Automatic feeding punch production line

An automatic feeding and production line technology, applied in the field of stamping production, to achieve the effect of quality assurance and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

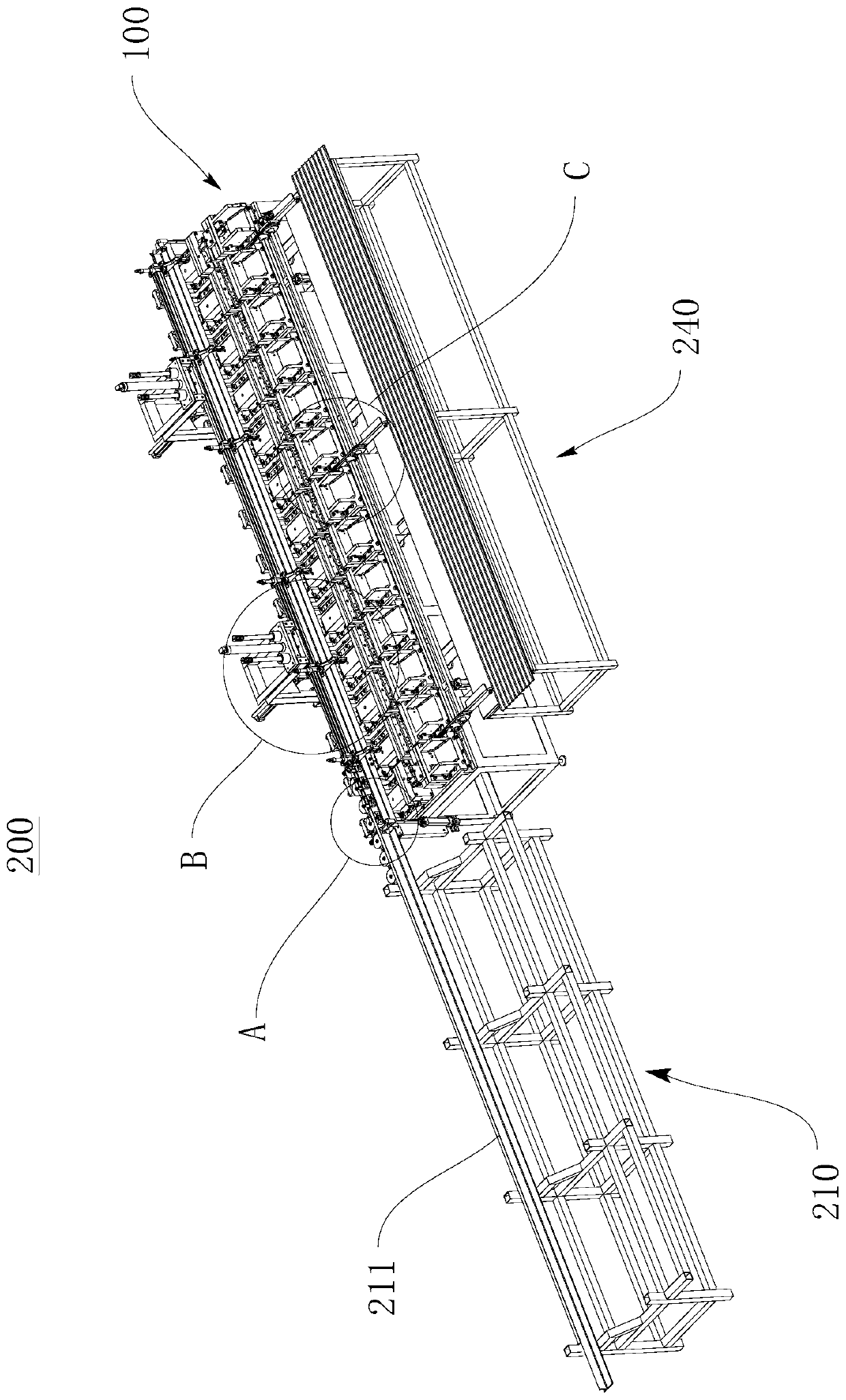

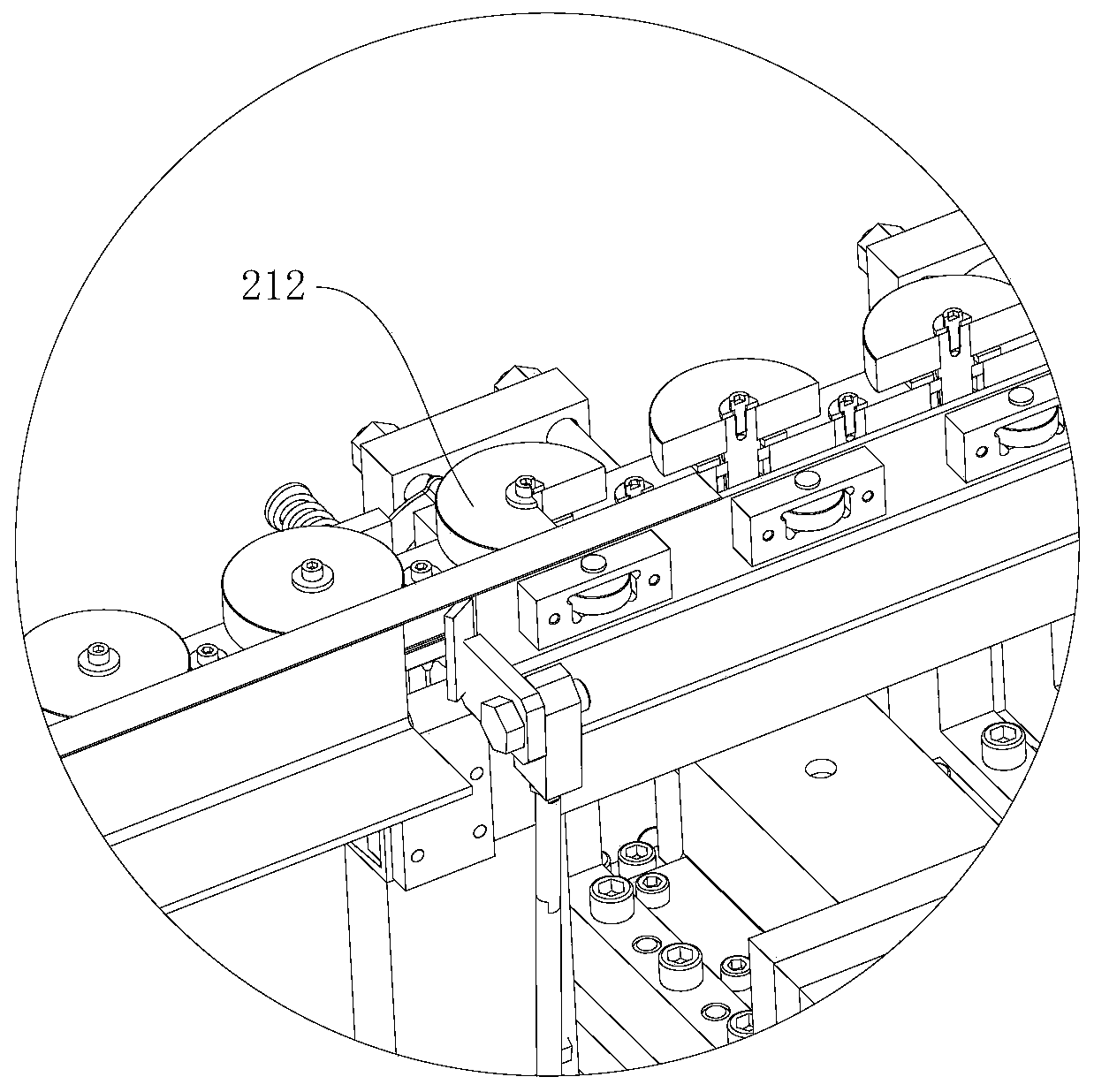

[0043] Please refer to Figure 1 to Figure 8 , the present embodiment provides an automatic feeding punch production line 200, including a loading unit 210, a clamping unit, a stamping unit group 100, a blanking unit 230 and a storage unit 240;

[0044] The feeding unit 210 is used to supply materials to the stamping unit group 100;

