Twisting mold of fat steel and flat steel twisting method

A flat steel and mold technology, applied in the field of flat steel torsion molds and torsion flat steel, can solve the problems of inability to guarantee the precision of torsion forming, high artificial torsion strength, material damage, etc. It is easy to guarantee the torsion accuracy, and the production continuity is good. The effect of high accuracy of torsion molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

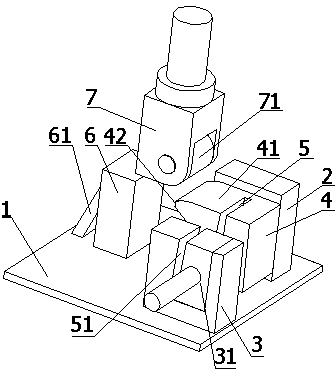

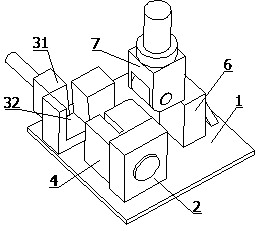

[0029] An embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

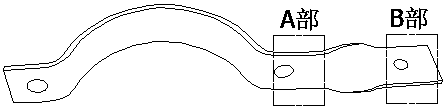

[0030] A kind of flat steel torsion die of the present embodiment, as Figure 2-4 As shown, it includes base 1, support one 2, support two 3 and rotating block 4, wherein support one 2, support two 3 are fixedly arranged on the upper surface of base 1 and support one 2, support two 3 Relatively arranged, and the rotating block 4 is located between the support one 2 and the support two 3, the rotating block 4 is rotatably connected with the support one 2, and also includes a rotary drive device for driving the rotating block 4 relative to the support one 2 rotate. In the initial state, the upper surface 41 of the rotating block 4 is parallel to the upper surface of the base 1 , and the front surface 42 of the rotating block 4 is perpendicular to the upper surface 41 . And the rotating block 4 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com