Angle adjusting structure of drawer panel

An angle adjustment structure and angle adjustment technology, applied in garbage collection, home appliances, applications, etc., can solve problems such as panel tilting up and down, gaps in cabinets, affecting the appearance of drawers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

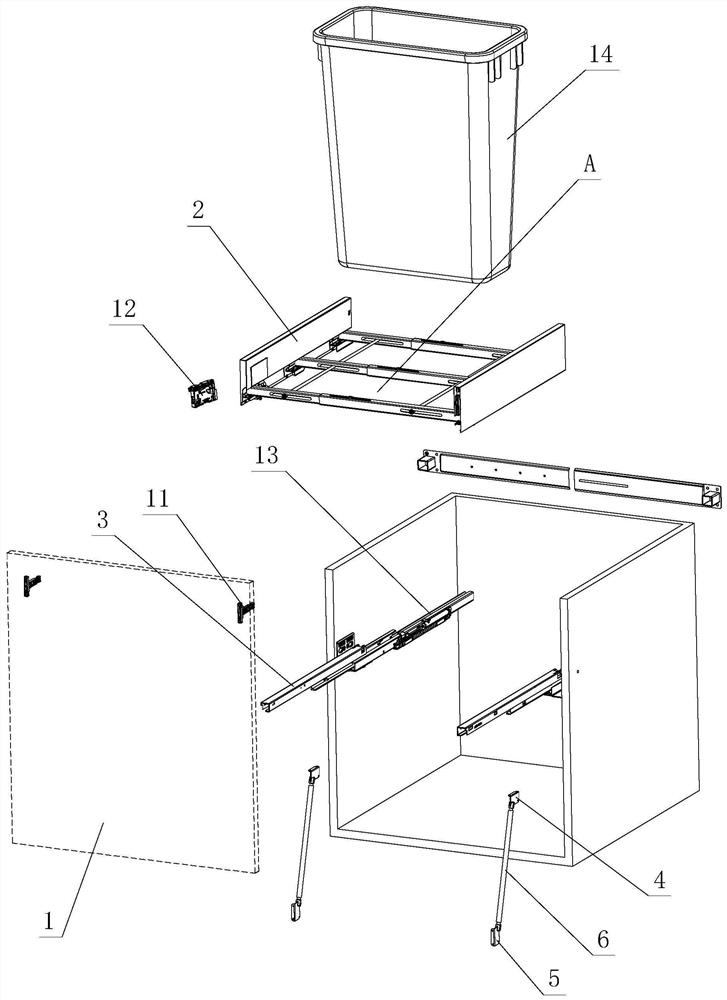

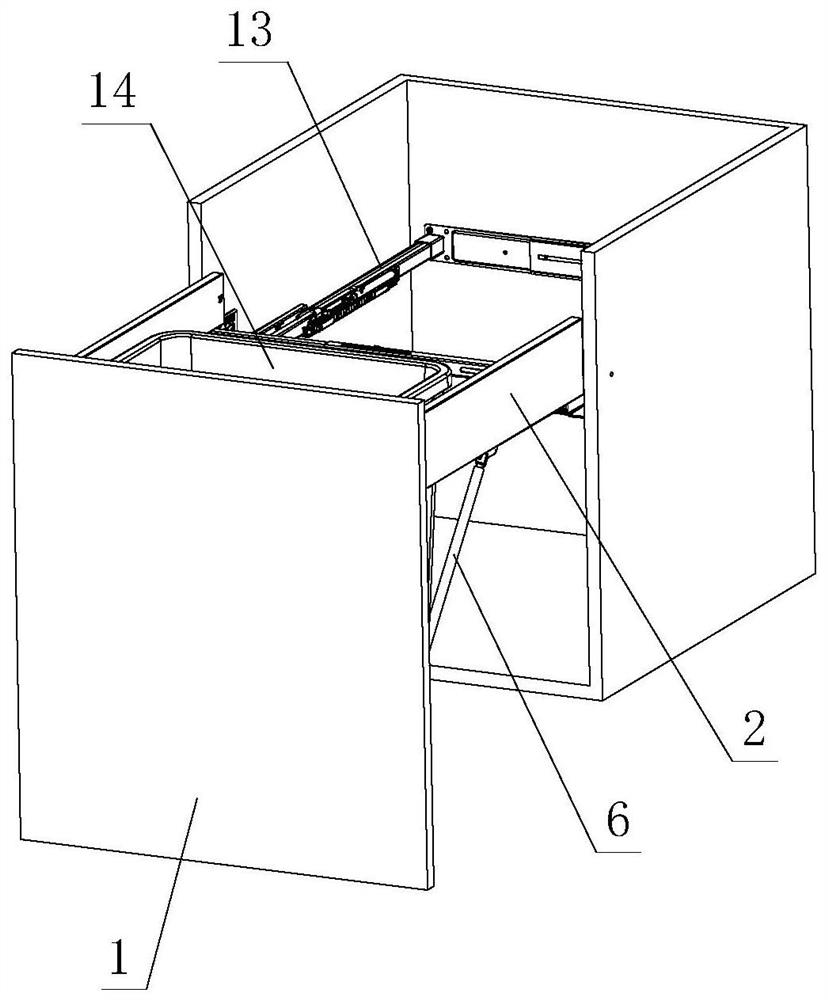

[0027] see Figure 1-Figure 6 , the angle adjustment structure of the drawer panel, comprising a panel 1, a side panel 2 and a slide rail assembly, characterized in that: the slide rail assembly at least includes a moving slide rail 3, the side panel 2 is detachably arranged on the moving slide rail 3, and the panel 1. It is detachably installed on the side plate 2; wherein, the side plate 2 or the moving slide rail 3 is provided with a first connecting piece 4, and the panel 1 is provided with a second connecting piece 5, and the first connecting piece 4 is connected with the second A connecting rod 6 is arranged between the parts 5, an adjusting member is arranged between the connecting rod 6 and the first connecting member 4 and / or the second connecting member 5, and the connecting rod 6 moves between the first connecting member 4 and the second connecting member 5 through the adjustment of the adjusting member. / or on the second connecting member 5, and when in motion, the...

