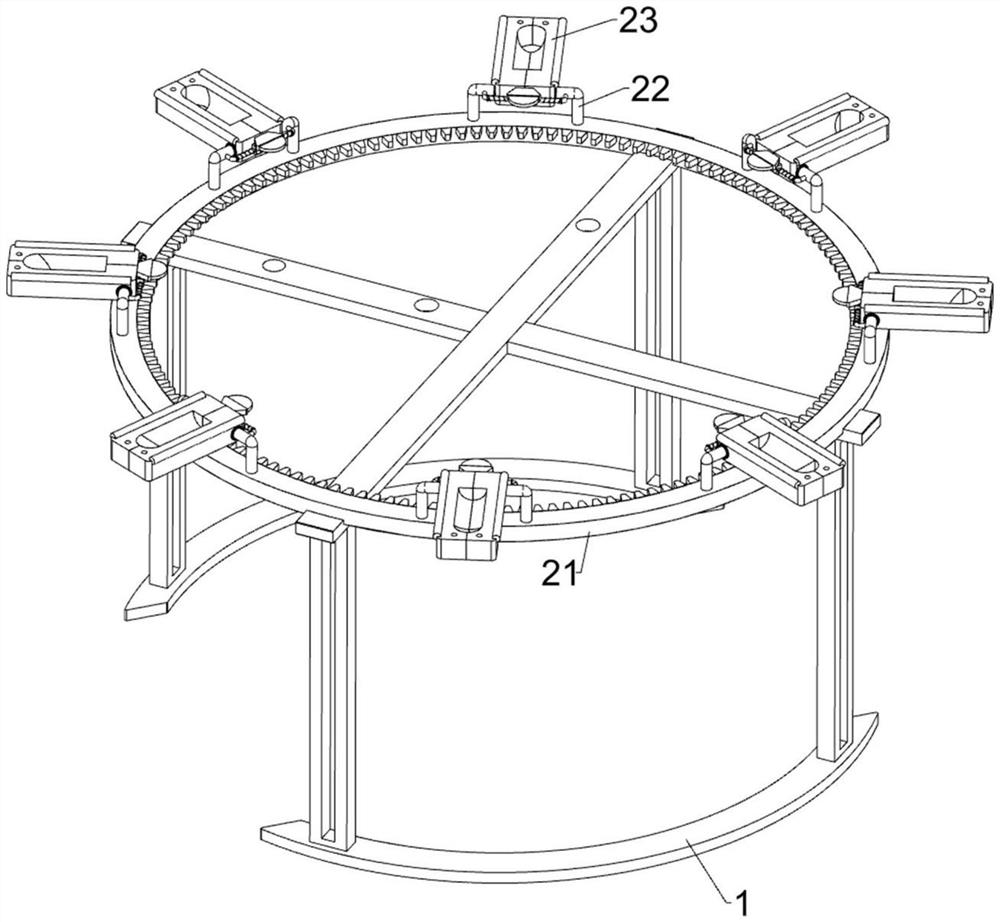

[0030] A plastic faucet spool assembly device, such as Figures 1 through 4 Shown, comprising a bracket 1, a rotating placement assembly 2 and a tightening assembly 3, the upper side of the bracket 1 is provided with a rotating placement assembly 2, the upper side of the bracket 1 is connected to the tightening assembly 3.

[0031] When the faucet needs to be assembled, the faucet and the spool are placed on the rotating placement assembly 2, and then the controlled tightening assembly 3 will be tightened with the spool, and after tightening, the rotation placement assembly 2 can be controlled, which in turn can make the control tightening assembly 3 to assemble the spool of other unassembled faucets, when all the faucets are assembled, the rotation placement assembly 2 and the tightening assembly 3 can no longer be controlled.

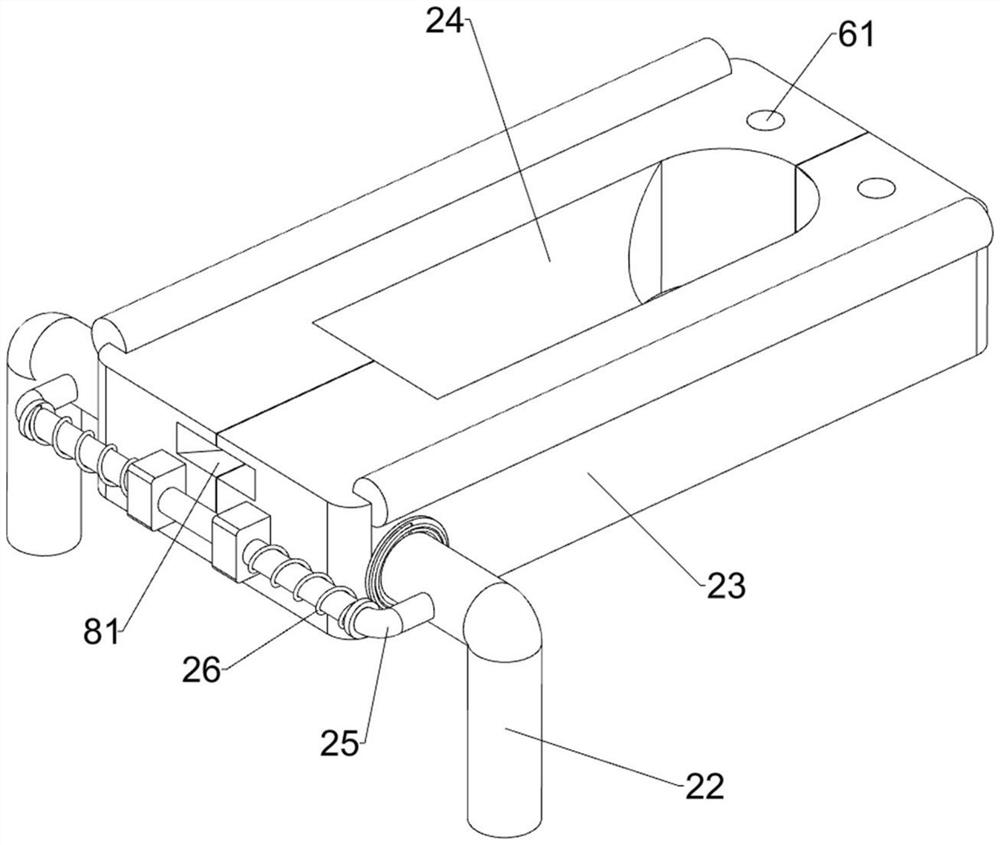

[0032] Rotating placement assembly 2 includes a ring plate 21, a recessed rod 22, a placing plate 23, a concave guide rod 25 and a first spring 26, the up...

Embodiment 2

[0037] On the basis of Example 1, e.g., Figure 1 、 Figure 5 、 Figure 6 、 Figure 7 、 Figure 8 and Figure 9 Shown, further comprising a power component 4, the power component 4 comprises a geared motor 41, a sector gear 42 and a ring gear 43, the left side of the bracket 1 is connected to the gear motor 41, the output shaft of the gear motor 41 is connected to a large sector gear 42, the inner side of the ring plate 21 is provided with a ring of gear 43, the ring of gear 43 and the fan gear 42 mesh.

[0038] When the faucet needs to be assembled with the valve spool, the gear motor 41 is started, and the fan gear 42 is rotated, so that the ring gear 43 is rotated, and then the ring plate 21 is rotated, so that the staff does not need to manually control the rotation of the ring plate 21, reducing the manpower consumed.

[0039] Further comprising a tightening fit assembly 5, a tightening fit assembly 5 includes a ring rail 51, a first curved rack 52, a guide sleeve 53, an arc guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com