A size-adjustable stamping body

A punching body and size technology is applied in the field of punching bodies and punching bodies with adjustable dimensions, which can solve the problems of non-adjustable size, inconvenient access and single punching structure, etc., and achieves the effects of convenient operation, simple structure and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

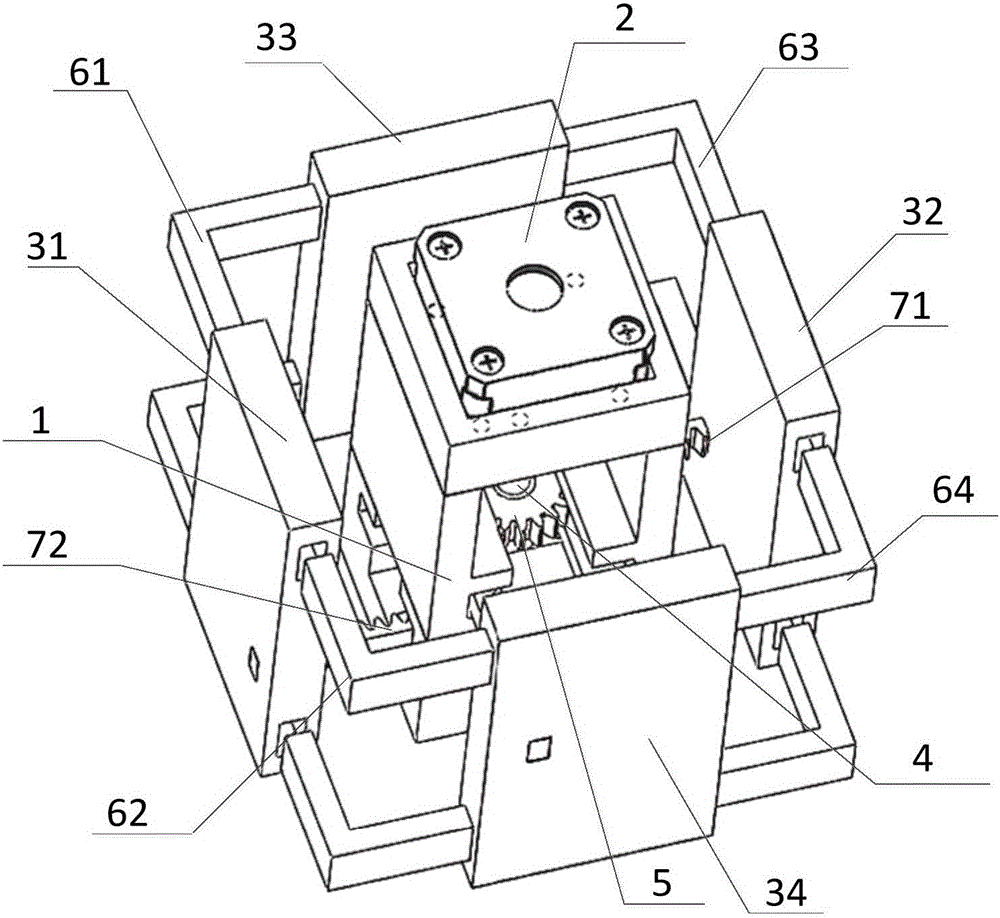

[0021] refer to figure 1 , the size-adjustable stamping body of the present invention includes a first side plate 31, a second side plate 32, a third side plate 33, a fourth side plate 34, a first rack 71, a second rack 72, a Three racks, the fourth rack, the first connector 61, the second connector 62, the third connector 63, the fourth connector 64, the pinion shaft 4, the double gear 5 and the stamping body frame 1; the double gear 5 is located in the stamping body frame 1, the lower end of the gear shaft 4 is inserted into the stamping body frame 1 and passes through the duplex gear 5, the first side plate 31, the second side plate 32, the third side plate 33 and the fourth side plate 34 Facing the four sides of the stamped body frame 1 respectively, one end of the first rack 71 is fixed on the inner side of the first side plate 31, and the other end of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com