Spinning and molding device for glassware

A spinning forming and glass product technology, applied in glass forming, glass pressing, glass manufacturing equipment, etc., can solve the problems of cumbersome installation of negative molds, time-consuming and laborious, and the accuracy of glass products cannot be guaranteed, and achieve reliable positioning. The effect of improved performance, accurate positioning and precise precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

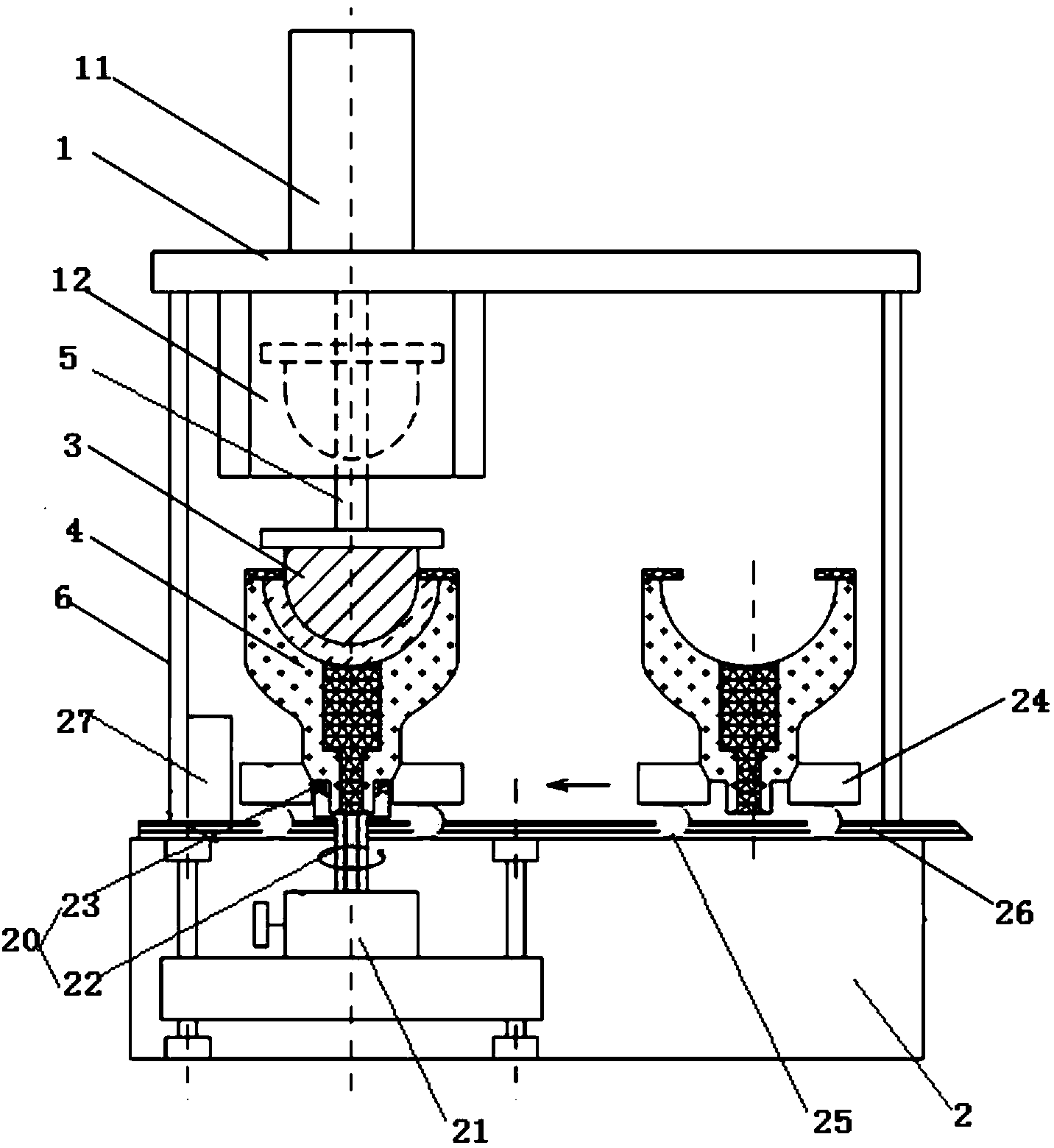

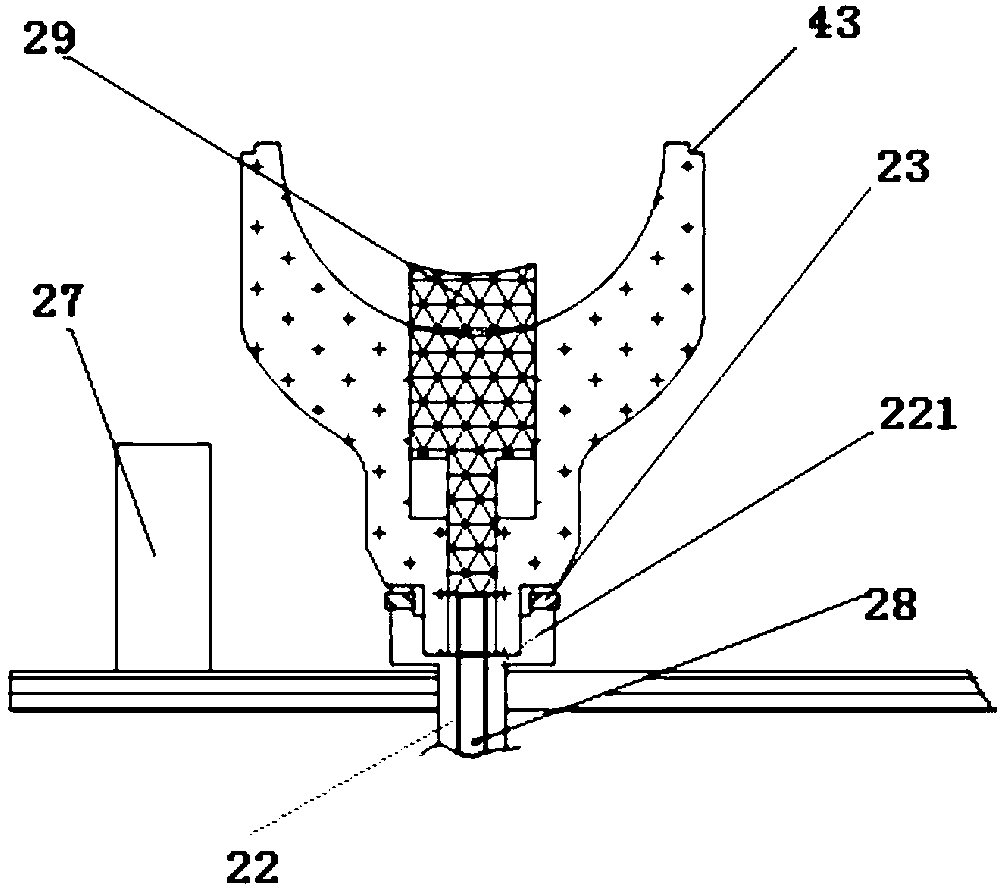

[0030] Please refer to figure 1 , figure 2 , image 3 As shown, the present invention provides a glass product spinning forming device, including a forming working system composed of an upper operating platform 1 and a lower operating platform 2, and a group of The upper and lower relative moulds, the upper mold is a male mold 3, and the lower mold is a female mold 4. The upper operating platform 1 is provided with a pressing and lifting device 11 that is connected to the male mold 3 at one end, and the lower operating platform 2 is provided with The positioning mechanism 20 for positioning the female mold 4 at the working position and the driving device 21 for driving the rotation of the female mold 4, the positioning mechanism 20 includes a support table 22 for supporting the female mold 4 and can be lifted, and The clamp 23 arranged on the support table 22 is configured to clamp the female mold 4 along the circumferential direction of the female mold 4 to achieve positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com