Round steel plate stamping equipment for steel processing

A kind of stamping equipment and circular technology, which is applied in the field of circular steel plate stamping equipment, can solve the problems of low automation, long time consumption, slow transportation speed, etc., and achieve the goal of improving processing efficiency, saving stamping and feeding time, and easy stamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A circular steel sheet stamping equipment for steel processing, such as figure 1 As shown, it includes an organic base 1, a machine foot 2, a stamping mechanism 3 and a feeding mechanism 4. Feeding mechanism4.

[0067] When people need to stamp the material, the material is first placed on the feeding mechanism 4, then the stamping mechanism 3 is started to stamp the circular material, and after the stamping is completed, the stamping mechanism 3 is closed.

Embodiment 2

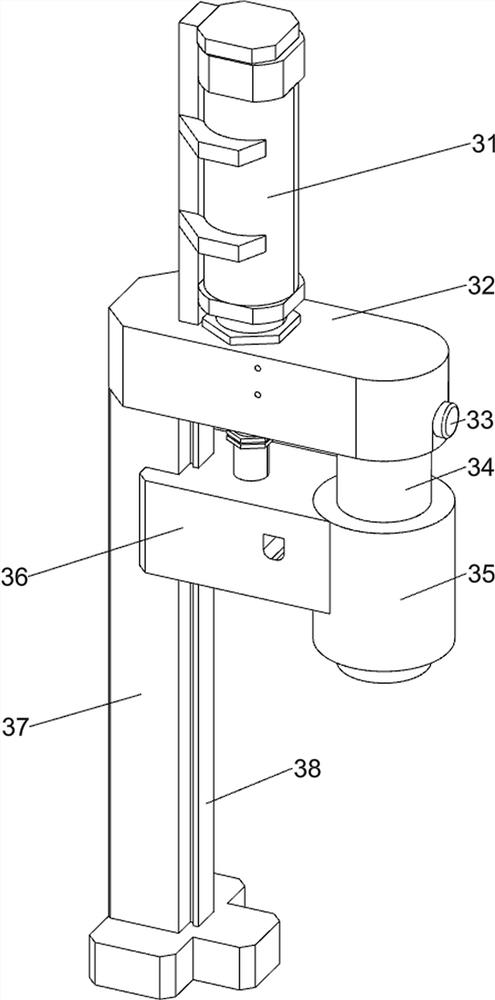

[0069] On the basis of Example 1, such as figure 2As shown, the stamping mechanism 3 includes a cylinder 31, a machine head 32, a positioning pin 33, a main shaft 34, a die 35, a slider 36, a support column 37 and a first guide rail 38, and the left side of the base 1 is provided with a support column 37 , the right side of the support column 37 is provided with a first guide rail 38, the support column 37 is provided with a head 32, the top of the head 32 is provided with a cylinder 31, the bottom of the head 32 is provided with a main shaft 34, and between the main shaft 34 and the head 32 Locating pin 33, main shaft 34 is slidingly connected with die 35, the left side of die 35 is provided with slide block 36, slide block 36 is connected with slide type between the first guide rail 38, and slide block 36 top is connected with cylinder 31 bottoms.

[0070] When the material is located on the lower side of the die 35, start the cylinder 31, and the stretching motion of the c...