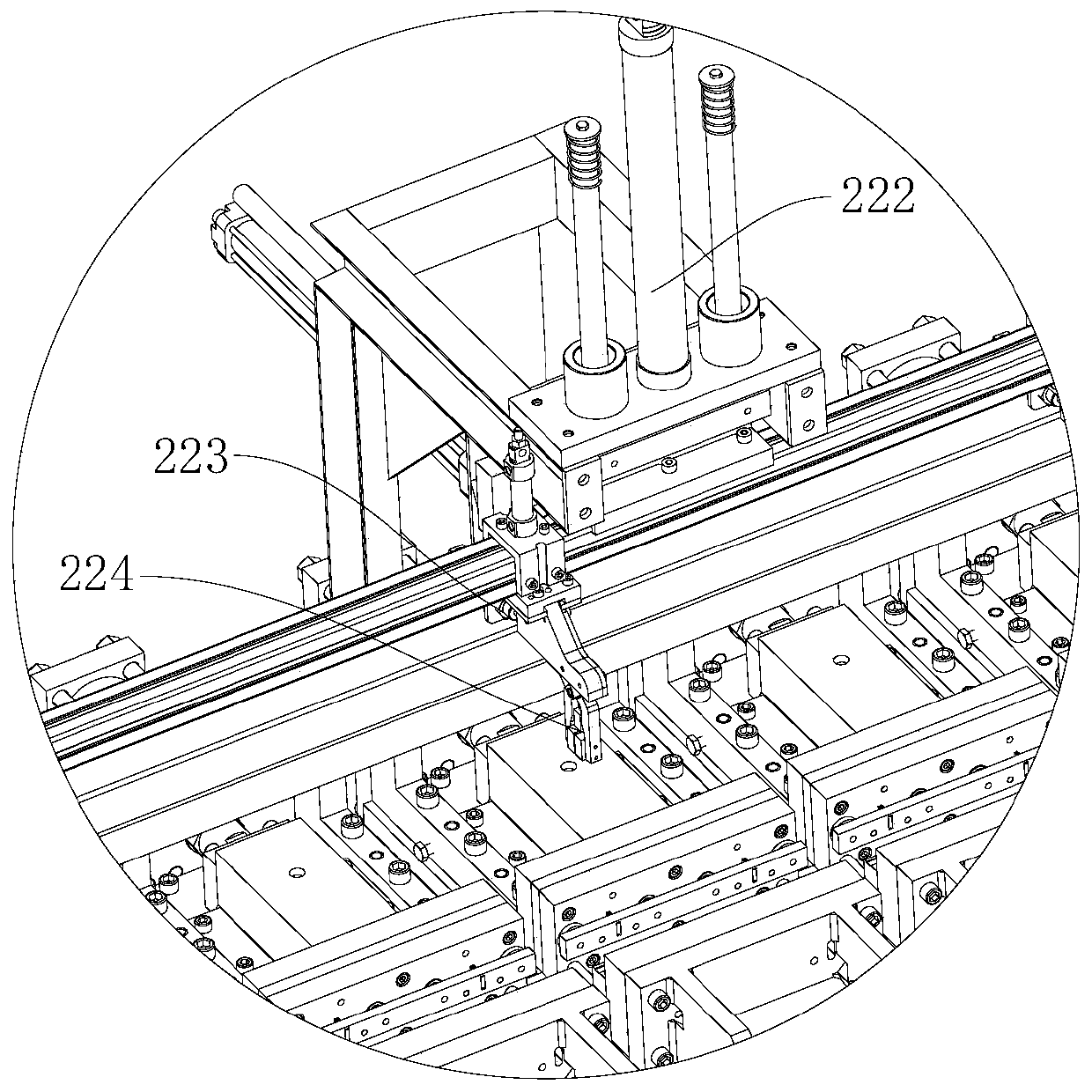

[0045] The clamping unit is used to clamp the material from the feeding unit 210 to the stamping unit group 100;

[0046] The punching unit group 100 includes a frame 10 and a punching unit 20, the number of the punching units 20 is multiple, and the multiple punching units 20 are arranged along the length direction of the frame 10;

[0047] The stamping unit 20 comprises a base 21, a stamping driver 22, a punch 23, a die 24 and a stamping table 25, the stamping driver 22 and the stamping table 25 are all arranged on the base 21, between the stamping driver 22 and the stamping table 25 The area is the stamping area 101, the punch 23 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com