Workpiece stamping device with clamping function

A stamping device and clamping component technology, applied in the field of stamping devices, can solve problems such as high stamping pressure and workpiece deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

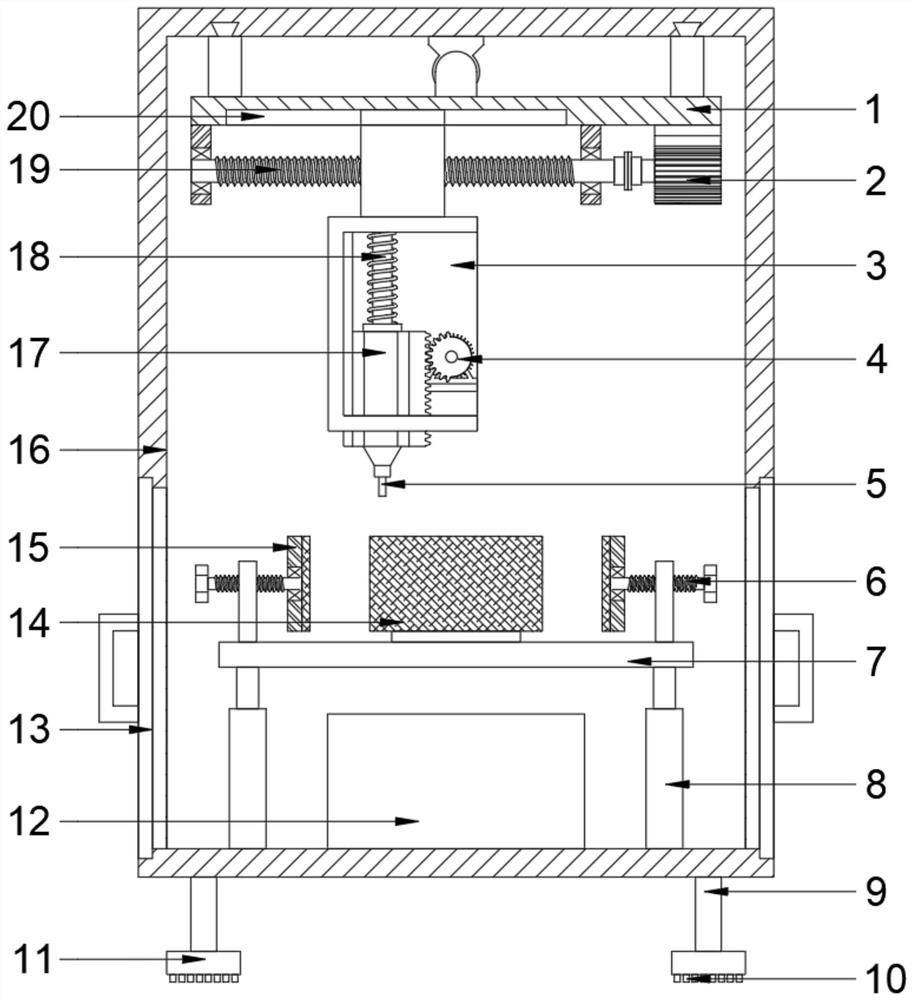

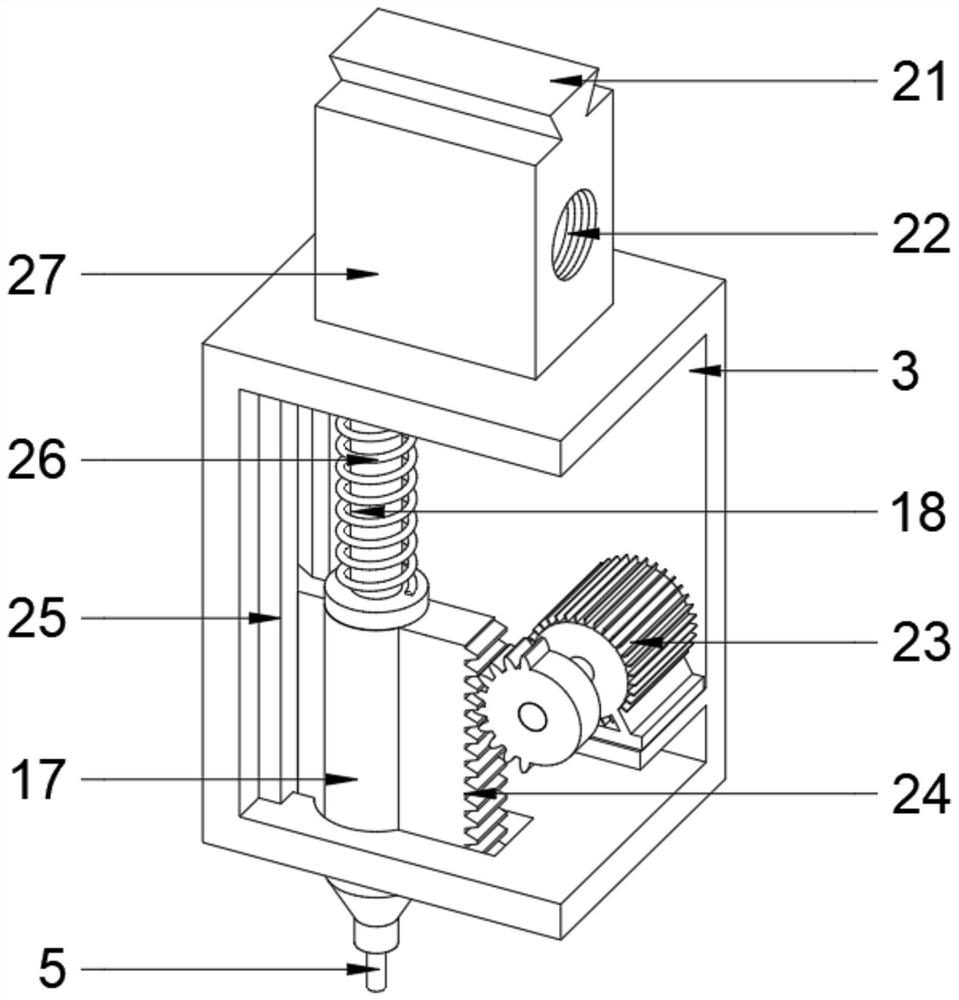

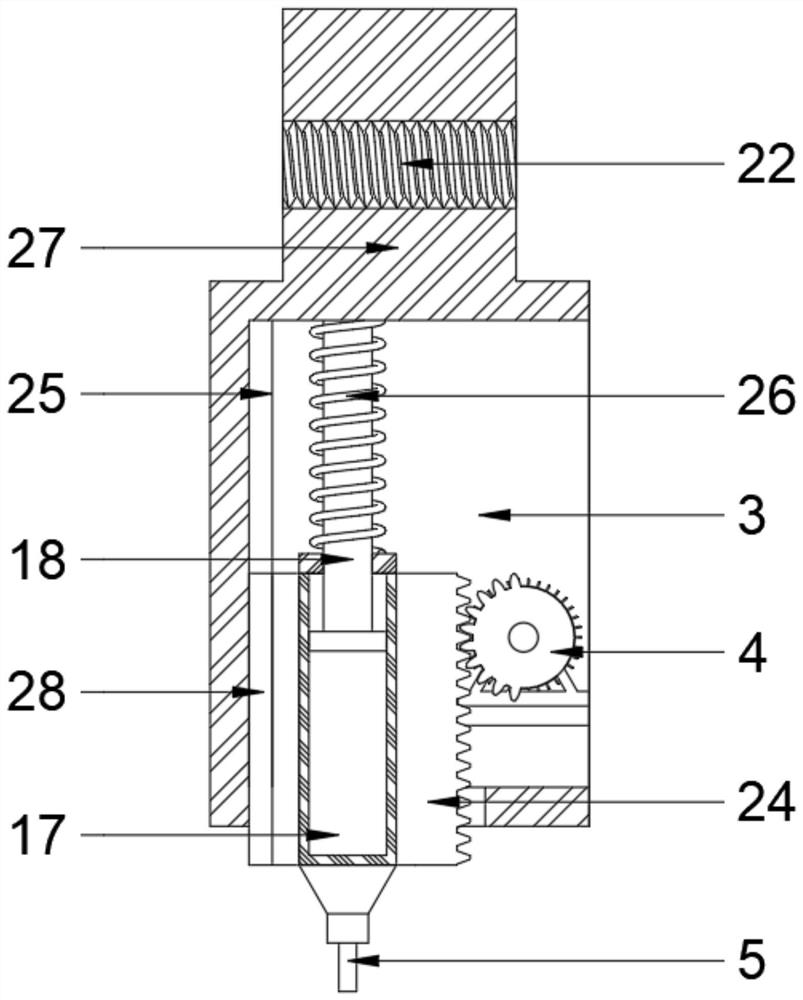

[0024] see Figure 1~4 , in an embodiment of the present invention, a workpiece stamping device with a clamping function includes a box body 16 and a stamping assembly and a clamping assembly arranged inside the box body 16, the stamping assembly includes a stamping mechanism, a first adjustment device and The second adjustment device, the stamping mechanism is threaded on the second adjustment device, the upper end of the first adjustment device is slidably installed on the top of the box body 16 and its lower end is fixedly connected with the second adjustment device; the first adjustment device Cooperate with the second adjustment device to drive the stamping mechanism to slide back and forth, left and right, and stamp at different positions of the workpiece, which is practical; the clamping assembly includes a workbench 7, a lifting rod 8 and a clamping device, and the workbench 7 is lifted by lifting Rod 8 is fixedly installed below the stamping mechanism and multiple gro...

Embodiment 2

[0031] see figure 1 , in an embodiment of the present invention, a workpiece stamping device with a clamping function, in order to prevent the debris generated by stamping from being scattered everywhere, on the basis of Embodiment 1, a waste box is also provided at the inner bottom of the box 16 12. The waste box 12 is placed under the workbench 7 and its position corresponds to the box door 13. The waste box 12 is used to collect the debris produced by the stamping tool 5 stamping the workpiece. Through the box door 13, the The waste bin 12 with debris is taken out from the inside of the casing 16 .

[0032] The working principle of the present invention is:

[0033] When working, rotate the support plate 11 to adjust the matching length of the support device and use the buffer pad 10 to support the device on the ground to keep the device stable; open the box door 13, place the workpiece on the workbench 7, and turn the four sets of clamping bolts 6 Adjust the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com