Shoe material processing method

A processing method and shoe material technology, applied in household components, applications, household appliances, etc., can solve the problems of affecting appearance and use, waste of materials and labor costs, and inability to repair, so as to enhance the sense of brightness and smooth aesthetics, and reduce the cost of materials. and labor costs, and the effect of enhancing the anti-hydrolysis performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

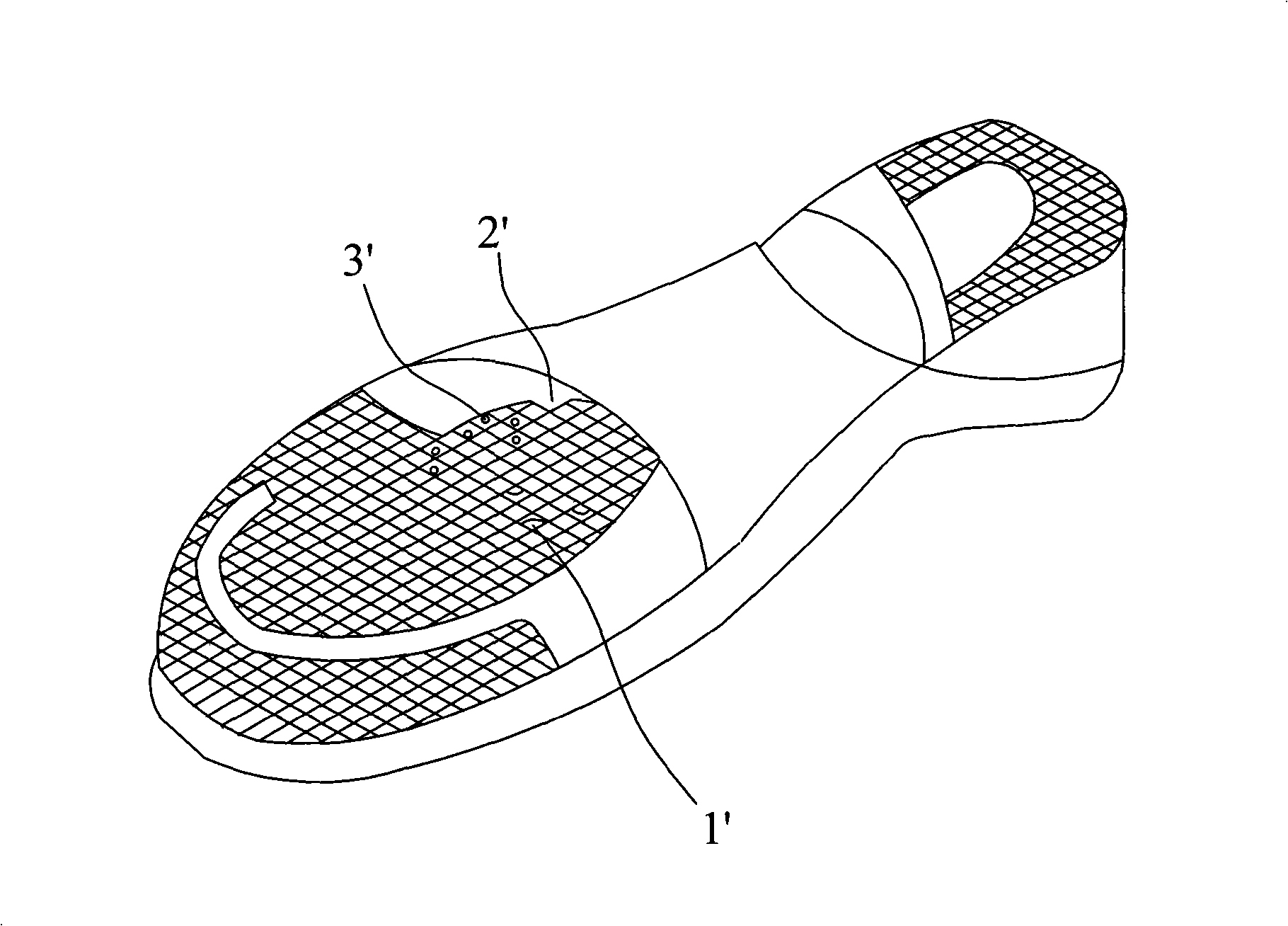

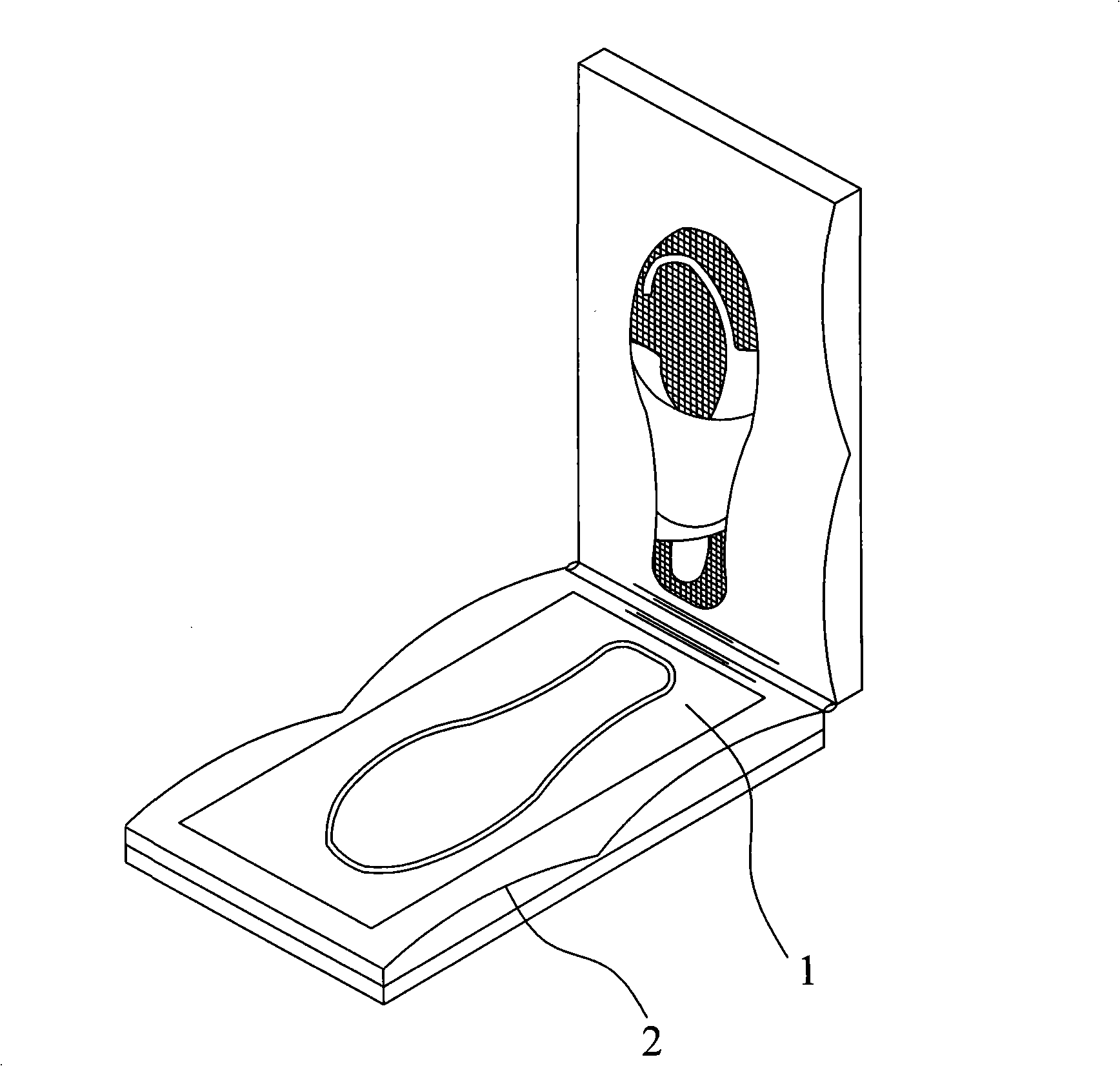

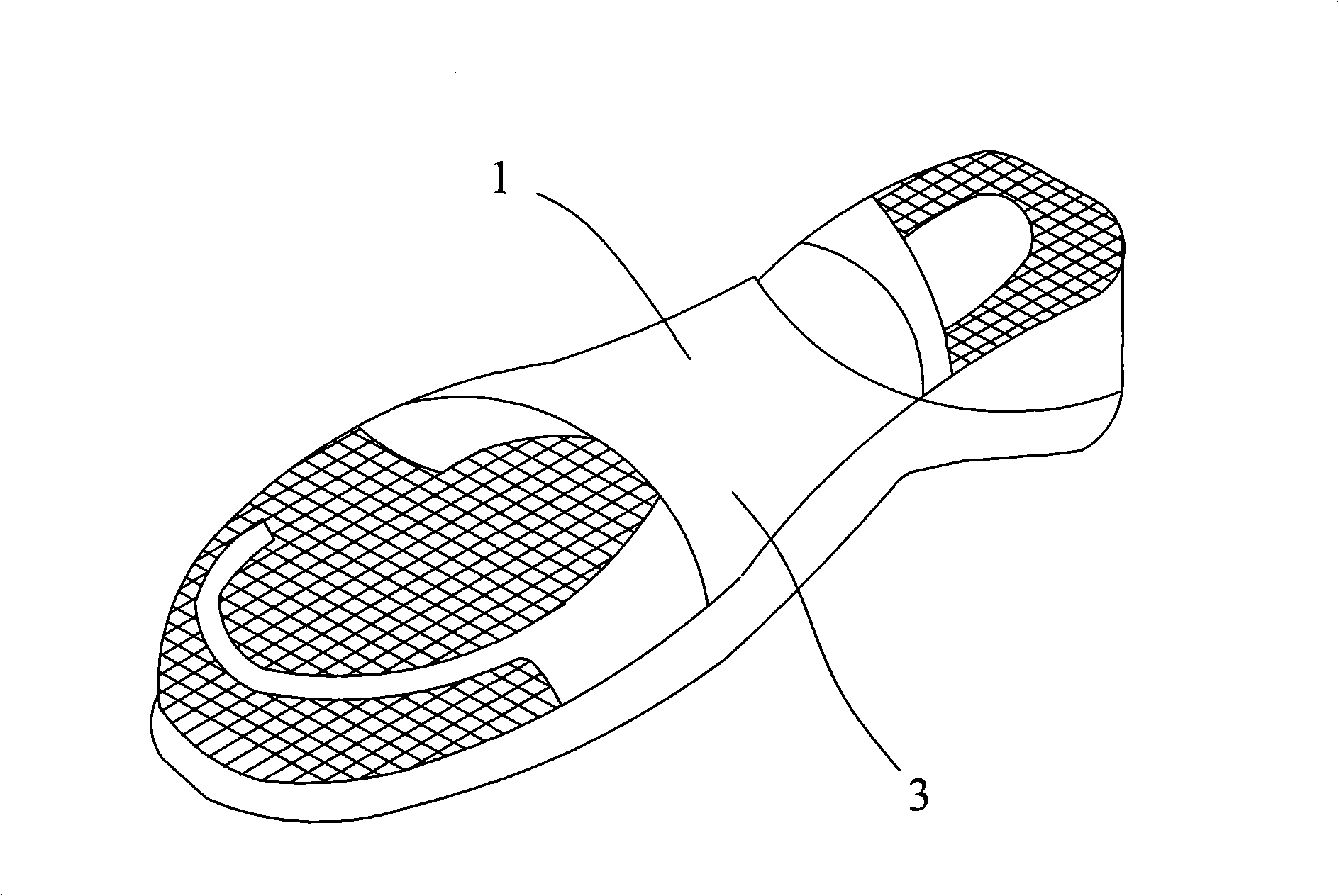

[0017] Please refer to figure 2 and image 3 , are respectively a stereoscopic schematic diagram of a preferred embodiment of the present invention when the TPU film 1 is laid in the mold cavity of the lower mold 2, and a stereoscopic schematic diagram of the shoe sole 3 made by this embodiment of the present invention. The shoe material processing method includes the following step:

[0018] First lay the TPU film 1 in the mold cavity of the shoe material lower mold 2;

[0019] Then inject liquid PU material into the mold to shape the shoe material in the mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com