Packaging sheet rapid stamping die

A technology for stamping dies and packaging sheets, which is applied in the direction of perforation tools, manufacturing tools, cleaning methods and appliances, etc. It can solve the problems of reducing the accuracy of hole spacing and the decline in the pass rate of stamping products, so as to improve the stamping accuracy and product pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

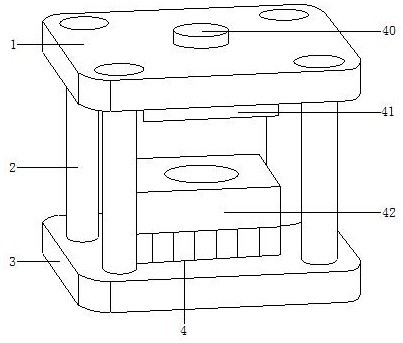

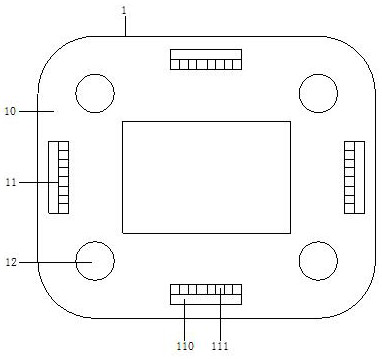

[0024] Example 1 see Figure 1-3 , the present invention provides a technical scheme of rapid stamping die for packaging sheet: its structure includes an upper template 1, a stamping strut 2, a lower template 3, and a stamping mold 4, and the stamping strut 2 is connected to the upper template 1 and the lower template 3 axes connected, the stamping die 4 is installed on the upper template 1 and the lower template 3, the upper template 1 and the lower template 3 have the same structure, and the stamping die 4 is composed of a shaft 40, an upper template 41, a lower template 42, the loading shaft 40 is installed and connected with the upper formwork 41 and the lower formwork 42, the upper formwork 41 is installed on the upper formwork 1, and the upper formwork 1 drives the upper formwork 41 on the stamping pole 2 Lifting and flexible transmission, the lower formwork 42 is installed on the lower formwork 3, the upper formwork 41 has the same structure as the lower formwork 42, an...

Embodiment 2

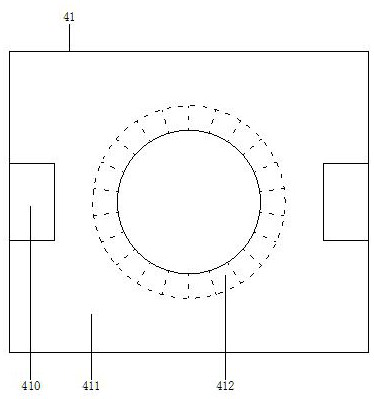

[0026] Example 2 see Figure 4 , 5 , the present invention provides a technical solution for a rapid stamping die for packaging sheets: the internal dust collection structure 410 includes a rotating dust collector 4100, a structural block 4101, a lateral moving dust collector 4102, and a structural rail 4103. The dust collector 4100 is used for dust collection of metal shavings between the mold and the plate, the traverse dust collector 4102 is used for collecting the metal shavings when opening holes, the structural block 4101 and the rotary dust collector 4100, traverse The dust collector 4102 is installed and connected, the dust collector 4102 is locked with the structural rail 4103, the plate body 411 is equipped with a lifting vertical rail 4110, and the plate hole 412 includes a connecting hole ring 4120 and a hole fan structure 4121, the connection hole ring 4120 is installed and connected with the hole fan structure 4121, the hole fan structure 4121 is installed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com