Injection die for unshadowed double-colour light-transmitting plastic products

An injection mold, shadow-free technology, used in household appliances, other household appliances, household components, etc., can solve problems such as affecting product quality, and achieve the effect of solving demolding difficulties, simple mold structure, and excellent product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] The directional terms mentioned in the following embodiments, such as "horizontal, vertical, left, right", etc., are only referring to the directions of the drawings, therefore, the directional terms used are for illustration and not for limiting the practical invention.

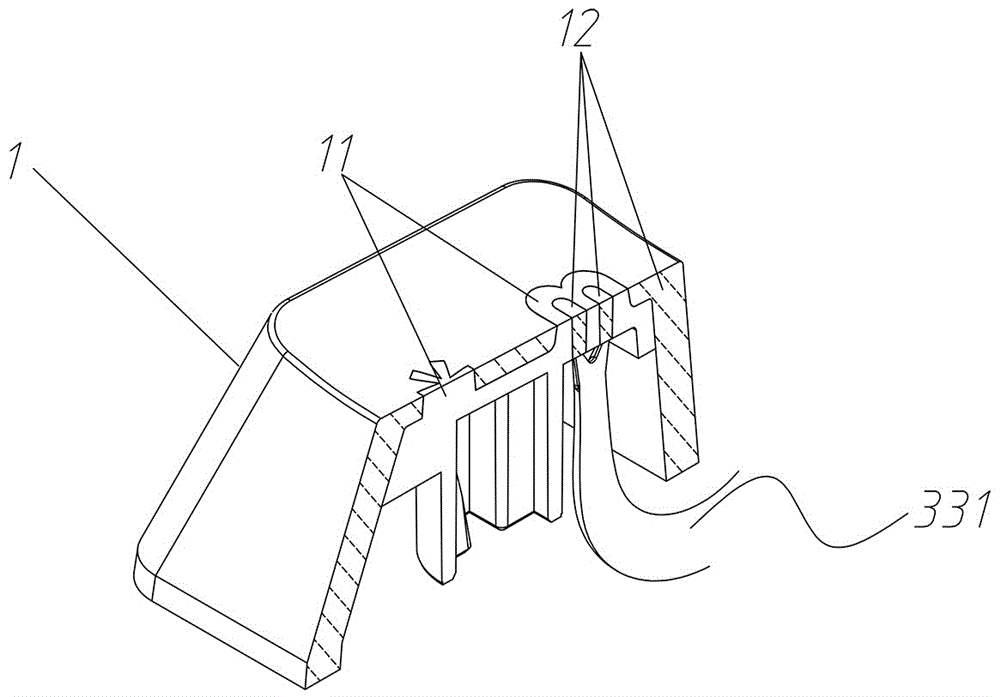

[0019] Such as figure 1 As shown, the present invention provides an injection mold for a shadowless two-color light-transmitting plastic product, which is used to manufacture a shadowless two-color light-transmitting product 1 with an island structure including a non-light-transmitting layer 12 in the light-transmitting layer 11, For example, the number "6", the letter "O", etc., when manufacturing this type of product 1, the light-transmitting layer 11 is injection-molded first, and then the non-light-transmitting layer 12 is injection-molded.