Embodiment 3

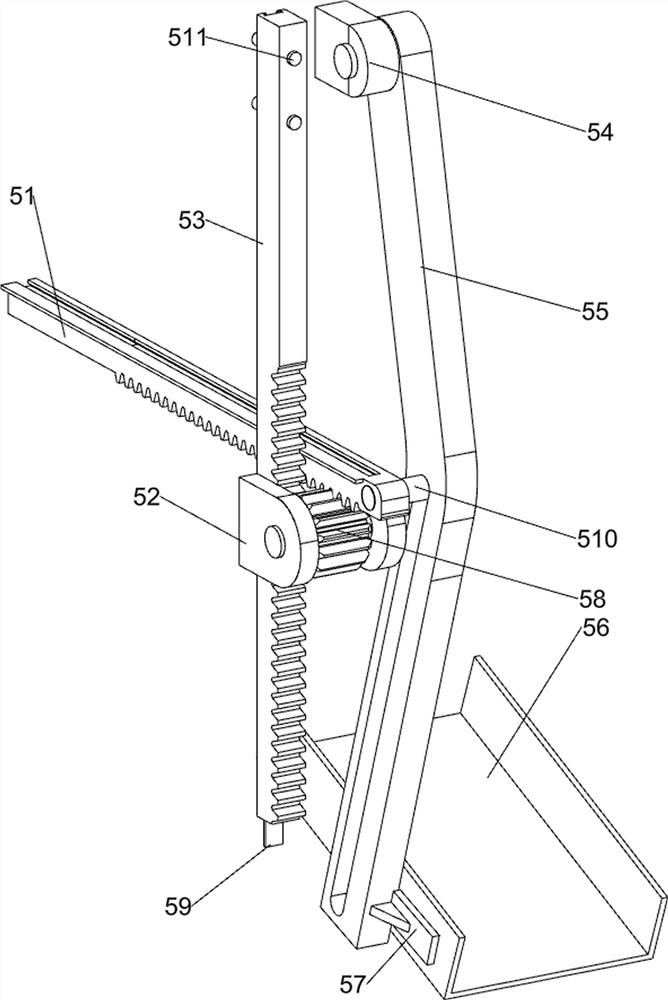

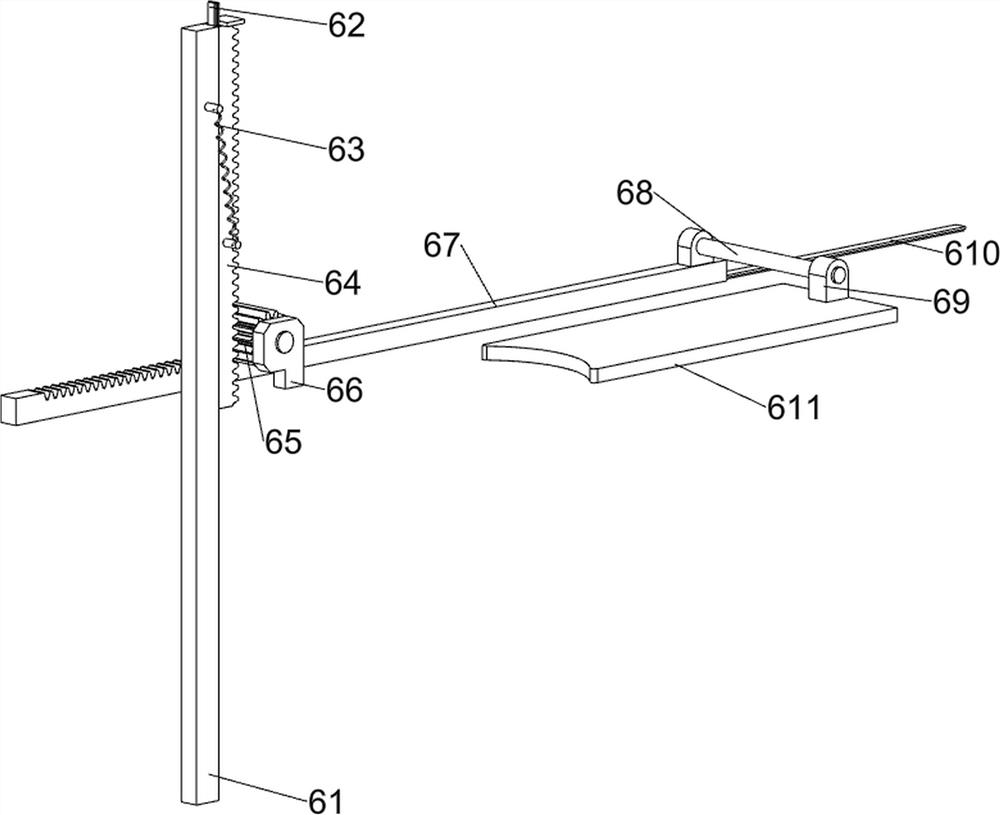

[0072] On the basis of Example 2, such as Figure 3 to Figure 7 As shown, the feed mechanism 4 includes a feed frame 41, a limit block 42 and a material storage box 43. The base 1 is provided with a feed frame 41, and the front portion of the feed frame 41 has a small opening. Bottom left and right sides are all provided with stop block 42, and stop block 42 is all positioned at the small opening front side, is provided with stock box 43 on the feed frame 41, and stock box 43 bottom front and rear sides all have push-out mouth.

[0073] When the material is positioned at the lower side of the die 35, the cylinder 31 is activated, and the stretching motion of the cylinder 31 drives the slider 36 to move downward. People place the material in the material storage box 43 and manually push the material to move forward. The material storage box 43 can A lot of materials are stored at one time, which saves the time for people to carry the materials. When the materials hit the limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com