A microstructure array precision machining machine tool with adaptive matching of dynamic characteristics

An adaptive matching, microstructure array technology, applied in the direction of microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems of limited punching accuracy, limited punching accuracy, and large variation of punching force of punching machines, and achieves improved The effect of machining efficiency, improving machining accuracy and reducing motion deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

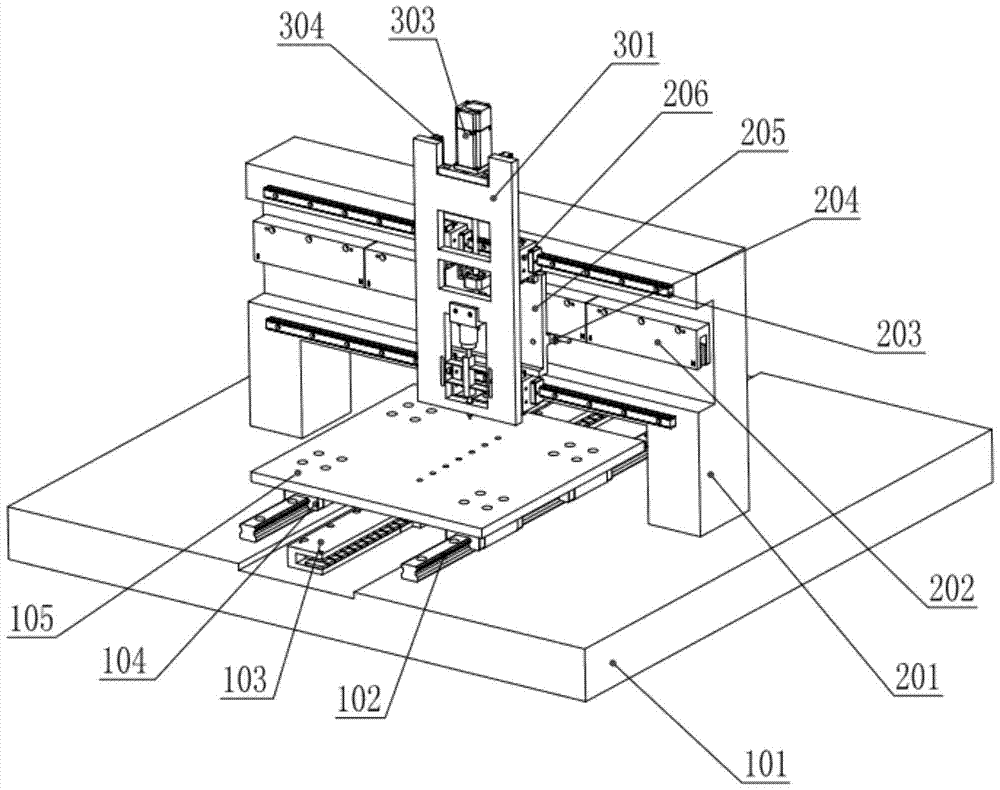

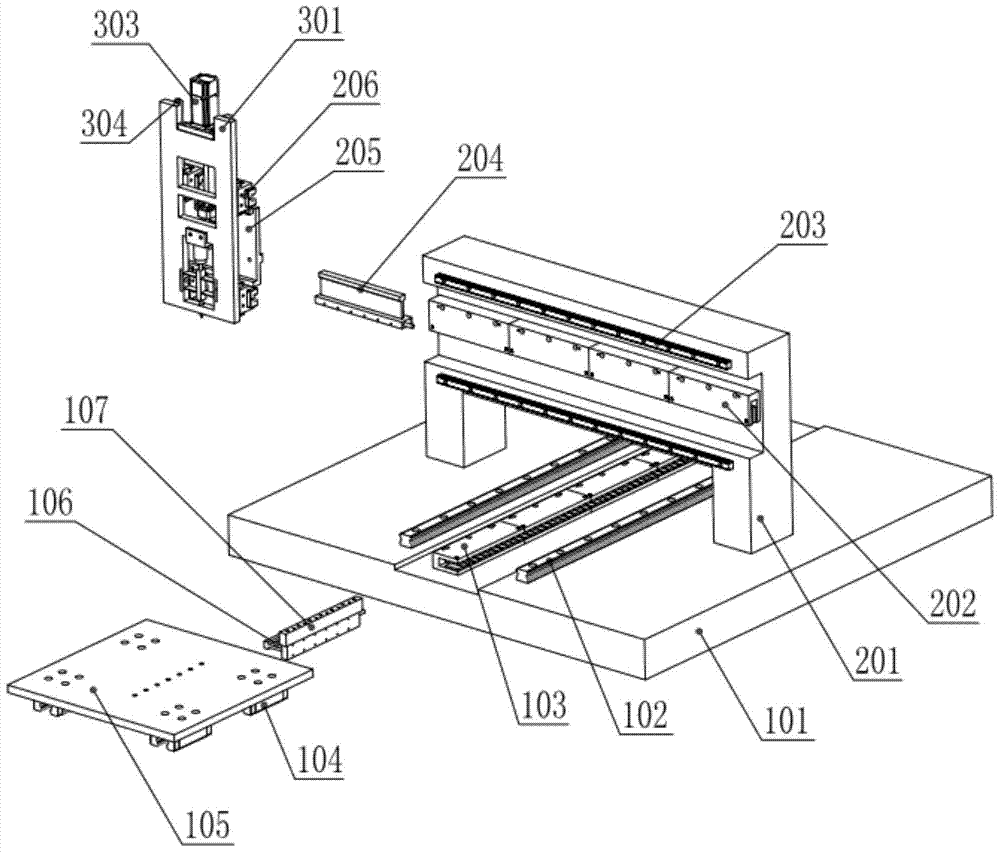

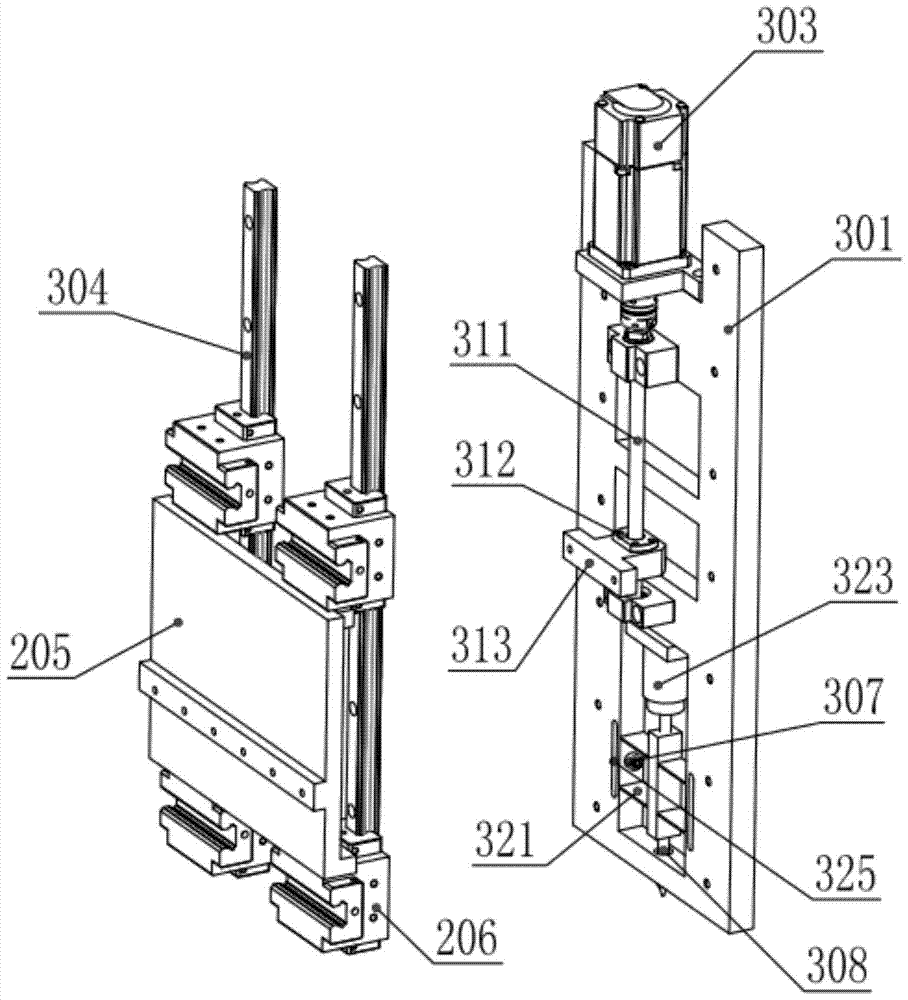

[0028] A microstructure array precision processing machine tool with adaptive dynamic characteristics, comprising a Y-direction movement mechanism 1, an X-direction movement mechanism 2 and a Z-direction precision stamping mechanism 3. The X-direction movement mechanism 2 is fixed to a base through an X-direction bracket 201 101, the Z-direction precision stamping mechanism 3 is installed on the X-direction rail 203 of the X-direction movement mechanism 2 through the X&Z linkage platform 205 and the X&Z composite guide rail slider 206, and is mounted on the X-direction guide rail 203 of the X-direction movement mechanism 2 Driven to achieve X-direction movement;

[0029] The workpiece is placed on the Y-direction movement platform 105 of the Y-direction movement mechanism 1, and the Y-direction movement is realized by the Y-directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com