Method and apparatus for half die demolding and transmitting of compacts

A technology for pressing products and demoulding, which is applied to the lower mold, realizes the demoulding and transmission method of the half-mould of the pressed products, and the field of demolding and transmission of flat products. Cost and other issues, to achieve the effect of convenient operation and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

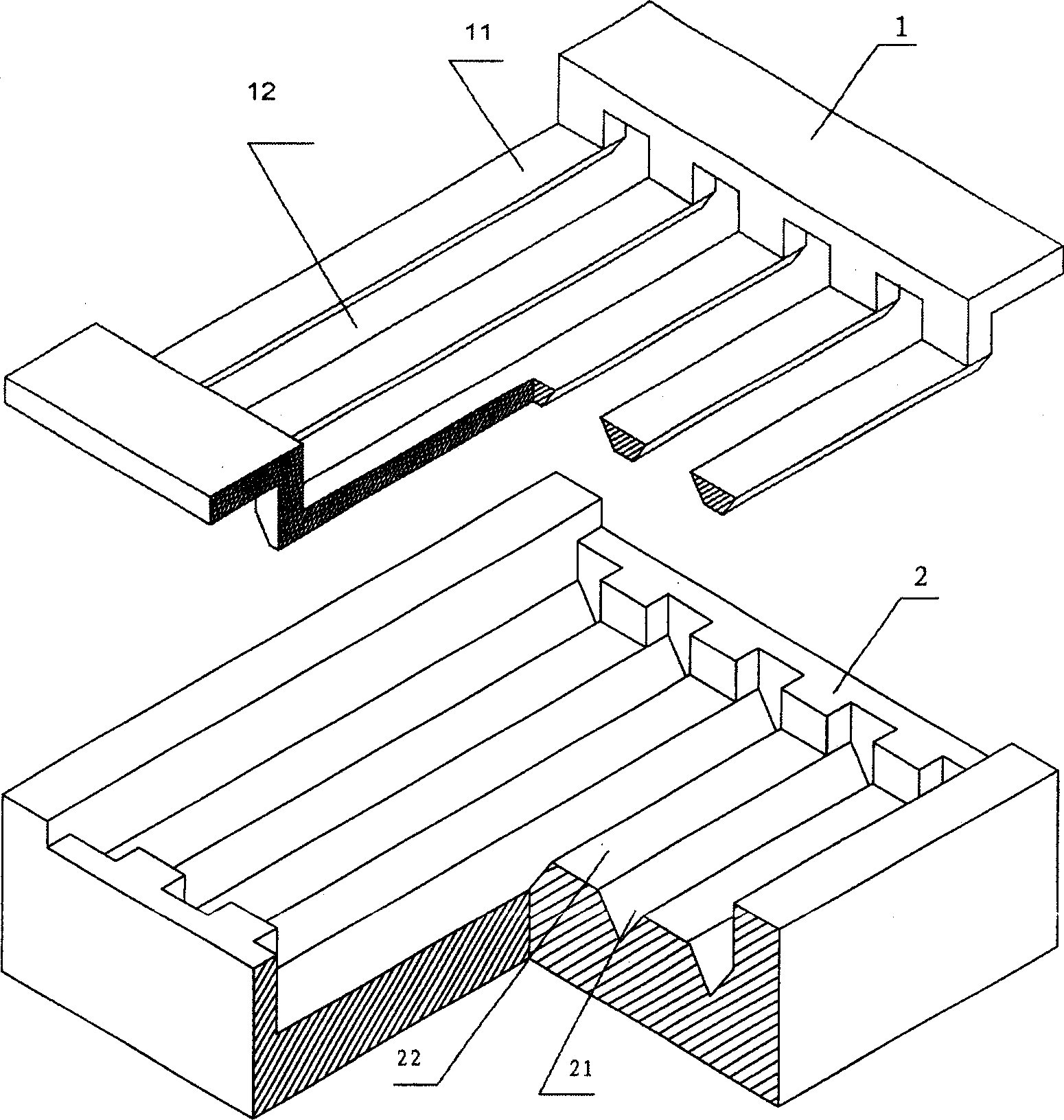

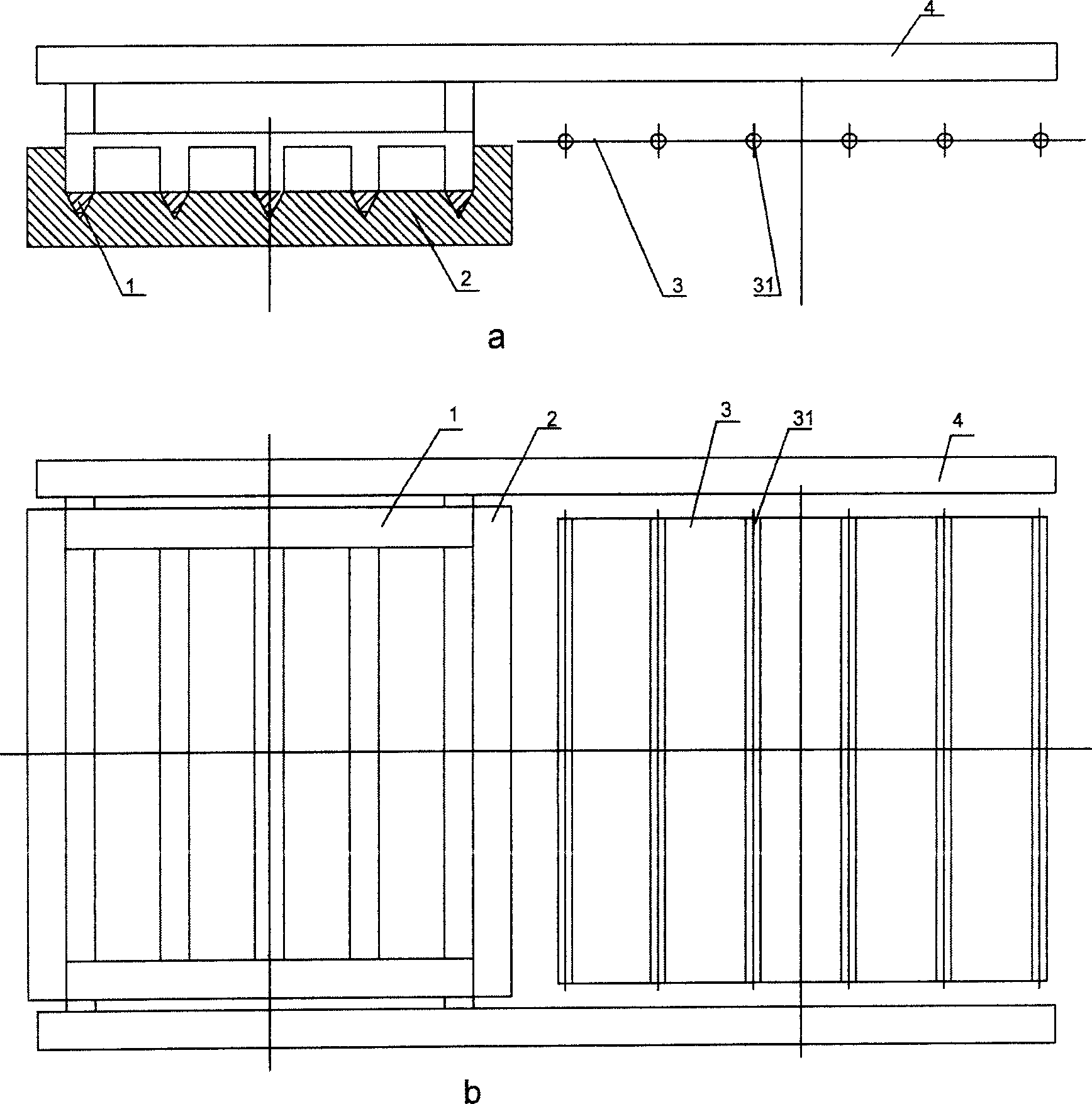

