Manual stamping device of sealing rubber and stamping method

A technology of sealing rubber and stamping device, applied in the field of high and low voltage electrical, can solve problems such as affecting the appearance and performance of products, failing to meet process requirements, roughness and other problems, achieving simple structure, good molding accuracy and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

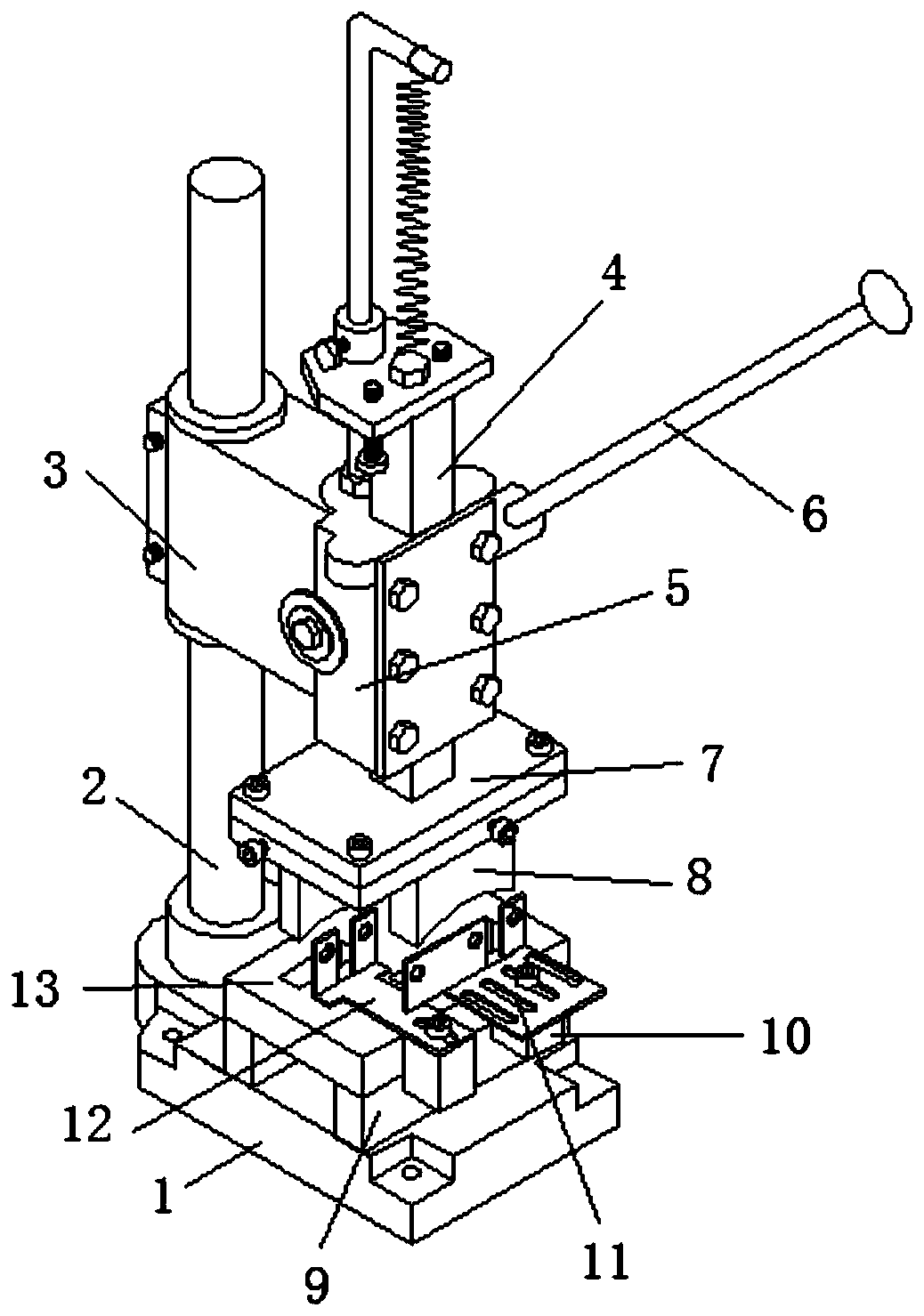

[0020] This sealing rubber manual stamping device of the present invention, as figure 1 As shown, the base 1 is included, the base 1 is provided with a support block 9 supporting the stamping pad 13, and the base 1 is provided with a reference block connected to limit the width of the sealing rubber; the base 1 is provided with a Stamping block for down stamping.

[0021] In the present invention, the reference block 1 includes a first reference block 11 and a second reference block 12 arranged in tandem, and the first reference block 11 and the second reference block 12 are movably and adjustablely connected to the base 1 superior. By adjusting the reference stopper to meet the sealing rubber suitable for stamping various widths.

[0022] In the present invention, the front end of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com