Light

A lighting equipment, edge technology, applied in the direction of lighting and heating equipment, lighting devices, components of lighting devices, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

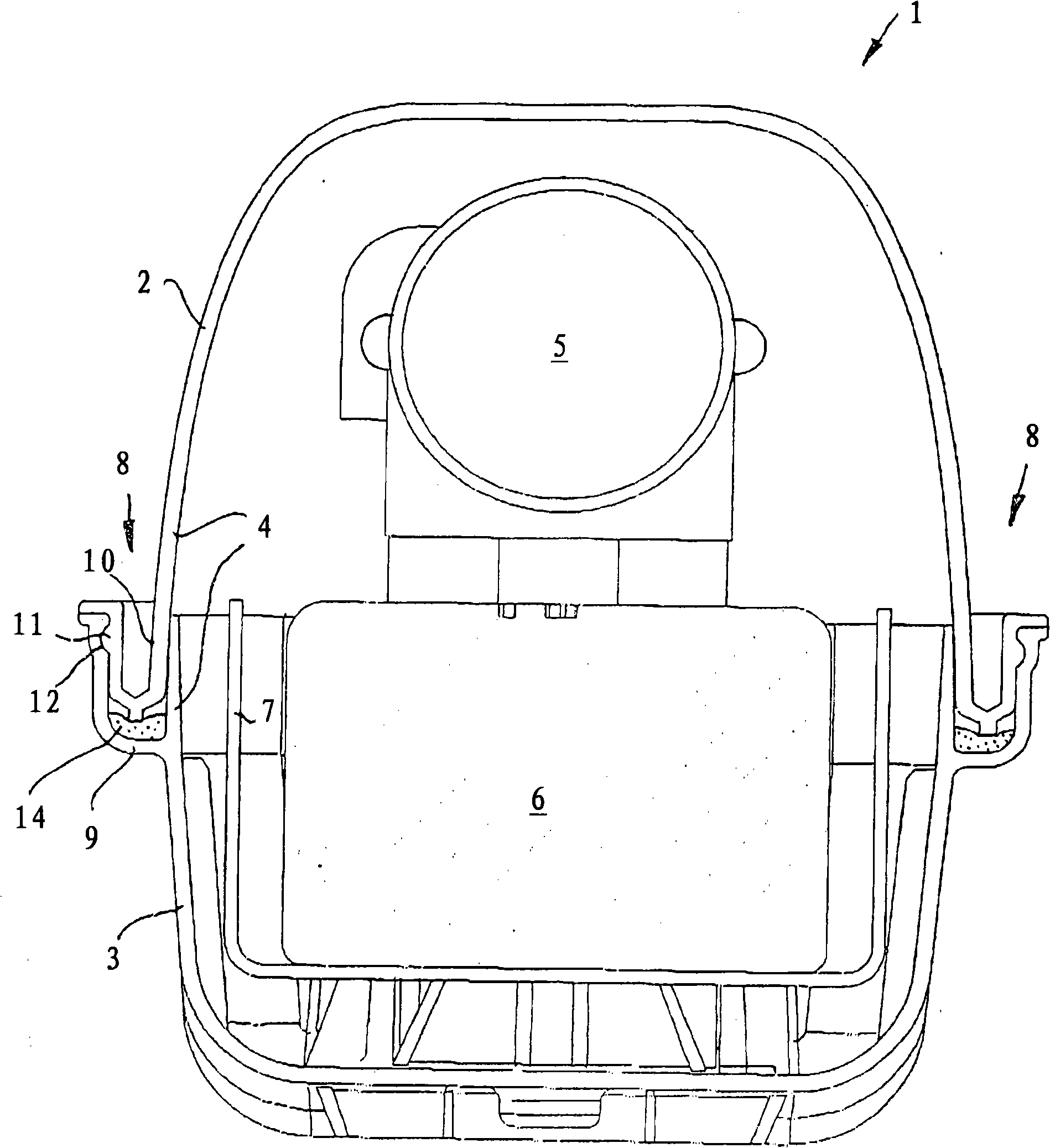

[0012] have basis figure 1 The lighting device 1 in cross-section has an elongated housing, indicated generally with 4, composed of a connecting part 2 and a base part 3, for accommodating a gas discharge lamp 5 located inside, wherein the housing The body 4 extends prismatically over almost its entire length and is closed cap-shaped at each end. In addition to housing the gas discharge lamp 5, the base part 3 also accommodates further (electrical) devices, including the ballast 6 and the associated shielding plate 7, which serves to reduce the risk of damage in the area of the ballast. Heat radiation from the ballast to the base 3 . The base part 3 can be used for fixed mounting of the lighting device on a wall or ceiling, while the connecting parts 2 of the individual fitting parts which are not usually provided with the lighting device are designed to be freely removable.