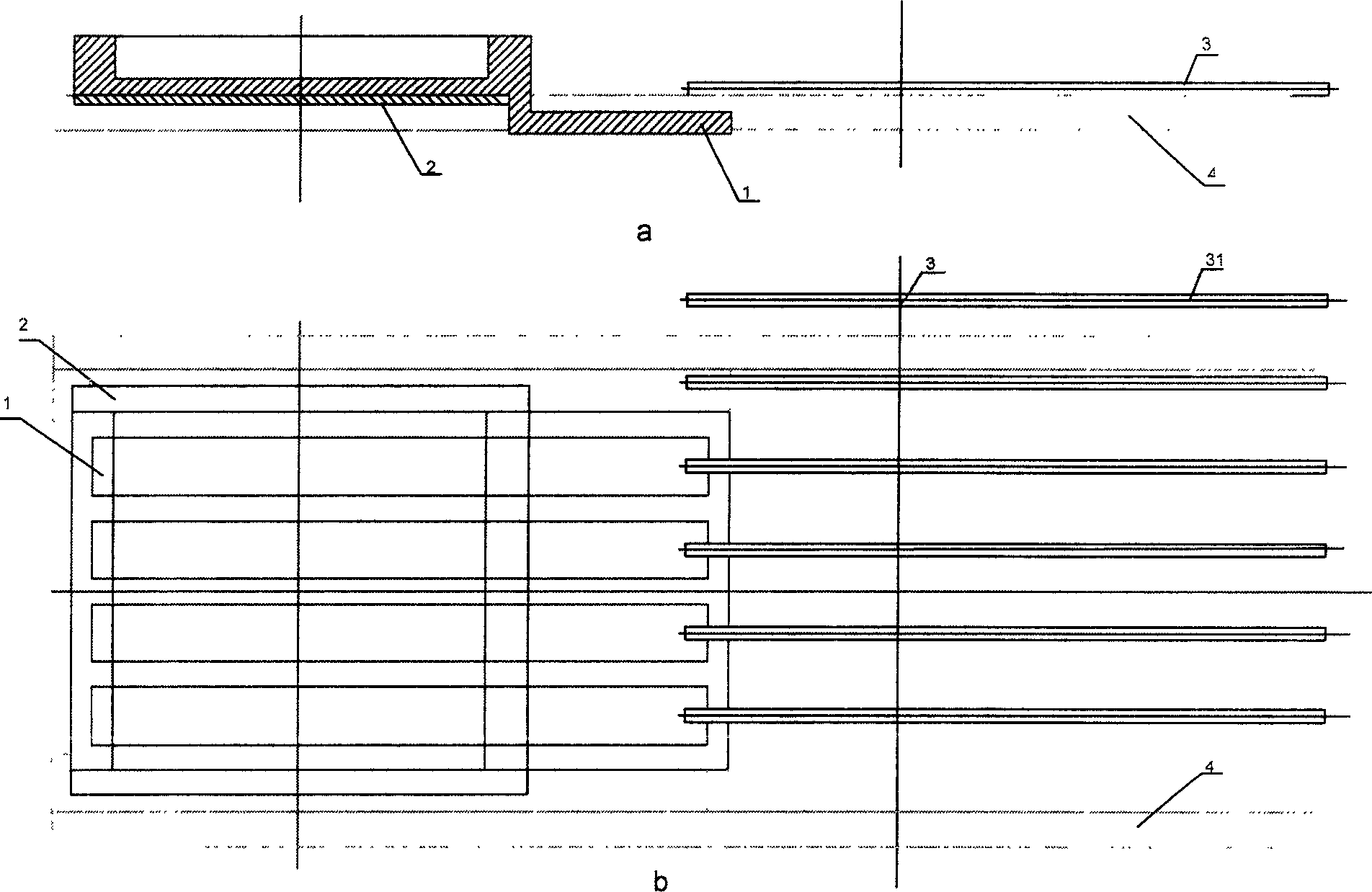

[0057] like Figure 10-Figure 13 As shown, take the ceramic wall and floor tile adobe (pressed product 5 is the ceramic wall and floor tile adobe in this embodiment) as an example to illustrate the specific implementation of the vertically placed half-mold demoulding and transmission of the vertically placed-belt model, including Follow the steps below:

[0058] Step I: The servo device 4 raises the bottom mold 2 so that the half mold 1 is embedded in the bottom mold 2 to form a complete lower mold cavity, and the powder material is distributed and pressed to form the brick adobe 5, such as Figure 10 ;

[0059] Step II: The bottom mold 2 is lowered by the servo device 4, and the adobe 5 is released from the bottom mold 2 along with the half mold 1, as Figure 11 ;

[0060] Step III: The servo device 4 translates the half-form 1 and the adobe 5 supported by the servo device 4 to the top of the working surface of the conveyor 3 consisting of a group of rubber belts 31 accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com