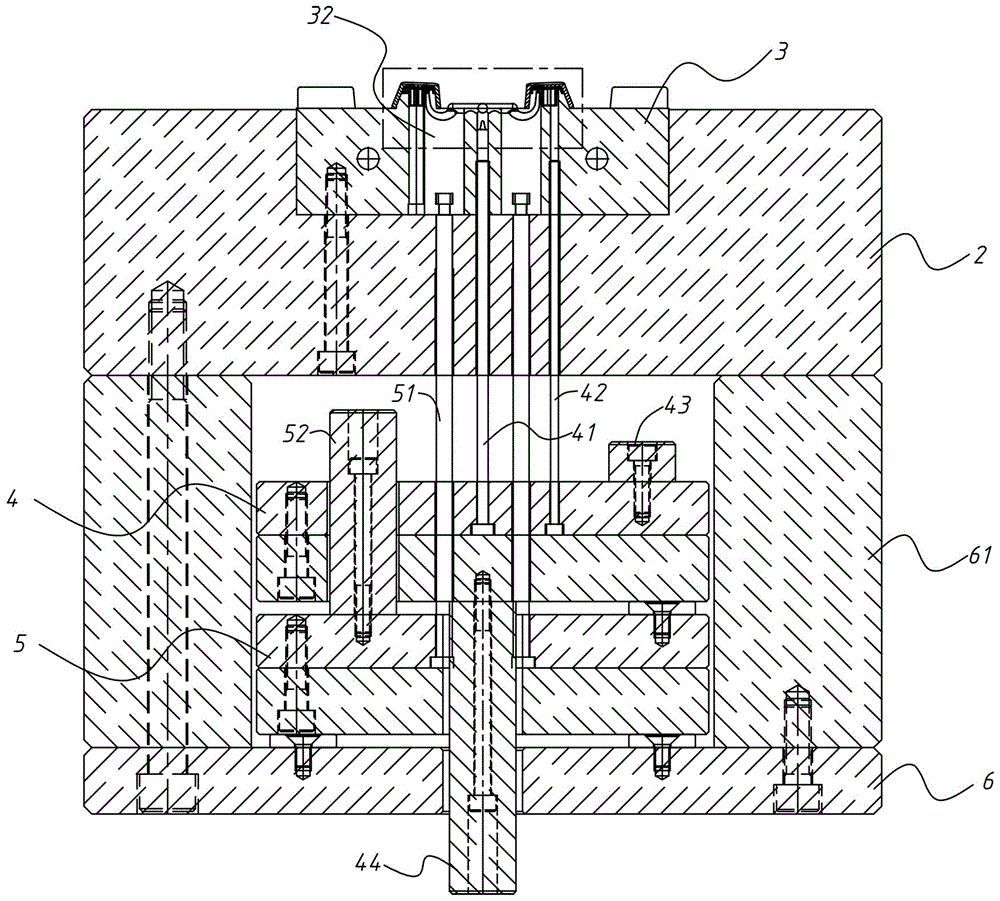

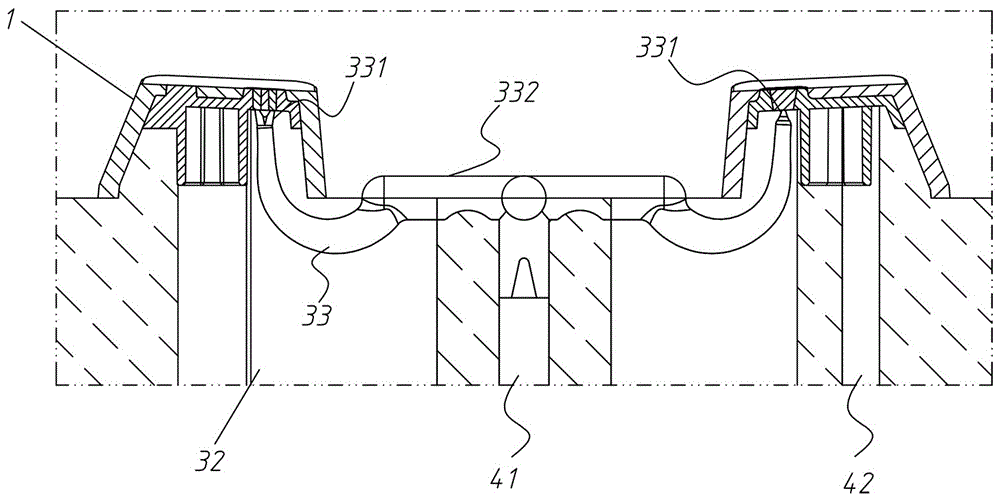

[0020] Such as Figure 2 to Figure 4 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com