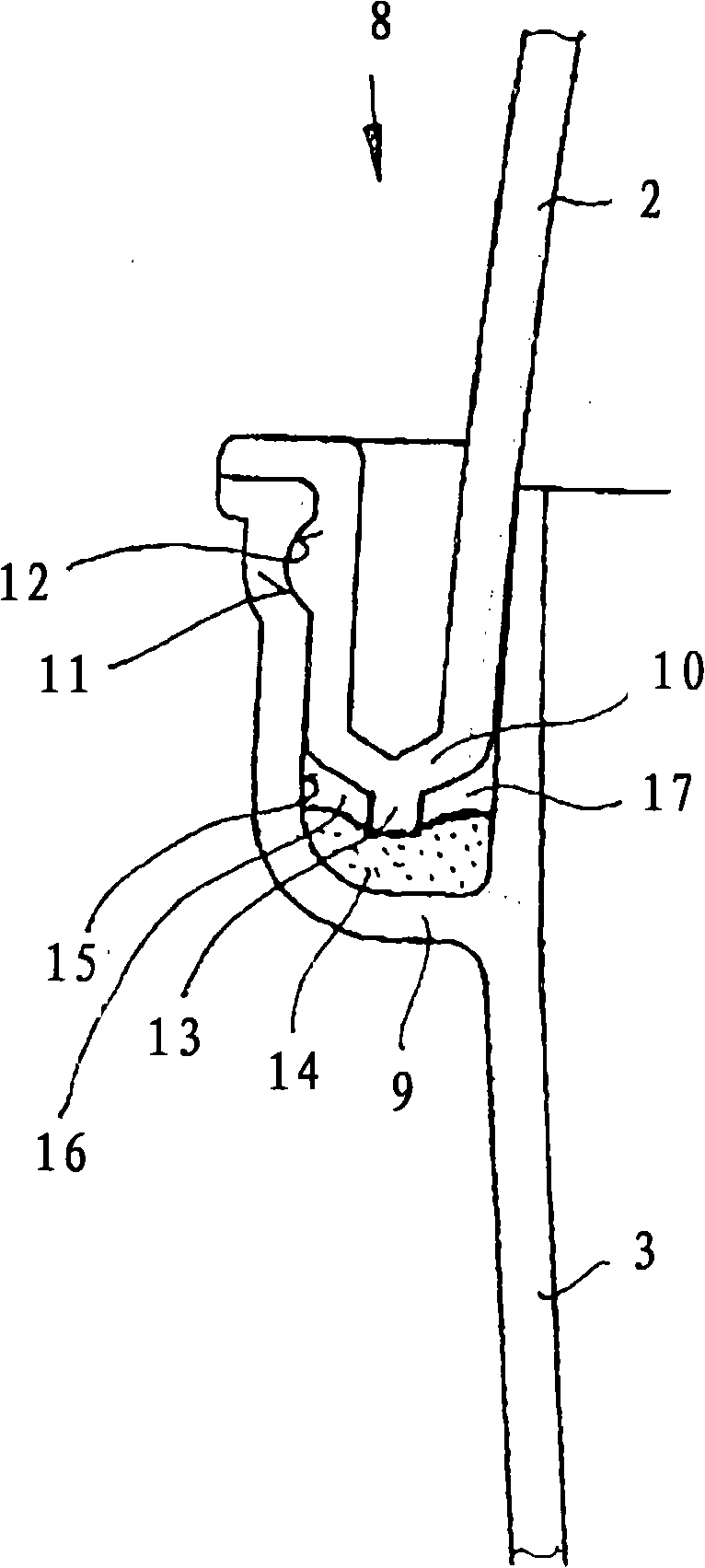

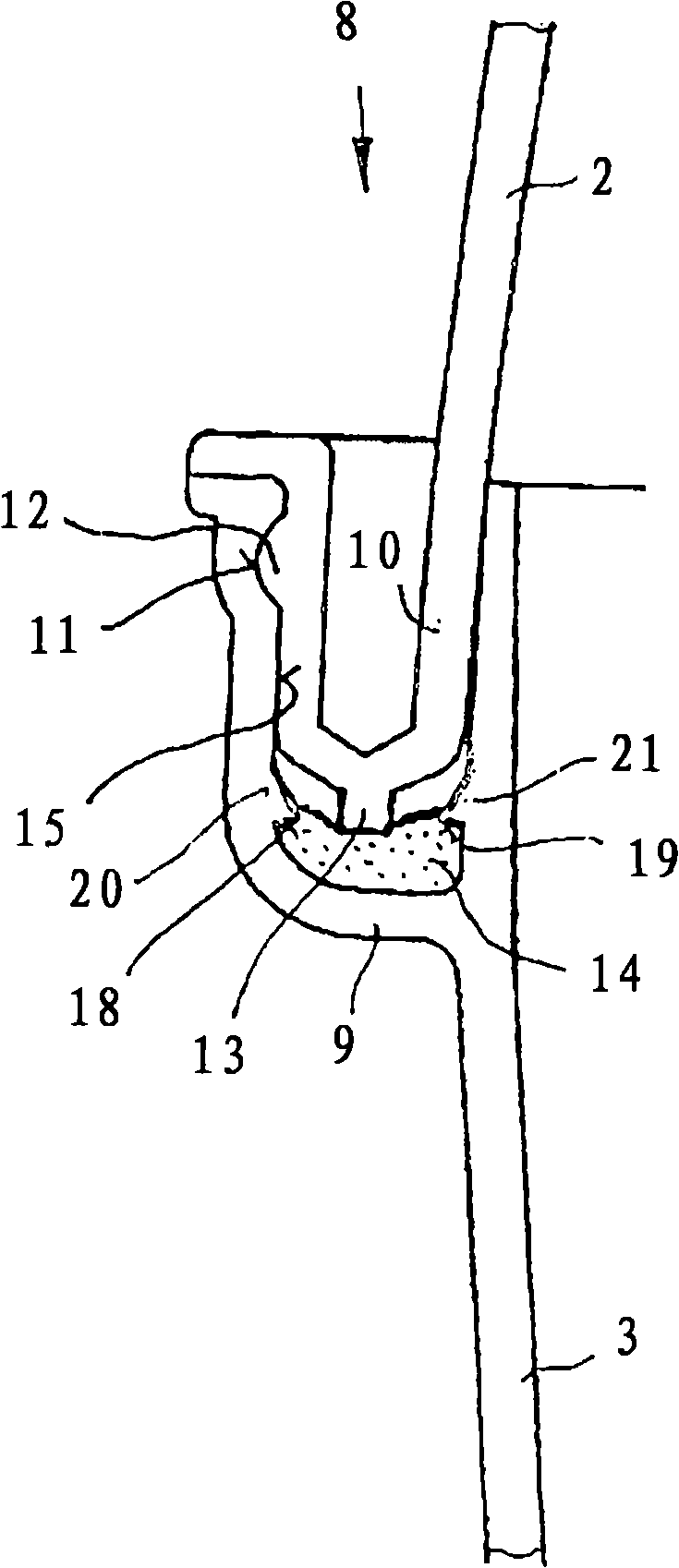

[0013] The connecting part 2 and the base part 3 are detachably connected to one another via a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com