no. 2 example

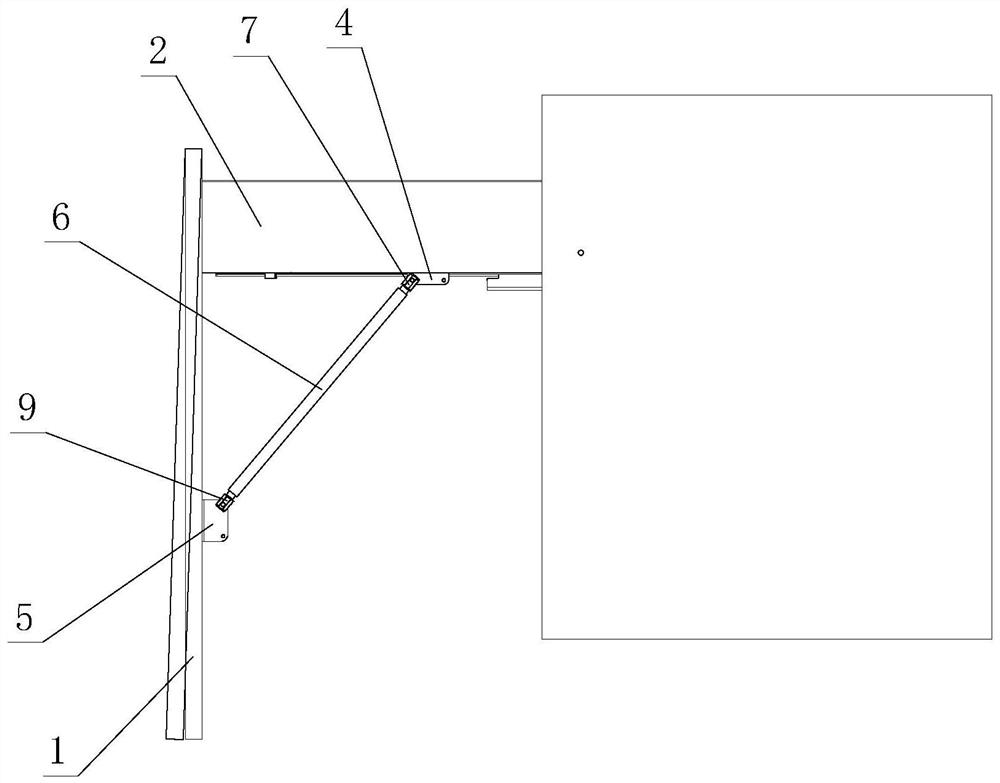

[0043] see Figure 7 , The angle adjustment structure of the drawer panel is different from the first embodiment in that: the first connecting piece 4 is arranged on the moving slide rail 3 .

[0044] The connecting rod 6 moves on the first connecting member 4 and / or the second connecting member 5 through the adjustment of the adjusting member, and drives the panel 1 to tilt relative to the sliding rail 3 when in motion, so as to realize the angle adjustment of the panel 1 .

[0045] The connection between the moving slide rail 3 and the first connecting member 4 forms a second action point.

[0046] Specifically, the first connecting member 4 is fixedly arranged on the movable sliding rail 3 and forms a second action point with each other.

[0047] Use a tool or manual action on the connecting rod 6, and drive the two ends of the connecting rod 6 to be threaded and rotate between the first adjusting member 7 and the second adjusting member 9, and the connecting rod 6 will dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com